Professional Documents

Culture Documents

ME3242Ch05 07

Uploaded by

Jecky Mitra Saini0 ratings0% found this document useful (0 votes)

49 views12 pagesmaybe this document can help you

Original Title

ME3242Ch05-07

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentmaybe this document can help you

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

49 views12 pagesME3242Ch05 07

Uploaded by

Jecky Mitra Sainimaybe this document can help you

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

320

(@) Derive an expression for the steady-state temper

ture Tex, #®) = Ty, leaving your result in terms of

plate parameters (M, c,), thermal conditions (Ti Tar

1 the surface temperature T(L, #, and the heating

time,

Lumped Capacitance Method

‘85 ‘Steel balls 12mm in diameter ae sunealed by heating

to 1150 and then slowly cooling to 400 K in an ait

envionment fr which T= 325 K and = 20 Win K.

‘Assuming the properties of th steel tobe k= 40 Wm

K, p= 7800 kg/m, and ¢ = 600 kg, estimate the

time required forthe cooling process.

Consider the steel balls of Problem 5.5, except now the

tir temperature increases with time as T.(9 = 325 K +

at where a = 0.1875 Kis.

(@ Sketch the ball wemperatre versus time for = # =

Th. Also show the ambient temperature, Ta in YOUF

‘graph, Explain speciat features ofthe ball emmpera-

ture bebavir.

(&) Find an expression for the ball temperetore as a

function of tine, TI, and plot te ball temperance

for = 5 1 8. Was your sketch comect?

56

157 The heat transfer coefficient for ar flowing over a sphere

fs to be determined by observing the temperature-time,

history of a sphere fabricated from pure copper. The

sphere, which is 12.7 mm in diameter, is at 66°C before

‘fs inserted into an airstream having a temperature of

ZIP. A therraccouple on the outer surface ofthe sphere

indicates 55°C 695 after the sphere is inserted in the

airstream. Assume, and then justify, thet the sphere

‘behaves as 2 spacemise isthermal object and calculate

the hear ransfer coefficient.

58 A soli sel ober (AS11010), 300mm in diameters

‘ened vith dec materia layer of thickness 2 mn

ia taal condo 004 Win" K. The coed sphere

i inal ara uniform temperate of 300°C an is d-

ely quenced ina lrg ol bat for which T= 100"C

and 3300 W/m?» K, Estimate the time required for

the coated sphere temperature to reach 140°C. Hin

Neplet the efec of energy storage in the dileczc

Pee sine themal eapacance jeP) is smal

Sopa to tht ofthe sel shew.

[Bi] base plate ofan ron has a thicknes of L = 7 mm

‘and ig made from an aluminum alloy (p = 2800 kg/t?,

SS soo tig k= 180 Wim-K, e = 080). An ele

{i revixanee heater isaac to the inne snfce of

the pute, wath tr erie i exposed to ambient

rand lang soundings at To = Tay = 25°C. The areas

‘of both the inner and outer surfaces are A, = 0.040 my"

510

sa

Chapter Sa Transient Conduction

‘Sunounnes Ta

if an spproximately uniform heat fx of gf = 1.25%

10! Win is applied to the inner surface of the bise

plate and the convection coefficient atthe outer surface

is h= 10 Wn? *K, estimate the time required forthe

plate to reach a temperature of 135°C. Hint: Numerical

Integration is suggested in order to solve the problem,

Carbon steel (AISI 1010) shafts of O.i-m diameter ae

heat treated ina gas-fired furnace whose gases are at 1200

XK and provide ¢ convection coefficient of 100 Winn? K.

Ifthe shafts enter the furnace at 300 K, how long must

they remain in the furnace fo achieve 4 centerline em

perature of 800 K?

‘A thermal energy storage unit consists of a large rectan-

‘gular channel, which is well insulated on its outer sur

face and encloses alternating layers of the storage

‘material and the flow passage.

