Professional Documents

Culture Documents

Sikasil SG-20

Uploaded by

Jorge CJ0 ratings0% found this document useful (0 votes)

134 views2 pagessilicón

Original Title

Sikasil SG-20 (1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsilicón

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

134 views2 pagesSikasil SG-20

Uploaded by

Jorge CJsilicón

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Product Data Sheet

Version 2 (07 / 2013)

Sikasil SG-20

High strength structural silicone adhesive

Technical Product Data

Chemical base 1-C silicone

1 Black, grey S6,

Color (CQP 001-1)

white S3

Cure mechanism Moisture-curing

Cure type Neutral

Density (uncured) (CQP 006-4) 1.37 kg/l approx.

Non-sag properties (CQP 061-4 / ISO 7390) 1 mm approx.

Application temperature 5 - 40C (40 - 105F)

2

Skin time (CQP 019-2) 15 min approx.

2

Tack-free time (CQP 019-1) 180 min approx.

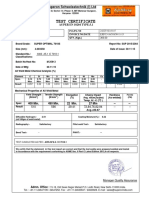

Curing speed (CQP 049-1) See diagram 1

Shore A-hardness (CQP 023-1 / ISO 868) 39 approx.

2

Tensile strength (CQP 036-1 / ISO 37) 2.2 N/mm approx.

Elongation at break (CQP 036-1 / ISO 37) 450% approx.

Tear propagation resistance (CQP 045-1 / ISO 34) 7 N/mm approx.

2

100% modulus (CQP 036-1 / ISO 37) 0.9 N/mm approx.

Movement accommodation (ASTM C 719) 25%

Thermal resistance (CQP 513-1) long term 180C (355F) approx.

Short term 4 hours 200C (390F) approx.

1 hours 220C (430F) approx.

Service temperature -40 - 150C (-40 - 300F)

Shelf life (storage below 25C) (CQP 016-1) 9 months

1) 2)

CQP = Corporate Quality Procedure 23C (73F) / 50% r.h.

Description Product Benefits Areas of Application

Sikasil SG-20 is a neutral-curing - Meets requirements of EOTA Sikasil SG-20 can be used for

silicone adhesive which combines ETAG 002 (carries ETA), EN structural sealant glazing, bonding

mechanical strength with high 13022, ASTM C 1184 of solar modules and other high-

elongation. It adheres excellent to - Fire rated (EN 11925-2 / DIN demanding industrial applications.

a wide range of substrates. 4102-B1) This product is suitable for profes-

Sikasil SG-20 is manufactured in - Outstanding UV and weathering sional experienced users only.

accordance with ISO 9001 / 14001 resistance Tests with original substrates and

quality assurance system and the - Bonds excellent to glass, metals, conditions have to be performed to

responsible care program. coated metals, plastics and woo ensure adhesion and material

- Provided with CE-mark according compatibility.

to ETAG 002, DoP 01 26 03 01

003 9 001000 1024, certified by

Factory Production Control Body,

0757, certificate Nr. 0757-CPD-

596-10-001 R1e, 2011-06-01

Sikasil SG-20 1 / 2

Cure Mechanism The above information is offered Further Information

for general guidance only. Advice

Sikasil SG-20 cures by reaction Copies of the following publications

with atmospheric moisture. The on specific applications will be are available on request:

reaction thus starts at the surface given on request. - Safety Data Sheet

and proceeds to the core of the - General Guidelines Structural

joint. The curing speed depends on Method of Application Silicone Glazing with Sikasil

the relative humidity and the tem- Surface preparation Adhesives

perature (see diagram 1 below). Surfaces must be clean, dry and

Heating above 50C to speed-up free from oil, grease and dust. Packaging Information

the vulcanization is not advisable Advice on specific applications and Cartridge 300 ml

as it may lead to bubble formation. surface pretreatment methods is

available from the Technical Ser- Unipack 600 ml

At low temperatures the water

content of the air is lower and the vice Department of Sika Industry. Pail 25 kg

curing process proceeds more Drum 270 kg

Application

slowly.

