Professional Documents

Culture Documents

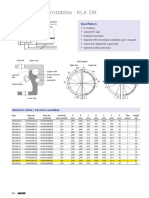

Shank Area Specifications

Uploaded by

ychodnekerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shank Area Specifications

Uploaded by

ychodnekerCopyright:

Available Formats

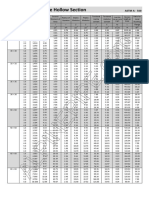

Table 1

Standard Metric and USA Bolt Shank Dimensions (All dimensions in units of mm or mm2 unless

otherwise specified.)

Coarse Pitch Threads Fine Pitch Threads

Size Nomi Nomi Thre Pitch Pitc Min M, MJ, Thre Pitch Pitc Min M, MJ,

Desi nal nal ads (mm h or UN UNJ ads h or UNF UNJ

g- (Maj Shan per per Dia- Dia- C, C per (mm Dia- Dia- , F

nati or) k inch, threa met met UN Tens inch, per met met UN Tens

on Diam Area, d),p er, er RC ile threa er, er RF ile

- An n dp Are Tens Stres n d), dp Are Tens Stres

eter, a, ile s p a, ile s

Dn As Stres Area As Stres Area

s , s ,

Area A ts Area A ts

, ,

A ts A ts

1.524 1.824 0.317 1.31 0.97 1.15 1.36

0 80

0 1 50 78 04 88 39

M1. 1.600 2.010 0.350 1.37 1.07 1.27 1.47

6 0 6 00 27 62 00 99

1.854 2.700 0.396 1.59 1.40 1.69 2.00 0.352 1.62 1.53 1.79 2.07

1 64 72

2 2 88 64 74 15 16 78 51 04 20 41

2.000 3.141 0.400 1.74 1.78 2.07 2.37

M2

0 6 00 02 90 32 84

2.184 3.747 0.453 1.88 1.99 2.38 2.80 0.396 1.92 2.18 2.53 2.91

2 56 64

4 6 57 98 86 47 49 88 66 74 83 53

M2. 2.500 4.908 0.450 2.20 2.98 3.39 3.82

5 0 7 00 77 01 08 80

2.514 4.966 0.529 2.17 2.62 3.13 3.70 0.453 2.22 2.91 3.37 3.87

3 48 56

6 2 17 09 22 86 14 57 00 16 41 07

2.844 6.356 0.635 2.43 3.20 3.89 4.64 0.529 2.50 3.65 4.26 4.91

4 40 48

8 1 00 24 45 22 67 17 11 55 11 30

3.000 7.068 0.500 2.67 4.47 5.03 5.62

M3

0 6 00 52 34 08 10

M3. 3.500 9.621 0.600 3.11 5.99 6.77 7.59

5 0 1 00 03 97 52 79

3.505 9.649 0.793 2.98 4.80 5.86 7.01 0.635 3.09 5.64 6.54 7.51

6 32 40

2 7 75 96 75 15 99 00 28 24 40 24

4.000 12.56 0.700 3.54 7.74 8.77 9.87

M4

0 6 00 53 96 87 20

4.165 13.62 0.793 3.65 7.71 9.03 10.4 0.705 3.70 8.29 9.50 10.7

8 32 36

6 8 75 00 66 79 64 56 73 10 16 95

4.826 18.29 1.058 4.13 9.35 11.3 13.4 0.793 4.31 11.3 12.8 14.5

10 24 32

0 2 3 86 46 11 52 75 04 11 99 93

5.000 19.63 0.800 4.48 12.6 14.1 15.7

M5

0 5 0 04 83 83 66

5.486 23.64 1.058 4.79 13.2 15.5 18.0 0.907 4.89 14.5 16.6 18.8

