Professional Documents

Culture Documents

BSL-4 08.01.2017

BSL-4 08.01.2017

Uploaded by

SE EST0 ratings0% found this document useful (0 votes)

7 views6 pagesear

Original Title

BSL-4_08.01.2017

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentear

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views6 pagesBSL-4 08.01.2017

BSL-4 08.01.2017

Uploaded by

SE ESTear

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

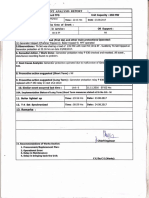

TRIPPING EVENT ANALYSIS REPORT

UNITNO :4 | TPS: Bhusawal TPS Unit Capacity: 500 MW

a 7 i synchi—

pee eae a Sinton Coa | Time: 09:21Hrs, | Date: 08/01/2017 Nes ot cave foes st

2, Last COH/ AOH Date:

3. Operating conditions at the time of Event: Tripping Event.

‘Load MW: Coal Cycles in service: Support:

251MW CDE NIL

4 Nature of Event: Due to tube leakage suspected in water wall of the boiler. The TG Set hand tripped.

43. Name of First Up, Main Protections & protection on which GCB tripped: Unit withdrawn for BTL.

First Up + Boiler protection.

Generator Tripped on: Reverse power protection, (Mechanical).

Turbine Tripped on: Turbine tripped.

Boiler Tripped on____: Turbine trip to boiler tripped.

6 A) Observations: Tube leakage in water wall of the boiler was suspected. As there was steam water leakage noise at

39M level since 07.01.2017, the drum level was maintaining at negative and difference in steam & feed water flow

increased up to 200 TPH.

B) Remedial Action / work done: 1) RHS water wall tube no.61 was having soot blower steam erosion at 43 mir

elevation.

2) RHS water wall tube no.56, 57,58,59,68 were eroded & Total no of joints is 14.

3) RHS water wall tube n0.60,61 were damaged due to overheating at 55 & 58 mtr elevation & total no of joints is 10

7. Root Cause Analysis: - 1) RHS water wall tube no.61 was having leakage soot blower steam erosion near SB no. -

30 at 43 mtr elevation.

2) RHS water wall tube no.60,61 was having fish mouth opening due to overheating at 55 mtr & $8 mtr elevation

respectively.

8, Preventive action suggested (Short Term): Joint inspection & trial BM, EM & Operation staff of WSB once in

every fortnight for correct operation of WSB.

9. Preventive action suggested (Long Term): In long shutdown of unit, soot blower erosion checking will be carried

‘out & eroded tubes will be replaced.

10.

ir event occurred last time: | Unit No. Time: Hrs. Date:

10A. Implementation Status of Long Term / Short Term measures stated at

No. 9:

11. Boiler lighted up: Time: 16:42 Hrs. Date: 10/01/2017

2. T-G Set Synchronized: Time : 03:09 Hrs. Date: 11/01/2017

13. Remark:

BTPS,Deepnagar

14. Recommendations of Works Section:

1. Procurement/Replacement Plan:

2. Operational Error:

3. Delay in Maintenance:

4. Delay in bringing back the Unit:

5. Training of Staff:

‘6. Whether rem:

action is completed satisfactory & point is elosed :

C.E./ Dy. CE (Works)

*HO Code will be given by Works Section.

Work carried out in unit 4 BTPS shutdown by TM500 from 8/1/17 to 10/1/17

1) HPH SA and 58 drip to deareator NRV bonet leakage attending.

2) HPH SA water box drain and 6A shell drain replacement.

3) Drain near DRV15 replacement

4) MS Line pressure sensing line isolation valve replacement

5) FOV 11 gland replacement

6) MDBFP AC DE side bearing oil leakage

7) LPBP breather filter checking and cleaning

8) TDBFP 4A and 4B rv coupling setting

9) TOBFP 48 BP suction pipe flange leakage

10) HPH 6A ext line drain vaive gland bolt replacement

11) HPH SA ext line isolation valve gland bolt replacement

12) TDBFP 48 main pump MS cooling line vent valve replacement

Add. sikeatie ingineer

TM 2X 500 MW,

MSPGCL, BTPS, Deopnagar

Executlve Engineer

‘TM 2x500 MW

MSPGCL, BTPS, Deepnagar

4 Work to be carried out by EMT-500 during U#4 shutdown,

From 08.01.17 to 11.01.17:-

1) GT-4A HV winding temp. not showing correctly at PCR, defect attended.

3) HRHV-109, SMV-1, SMV-7, S0-35, FDV-13, FDV-7, FDV-8, TDBFP-44

MTW70AA252, $-174, CHDV-6 MOV defect attended. Trial taken, found OK.

3) ID Fan-4A, 4B Ch-l & Ch-2. one by one Zener diode installation,

4) BCW-4A, Coal Mill-4A, its RCF & LOP one by P/M

5) DC scanner fan, HP seal water pump-1, LP seal water pump-1 & 2, Fludizing Blower

PIM carried out.

6) BASP A6 breaker alignment done

7) ESP field 2B21 & 7C11 attended after B/M work completion.

Focbtore

Adl. Executive €1

ngineer

Al | ale Elect. Maint.,500 MW.

Exeeutive En

ji

E.M.&T., xE00MW.