After suitable joint and substrate

preparation, Sikasil

SG-20 is Value Bases

10 50C 35C 23C

gunned into place. Joints must be All technical data stated in this

Curing speed [mm]

8 properly dimensioned as changes Product Data Sheet are based on

8C are no longer possible after con- laboratory tests. Actual measured

6 data may vary due to circumstan-

struction. Basis for calculation of

4 the necessary joint dimensions are ces beyond our control.

50C / 95% r.h.

35C / 90% r.h. the technical values of the adhe-

2 23C / 50% r.h. sive and the adjacent building Health and Safety Information

8C / 30% r.h.

0 materials, the exposure of the For information and advice re-

0 2 4 6 8 10 building elements, their construc- garding transportation, handling,

Time [days]

tion and size as well as external storage and disposal of chemical

Diagram 1: Curing speed 1-C-Sikasil loads. Joints deeper than 15 mm products, users shall refer to the

should be avoided. actual Safety Data Sheets

Application Limits For more information please con- containing physical, ecological,

Most Sikasil WS, FS, SG, IG, WT, tact the Technical Service Depart- toxicological and other safety-

AS and other engineering silicone ment of Sika Industry. related data.

sealants manufactured by Sika are

compatible with each other and Tooling and finishing Legal Notes

with SikaGlaze IG sealants. For Tooling and finishing must be The information, and, in particular, the

specific information regarding carried out within the skin time of recommendations relating to the appli-

compatibility between various the sealant or adhesive. cation and end-use of Sika products,

are given in good faith based on Sika's

Sikasil and SikaGlaze products When tooling freshly applied

please contact the Technical

Sikasil SG-20 press the adhesive current knowledge and experience of

Service Department of Sika the products when properly stored,

to the joint flanks to get a good

handled and applied under normal

Industry. All other sealants have to wetting of the bonding surface. No conditions in accordance with Sika's

be approved by Sika before using tooling agents should be used. recommendations. In practice, the

them in combination with Sikasil differences in materials, substrates and

SG-20. Where two or more Removal

actual site conditions are such that no

different reactive sealants are Uncured Sikasil SG-20 may be warranty in respect of merchantability

used, allow the first to cure removed from tools and equipment or of fitness for a particular purpose,

completely before applying the with Sika Remover-208 or an- nor any liability arising out of any legal

next. other suitable solvent. Once cured, relationship whatsoever, can be in-

the material can only be removed ferred either from this information, or

Sikasil SG, IG and WT sealants from any written recommendations, or

and adhesives may only be used in mechanically.

Hands and exposed skin should be from any other advice offered. The user

structural glazing or window bond- of the product must test the products

ing applications by experienced washed immediately using Sika

suitability for the intended application

professionals and after a detailed Handclean towels or a suitable and purpose. Sika reserves the right to

examination and written approval industrial hand cleaner and water. change the properties of its products.

of the corresponding project details Do not use solvents! The proprietary rights of third parties

by the Technical Service Depart- must be observed. All orders are ac-

Overpainting cepted subject to our current terms of

ment of Sika Industry.

Sikasil SG-20 is an elastic adhe- sale and delivery. Users must always

The compatibility of gaskets, sive and cannot be overpainted. refer to the most recent issue of the

backer rods, setting blocks and local Product Data Sheet for the pro-

other accessory materials with duct concerned, copies of which will be

Sikasil SG-20 must be tested in supplied on request.

advance.

Further information available at:

www.sika.co.uk

www.sika.com

Sika Limited

Business Unit Industry

Sikasil SG-20 2 / 2

Watchmead, Welwyn Garden CIty

Herts, AL7 1BQ

United Kingdom

Tel. +44 (0)1707 394444

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Aplikasi Teknologi Pengolahan Air Asin Desa Tarupa Kecamatan Taka Bonerate Kabupaten SelayarDocument15 pagesAplikasi Teknologi Pengolahan Air Asin Desa Tarupa Kecamatan Taka Bonerate Kabupaten SelayarChrist ManapaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Technical Specification - JH ExoTec Facade PanelDocument20 pagesTechnical Specification - JH ExoTec Facade PanelSudhakar KrishnamurthyNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Choice of ProfessionalsDocument32 pagesThe Choice of ProfessionalsSandipNo ratings yet