12 24 28

4 1 3 90 77 90 88 14 72 76 38 36

6.000 28.27 1.000 5.35 17.8 20.1 22.4

M6

0 4 0 05 94 23 84

0.25 6.350 31.66 1.270 5.52 17.3 20.5 23.9 0.907 5.76 21.0 23.4 26.0

20 28

00 0 9 0 51 51 30 76 14 08 06 67 65

0.31 7.937 49.48 1.411 7.02 29.2 33.8 38.7 1.058 7.25 33.8 37.4 41.2

18 24

25 5 3 1 10 67 26 15 3 01 26 62 84

8.000 50.26 1.250 7.18 32.8 36.6 40.5 1.000 7.35 36.0 39.1 42.4

M8

0 5 0 81 41 09 81 0 05 30 67 35

0.37 9.525 71.25 16 1.587 8.49 43.7 49.9 56.6 24 1.058 8.83 52.1 56.6 61.3

50 0 6 5 39 41 94 63 3 76 70 63 42

M1 10.00 78.54 1.500 9.02 52.2 57.9 63.9 1.250 9.18 56.2 61.1 66.3

0 0 0 0 57 92 90 81 0 81 97 99 04

0.43 11.11 96.98 1.814 9.93 60.2 68.5 77.5 1.270 10.2 70.3 76.5 83.1

14 20

75 2 7 3 41 10 86 08 0 88 27 91 23

M1 12.00 113.1 1.750 10.8 76.2 84.2 92.6 1.250 11.1 86.0 92.0 98.3

2 0 0 0 63 47 67 87 0 88 37 72 11

0.50 12.70 126.6 1.953 11.4 81.1 91.5 102. 1.270 11.8 95.9 103. 110.

13 20

00 0 8 8 31 03 48 63 0 75 03 20 76

M1 14.00 153.9 2.000 12.7 104. 115. 126. 1.500 13.0 116. 124. 133.

4 0 4 0 01 71 44 70 0 26 13 55 26

0.56 14.28 160.3 2.116 12.9 104. 117. 130. 1.411 13.3 121. 130. 140.

12 18

25 8 3 7 13 55 38 96 1 71 82 96 42

0.62 15.87 197.9 2.309 14.3 130. 145. 162. 1.411 14.9 154. 165. 175.

11 18

50 5 3 1 75 20 81 30 1 58 86 13 74

M1 16.00 201.0 2.000 14.7 144. 156. 169. 1.500 15.0 157. 167. 177.

6 0 6 0 01 12 67 74 0 26 47 25 32

0.75 19.05 285.0 2.540 17.4 194. 215. 237. 1.587 18.0 226. 240. 255.

10 16

00 0 2 0 00 84 78 79 5 19 65 62 00

M2 20.00 314.1 2.500 18.3 225. 244. 265. 1.500 19.0 259. 271. 284.

0 0 6 0 76 19 79 22 0 26 00 50 30

M2 22.00 380.1 2.500 20.3 281. 303. 326. 1.500 21.0 319. 333. 347.

2* 0 3 0 76 53 40 09 0 26 20 06 21

0.87 22.22 387.9 2.822 20.3 270. 297. 326. 1.814 21.0 310. 328. 347.

9 14

50 5 5 2 92 51 89 59 3 47 03 69 90

M2 24.00 452.3 3.000 22.0 324. 352. 381. 2.000 22.7 364. 384. 404.

4 0 9 0 51 27 50 91 0 01 61 42 74

1.00 25.40 506.7 3.175 23.3 355. 390. 427. 2.116 24.0 402. 427. 453.

8 12

00 0 1 0 38 51 80 77 7 25 94 77 34

M2 27.00 572.5 3.000 25.0 427. 459. 492. 2.000 25.7 473. 495. 518.

7* 0 6 0 51 09 41 90 0 01 22 74 79

1.12 28.57 641.3 3.628 26.2 447. 492. 539. 2.116 27.2 523. 552. 581.

