Professional Documents

Culture Documents

BS3550 PDF

BS3550 PDF

Uploaded by

pradelles89%(9)89% found this document useful (9 votes)

5K views49 pagesOriginal Title

BS3550.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

89%(9)89% found this document useful (9 votes)

5K views49 pagesBS3550 PDF

BS3550 PDF

Uploaded by

pradellesCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 49

Licensed Copy: London South Bank University, London South Bank University, Sat May 05 05:35:02 GMT+00:00 2007, Uncontrolled Copy, (c) BSI

BRITISH STANDARD 3550 : 1963

UDC 621,824.45

SPECIFICATION FOR

INVOLUTE

SPLINES

Licensed Copy: London South Bank University, London South Bank University, Sat May 05 05:35:02 GMT+00:00 2007, Uncontrolled Copy, (c) BSI

SPECIFICATION FOR

INVOLUTE

SPLINES

B.S. 3550 : 1963

Incorporating amendments issued May 1976 (AMD 1985)

‘and September 1983 (AMD 4371)

BRITISH STANDARDS INSTITUTION

Incorporated by Royal Charter

Licensed Copy: London South Bank University, London South Bank University, Sat May 05 05:35:02 GMT+00:00 2007, Uncontrolled Copy, (c) BSI

B.S. 3550 : 1963

‘Tus Barris StANDARD, having been approved by the Mechanical Engineering Industry Standards

‘Committee and endorsed by the Chairman of the Engineering Divisional Council, was published under

the authority of the General Council on 30th January, 1963.

‘The Institution desires to call attention to the fact that this British Standard does not purport to include

all the necessary provisions of « contract.

In order to keep abreast of progress in the industries concerned, British Standards are subject to

periodical review Suggestions for improvements willbe recorded and in due course brought to the notice

Of the committees charged with the revision of the standards to which they refer.

‘A-complete list of British Standards, numbering over 9000, fully indexed and with a note of the

‘contents of each, will be found in the BSI Catalogue, The BSI Catalogue may be consulted in

many public libraries and similar institutions

‘This standard makes reference to the following British Standards:

BS, 1044. Recommended designs for plug, ring and gap gauge

BS. 2089, Staighrsided splines and serrations:

British Standards are revised, when necessary, by the issue either of amendment slips or of revised editions.

is important that users of British Standard: should ascertain that they are in possession of the latest

‘amendments or editions.

CO-OPERATING ORGANIZATIONS

‘The Mechanical Engineering Industry Standards Committe, under whose supervision tis British Standard was prepared

Cansns of representatives from the Following Goverament departments and scentie and industrial organizations

Admiralty High Commission of India

‘Air Ministry

‘Associsted Offices’ Technical Committe

‘Reocition of Mining Elctrieal and Mechanical

Tnatation of Chil Engineers

‘Brush Chersical Pint Manufactures’ Assocation

British Compresed Air Society

‘Association

‘nda Iron and Stee! Fede

‘rich Railways Te Brita Transport Commission

{Grown Agents for Oversea Governments and

‘Aaminmtrations

*DSI1R—Nationl Engineering Laboratory

‘lccricty Counc, The Generating Board snd the

‘Arca Boards in England and Wales.

Engineering Equipment User’ Association

‘Gas Couaal

“The Government departments and scientie and industial organizations marked with an asterisk in the

tah Electrical and Alied Manufacturers’ Association

tation of Ges Engineers

ution of Heating and Veotlatng Engineers

sTnsttution of Mechanical Engineers

“aettution of Mechanical Engineers (Automobile

Division).

tution of Production Engineers

“ocomotve and Aled Manufacturers’ Association of

“Great Britain,

Machine Too! Trades Associaton

Minty of Labour (Factory Inspectorate)

Ministy of Power

ioe Building and Works

sport

Ministry of

National Coa! Board

National Payscal Laboratory (D-.1.R.)

adie Iedusry Counell

War omtce

ceeiae Sark tofowing, mere recy represented on the Commitee entrusted with tbe preparation ofthis standard

‘Association of Crane Makers

‘Ascciation of Hydraulic Equipment Manufactures

‘Brig Stee! Bar Assocation

fish Cycle aad Motor Cycle Industries Asocation

Te

‘British Internat Combustion Engine Research

"Association

Brita Ship Ressareh Associaton

Gauge and Toolmakers Asociation

Institution of Engineers and Shipbuilders in Scotland

Miling Cuter and Reamer Assocation

Mini

Shipbulders

Sociey of Brtsh Airraft Constractors Lt,

Steel Works Plant Assocation

{Taper Pn Manulacuters” Assocation

“The following B..L. references relat 1o the work oo this standard:

Telaltae erences MEE MEEIA/3 Drafts for comment A(MEEISS?, AA(MEE)278S

Licensed Copy: London South Bank University, London South Bank University, Sat May 05 05:35:02 GMT+00:00 2007, Uncontrolled Copy, (c) BSI

Co-operating organizations

Foreword

‘SPECIFICATION

1, Seope 5

2. Terms, definitions and symbols

3. Types of fit

4, Formulae for basic dimensions

5. Fillets and chamfers

6, Classes of fit

7. Spline errors

8, Effect of spline errors

9, Effective and actual dimensions

10, Use of effective and actual dimensions

1, Spline tables

12, Drawing data

13, Calculation of filets

4, Modifications for low numbers of splines

FIGURES

1. Terms and symbols

2, Profile errors a

3. Effect of splined hole errors

4, Effect of splined shaft errors

5, Spline Bt control

6-12, Drawing data

13, Fillet for filet root, internal

14, Fillet for fillet root, external

TABLES

Formulae for basic dimensions

Basic dimensions

Effective clearance

2-5/5 piteh-flat root side fit

CONTENTS

Part 1. Dimensions

Page

2

5

10

10

ei

u

B

B

B

8

°

Internal (hole) and external (shaft) spline tolerances 10,

2

18

6 316 pitch-flat root side fit

7. 4/8 pitch-flat root side fit

8. 5/10 pitch-flat root side fit

9, 6/12 piteh-flat root side fit

10, 8/16 pitch-fat root side ft

LL, 10,20 pitch-ftat root side fit

12, 12/24 piteh-at root side fit

13, 16/32 piteh-fat root side fit

14, 20/40 pteh-fat root side it

15. 24/48 pitch-flat root side fit

16. 32/64 piteh-flat root side fit

17.46 pitch-Rat root major diameter fit

18. 4/8. pitch-fat root major diameter fit

19, 5/10 pitch-fat root major diameter fit

20, 6/12 pitch-fat root major diameter fit

21. 8/16 piteh-flat root major diameter fit

22, 10/20 piteh-flat root major diameter fit

23, 12/24 pitch-flat root major diameter fit

24, 16/32 pitch-flat root major diameter fit .