Bach Jayer of the storage material isan aluminum sib

‘of width W = 0.05 m, which is at an inital semper

of 25°C. Consider conditions for which the storege uit

jis charged by passing a hot gas through the passes

‘ith the gas temperature and the convection coeffi

‘assumed f0 have constant values of T. = 600°C aa

100 Wit?» K throughout the channel, How 1088

‘wil it take to achieve 759% of the maximum possible

i

E

f

i

i

= Problems

corresponding temperature histories of the plate for

05152500.

1420 An electonic device, such as a power transistor mounted

‘on @ finned heat sink, can be modeled ss a spatially

jaothermal object with intemal heat generation and an.

extemal convection resistance,

(a) Consider such a system of mass M, specific beat c,

and surface area 4, which is intially in equilibrium

with the environment at T,. Suddenly, the elec-

tronic device is energized such that a constant heat

seneration E, (W) occurs. Show thatthe tempera-

tue response of the device is

reels)

seme tie where 0 = T— Te) and Ti) is the steady-state

‘pismovig temperate conesponing to fre 8) ~

| 7(2); T= inal temperature of device R

ected (ie | resistance VhA,; and C= thermal capacitance Me.

te avian (0) An electtonic device, which generates 60 W of

aace length teat, is mounted on an slurinam heat sink weigh-

‘prot fc ing 01 kg and echt a temperstire of 100°C fa

wre Fee ambient at at 20°C under steady-state conditions

850, TFtbe device i inialy st 20°C, what tenperanure

ems fine wil reach 3 min fhe oer vices en?

wheat tas 521 Before being fjeted into a furnace, palverzed coat is

» — prehened by passing i through cylindrical tube

o ‘whose surece (maintained 3 Ty = 1000°C. The coal

ee pellets are suspended in an sitfow and are known to

vit te 0 tnove with a speed of Sms, If the pellets mey be

wane approximated ab apheres of Lam diameter and it may

ee be sssumed that ty ate heated by radiation tnsfer

plete from the tube surface, how long mvs the tbe be to hest

wi coal entering st 25°C ta temperature of 600°C? Is the

esitake eg oe ofthe lumped capacitance method jusiied?

sine ae 9 522 A metal sphere of diameter D, which is at uniform

Win K temperature Tis sudrly removed from a furnace and

eee suspended fom fine wire i lege room with air ata

raeeh uniform temperature 7. andthe suroanding walls at 2

temperate Toy

(@) Neglecting beat tansfer by radiation, obtain an

‘expression forthe time required to coo} the sphere

to some temperature T.

(© Neglecting heat tansfer by convection, obtain an

expression forthe time required t9 coo! the sphere

to the temperature 7.

(© How would you go about determining the time

required for the sphere t9 cool to the temperature

Tf both convection snd radiation are of the sume

onder of magnitude?

323

|Consider an anodized aluminam sphere (e = 0:75)

50 mm in diameter, which is at an intial temper

ture of 7; = 800K. Both the air and surroundings

sre at 300K, and the convection coefficient is

10 Win? K. For the conditions of pars (@), (b),

and (©), determine the time requied for the sphere

to cool 0 400 K. Plot the corresponding tempera-

ture histories. Repest the calculations fora polished

aluminam sphere (© = 0.1).

5.23 As permanent space stations inrease in sine, there is an

attendant increase in the amount of electrical power

they dissipate. To Keep station compartment tempera-

tures from exceeding presribed limits, itis necessary

to tcansfer the dissipsted heat to space. A novel heat

rejection scheme that has been proposed for this por

pose is termed a Liquid Droplet Radiator (LDR). The

heat is first transferred to a high vacuum oil, which is

thea injected into outer space as a steam of small

droplets, The stream is allowed to averse a distance L,

‘over which it cools by radiating energy to outer space at.

absolute eo temperature. The droplets are then col-

lected and routed back to the space station,

Calder

(Consider conditions for which droplets of emissivity

‘£095 and diameter D = 0.5 mm are injected at ter

perature of T)= 500K and a velocity of ¥ = 0.1 mis

Progertes ofthe oil ae p =: 885 kg/m, c = 1900 kg

K,and k= 0.145 Wim K. Assuming each drop to radi-

at to deep space at Tuy = OK, determine the distance L

required forthe droplets fo impact the collector at final

‘temperature of T; = 300K. What is the amount of ther

tal energy rejeted by each droplet?