7 12

50 5 0 6 18 18 44 88 7 00 82 08 08

M3 30.00 706.8 3.500 27.7 518. 560. 603. 2.000 28.7 595. 621. 646.

0 0 6 0 27 99 59 79 0 01 96 20 97

1.25 31.75 791.7 3.628 29.3 574. 625. 678. 2.116 30.3 660. 692. 724.

7 12

00 0 3 6 93 10 23 55 7 75 54 22 65

M3 33.00 855.3 3.500 30.7 647. 693. 2.000 31.7 732. 760. 789.

3 0 0 0 27 19 55 0 01 83 80 29

1.37 34.92 957.9 4.233 32.1 680. 745. 813. 2.116 33.5 813. 848. 884.

6 12

50 5 9 3 75 06 09 09 7 50 09 20 06

M3 36.00 1017. 4.000 33.4 759. 816. 876. 2.000 34.7 883. 914. 945.

6 0 9 0 02 28 72 26 0 01 85 53 74

1.50 38.10 1140. 4.233 35.3 834. 906. 981. 2.116 36.7 981. 1020 1059

6 12

00 0 1 3 50 73 62 47 7 25 47 .0 .3

* M22 x 2.5 and M27 x 3 for high strength structural steel fasteners only.

M and MJ are metric thread profiles. Size designations not beginning with "M" in Table 1 are UN and UNJ thread profiles

(non-metric), no longer used anywhere in the world except in a few behind-the-times organizations in USA.

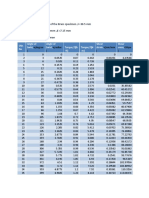

You can look up each value in Table 1, above, or you can use the Table 2 formulas to calculate the values yourself. In the

following table, Dn is nominal shank diameter (fastener size) from Table 1. Pitch p is fastener longitudinal length per

thread. Note that p = 1 / n, where n = threads per unit length. Le is thread engagement length.

Table 2 Bolt Shank Geometric Formulas

Fastener Stress Analysis Sym- Value (for various Thread Profiles) Source

Quantity Description bol M UN, UNR MJ UNJ

ISO 68-1, 1998, Fig. 1,

Thread profile angle 60° 60° 60° 60°

p. 2.

ISO 898-1, 1999, Sect.

Same as Same as 8.2, p. 13; ASME

Minor diameter Dm Dn – 1.226869 p Dn – 1.299038 p

M profile. UNR profile. B1.1, 1989, Sect.

8.3.1.f, p. 53.

ISO 898-1, 1999, Sect.

8.2, p. 13; MIL-

Tensile stress diameter Dts Dn – 0.938194 p Dn – 0.974279 p dp

HDBK-60, 1990, Sect.

110.1, p. 27.

Pitch diameter dp Dn – 0.75 p sin ISO 724, 1993, p. 2.

Shear stress diameter, shank

Ds Dn

in shear plane

Shear stress diameter, NASA TM-106943,

Ds Dts. Or you can conservatively use Dm.

threads in shear plane 1995, p. 16.

Barrett, Fastener

Thread shear (stripping) area, Design Manual,

Ath 0.333 dp Le

sloppy thread tolerances NASA RP-1228, 1990,

p. 21.

Thread shear area, both FED-STD-H28/2B,

threads class 2 or 3 (ISO Ath 0.5 dp Le 1991, Table II.B.1,

class 6H/6g) thread tolerance p. 57, Eq. 7.

Thread engagement length. In general, according to Machine Design magazine, the minimum recommended length of

engagement is 0.75 to 1 times the bolt major diameter for threading into steel and other materials of comparable hardness;

and 1 to 1.5 times the bolt major diameter for threading into brass, cast iron, and aluminum. These lengths of engagement

specified are for full threads engaged, not overall bolt length. Regarding partial threads in the chamfers on the ends of internal or external threads, FED-STD-

H28/2B, 1991, Sect. 7.7.2, p. 61, specifies that approximately half the countersink or chamfer depth may be included in the length of engagement calculation.