25. 25/5 pitehsillet root side fit

26. 3/6 pitehsillet root side fit

27, 4/8 pitch-fillet root side fit

28. 5/10 pitch-fillet root side fit

29, 6/12 piteh-fillet root side fit

30, 8/16 pitehsfillet root side fit

31. 10/20 pitehsillet root side fit

pitch-Sllet root side fit

piteh-fillet root side fit

pitehsfilet root side fit

pitchstilet root side fit

pitch-filet root side fit

pitch-filet root side fit

38, 48/96 pitch-fillet root side fit

39. Machining tolerances

40, Formulae for dimensions and tolerances in

lables $ to 38 inclusive

41, One/Two pitch basie dimensions

42, Basic spline data

BS. 3880: 1963,

Page

19

2

of

2

SIRIRAR

3

2

3

35

6

37

38

9

41

2

8

45

46

a7

48

“0

50

st

32

3

3s

56

3

5

8

£

5

y

8

8

a

2

2

s

s

2

aa

=

6

a

3

9

2

0

Ss

o

s

=

s

=

B

3

o

2

2

5

€

5

a

g

3

3B

§

2

5

43

=

#

@

2

=

5

z

=

§

a

3

3

8

5

§

3

2

3

5

a

8

8

R

2

8

BS. 3550

11963

CONTENTS (continued)

Part 2. Gauging and Inspection

Foreword .

15,

16.

ra

18.

19.

2.

2

4,

15.

16.

1".

18,

1,

BRE

m4,

SRB

Analyt

‘SPECIFICATION

Inspection methods

Inspection with gauges

Gauges for splined holes

Gauges for splined shafts.

Gauge tolerances

Relationship between gauge and work

Measurement with pins

inspection

Change factor

FIGURES

Space width and spline thickness inspection

«Go full form plug gauge for side fit and Nor co

‘composite plug gauge for side ft and major

diameter ft

G0 full form major diameter fit plug gauge

Nor Go sector plug gauge. :

‘NOT Go major diameter fit sector plug gauge

‘ing gauge: co full form side ft, Nor Go

composite side fit and major diameter fit

|- Go full form major diameter fit ring gauge

. Nor Go sector ring gauge

Relationship between full form and composite

ring gauges and splined shafts

Relationship between full form and composite

ring gauges and splined holes

‘Measurement between pins

s. Measurement over pins

. Six spline, internal

Page

37

7

7

37

39

6t

65

8

m

3”

38

see

g

SBaR

Page

28. Measurement with three pins o

29, Cumulative pitch error chart n

30, Pitch readings due to eccentricity 0

31. Typical chart record 70

32, Measurement change factor K, 1"

32, Measurement change factor A, 1

TABLES

43, Relationship between work and gauge tolerances 63,

44, Allowable errors for gauges. o

45. Tolerances for actual space width and spline

thickness of gauges 64

46. Tolerances over measuring pins: plug gauges. 64

47, Tolerances between measuring pins: ring gauges 65

48, Tolerances for major and minor diameters of

gauges 6s

49. Measurements between pins for maximum actual

space width, splined hote n

50, Measurements over pins for minimum actual spline

thickness, splined shaft, Class 1 ft n

S1, Measurements over pins for minimum actual

spline thickness, splined shaft, Class 2 fit 4

'52, Measurements between pins for basie space

width, splined hole 1

53, Measurements over pins, for basic spline

thickness, splined shaft 16

APPENDIX

4, Sevolutes of angles 7

INDEX

Index n

Licensed Copy: London South Bank University, London South Bank University, Sat May 05 05:35:02 GMT+00:00 2007, Uncontroll

BS. 3550; 1963

BRITISH STANDARD SPECIFICATION FOR

INVOLUTE SPLINES

Part 1. Dimensions

FOREWORD

“This British Standard has been prepared under the direction of the Mechanical Engineering Industry Standards Committe,

and is complementary to H.S. 2089, ° Straight sided splines and serrations"

‘After the publication of B.S. 2059 in 1953 preliminary work on a standard for involute splines was commenced. It

became apparent that the A.S.A. '35 Standard was in use to some extent and that interchangeability of parts made 10

British and American Standards would be most desirable. It was decided to publish a British Standard for Involute splines

omitting reference to the serrations which appear in A.S.A. Standard BS as the Committee considered that a satisfactory

choice of serrations was available from B.S. 2059 : Part 2

‘The basic dimension of all sizes of splines covered ate the same as those given in the American Standard A.S.A. BS-15

1960 for

‘a, major diameter ft

bs side fit

‘The Committee considered the terms defined in B.S. 2517, * Definitions for use in mechanical engineering" and the

terms and novation defined in B.S. 2519, * Glossary of terms and notation for toothed gearing * but decided to adhere to

those given in the A.S.A, standard. Definitions of the terms used are included in this standard.

‘Details of gauges and inspection are given in Part 2

Obsolescent (by Amendment No. 2)

‘The need for the equipment covered by this British Standard has been reviewed and it has been decided that, in the

interests of rationalization, it should be regarded as obsolescent and not therefore used for new designs. The standard

will be withdrawn in due course

NOTE. Reference should now be made to BS 6186 ‘Specification for involute spines; metric module’ Part I ‘Dimensions and tolerances’

SPECIFICATION

1, SCOPE

‘This British Standacd provides data and guidance for the

design of straight involute splines of 30” pressure angle,

tabulates limiting dimensions and deals with manufac

turing errors and their effect on the fit between mating

spline elements.

‘The range of splines covered is:

Side ft, 25/5 to 32/64 pitch,

flat root 6 to 60 splines inclusive

Major diameter 6, 3/6 to 16/32 pitch,

fat root 6 to 60 splines inclusive

2-8/5 to 48/96 pitch,

6 to 60 splines inclusive

(see figure 1)

2. TERMS, DEFINITIONS AND SYMBOLS

For the purposes of this standard the following terms

‘and definitions apply.

24 An involute spline is a spline having involute

profiles.