In & material processing experiment conducted aboard

the space shutle, a coated niobium sphere of 10-mm

iameter is removed from a furnace at 900°C and

cooled to a temperature of 300°C. Although properties

fof the niobium vary over this temperature range,

constant valves may be assumed to a reasonable

approximation, with p = 8600 kg/m’, ¢ = 290kg-K,

63 Wim K.

524

324,

528

Chapter 5 9 Transient Conduction

(@) If cooling is implemented in a large evacuated

chamber whose walls are at 25°, determine the

time required to seach the final temperature ifthe

coating is plished and has an emissivity of e = 0.

How long would it take ifthe coating is oxidized

and © = 0.67

() To reduce the time required for cooling, considers-

tion is given to immersion of the sphere in an inert

‘gas stream for which T = 25°C and h = 200 Wim?

*K. Neglecting radiation, what is the time required

for cooling?

(© Considering the effect of both radiation and con-

vection, what is the time required for cooling if

= 200 Wim? -K and e = 0.6? Explore the effect on

the cooling time of independent varying h and e,

Plasma spray-coating processes are often used to pro

‘ide surface protection for materials exposed to hostile

environments, which induce degradation through fac~

tors such as wear, comrsion, or outright thermal failure.

Ceramic coatings aze commonly used for this purpose

By injecting ceramic powder through the nozzle (anode)

of a plasma torch, the particles are entiined by the

plasma jet, within which they are then acceleatsd and

heated,

Pass et wth entined

‘ori ples a 9

Ceramic enone

suberate

Dosing thie sime-in-ight, the ceramic paticies must

be heated to their melting point and experience com-

plete conversion to the Tigad state, The coating is

formed asthe molten dropets impinge (plat) on the

substrate material and experience rapid solidification,

Consider conditions for which spherical alumina

(AL) panicles of diameter D, ~ 50 aan, density y=

3970 kg/m’, theemal conductivity &, = 10.5 Wim K,

and specific heat c, = 1560 Vg K ar injected into an

5.26

527

face plasma, which is at Tz = 10,000 K and provides »

coefficient of = 30,000 Whn?»K for convective

heating of the particles. The melting point and latent

‘eat of fusion of alumina are Typ = 2318 K and hig =

3577 klik, respectively.

(a) Neplecing radiation, obtain an expression forthe

time-in-ight, 1. required to heat a particle from

its initial temperature T, to its melting point Ty,

and, once at the melting point, for the particle

to experience complete melting. Bvaluate fy for

T, = 300 K and the prescribed heating conditions

()) Assuming alumi to have an emissivity of ¢, = 04

and the particles to exchange radiation with large

surroundings at Tye = 300 K, ascss the validity of

neglecting radiation

‘Thin film coatings characterized by high resistance to

abrasion and fect may be formed by vsing mic

Scale composite particles ina plasma spraying proces.

‘A spherical pale typically consists of a ceramic

core, ch 88 tungsten carbide (WC), and a metalic

shell soch as cobalt (Co). The ceramic provides the

thin fim coating with its desired hardness at elevated

temperatures, while the metal serves to coalesce the

paroles on the coated surface and inhibit ereck fo:

ration. Inthe plesma spraying proces, the particles

ae injected into plasme gas jet that heats them toa

temperature above the melting point of the metalc

casing and mets the casing before the particles impact

the surface.