You might also like

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesFrom EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesRating: 5 out of 5 stars5/5 (3)

- Bar Area CalculationDocument5 pagesBar Area CalculationPranay WaghmareNo ratings yet

- 27.00 MM Jobthickness: A/l A/t A/l A/tDocument1 page27.00 MM Jobthickness: A/l A/t A/l A/tSatyabrata KunduNo ratings yet

- CC 34mm THK 2Document1 pageCC 34mm THK 2Satyabrata KunduNo ratings yet

- Steel Pipes Standard SizesDocument2 pagesSteel Pipes Standard SizesCarolie BacatanoNo ratings yet

- (In) (In) (In) (Per Sq. Foot Of) (In) (F /F)Document1 page(In) (In) (In) (Per Sq. Foot Of) (In) (F /F)Sidik SitepuNo ratings yet

- Engineering Tables Standard Wire GaugeDocument1 pageEngineering Tables Standard Wire GaugeTamandeep Sehmi56% (9)

- Thrust Block Designxls PDF FreeDocument8 pagesThrust Block Designxls PDF FreeTAHANo ratings yet

- Calculos ElectricosDocument2 pagesCalculos ElectricosYerson BahamondesNo ratings yet

- Volumen en Tanques Cilindricos HorizontalesDocument2 pagesVolumen en Tanques Cilindricos HorizontalessmalealNo ratings yet

- AWG Specifications TableDocument6 pagesAWG Specifications TableMaralo SinagaNo ratings yet

- Multiple Regression Juni 2019 (R 0.94)Document20 pagesMultiple Regression Juni 2019 (R 0.94)Multindo Barra KaryaNo ratings yet

- Standard Metric Bolt Shank DimensionsDocument4 pagesStandard Metric Bolt Shank DimensionsVIVEK YADAVNo ratings yet

- Advantage FYI166Document1 pageAdvantage FYI166mohanadsamaraNo ratings yet

- Hdpe ChartDocument2 pagesHdpe Chartmohamedaymansufpme2021No ratings yet

- Heavy Hex Bolt DimensionsDocument6 pagesHeavy Hex Bolt DimensionsSUJIT PATEL100% (1)

- Thrust Block DesignxlsDocument8 pagesThrust Block DesignxlsRuben Dario Posada BNo ratings yet

- Marco X Ring Size ChartDocument9 pagesMarco X Ring Size ChartThariqNo ratings yet

- Motorola Six Sigma Conversion TableDocument1 pageMotorola Six Sigma Conversion TableMars HNo ratings yet

- CC 33mm THK 2Document1 pageCC 33mm THK 2Anonymous ePjHLvJy4pNo ratings yet

- HPV Hydrostatics Run2Document6 pagesHPV Hydrostatics Run2maaathanNo ratings yet

- Pipe SizesDocument1 pagePipe SizesNimesh SinghNo ratings yet

- Tirante (Y) Area Velocidad v2/2g E. EspecíficaDocument4 pagesTirante (Y) Area Velocidad v2/2g E. EspecíficaHo AlexanderNo ratings yet

- Square Hs Final EnglishDocument3 pagesSquare Hs Final EnglishVasilis LappasNo ratings yet

- Tugas BanjirDocument4 pagesTugas BanjirnindiaNo ratings yet

- Astm A500 SHS 1Document4 pagesAstm A500 SHS 1Wong JowoNo ratings yet

- Standard Metric and USA Bolt Shank Dimensions: MM MMDocument2 pagesStandard Metric and USA Bolt Shank Dimensions: MM MMLan MendietaNo ratings yet

- Chi-Square Distribution TableDocument4 pagesChi-Square Distribution TableKent CoronelNo ratings yet

- App3Document2 pagesApp3hamidrezaee008No ratings yet

- Criterios de DiseñoDocument8 pagesCriterios de DiseñoKARITO SUAREZNo ratings yet