2.2 Pitch circle is the reference circle from which all

transverse spline dimensions are derived and is the circle

‘on which the pressure angle ofthe involute has the specified

standard valve

23 Pitch diameter (D) is the diameter of the pitch

circle

24 Pitch is a combination number; the upper of frst

‘number isthe diametral pitch, the lower or second number

is the stub pitch,

28 Diametral pitch (P) is the number of splines

inch of pitch diameter. pines

2.6 Stub pitch (P,) is a number used to compute

‘addendum and dedendum; 1 inch divided by the stub

pitch is the basic addendum.

2.7 Circular pitch (p) is the distance between corres:

ponding points of adjacent splines along the pitch circle.

2.8 Pitch point is the intersection of the spline profile

with the piteh circle,

29 Pressure angle is the acute angle between a line

tangent to an involute and a radial line through the point

of tangency. Unless otherwise specified, it is the main

pressure angle.

2.10. Main pressure angle (4) is the pressure angle at

the pitch point

2A Base circle is the ciecle from which involute

spline profiles are constructed.

212 Base diameter (D,) is the diameter of the base

circle

2.13 Major diameter is the diameter of the outermost

surface of the spline (major circle). It is the outside

diameter (D,) of the splined shaft or the root diameter

(D,) of the splined hole.

5

Licensed Copy: London South Bank University, London South Bank University, Sat May 05 05:35:02 GMT+00:00 2007, Uncontrolled Copy, (c) BSI

B.S. 3550 : 1963

2.14 Minor diameter is the diameter of the innermost

‘surface of the spline (minor circle). Its the inside diameter

(D) of the splined hole or the root diameter (D,.) of

the splined shaft.

245 Addendum (a) is the radial distance from the

pitch circle to the minor circle of the splined hole and

from the pitch circle to the major circle of the splined

shaft

2.16 Dedendum (b) is the radial distance from the

pitch circle to the major circle ofthe splined hole and from

{he piteh circle to the minor circle of the splined shaft.

27 Depth of engagement is the sum of the addenda of

internal (hole) and external (shaft) splines, less the height

of any chamfer.

2.18 Form clearance (c,) isthe radial depth of involute

profile beyond the depth of engagement with the mating

part,

2.19 Form diameter (De) is the diameter atthe deepest

point of desired true involute form (TIF).

2.20 Fille is the concave portion of the spline profile

which joins the sides to the bottom of the space.

2.21 Fille root splines are those in which a single filet

in the general form of an are joins the sides of adjacent

splines.

2.22 Flar root splines are those in which filets join the

ares of major or minor circles to the spline sides.

2.23 Effective space width of a splined hole is equal to

the circular spline thickness on the pitch circle of an

imaginary perfect splined shaft which woul fit the splined

hole without looseness or interference,

2.24 Effective spline thickness of a splined shaft is

equal to the circular space width on the pitch circle of an

ry perfect splined hole which would fit the splined

shaft without looseness or interference,

228 Actual space width (s) is the length of are on the

pitch circle of any single space

2.26 Actual spline thickness () is the length of arc on.

the piteh circle of any single spline.

227 Cumulative pitch error is the value obtained by

subtracting the desiga length from the actual length

between corresponding profics of splines not adjacent 10

each other.

2.28 Profile error is the deviation from the specified

spline profile (see Fig, 2)

2.29 Alignment error (sist) is the deviation of the

splines from parallelism with the axis of the splined shaft

oF splined hole.

2.30 Effective error is the accumulated effect of the

spline errors on the fit with the mating part.

231 Error allowance (e) is the permissible effective

232 Machining tolerance (m) is the permissible

variation in actual space width or actual spline thickness.

2.33 Total tolerance (m +. e)s the machining tolerance

plus the error allowance.

2.34 Effective clearance (c,) is the effective space width

‘of the splined hole minus the effective spline thickness

‘of the mating splined shaft,

2.35 Lengch of engagement (L,) is the axial length of

‘contact between mating spines.

2.36 Active spline length (L,) is the length of spline

which contacts the mating spline. On sliding splines it

exceeds the length of engagement.

237 Symbols

a addendum

1b dedendum

ey effective clearance

ce form clearance

D pitch diameter

base diameter

pin contact diameter, internal spline

‘pin contact diameter, external spline

form diameter

form diameter, internal sp'ine

form diameter, external sp ine

D,_ minor diameter, internal

), major diameter, external

re_minor diameter, external

‘major diameter, internal

diameter of measuring pin for external spline

d, diameter of measuring pin for internal spline

2 error allowance

K, change factor for external spline

K, change factor for internal spline

spline length

Ly active spline length,

L, length of engagement

im machining tolerance

M, measurement over pins

measurement between pins

N-number of splines

P—diametral pitch

P, stub piteh

circular pitch

fillet radius

actual space width, circular

4 effective space width, circular

1 actual spline thickness, circular

1, effective spline thickness, circular

4 main pressure angle

4a pressure angle at contact diameter, internal

pressure angle at contact diameter, external

4° pressure angle at pin centre, interval

44 pressure angle at pin centre, external

4p) pressure angle at form diameter

hotvw com SBR

Licensed Copy: London South Bank University, London South Bank University, Sat May 05 05:35:02 GMT+00:00 2007, Uncontrolled Copy, (c) BSI

BS. 3550 : 1963

Main pressure angie Circular pitch p

ramfer-heig

\4 ae bes a

Major dia. fit, lat root

Addendum) Dedendum —

os i,

f WL x Ve Mey Uy

Side fit, fillet root

Fig. 1. Terms and symbols

Licensed Copy: London South Bank University, London South Bank University, Sat May 05 05:35:02 GMT+00:00 2007, Uncontrolled Copy, (c) BSI

B

by

8

3. TYPES OF FIT

(ee Fig. 1)

3.1. Major diameter fit. In this type the members ft on

the major diameter, the sides of the splines act as drivers

‘and the minor diameters are clearance dimensions. The

roots of the spline spaces of the splined hole are flat

and those of the splined shaft are flat or approximately

semi-circular,

2.2 Sie fi. In this type the splined hole and splined

sss

tajor tnd minor diameter re caranct dimensions and

the root of the splines of each member may be at or

sppronimatelysemicirlr.