Consider spherical particles comprised of a WC

core of diameter D, = 16 ym, which i encased in a Co

shell of outer diameter D, ~'20 um. Ifthe partles

flow ina plasma gas at 7. = 10,000 K andthe cost

cient associoed with convection from the gas t the

particles is = 20,000 Wir? K, how long does it tke

to best the particles from an inital temperate of

7, = 300 K tothe melting point of cobal, Tay ~ 1710

K?‘The density end specific heat of WC (ie cae ofthe

Particle) are p, = 16,000 kgin? and c, = 300 tg -K,

‘hile the corresponding values for Co (he outer shel

axe p= 8900 ka/m? and c, = 750.5“. Once ha

ing reached the melting point, how much addtional

time is requited to completely melt the cobalt if i

Jatent beat of fasion is hy = 2.59 10° kg? You may

use the lumped capacitance method of analysis and

seplect adiation exchange between the particle andi

suroundings.

A chip that is of length Z = 5 mm on a side aed thick

ness 1 = I mm is encased in ceramic substrate, and is

‘exposed surface is convectively cooled by a dielectie

liquid for which h = 150 Win? +K apd 7, = 20°C.

1 Problems

of te bet are the same asic, end assume 3% of

Sheovea power (P = LEW tu is absorbed inthe

fond

¢e) Afr all the eis convened 19 Hguld, dete

fh tone it wl tix ro hea the bee to T= 80°C

199% ofthe oven power is absorbed in the fod

‘ham the properies ofthe beef ae the sane as

iui water

Neopets, (9 When daving fol In nicovave oven, ne ay

ra eee

‘while other parts ofthe food are overcooked. Explain

way this occurs. Explain why most microwave

‘ovens have thaw cycles that are associated with

very low oven powers.

3uid wane

ing tempera:

the eps tee :

aT) $e One-Dimensional Conduction:

The Plane Wall

| 3h Consider the series solution, Equation $.39, for the

plane wall with convection, Caleulate midplane (2* = 0)

land surface (° = 1) temperatures # for Fo = 0.1 and

{using Bi = 0.1, 1, snd 10, Consider only the first four

eigenvalues. Based on these results discuss the validity

ofthe approximate solutions, Equations 5.40 and 5.41

1535 Consider the one-dimensional wall shown inthe sketch,

‘whic i nitlly ata uniform temperature T, and s sue

enly subjected to the convection boundary condition

with a fid at

For a particular wall, case 1, the temperature at x

ater = 100s is TiLy, 4) = 315°C. Another wall

case 2, hes different thickness and thermal conditions

asshown below,

be peaaar eirsraten

=) (mis) (Wim-K) (°C) CC) (Wem? K)

oe Ee wer

2 nl 0 asx 100 302910)

‘ae te eel

How long will it tke for the second wall to reach

BSC at the position x= L;? Use as the basis for

327

analysis, the dimensionless funcional dependence for

the ‘transient temperature distabution expressed in

Equation 5.38

[5.36 Refercing to the semiconductor processing tool of Prob-

Jem 5.12, tis desired st some point inthe manufactur

ing cyee to cool the chuck, which is made of alursinurs

alloy 2024, The proposed cooling scheme passes air at

20°C between the air-supply head andthe chuck surface

Cooling heed

> bit ai

| —ohwok

tadbom

Fd teieost

a

CO peston

(@ IF the chuck is intl a «uniform temperatre

oF 100°C, calculate the tne required fort lower

Surtnce to reach 25°C, essing =

tion ooetcent of $0 Win#= Km the heed-chick

interface.