- ANSI B16.9 Elbow PDFDocument3 pagesANSI B16.9 Elbow PDFRamadan RashadNo ratings yet

- Dimensions (Based On ASME/ANSI B16.9) and Example Weights For Long Radius ElbowsDocument3 pagesDimensions (Based On ASME/ANSI B16.9) and Example Weights For Long Radius ElbowsRAFAEL BRAVONo ratings yet

- Elbow 2Document3 pagesElbow 2robert_candra_tarunaNo ratings yet

- Dimensions (Based On ASME/ANSI B16.9) and Example Weights For Long Radius ElbowsDocument3 pagesDimensions (Based On ASME/ANSI B16.9) and Example Weights For Long Radius ElbowsHai lm5No ratings yet

- Ppoo, PP00 A, XP00, XP00 ADocument12 pagesPpoo, PP00 A, XP00, XP00 AKenan KuloglijaNo ratings yet

- Flow of Water Through Schedule 40 Steel Pipe: Table B8.8Document2 pagesFlow of Water Through Schedule 40 Steel Pipe: Table B8.8LUDERNo ratings yet

- Resolución Práctica Calificada 3: Subcuenca 01 Subcuenca 02 TC TCDocument2 pagesResolución Práctica Calificada 3: Subcuenca 01 Subcuenca 02 TC TCNicole HuamaníNo ratings yet

- Consteel Hot Finished Hollow SectionsDocument13 pagesConsteel Hot Finished Hollow SectionsAnonymous dWa1xtpKmfNo ratings yet

- Quantity Between OGL & ETL (0/0 TO 8/0) : Rajdongari-Devnala-Chatva-Pipalpani-Tee Gaon Road KM 0/0 To 16/080Document8 pagesQuantity Between OGL & ETL (0/0 TO 8/0) : Rajdongari-Devnala-Chatva-Pipalpani-Tee Gaon Road KM 0/0 To 16/080popemiNo ratings yet

- Ejercicio Caso ABC Plantilla Dariela Zepeda 20191006742Document8 pagesEjercicio Caso ABC Plantilla Dariela Zepeda 20191006742Dariela ZepedaNo ratings yet

- Surface Calculation & PaintDocument14 pagesSurface Calculation & Paintsaid aminNo ratings yet

- Conversion Table of PCS-KG Table of Different Size of Wire NailsDocument5 pagesConversion Table of PCS-KG Table of Different Size of Wire NailsDraude OlabNo ratings yet

- C ChannelDocument1 pageC ChannelJuan Gutier CcNo ratings yet

- Light Lip Pped ChannelDocument3 pagesLight Lip Pped ChannelArif RusyanaNo ratings yet

- DataDocument3 pagesDatalaura sageNo ratings yet

- Data Set 3A For CoursesDocument6 pagesData Set 3A For CoursesDlanorNo ratings yet

- A1085 Dimensions and Properties Rect. HssDocument10 pagesA1085 Dimensions and Properties Rect. HsswalaywanNo ratings yet

- Obs. TableDocument2 pagesObs. Tablemanoj_varma_1No ratings yet

- CALIBTKDocument1 pageCALIBTKPaul CarlyNo ratings yet

- PRKTKM Kelompok 9Document65 pagesPRKTKM Kelompok 9Sudirman SyuaibNo ratings yet

- Surface Calculation & PaintDocument14 pagesSurface Calculation & PaintRajkumar ANo ratings yet

- Bolt Weight CalDocument10 pagesBolt Weight CalwahyuokkNo ratings yet

- Weight OF STEEL BARS PDFDocument14 pagesWeight OF STEEL BARS PDFAngelica Suico MayolNo ratings yet

- Data Set 13b: New Feed To Cyclone BM CCT Feed Cyclone Feed Cyclone U/f BM Discharge Cyclone O/fDocument4 pagesData Set 13b: New Feed To Cyclone BM CCT Feed Cyclone Feed Cyclone U/f BM Discharge Cyclone O/fFuneral Shop NilaNo ratings yet