‘TUBE LEAKAGE REPORT 1

REPORT NO.: 16-17/4 UNIT: 4

DATE OF WITHDRAWAL: 08 /01/2017, 09:21 hrs

.* OBSERVATIONS:-

Noor |NOOF

ZONE LOCATION | PRIMARY FAILURE | SECONDARY FAILURE ag

JOINTS | Rays

RHS WW__| 1) RHS Water |-1) RHS Water Wall | 1) RHS water wall tube no. 56,

: Wall tube | tube no. 61 was having | 57,58,59,60 were eroded.

n0.61 at 43 | soot blower steam

meter erosion at 43 meter 4 4

elevation. _| elevation.

b) RHS Water 2) RHS water wall tube no, 60&

Wall tube no. 61 were damaged due to

60 at 55 meter overheating at 55 meter & 58

& RHS Water meter elevation 10 10

Wall tube no.

61 at 58 meter

elevation.

TOTAL| 24 [24

ANALYSIS:

RCE aA TERIA Rifled Tube SA210 Gr.C 6 51. X 5.6 mm.

DATE OF INSTALLATION OF TUBE Since commissioning.

1) RHS Water Wall tube no. 61 was having soot blower steam|

VISUAL EXAMINATION erosion at 43 meter Elevation.

1) RHS water wall tube no 61 having erosion opening @ 10

PHYSICAL EXAMINATION mm near soot blower no, 30 at 43 meter elevation,

L

FINDINGS:

1) RHS water wall tube no 61 having leakage due to soot blower steam erosion near SB no -30 at 43 meter

elevation,

2) RHS water wall tube no 60 & 61 having fish mouth openings due to overheating at 58 meter & 55 meter

elevation respectively.

Short Term:

Joint inspection & trial by BM, EM & Operation staff of WSB once in every fortnight for correct

operation of WSB.

Long Term:

In long shutdown of unit, soot blower erosion checking will be carried out & eroded tubes will be

replaced.

wr

xe

E.E, (BM-S00MW)

HH LING PI

Work carried out during U4 shutdown 08/01/2017

> BOTTOM ASH & FLY ASH EVACUATION SYSTEM

* Bottom ash hopper- cleaning work done

* Seal trough cleaning work done.

© Clinker grinder 3 replaced.

* B/A hopper flushing line choke up removed & modification done.

* ALA. B, C, D buffer hopper internal inspection done.

* Fluidizing pad leakages attended.

* Seal trough overflow line modified.

* C&D pass conveying line bends replaced.

Executive Engineer

AHP Maintenance-500 MW.

B.T.P.S. Deepnagar

Start Up Analysis during the month

UNIT NO.IV

Date & Time of trip

Turbine Casing Temp at Start up ( Deg

c)

Tyre of Start UP ( Cold / Warm / Hot)

BLU ON

PRDS Charging

FO Changeover

Fire Killing

Header Blow Down Completion

Boiler Relight UP

Vacuum Pulling

R “ing started

Synchronization

Oil Support withdrawn at

Oil Cons (LDO / FO) till Oil withdrawn

KL.

Full Load/Max Load achieved at (Load

& Time)

Date & Time Time Benchmark

08/01/2017 09:21 hrs taken

from BLU

08/01/2017 09:21 Hrs

323/293°C

Warm Start Up

40.01.17 at 16:42 hrs

18:50 hrs

CD Elevation:21:00hrs

AB Elevation:22:45 hrs

23:21hrs

22:30 hrs

11.01.17 at01:03 Hrs

11.01.17 at 03:09 Hrs

41.01.17 at 08:30 Hrs

LDO: 24 KL

HFO: 90 KL

492 MW at 12:00Hrs

Problems Faced During Start UP: While change over LDO to HFO for AB elevation oil guns. The

guns did not proved early. After so many times try, took about 30 min time to prove all light up

process at every command to guns tembha utilized to ignite.

The generator breaker was not getting closed while synchronizing problem occurred in switch yard

breaker control circuit. 1hrs 45 min i.e. 01:20hrs to 03:05 hrs time taken to investigate and attend

the problem.

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- NTPS - Highlights and Records For FY 2017-18Document2 pagesNTPS - Highlights and Records For FY 2017-18SE ESTNo ratings yet

- BTL Index Nov2017Document4 pagesBTL Index Nov2017SE ESTNo ratings yet

- Sop Chlorine and Ammonia GasesDocument3 pagesSop Chlorine and Ammonia GasesSE ESTNo ratings yet

- All India Nov-17Document2 pagesAll India Nov-17SE ESTNo ratings yet

- Compiled by EST-HO MumbaiDocument47 pagesCompiled by EST-HO MumbaiSE ESTNo ratings yet

- Station Capacity (MW) Rank PLF (%) : Central Central CentralDocument2 pagesStation Capacity (MW) Rank PLF (%) : Central Central CentralSE ESTNo ratings yet

- Event Analysis: TPS: Unit - Date: Operating Coal SeruiceDocument1 pageEvent Analysis: TPS: Unit - Date: Operating Coal SeruiceSE ESTNo ratings yet

- Sept 17 New DataDocument8 pagesSept 17 New DataSE ESTNo ratings yet

- At Of: Eyent Analysis NewlarliDocument1 pageAt Of: Eyent Analysis NewlarliSE ESTNo ratings yet

- BTL 500MW U4 Updated 06072017Document1 pageBTL 500MW U4 Updated 06072017SE ESTNo ratings yet

- PRS-4 16.12.2015Document1 pagePRS-4 16.12.2015SE ESTNo ratings yet