[Doenerate a plot of the dine-o-<00 a a function of

the conection coefficient for the range 10 = h =

2000 Wim? - K. If the lower limit represents a free

convection eondiion witout aay fend presen,

Comment oe effectiveness of ti esd design a

A mnethod for oolng the chock

537 Annealing is a process by which steel is reheated end

then cooled to make it less bette. Consier the reheat

stage for a 100-mmthick steel plate (p = 7830 kg/m,

= 550 kg K, k= 48 When: K), which is initially

1 uniform temperature of T,= 200°C and is to be

heated to ¢ minimum temperature of 550°C. Heating is

effected in a gas-fired furnace, where products of com=

‘bastion at T= 800°C maintain a convection coc

cient of h = 250 Wins» K on both surfaces ofthe plat,

How long should the plate be left inthe furnace?

[E3B) consider tne bevy inslned pipe of Example 5.4,

ic i oso subjeed ote Bow of bo a. Use

the rauiew Conducton, Plane Wall nodl oT ©

bain be flowing ston.

(a) Cateuate the emperte of einer and er

sorte ofthe io te het le athe fe a

fice td te egy steed tthe wal fer

Sra. Compre yur eu wih hose otined in

the example.

(o) At eat ine wi ower suri tempers of

epi. 0,0, ea 25°C?

2 Problems

[fro accelerate he beating procest, it is recom.

Inended thatthe steam flow be made sufficiently

figoroos © maintain the tre sureces at 200°C

fhroughout the proses. Compute and plo the mid

plane and suciace temperatures for this ease,

tela forthe conditions of part (a)

5 Coppr-coste,epoxy-filled fiberglass circuit boards are

As aed by beating & stack of them uncer high pressures

‘Sov in the setch. The parpose ofthe pressing-eatng

‘operation isto eure the epoxy that bonds te fiberglass

ects, imparting siffuess to the boards, The stack,

refered toes a Book, is comprised of 10 boards and 11

pressing plates, which prevent epoxy fom flowing

ferveen the boards and impart a smooth finish to the

ured boards, In order to perform simplified thermal

Shlyse, itis reasonable to approximate the book as

having an effective thermal conductivity (2) and an

fictive thermal capacitance (p,). Caleuate the effeo-

tive properties if each of the boards and plates has @

thickness of 2.36 mm and te following thermopsical

board (6) pp = 1000 kel, cay = 1500

5ikg K, fy = 0.30 Win °K; plate (p)p, = 8000 kg,

yp = 480 ks“ K, Ky = 12 Wir

Aowted ce

x10" ms) a

2

LEA bb [eetatias

Ee ae}

ta pressing

pte

Te

ee Circuit

oe

46 Ciscut boards are treated by heating a stack of them

ter high pressure as illustrated in Problem 5.45. The

platens at the top and bottom of the stack are min

tained at 2 aniform temperature by a eiealating fluid.

‘The purpose ofthe pressing-eating operation is to cure

the epoxy, which bonds the fiberglass sheets, and

impart stifness to the boards. The cure condition is

achieved when the epoxy has been maintained at or

above 170°C for at least 5 min. The effective thermo-

physical properties of the stack or book (boards and

etal pressing plates) are k = 0.613 Wim K and pp =

273 X 108 Ji? “K.

(@) Ifthe book is initially at 15°C and, following eppli-

cation of pressure, the platens are suddenly brought

0 a uniform temperature of 190°C, calculate the

lapsed time £, required for the midplane of the

‘book to reach the cure temperature of L70°C.

(©) If at this instant of time, f= f the platen tempera-

ture were reduced suddenly to 15°C, bow much

‘iffusivity of

329

energy would have to be removed from the book

bby the coolant cizcalating in the platen, in order to

return the stack to its intial uniform temperature?

547 A plastic costing is applied to wood panels by first

‘depositing molten polymer on a panel and then cooling

the surface of the polymer by subjecting itto ait ow at

25°C. As frst opproximations, the heat of reaction associ

sted with solidification ofthe polymer may be neglected

‘and the polymes/wood interface may be assumed to be

adiabatic

Fate castes

war

Wood pana

If the thickness ofthe coating is = 2mm and it has

a inital uniform temperature of = 200°C, how lng

will it take for the suace to achieve a safe.sozouch

temperature of 42°C if the convection coeiient is

200 Win! -K? Whats the coresponding value of

the interface temperature? The tbeml conductivity

and diffusivity ofthe plastic ace & = 0.25 Wi K and

= 1.20 X 10°” mi, respectively.