4, FORMULAE FOR BASIC DIMENSIONS

‘The formulae for the basic dimensions are given in

Table 1.

ich ie

stb pitch » | 2 | 2 | a

Pin daneer | 0 | mp | me | MP

Base diameer | D, | Deos¢ | Deos #| Deos

Circular ich |p | nih | we | miP

cere (on) coe |e

Adéenduminwroal] a | wes | ume | Hie

Addendum, external| 08/P,-0002 | 1/P, | WP,

Desendum, intemal] | um | 1m | 18m

Dedendumenternall , | 12, | aim | 8

zspstoiasine,| ™ | +0002 |+o00d | ‘F

Dedendum,external | 5 rap, | 19, | 20

Tes2r0826 ine} * | +000 |+o008 | %

Forckanece | & 2001 D max, o018

5 correct for To

Tumben of aplnes” Gee todiied

diameter, Cause {4 For formule for dimensions and tolerances

sce Table 40

Licensed Copy: London South Bank University, London South Bank University, Sat May 05 05:36:02 GMT+00:00 2007, Uncontrolled Copy, (c) BSI

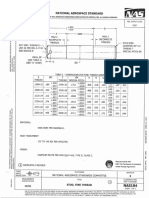

TABLE 2. BASIC DIMENSIONS (INCHES)

BS. 3550: 1963,

Relative size ited Circular pitch | Mine

|

_ 1

LT _ owe osu

News =

LT 46 07054 osser

a=

rw ao ass one

rm |e |.

<= t

ro ans ossat oases

wee

tI mwa one oun

wee

SN | sar ome 01309

a0

aman 1s ons ote

wow

re 20/40 o1STL 00785:

we

rey, 24/48 0109 00654

ww

_ sp oma coms

N= '

wenn om cor cows

y=

ven cose ost

5

Licensed Copy: London South Bank University. London South Bank University, Sat May 05 05:35:02 GMT+00:00 2007, Uncontrolled Copy, (c) BSI

BS. 3850: 1963,

5. FILLETS AND CHAMFERS

1 Filles for fet rot splines, The fle s contol

bythe orn dlr, son radio at man

han neil condone i eren Inthe le the

Alt produce by geesing procs It wil have &

‘arg ad of corvatr

Upeienion of ue let is not tually neesary.

Woelsit neuer oredr sre contents te

umm amu ras may be speed.

Tat oo spline nesta or os ppc,

52 Piers for ile ror spines. Te tbls give ull

tangent radii for maximum depth with a minimum value

(of 0-004 inch. These values are intended as a guide for the

specification of approximate radii for highly stressed parts.

‘The curvature along any generated fillet varies and

cannot be properly specified by a radius of any given value.

Fillet root splines are recommended for heavy loads

because larger filets reduce stress concentrations.

5:3 Chamfers for external (shaft) splines. These are

ured for major diameter fits to provide clearance for

the fillet of the internal (hole) spline.

‘Where the same tooling is used for producing major

diameter and side fit external (shaft) splines, a chamfer

(which is usually permissible) may be generated on the

side fit spline.

5.31 Standard internal (hole) splines have no chamfer

fat the minor diameter. Where the design requirements

‘demand a chamfer, special tooling or a further operation

will be required,

6. CLASSES OF FIT

6.1. Basis of system. The dimensions and resultant fits

given in the tables are based on the basic hole system.

In this system the design size of the splined hole is the

basis, and variations in fit are obtained by varying the

allowance on the splined shatt.

62 Major diameter fit is a close fit on the major

diameter. The space width and spline thickness are the

same as for the Class I (Ire) side fit.

6.3 Side ft. The members fit on the sides of the spines

only. Two classes of ft are provided viz Class 2 (close)

Wwhare the backlash is minimum and Class # (Cee) where

greater backlash is allowed, The same tolerances are used

for both fis

7. SPLINE ERRORS

‘The permis tolerances for pitch, profi alignment

cine wel as fr machining ee lem Table 3

TABLE 3. INTERNAL (HOLE) AND

EXTERNAL (SHAFT) SPLINE TOLERANCES

Pion | 2.98

36

alelalela ls]

| 2 | 20 19 16 6

er er

al 2) 2/2) a]3) e

| «@ | wo | a | | ~ | 18

* i

Fath ee

w]e] ss) «| s] 2

ef] a] Bp SEs

od

gin oe 1 fs) 4) het 0 20

Error 305 6 78 PN Bs

+ For basis of calculation see formulae in Table 40.

1 For numbers of spins aot given, proportionate values shal be

taken

au, com BIRR

led Copy, (c) BSI

Licensed Copy: London South Bank University, London South Bank University, Sat May 05 05:35:02 GMT+00:00 2007, Uncontr

TA Positive and negative profile errors ae illustrated in

Fig, 2. The reference profile, from which deviations occur,

passes through the pitch point which is used to determine

the actual space width or spline thickness. Profile error is

positive in the direction of the space, and negative in the

direction of the spline.

Internal External

tole} space (ahatt)

2. Profle errs

12 Alignment

72.1 Tolerances for alignment error include the effec,

of taper.

7.22 The alignment tolerance applies to the tota

spline length or any portion thereof, unless otherwise

specified,

73 Our of roundness may appear merely as a result of

piteh and profile errors given in Table 2 and requires no

Further allowance, However, heat treatment and deflection

‘of thin sections may cause out of roundness, which

increases pitch and profile errors. Allowance for this will

depend upon circumstances and is, therefore, not tabulated.

14 Eccentricity

TAX Eccentticity of major diameters in relation to

the pitch diameters of major diameter fit splines should be

absorbed within the maximum material limits established

the tolerances on major diameters and effective space

Width or effective spline thickness.

7.4.2 Becentricity of major and minor diameters, in

relation to the pitch diameters of side fit splines must be

controlled within the form diameters of the mating splines,

ven under conditions of maximum effective clearance.

‘This standard does not establish specific tolerances.

NOTE, Spline rar due to eccentricity. his standard does not

include corrections to Take account of the ecentity of locating

surlaces

If the alignment of mating spliaes i aflected by the eccenteety

of lgcting surlucs fe Searing surfaces) elie to each other

Sncfor to the splines it may be necessary to decrease the eMetve

Bnd deual spline thckaess of tbe external member in onder to

Fits the Geired fe condition

8, EFFECT OF SPLINE ERRORS

8.1 Pitch errors cause the clearance to vary between

‘mating splines. Any pitch error reduces the clearance.

BS. 3580: 1963,

8.2 Profile errors. Positive profile errors affect the fit

by reducing the clearance; negative profile errors do not

affect the fit.

8.3 Alignment errors cause clearance variations and

therefore usually reduce the clearance.