- Practical Electronics - SWG - Wikibooks, Open Books For An Open WorldDocument4 pagesPractical Electronics - SWG - Wikibooks, Open Books For An Open WorldZia ur rehmanNo ratings yet

- Steel Section DLDocument1 pageSteel Section DLenggNo ratings yet

- Experimental Data: Length of The Brass Specimen, L 80.5 MMDocument2 pagesExperimental Data: Length of The Brass Specimen, L 80.5 MMal imranNo ratings yet

- Input: kN L= mm E= k= Section = ISHB 400 at 77.4 kg /m mm mm mm mm A= α = P= N/mm f = N/mmDocument4 pagesInput: kN L= mm E= k= Section = ISHB 400 at 77.4 kg /m mm mm mm mm A= α = P= N/mm f = N/mmychodnekerNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Presents: Concrete-Techgroup Indian Guide To Quality ConcreteDocument2 pagesPresents: Concrete-Techgroup Indian Guide To Quality ConcreteychodnekerNo ratings yet

- Goa Engineering College Civil Engineering SyllabusDocument7 pagesGoa Engineering College Civil Engineering SyllabusychodnekerNo ratings yet

- Calculation Sheet: Job No. Sheet Rev. Job. Title Date Checked by DateDocument1 pageCalculation Sheet: Job No. Sheet Rev. Job. Title Date Checked by DateychodnekerNo ratings yet

- DNV Code ListDocument3 pagesDNV Code Listychodneker100% (1)

- (ANSYS AQWA) Study On Mooring System Design of Floating Offshore Wind Turbine in Jeju Offshore AreaDocument9 pages(ANSYS AQWA) Study On Mooring System Design of Floating Offshore Wind Turbine in Jeju Offshore AreaychodnekerNo ratings yet

- Solid Works To Ansys Awesome!!Document2 pagesSolid Works To Ansys Awesome!!ale80ingNo ratings yet

- All The Best For Your Test !Document1 pageAll The Best For Your Test !ychodnekerNo ratings yet

- TestDocument1 pageTestychodnekerNo ratings yet

- Moment & Deflections in Simply Supported BeamsDocument38 pagesMoment & Deflections in Simply Supported BeamsychodnekerNo ratings yet

- List of IRC CodesDocument10 pagesList of IRC CodesychodnekerNo ratings yet

- IS 10322: 1987 (Part 5 / Sec 3)Document11 pagesIS 10322: 1987 (Part 5 / Sec 3)ychodneker0% (1)

- A Comprehensive Guide To Farmville v0.5: Johan H Agg September 2, 2009Document5 pagesA Comprehensive Guide To Farmville v0.5: Johan H Agg September 2, 2009ychodnekerNo ratings yet

- Parts Book Hd465-7r - Lepbh467r4Document710 pagesParts Book Hd465-7r - Lepbh467r4Royan Firdaus100% (1)

- AIRMAN pds70s-5b1 pds70sc-5b1 pds90s-5b1 pds90sc-5b1Document62 pagesAIRMAN pds70s-5b1 pds70sc-5b1 pds90s-5b1 pds90sc-5b1sedminNo ratings yet

- Din 6331 2003 Öøðí À ÂýäDocument3 pagesDin 6331 2003 Öøðí À ÂýäsbalajimNo ratings yet

- Parts Catalog RicoH VT1730Document157 pagesParts Catalog RicoH VT1730AgostinhoNo ratings yet

- Final Drive Gear and SprocketDocument2 pagesFinal Drive Gear and SprocketOZON cc100% (1)

- 2013 sbk1199 RDocument156 pages2013 sbk1199 RNyende DanielNo ratings yet

- Duo TaptiteDocument6 pagesDuo TaptiteMarija BoricicNo ratings yet

- Oc MTB Components Bluepaper en EsDocument16 pagesOc MTB Components Bluepaper en Esronare6613No ratings yet