One-Dimensional Conduction:

The Long Cylinder

548 A tong rot of Oem disses snd themopbysice

properties p = 8000 kg/m’, ¢ = 500 Wkg-K, and k=

So Wns is nally at «ior epee es

eat in forced conection furnace fsiaied =

TSDK. The convection coffe is estimated t Fe

1000 Wim? * K.

(a) Wha is te cemedine emprane ofthe rod when

the surface tempera 350K?

hearing process, the cntetine emer

tue ofthe Fd must be rested fom 7, = 300

to P= 500K, Compute aa plot the cotetne

tevgeratae bstres for = 10D, 500, and 1000

Wim In each cae te cxclaon tay bet

nated when T= 500 K

5.49. A long cylinder of 30mm diameter, iiially at a uniform

temperature of 1000 K, is suddenly quenched in «large,

constant-rempersture ol bath at 350 K, The cylinder prop-

eres are = 1.7 Wim K, ¢ = 1600.Vig-K, and p = 400

ign’, while the convection coefficient i 50 Win? K

1 Probleme

surfaces must not exceed 328°C and 25°C, respectively,

after 30 min of hecing, will the requirements be met?

© gg0 iis well known that, elthough two materials are atthe

same temperature, one may feel cooler tothe touch than

the otter. Consider thick plates of copper and glass, each

stan inital temperatare of 300 K. Assuming your finger

tobe at an intial empertue of 310 K and to have tbemno-

physical properties ofp = 1000 kg ¢ = 4180 kg -K,

tad = 0.625 Wim K, determine whether the copper ot

the glass will feel cooker to the touch

4581 Two stainless steel plates (p = 8000 kgim®, c = 500

sikgK, k= 15 Wim K), each 20 men thick and insu

Jated on one susfice, ate initially at 400 end 300K

swben they are pressed together at their uninsulated sur-

faces. What isthe temperature of the Insulated surface

ofthe hotplate after I min has elapsed?

582 Special coatings are often formed by depositing thin

layers ofa molten material on a solid substrate. Solidi

cation begins atthe substrate surface and proceeds unt

the thickness $ of the soli lnyer becomes equal to the

thickness 8 ofthe deposit.

(©) Consider conditions for which molten material at

sits fusion temperature 7; is deposited on a large

substrate that sat an inital uniform temperatare

With $= O at = 0, develop an expression for eti-

rating the time ¢, required to completely solidify

the deposit if it remains at 7; throughout the slii-

fiation process. Express your result in terms ofthe

sabsrate thermal conductivity and thecmal dif

sivity (E,a.), the density and latent heat of fasion

of the deposit (pi) the deposit thickness 8, and

the relevant temperarres (ZT).

(©) The plasma spray deposition process of Problem

525 is used to apply a thin (= 2mm) alumina

‘coating on a thick tungsten substrate, The substrate

has ¢-aniform initial temperature of 7, = 300 K,

and is thermal conductivity and thermal diffusivity

‘may be approximated as f= 120Wim*K and

a, = 40X10 nis, respectively. The density

and latent heat of fusion of the alumina ere p =

3970 kai and hy = 357 kik, respectively, and

the alumine solidifies at its fusion temperatre

(F, = 2318 K), Assuming that the molten layer is

5.83

584

335

instantaneously deposited on the substrate, estimate

the time required forthe deposit to solidity

When a molten metal is cast in a mold that is a poor

conductor, the dominant resistance to heat flow is

Within the mold wall. Consider conditions for which a

Tiguid metal is solidifying in a thick-walled mold of

thermal conductivity b, and thermal diffusivity a,."The

density and latent heat of fusion of the metal are desig-

nated as p and hy, respectively, and in both its molten

and solid sates, the thermal conductivity of the metal is

very much larger than that ofthe mold

Sols mete

Phe

Just before the start of solidification ($ = 0), the mold,

‘wall is everywhere at an inital uniform temperate T;