84 Error cllowance. The effec of individual spline

errors on the elective fit Isles than thet toa, besuse

feat of more than minimum clearance ean be altered

without changing theft Te er allowances 6 pe cent

tthe sum of ce the positive profl error the maximum

umlative pitch error (eee Fig. 29 of Part 2) and the

Alignment eror for the length of engagement. "The ervor

allowances in Table are based on an slgnment error for

an assumed length of engagement equal to one-half the

pitch diameter AGjstnent tay be required fora grester

Feng of engegement

9, EFFECTIVE AND ACTUAL DIMENSIONS

9.1 Ejective and actual space width. Fig. 3, view A,

iitustrates a splined hole with errors of pitch and profile

‘View B shows that a perfect splined shaft contour (without

errors) does not ft, even though each spline has the same

Width as the mating space. To allow the perfect splined

shaft to fit in any position, all spaces of the splined hole

rust be widened by the amount of interference. This width

as shown in view C, is the actual space width of the

splined hole. The effective space width is the spline

thickness of the perfect mating spline.

9.2 Effective and actual spline thickness. The same

reasoning applied to the splined shaft leads to the concept

‘of effective Spline thickness which exceeds the actual

spline thickness by the effective error. See Fig. 4

9.3 Effective clearance. The effective space width of the

splined hole mious the effective spline thickness of the

splined shaft is the effective clearance, which defines the

fit mating parts (this is strietly true oniy if high points of

muting parts come into contact), Values are given in

Table 4, which are summarized from Tables $ to 38 ine.

9.4 Space width and spline thickness limits, The varia-

tion of actual space width and actual spline thickness

Within the machining tolerance causes corresponding

variations of effective dimensions, s0 that there are four

limit dimensions for each component part, as illustrated in

the bar chart, Fig 5

9.4.1 The minimum effective space width is always

basic, and is half the circular pitch; the maximum effective

spline thickness is determined by the desired minimum

eifective clearance. The permissible variation of the

elfective clearance is then distributed between the internal

(hole) and external (shaft splines to arrive at the maximum

‘effective space width and the minimum effective spline

thickness. ‘Limits of the actual space width and actual

spline thickness are constructed from suitable error

allowances,

uw

‘TABLE 4, EFFECTIVE CLEARANCE

(In 0-001 inch units)

2

Licensed Copy: London South Bank University, London South Bank University, Sat May 05 05:35:02 GMT+00:00 2007, Uncontrolled Copy, (c) BSI

oon

pra] ass | as | er | 1020 | soar | ese [oven en | soz | som | aes

St) a | te | ae | ee |e oe ah |e ae

1 : hme dancesneatnchinemaneete

W ‘aaa at we w ae

1 yt ee

wo| mse | ear | asm | sae | asse | asa oat | os | ot

| mss | ws | aise | ise | tae | nm | cas | Ga | ose

3) ire | ws fim | tea | ia | ia [om | oa | om

| ase | ace | imse | ier | anu | iss oo | 8-08 | o.a8

| 26-78 | 2565 | rest | ra | iss | 505 | 032 | 0-30 | 0.50

| S80 [os | 8 | os

Profile

[A Each space is basic width Perfect splined shaft with basic spline

= hickness interferes at

‘Actual space width

Effective space width

equals spline thickness of

perfect splined shaft

CC. The perfect splined shaft spline fits in any position,

spaces of the splined hole are widened by the amount of interference

Fig. 3. Effect of splined hole errors

_—Actual spline thickness

Effective spline thickness

‘equals space width of

perfect splined hole

‘The perfect splined hole fits in any position,

if all shaft splines are narrowed by the amount of Interference

Fig. 4. Effect of splined shaft errors

SEALDIAPL wu. bzFen, com RAB,

Licensed Copy: London South Bank University, London South Bank University, Sat May 05 05:35:02 GMT+00:00 2007, Uncontrolled Copy, (c) BSI

BS. 3550: 1963,

10, USE OF EFFECTIVE AND ACTUAL DIMENSIONS

—_—

] Dimensioning

| | [alternatives

bimension) _ettective etuel standard | A] 8

p cecal see cio

!

| ry max} pequired-+Required + (AUX)

iepece: Js min. {

atm f4e wav nun

I | sym

ina a 1 sus requires tRequired

n T

theta) | T | |

|pasic ee 1 Required + Required + Required

Peneae Tmax a cee emcee (acer |

+ 1 Required-+Required-+-Required

‘Spline 7

thekness| ‘vf 4 1 urxitreguired-+Required

of imax.

| ex tina (aun AUK) (ux)

(shatt)

AUX)

Effective clearance e Error allowance

Required-+ Required:

Tm = Machining tolerance (see Tables 39 and 40).

Fig. 5. Spline ft controt

Fig, 5 presents four dimensions for space width and fr

spline iickness. Each ofthese bas 2 dst Function,

TAL Munmum.efecive space width (min) and

maxinunefectve spline thickness (max) These dimer

Slons conse the minimum effective clearance, and mun

always be specified

102 Mumm actual space wiih min) and maxima

actual spline thickness (1 ax) These dimension cannot

te sed for asceptance or rejection of parts I the actual

Space with is less thn the minimum without causing the

tfeeive space width tobe underso, orf the actual spline

thickness 1s more than the maximum wilbout easing the

ttfcive spline tcknes to be oversie, the eetive ere

{Ses than aniipated; such parts are acepiable and not

‘efetve. The speciation of these actual dimensions as

processing auxiliary dimensions is recommended. They

Fre used to analyee undersie eflectve space with of

‘versie elective spine thickness conditions to determine

Sthuther or nt they are cased by excestive effective err

103 Maximum actual spoce width (ony) and minimum

actual spine thcknest (ng). These. diensions. define

the machining tolerances and contol the effective eteor.

‘The diflerence between these dimensions reduced by the

ffoive error ofthe intemal (hole) and external (hal)

Spine, is the maximum effective clearance. Where the

‘ffctive ettorobtaned in machining is apprecably les

than the error allowance, these dimensions, must be

adjusted in order to maintain the desired fi

0A Maximum effective space wilh (i, max) and

minimion efective spline thickness (min). These der

Sons define the maximam effete clearance, but they

So not contol the effective ero.