- Manitowoc 4600 S4 Parts Manual PDFDocument108 pagesManitowoc 4600 S4 Parts Manual PDFnamduong36850% (2)

- Advance IC Engine Assignment - 81,82,84Document4 pagesAdvance IC Engine Assignment - 81,82,84Somesh SaurabhNo ratings yet

- MFPL.1506PNNP.D. PresentationDocument11 pagesMFPL.1506PNNP.D. PresentationPawan NagarkarNo ratings yet

- KLKDR1200 26Document1 pageKLKDR1200 26Carlos GuzmanNo ratings yet

- Activity Sheet Quarter 0-MELC 1: Tle - Ia (Electrical Installation & Maintenance)Document11 pagesActivity Sheet Quarter 0-MELC 1: Tle - Ia (Electrical Installation & Maintenance)ELMER DEMITNo ratings yet

- ALMA M50.: Available in These ColorsDocument2 pagesALMA M50.: Available in These ColorsCatalinSNo ratings yet

- 988h Lift and Tilt Sensor Cat - Cis.sis - PcontrollerDocument2 pages988h Lift and Tilt Sensor Cat - Cis.sis - Pcontrollerrao abdul bariNo ratings yet

- Barossa ATV - Quaterback 250 E - Spare Parts List PDFDocument45 pagesBarossa ATV - Quaterback 250 E - Spare Parts List PDFgabysurfNo ratings yet

- Pumppar 2020 KatologDocument87 pagesPumppar 2020 KatologUygar SaraçNo ratings yet

- (TM) Toyota Manual de Motor Toyota Yaris Verso 2001 en InglesDocument11 pages(TM) Toyota Manual de Motor Toyota Yaris Verso 2001 en Inglesjonathan matusNo ratings yet

- Autonext Study Material 1 (Engine) PDFDocument23 pagesAutonext Study Material 1 (Engine) PDFAbhishek Jain100% (1)

- CPS 800 12 900 10 Parts List 2012 02 ENG 2205 6006 51 PDFDocument51 pagesCPS 800 12 900 10 Parts List 2012 02 ENG 2205 6006 51 PDFMar SolNo ratings yet

- Installation Manual Serial 4000 HW - Tuf-Lite IIDocument8 pagesInstallation Manual Serial 4000 HW - Tuf-Lite IIAnonymous LBwADkNZHNo ratings yet

- Cg47ej Cg47ej (L) Cg47ej (T) Cg47ey (T) PDFDocument156 pagesCg47ej Cg47ej (L) Cg47ej (T) Cg47ey (T) PDFGabriel Reiriz SanchezNo ratings yet

- Catalgo Cadenas - Imperial - ENDocument35 pagesCatalgo Cadenas - Imperial - ENEstokador LekNo ratings yet

- InstrukcijaDocument12 pagesInstrukcijaBaltija MechanikasNo ratings yet

- XT125R 2008Document50 pagesXT125R 2008ToniNo ratings yet

- Belt Conveyor (131.160.J06)Document6 pagesBelt Conveyor (131.160.J06)shani5573No ratings yet

- Bluroc Hero-250 Manual EN-2021Document116 pagesBluroc Hero-250 Manual EN-2021Dunton GreeneNo ratings yet

- Table of Common Electrical Wire Sizes and Amps or Fuse Ratings - ResidentialDocument1 pageTable of Common Electrical Wire Sizes and Amps or Fuse Ratings - ResidentialHectorNo ratings yet

- Cars Under The Bonnet or Hood ExplainedDocument3 pagesCars Under The Bonnet or Hood ExplainedMohan RajNo ratings yet

- Singer 491D Service & Parts ManualDocument44 pagesSinger 491D Service & Parts Manualoswaldo acostaNo ratings yet