Professional Documents

Culture Documents

6 D 4 D ErosionControlFabric 0

6 D 4 D ErosionControlFabric 0

Uploaded by

GihasAbd0 ratings0% found this document useful (0 votes)

6 views7 pagesErosion Control Fabric

Original Title

6 D 4 d ErosionControlFabric 0

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentErosion Control Fabric

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views7 pages6 D 4 D ErosionControlFabric 0

6 D 4 D ErosionControlFabric 0

Uploaded by

GihasAbdErosion Control Fabric

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

Tom Mountford

Schutz, Jeremiah ~ NRCS, Fremont, NE

Tuesday, December 09, 2014 8:01 AM

tmountford@Ipnnrd org

\Walkenhorst, Mark - NRCS, Wahoo, NE

Fabric Checks

Attachments: ‘SKMBT_C35314120908210.pdf

Tom,

| would like to present an idea I have a facilitate the installation of fabric checks for erosion control on existing and new

grassed waterway construction, From 2012-2014 in Dodge County the NRCS has designed and completed 4 grassed

waterways and we are currently designing 3 new waterways. The NRCS in Fremont would like to install fabric checks in

all new waterways to eliminate the initial erosion issues that occur during grass establishment. These projects only

require 100 ~ 150 ft of fabric and buying a bulk 600 ft roll increases the landowners cost. am requesting the NRD

purchase this fabric material with the intent to sell to contractors. | would lke to store this material at the NRCS Field

Offices and provide to contractors and landowners as needed. Attached is the material and design specification for

fabric checks. Installation is completed with a small trencher, backhoe or silt fence plow.

Thanks,

Jeremiah Schutz

USDA Natural Resources Conservation Service

2450 Business Park Drive | FREMONT, NE 68025,

Phone: (402) 721-2455 x- 110

This electronic message contains information generated by the USDA solely for the intended recipients. Any

unauthorized interception of this message or the use or disclosure of the information it contains may violate the

Jaw and subject the violator to civil or eriminal penalties. If you believe you have received this message in error,

please notify the sender and delete the email immediately.

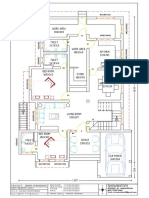

Geotextite Fabric Check

Notes:

1, Geotextie shall meet the U-85 Geotextile Construction

§

&

2. Geotentile fabric checks shol! be installed according to y

NEBRASKA STANDARD DRAWN

ineto0 10-003

Specification: Type-Nonwoven, Class 3, 2, or I. ‘Compacted Earthtiy

the TYPICAL SECTION shown or with @ mechanical device TRIGA,

(fabric plow) specitioaly designed for geotertite instalation 7 SPTON

% Compact the geotextile trench in six inch fifts, ensuring he

the top of the trench is lee! with the surrounding ground

surtoce

Geotextile Fabric Check Dato

|

J Moterwoy| stort | tnd | Shiitys| Noor | "eter | rota | Total

Number | Station | Stotion 0) Checks | section A-a)| (inst) | (oayd.)

WW2 e778 | WES lot se 2z 88" (27.3

47

Zt Y7

447

~ TOTALS:

Hoternay Grade Maximum Soacing between Checks

2 to 1.5 percent 100 Feet

15 to 30 percent 75 Feet

Greater thon 3 percent 50 Feet

TRAPEZOIDAL FILTER FABRIC CHECK

Owner: Bars (Kerr

Location: Sec BE TLBN, RE. w /B|

Tonnsbio

‘tae bpmetae

eet fo /

MATERIAL SPECIFICATION

592. GEOTEXTILE

SCOPE

This specification covers the quality of geotextiles

GENERAL REQUIREMENTS

Fibers (threads and yarns) used in the manufacture of

geotextile shall consist of synthetic polymers composed

of a minimum of 85 percent by weight polypropylenes,

polyesters, polyamides, polyethylene, polyolefins, or

polyvinylidene-chlorides. They shall be formed into a

stable network of filaments or yarns xetaining

@imensional stability relative to each other. The

geotextile shall be free of defects and conform to the

physical requirements contained in Tables 1 and 2. The

geotextile shall be free of any chemical treatment or

coating that significantly reduces its porosity. Fibers

shall contain stabilizers and/or inhibitors to enhance

resistance to ultraviolet light.

Thread used for factory or field sewing shall be of

contrasting color to the fabric and made of high strength

polypropylene, polyester, or polyamide thread. Thread

shall be as resistant to ultraviolet light as the

geotextile being sewn.

CLASSIFICATION

Geotextiles shall be classified based on the method used

to place the threads or yarns forming the fabric. The

geotextiles will be grouped into the types described

below:

@. Woven. Fabrics formed by the uniform and regular

interweaving of the threads or yarns in two

directions.

Woven fabrics shall be manufactured from

monofilament yarn formed into a uniform pattern with

distinct and measurable openings, retaining their

position relative to each other. The edges of

fabric shall be selvedged or otherwise finished to

prevent the outer yarn from unraveling.

592-1

NRCS-Nebraska (3/00)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Rotational Moulding-Technical StudyDocument24 pagesRotational Moulding-Technical StudyGihasAbdNo ratings yet

- P R O J E C T: Design of ResidenceDocument1 pageP R O J E C T: Design of ResidenceGihasAbdNo ratings yet

- Fpi 20.3PDocument2 pagesFpi 20.3PGihasAbdNo ratings yet

- Sikadur®-42 MP SlowDocument6 pagesSikadur®-42 MP SlowGihasAbdNo ratings yet

- PN 16 Flange Tables: Ring Joint Gasket Full Faced GasketDocument1 pagePN 16 Flange Tables: Ring Joint Gasket Full Faced GasketGihasAbdNo ratings yet

- The Adventures of Sherlock HDocument180 pagesThe Adventures of Sherlock HGihasAbdNo ratings yet

- 0002 DG 0 Ma 5500Document1 page0002 DG 0 Ma 5500GihasAbdNo ratings yet