At They may be Used, in addition to the mis in

Ctause 10.3 in order to prevent the Increase of maximum

‘ffxive clearance, eto reduction of estive errors

See Fig 5, alternative A

1042 Where the actual sie (¢ max. of # min) nesds

no control or is contoled by independent and separate

melrologicl inspection, dimensions $5 max. of fy mio.

thay be substituted for those given in Clause 103. See

Fig Sv ahemativeB

11, SPLINE TABLES

“ables 5 10.38 inclusive give the dimensions for splines

of the side fit Rat root spe, major diameter flat root

types and side Atle 700 pe. Dimensions for the

Ghliwo pitch splines Table 41, are given for reference

tectuse Spline dimensions in other tales are inversely

proportioned tothe onetwo pitch spine dimensions

NOTE, Adsmena may be rege to lw fr bat taint

inure! econ vy eg splaen pron rumen

sar

Ti'Pormula for dimensions and tolerances ited in

‘Tabes $10 8 até shown in Table 40. Some dimensions

are modiied as explained in clause IM. Space widih and

Spline thickness tolerances are based on the sum of the

tachiing tolerance and error allowance given iTable 3.

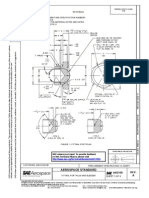

12, DRAWING DATA

Its important that uniform methods of presentation

be used to show compete information on detail drawings.

Much misunderstanding wil be avoided by following the

Suggested arrangement of dimensions and data a shown

in'bigs 6 to 12 The Xs induate where the dimensions are

to be placed, ad the number of X's indeate the number

‘of decimal places normaly wed

STE Deals efpa cans st meson ovr po ae pea

run tine

24 Spline data and auxiliary dimensions, Spline data

ae used for design snd manufacturing purposes. Auilry

dlmensions are dimensions without tolerances ised a the

basi of caltlation only and do not govern manvfactaring

or icpetion operations in any way.

12D, Wheve filet root external splie is wed for a

maj clametr ft the drawing should conform with Fig.

12 the minor diameters and fie radi are obtained from

tables 3-38 inclusive columns 18:3 and 19 respectively

andother dimensions fom tables 1724 inlaive.

13

Licensed Copy: London South Bank University, London South Bank University, Sat May 05 05:35:02 GMT+00:00 2007, Uncontrolled Copy, (c) BSI

BS. 3850: 1963,

Circular space width min. effective XXXX

max effective XXXXAUX)

min actual JOOXKAUX)

max. actual 20K

Involute spline date

Flat root side tit

Number of splines xx

rexionx Pitch Piten XxInx

ia. Pressure angie 30°

S har (AUR) :

S ‘dia, KKK The following intormation may be added

rad ‘ form ab required

A pene sia Base diameter wexeeK AUX)

XKKKK Max. measurement between two

neal pins XXXXX (AUX)

oy Pin diameter X4XxK

Involute profile error + XXXx

{ (Zero at pitch point) ~ Xxx

Max pitch error 200K

Max. slignment error XXX

Length of engagement XK

Fillet rad a

Fig. 6. Drawing data : Splined hole, side fit, flat root type

Cireular spline thickness max. effective XXXX

min. effective XXX (AUX)

max actual XXXx(AUX)

min. actual -XXXXx

Involute spline date

Flat root side fit

Number of splines x

Piten xxix

x Pressure angle 30"

NN i The following information may be added

” i requires

HoxxKK torn base diameter HexKRXIAUKD

AOHXKK Minmeascrement over two pins XXKEXIAUX)

Bin diameter “XXXX

Involute profile error + -XXXX

ero at piteh point) ~ xXx

Max. pitch error XXRX

Max alignment error XXX

Length of engagement. XXX

Fillet rod xx

Fig. 7. Drawing data : Splined shaft, side fit, fat root type

“

Licensed Copy: London South Bank University, Londof’South Bank University, Sat May 05 05:35:02 GMT+00:00 2007, Uncontrolled Copy, (c) BSI

Cireular apace width

Exeantricity between these

diameters must be absoried within

the limits of major diameter end

effective space width

BS. 3550 : 1963

sn eftective Kxxx

x effective xxxMAuR)

min getual OOKMAUE)

max actual -XXKX

Involute spline date

Flat root major diameter fit

Number of splines

Piten xr,

Pressure angie 0°

Tye, tptowing tarmation may be

aprequired =

dase diameter yoKOEMAUED

ax meesure nent betwe

“feo pins KCAL)

Pin diameter Kxxx

Involute profile errar + XXXX

(Bero at pitch pointl~ xXx

Max pitch errot EK

Max. alignment error HOKK

Length of engagement xxx

Fillet ead 20K

Fig. &. Drawing data : Splined hole, major diameter fit, flat roat type

Eccentricity between these

dismeters must be absorbed within

tha limits of major diameter and

effective spline thickness

Circtdar spline thickness max effective XXK

i etect ve XX KXAUK)

fax actual 2XXXAUE,

min Sctual XXXX

Involute spline data

Flat root major diameter fit

Number of splines xx

Pitch KEK,

Pressure angle 30°

Ths following intermation may be

added as required

Base diameter 2OIAURD

Min. measurement over two

ping XXXXXIAUR)

Bin diameter Xxxx

Invoiute profile error + KNX

(ere at piteh paint)- 20K

pitch error YK

Max.alignment error 5

Length of engagement — XXX

Fillet rad. XX

Fig. 9. Drawing data : Splined shaft, major ameter fit, at root type

BS, 3550; 1963

Circular space width min effective XXXX

maxeffective XXXXALK)

min, actual -XXXXiAUK}

fax aetual — XXKX

Involute spline data

Fillet root side fit

© Number of splines xx

15:02 GMT+00:00 2007, Uncontrolled Copy, (c) BSI

rea “pies pa wales

KXREX Gia Pressure angle

2x "major (ty iden The following information may be

‘ad mK Sade es Tequired

Leary a me diameter XRMIHAID

imearorement between

RR Macmeasy ‘no. pind KXXXXCAUK)

minor Pin diameter 3%

ae Involute profile enter XXX

{defor at pitch pond) sa

Max pen error mm

Max alignment ecrar eK

Uemgth ot engagement XXX

Piet rad. OK AUX)

Fig, 19, Drawing data : Splined bole, side St, filet roat type

Circular spline thickness. max effective X2xX

‘min. effective EKXAUX)

max aetual SOOKIAUX)

min actual xxx

Invotute spline date

Fillet root side fit

Number of spline xx

Piten XK,

Pressure angie 30

The tollowing information may be

added 4s required =

jase diameter OOOMAUY

Min, measurement aver two

Bins XXKXRIAUI)

Pin Siametar XXX

Involute profile error # XXX

(Zero at piteh pointh~ XXxx

Max. gitch error HXXK

Max alignment error HK

Length of engagement = Xxx

Fillet rad, 2K (AUK

Fig. 11. Drawing dats : Splined shaft, side fit, fillet root type

Licensed Copy: London South Bank University, Londoti'Soulh Bank Universily, Sat May 05 0!