- Activated Carbon Beds in Amine UnitsDocument4 pagesActivated Carbon Beds in Amine UnitsKevin DrummNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- DP PriceDocument28 pagesDP PriceWarren JaraboNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Jotatherm TB550Document5 pagesJotatherm TB550Biju_PottayilNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 7607 E7018 SUPER OPTIMAL 4.0mm - BNM25913Document1 page7607 E7018 SUPER OPTIMAL 4.0mm - BNM25913魏利强No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Abistir 7120Document2 pagesAbistir 7120Phung LucNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Interlocking Paver Block Making Cost: Top Layer 500Document5 pagesInterlocking Paver Block Making Cost: Top Layer 500Rajan KumarNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Determination of The Effects of Biogenic Acidification On Concrete Antimicrobial Additives And/or Concrete ProductsDocument13 pagesDetermination of The Effects of Biogenic Acidification On Concrete Antimicrobial Additives And/or Concrete ProductsYoshi TaissonNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- STD Solution of VHGDocument97 pagesSTD Solution of VHGmohamedNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Acc CementDocument1 pageAcc CementAbhinav BharatNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Robert 2015Document6 pagesRobert 2015Mary VettoriNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Norsok Systems No 1Document0 pagesNorsok Systems No 1junidomarNo ratings yet

- Meat and Bone Meal As A Renewable Energy Source inDocument7 pagesMeat and Bone Meal As A Renewable Energy Source inIhsan FajrulNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hex Bonde A 9394 Structi L PDFDocument2 pagesHex Bonde A 9394 Structi L PDFFlorian Le MaoNo ratings yet

- Visual Inspection HRSG # 02Document2 pagesVisual Inspection HRSG # 02Muhammad RezaNo ratings yet

- Construction and Building Materials: Tahereh Ansari Rad, Javad Tanzadeh, Azin PourdadaDocument11 pagesConstruction and Building Materials: Tahereh Ansari Rad, Javad Tanzadeh, Azin PourdadaKashif NazirNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Table (1) Areas and Weights of Reinforcing Steel BarsDocument2 pagesTable (1) Areas and Weights of Reinforcing Steel BarsLynx101No ratings yet

- Belami NYLO Coating Additive CatalogueDocument8 pagesBelami NYLO Coating Additive CatalogueNihar Mango VakilNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Coordination Compound Level-0 Part IDocument3 pagesCoordination Compound Level-0 Part IAnumuskan KashyapNo ratings yet

- A Guide To BS en 998 - 1 and BS en 998 - 2Document6 pagesA Guide To BS en 998 - 1 and BS en 998 - 2Emmanuel MzenaNo ratings yet

- Sierra Pine Green EncoreDocument1 pageSierra Pine Green EncoreBMCWest-LudwigGroupNo ratings yet

- How To Identify Metal Surface Preparation Standards GradesDocument2 pagesHow To Identify Metal Surface Preparation Standards GradesMahmoud GwailyNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- MIL-H-6875H Heat Treatment of Steel, Process For (SS by SAE-AMS-H-6875)Document29 pagesMIL-H-6875H Heat Treatment of Steel, Process For (SS by SAE-AMS-H-6875)320338100% (4)

- Air Pollution ControlDocument76 pagesAir Pollution ControlSayyid Syafiq Syed MohamedNo ratings yet

- Effects of Oxidation in Everyday LifeDocument8 pagesEffects of Oxidation in Everyday LifeNur Masyittah IrmiNo ratings yet

- Aluminum Alloy Specification'Document12 pagesAluminum Alloy Specification'ArjunNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Ancon - Masonry Support PDFDocument38 pagesAncon - Masonry Support PDFESNo ratings yet

- Transition Elements Final 1Document44 pagesTransition Elements Final 1Venkatesh MishraNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)