BS Or BS. 2802 196

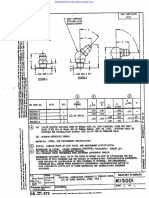

8 a [TABLE 5. 25/5 PITCH, FLAT ROOT SIDE FIT ascurs

Sia” Geer ve igen) oe Nori at)

| ite se data (ene

Finet rot major olamater it iat Seat |Seaua| ease | #300

Number st spines ox at dest Satis | is eae

Puen ap Siu See Stas | Sas a

Pressure angie 30° eet neg ox oes) un

Som TEissngpa ners nye eed Raed =

yr Oe ae ead sx mavo ous |evs| sal oca [peur | aay |ouss| em ewe

as sie 7 Ee cain Sa | ' | cases 2

She roe Fees” ak =

ig 12 Drawag du: Spe ae ot nao amc ti ecb sea [oct

London South Bank University, Sat May 05 05:35:02 GMT+00:00 2007, Uncontrolled Copy,

GIA cies aire ceh ad nities ah Sh

Licensed Copy: London South Bank University, London South Bank University, Sat May 05 05:35:02 GMIT+00:00 2007, Uncontrolled Copy,

5

z

5

8

3

3 TABLE 6 36 PITCH, FLAT ROOT SuE‘EIT vcs

Se? eerie oy oni

j ee lelcle

a Load ine Se | “a

: = _ as

8 3 esi SSB | $285) cea) aks So Pe

3 em Josue esins|osuze osnae| 93ees| 33mm] gzam gue ie

8 2) ease AE SH S| 72s] 2M | ts Se ee

£ Ed esis ita Sut S| SPS CESS Bed

5 / i gs

. ed seer

2

3 ps asmy sae estou oe at

& |e sliae ee (eee See ee E

& ssa heat e282 |S | fe 4) ER) 238 Bite 3

oom asp au ea : ict aa

esa Ss Sa SEs ES] bed ee

per ia SRR RE

Licensed Copy: London South Bank University, London South Bank University, Sat May 05 05:95:02 GMT+00:00 2007, Uncontrolled Copy, (o) BS

Licensed Copy: London South Bank University, London South Bank University, Sat May 05 05:95:02 GMT¥+00:00 2007, Uncontrolled Gopy, (¢} BSI

see

z

5

E

is

i

i

nS. 35901955

Any», 2 PITCH, FLAT ROOT SDE ETE micas

=e aaneiESies eee

aes | eae *

gp ele et tielehoeiere fle ES

a HERE HEHE

SESE

LUcensed Copy: London South Bank University, London South Bank University, Sat May 05 06:25:02 GMT+00:00 2007, Uncontrolled Copy, (¢) BS!

SLOT Spaeth me awe

S290: 1968

TABLE HL 1020 PITCH, FLAT ROOT SIDE FIT incwes

“pm” exer orig ts) om a rin

| T [eas maa | sone TT

ii

i

S/o Si amt) ASE PIB Sue

|Siste ines ‘ctvet| Samo| Saas San ons

| Ha

5

ql

Tait

af

f

Se] SE CHIE) 8] EB] SIS

Sat May 05 05:35:02 GMT+00:00 2007, Uncontrolled Copy, (c) BSI

BE

:

i

s

feuwe veuee sueee wzmes euese

2 seek em

seBBE G8ERE

3 Sign jours |eaver| $8) 2am) 228/08 3 ist

avers wseae geese

ae Pema pa a Se Sa ee ee Hea a RTE

Ah pr nl ep

Al

Licensed Gopy: London South Bank University, London South Bank University, Sat May 05 05:35:02 GMT+00:00 2007, Uncontrolled Copy, (¢) BSI

332 3]

ce

8

5

5

5

z

8

3

3

5

=

8

3

TAMLE 18.1952 PITCH, FLAT ROOT SIDE EIT ines

ee. ese |g aes

au oH

, London South Bank University, Sat May 05 05:35:02 GMT+00:00 2007, Uncontrolled Copy, (c) BS!

, London South Bank University, Sat May 0S 05:35:02 GMT+00:00 2007, Uncontrolled Copy, (c) BSI

Beoh REude Eszet Sae|r suEMY oHEKE EUuSE HEEEE

as

fe

ug

renee TR Pe

eden ae a am

LUcensed Copy: Landon South Bank Uni

§

&

3

s

&

H

BS. 15902186

a asus 1e 0 mci, rr nor se et sae 2 san 1g 4 roa, rar noo7 pee seus

= T o sme | i e

& | ie 1 | Me na 8

3 eer Og

8 f 13

s le | 5 a

2 [oat 8 | oater| ous | ase ea name ez see en ee foam tao ‘ime ome

& fe i) Sab] S Es cet Sa i 8 ee se

2} a a ed SE Ba em Sa (as! FR] FB] SE

Ss 4 sao ocr exe ee ona cn | saa giz saz oe

3 Bue $35) SEER ses : ce a) S| He eae gan den fan fe as Seat

s ali ‘| cl ee rag| © be 8 on ea as ea oan raw om evae|omt| om emm| oxelomr

BS Eu ES) |B) cy Sa se RS | HS) 8 aR | Hs) a an Sake i) ake

Bo ssh ae sae sacl savleaemalselecelocleerccelvosleeel cane | a: (anal esl var ee fer cles es os co _ ee

= BSS) HES) He) EIU ieee eae] | s/c 2B Bee ES a) sne[onay S88 Sa EL HR TESS

a | oop sagt] tere] ye] tg oles leseleamelarpleza tem rae eae] nessa Bama! rd saps! ls ese faage a as eae

By ERB] HEE] Fs) #s) !ee/S Sse gs etm] Has | fe) de ea tc eae 2 Be

3 36 | wyaoa| sa] tuo! 22400] s-s0e] oxo [eon | ones | osama |o-os | pares ‘er | 11360 0008 2 ws baeme| combs] eal & vases! anes Joon

2 2 ge) She eigt site| Belgie 2 BS) ERS Ree

Bole ig al es ce| eq smel mele; |g | col el tae rae ial

5 S| FS) Fah on (So ls deat] sea lms § S| We SR) E08) dai] esi |p |sea pa |e Yea! 150 oer

i 3 | BB| Bay hg [OS] SERS SS] ES] EES BS |S Se] Sees aS) IS Se alan eg a S| Sg a cee

ee) & Saleesliareelel eles eeie 6 2B ERIE) Ee eee a as ee

fe Ban 2: sv bua ras for oars foots Sain) SNE) Seen, Fie en BS | SSS) ESS] Sts) 222] $F) Sas | SS oome | ose jomer| oe ian be um| dems | ata

z 2 | 33] esa [agrees saul sema/ sina) suusieag om | sal une! sien| se] nx lonm! ecm eel un cam [aes loses | fuss] te] ae ism

2 5 [sais [mt foams were ser eset] deea| Ea foe 2 48 2 1a pe el iB ‘ie | beet ect ea] Oe er Bea] fu lea

S # azleam[sza one larecaa| te] meal ancl wy | nap) al uel eat aa ex co xl ere

é 2 act[eme|tealtae|emelena| lea iae/ imei = | te fa gee Ba ee

g 8 sss Setar Ra ES CETTE SE so | ee (et eae 1 Beat ES

= a BOF Scau —

& § *

i 3

TABLE 16.3265 PITCH, FLAT ROOF SIDE FIT iNcHEs

2

[TABLE 17.36 PITCH, FLAT ROOT MAJOR DIAMETER FIT ixcuEs

8 set | SER) SRE] cee | Saag] gaE soe ese ese oa Sea) tame | fat ee

5 | RR) SS | Sh) Se eS Seale 1 SES

a

g

:

5

i ea Si | see] yet cea | sate] sm slau ae st

z SR SBR SS SE | HES) fee] 8 | ea] ise set Se

: sora lan ew ees] ctp| soa zs) rele

fs f= fos fst til til nt ol

2 HER) | aS ( e Reece tt a

: pa cra smz cag ame sezese Es ise uel em (eae am oxo calm naan Eon eluates

3 EBs ie elite 68 3] 2B SES eee Seeks ie

8 | 155] BS GREE € 3 BES (BESS ats [te (ne |S its |e oe

g ag] 2B | 2a uptime = Bg [sn [sm asa tase

: Ha 8] oS Heese |g R es [ras |e ot

g Ff welemie 2g sc gal es ao

ele Hag EERE gg 28 3 a TE a a

z a | sel 1 ge] aaa | Eg [ison amet wane asec sa oun |e elon

3 8 i ste eo fes/ies 6a BB URS) SER fe seas 2S SES] eS [8a eSBs eg a at

3 HE Ha) ae oa a SBS SE |S (eta Sa Bo sa

oberon. a § [ae Lara aa oa aT

5 Bh metre 3 Saal tge oti AUR)

2 RRR . i

8 8

} i °

ance 184 PITCH, FLAT ROOT MAJOR DIAMETER FTE rect P __mus a0 sc, 14 ROOT MOR AMEE IE mies

a sent ont 2 Sa ne

T elt

mete |e} oe Se

SSS ECE es

= is

ee Vise ame

Be LS

eee 98 sp | emmy eae] sa | cask) cme eu gt on i 3

2 i Sos Ca (ole BED 128) TBS | Pee) co ce pon lova|ise Sam

5

5

2222 22808

g| ssees eeeee voese azcee susue wie

Apart ar oe RP»,

a et

GS Cau miter sae ncaa nay ee tae ea oT

SRST coe e ae

ci

Licensed Copy: London South Bank University, London South Bank University, Sat May 05 05:35:02 GMT}00:00 2007, Uncontrolled Copy, (c) BSI

icensed Copy: London South Bank University, London South Bank University, Sat May 05 05:35:02 GMT+00:00 2007, Uncontrolled Copy, (c) BS!

asso: 5 ns. 20:16

{anu 3,2 ore, FLAT ROOT MAJOR DlaMEtER BOT now = @ {TABLE 2. $26 PITCH. FLAT ROOT MAJOR DIAMETER EIT cuss

Siereaah See Pb ero tt) z = mE? ata rl ‘See Dring ae)

T z 1

sate | e Se SSS]

sits aE 8

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- BS8888Document13 pagesBS8888pradelles0% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Iso 7380Document8 pagesIso 7380pradelles100% (1)

- Astm D999Document5 pagesAstm D999pradellesNo ratings yet

- Iso 261Document4 pagesIso 261pradellesNo ratings yet

- Nas 184Document2 pagesNas 184pradelles100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MSRR 6523Document5 pagesMSRR 6523pradelles100% (1)

- MSRR 6522Document7 pagesMSRR 6522pradellesNo ratings yet

- Def Stan 01-8Document33 pagesDef Stan 01-8pradellesNo ratings yet

- Astm A689 PDFDocument4 pagesAstm A689 PDFpradellesNo ratings yet

- Astm A513 PDFDocument20 pagesAstm A513 PDFpradelles89% (9)

- Astm A500.1978 PDFDocument8 pagesAstm A500.1978 PDFpradellesNo ratings yet

- As 5169Document5 pagesAs 5169Wuod JipangaNo ratings yet

- Astm A681 PDFDocument14 pagesAstm A681 PDFraulNo ratings yet

- TKG® HGW 2083 / 2082: Density Colour DesignationDocument1 pageTKG® HGW 2083 / 2082: Density Colour DesignationpradellesNo ratings yet

- MSRR 6011Document14 pagesMSRR 6011pradellesNo ratings yet

- Iso 4014-Din 931Document2 pagesIso 4014-Din 931serzo75No ratings yet

- 605m36 SteelDocument2 pages605m36 Steelhimanshudhol25No ratings yet

- AN2442Document22 pagesAN2442pradellesNo ratings yet

- Undercut TableDIN 509Document6 pagesUndercut TableDIN 509Dwi DarsonoNo ratings yet

- Mil-Std-1251a - Listing Screw and Bolts - An-Nas-MsDocument182 pagesMil-Std-1251a - Listing Screw and Bolts - An-Nas-Mspradelles100% (2)

- An3 Thru An20 Rev-12Document4 pagesAn3 Thru An20 Rev-12pradellesNo ratings yet

- Mil W 12133 3Document6 pagesMil W 12133 3pradellesNo ratings yet

- MS15001ADocument1 pageMS15001ApradellesNo ratings yet

- MS16997DDocument7 pagesMS16997DpradellesNo ratings yet

- MS17984F - Broche À BillesDocument6 pagesMS17984F - Broche À BillespradellesNo ratings yet

- MS9390CDocument4 pagesMS9390CpradellesNo ratings yet