and the molten metal is everywhere at its fusion (melting

point) temperature of 7; Following the start of sliifi-

cation, there is conduction heat wansfer into the mold

wall and the thickness of the solidified metal, S,

increases with time

(@) Sketch the one-dimensional temperature distribu.

tion, 7(2), in the mold wall and the metal at ¢ = 0

and at two subsequent times ducing the solidifica-

tion, Cleary indicate any underlying essumptions.

(©) Obtain a relation forthe variation ofthe solid layer

thickness $ with time f, expressing your result in

‘terms of appropriate parameters ofthe system.

Joints of high quality can be formed by fiction weld-

ing, Consider the friction welding of two 40-mm-diameter

Inconel rods. The bottom rod i stationary, while the top

rad is forced into a back-and-forth linear motion char-

sctetized by an instantaneous horizontal displacement,

dG = a costa) where a= 2.mm and w = 1000 rads.

‘The coefficient of sliding friction between the to

pleces is x = 0.3. Determine the compressive force that

rust be applied in order to heat the joint to the Inconel

melting point within r= 35, stating from en initial

temperature of 20°C. Hn: The frequency of the motion

and resulting heat rate are very high, The temperature

response can be approximated as if the heating rate

‘were constant in time, equal it average valu,

eat rate)

‘in molar

rent,

det what

thermal

by con.

ay deter.

aw tothe

uinar to

?

omentum

servation

velocity,

on? What

relative

ver a sur

U number

are their

tonal, and

ce?

umber?

ters that

ay lye |

er Theory,

‘Tran

02.

= Problems

5, Harnet, J.P, “Mass Transfer Cooling," in W.M.

Rohsenow and J.P. Harett, Bds., Handbook of Heat

Transfer, MeGraw-HBIl, New York, 1973.

6, Kays, W.M., M.B. Crawford, and B. Weigand, Convec-

tive Heat and Mass Transfer, 4th ed., McGraw-Hill

Higher Béucation, Boston, 2005.

+7. Burmeister, L.C., Convective Heat Transfer, 2ad ed,

‘Wiley, New York, 1993,

8, Kaviany, M., Principles of Convective Heat Transfer,

‘Springer-Verlag, New York, 1994

Problems

387

9, Patankar, $.¥., Numerical Heat Transfer and Fluid

FFlov, Hemisphere Publishing, New York, 1980

10, Fox, RW., A-T, MeDonalé, and P. J. Pritchard, Zntro-

duction 10 Fluid Mechanics, 6th ed., Wiley, Hoboken,

NJ, 2008.

11. Colbum, A. P., Trans. Am. Inst. Chem. Eng. 29, 174, 1933.

12, Chilton, T.H., and A. P, Colburn, Jnd, Eng. Chem, 26,

1183, 1934

Boundary Layer Profiles

4641 Inflow over 2 surface, velocity ad temperature peofiles

are ofthe forms

ui) Ay + By Cy and

10)=D+ By+ PF - GY

where the coefficients A though G are constants

(Obtain expressions for the friction coefficient C, and

the convection coefficient ft in terms of tay To and

appropiate profile cooffcients and fluid properties.

62 Water at a temperature of T, = 25°C flows over one of

the surfaces ofa ste] wall (AISI 1010) whose tempers-

ture is 7, = 40°C. ‘The wall is 0.35 m thick, and its

ther surface temperature is 7, = 100°C. For steady-

state conditions what i the convection coefficient asso-

ciated with the water low? What is the temperature

‘gradient in the wall and in the water that isin contact

With dhe wal? Sketch the temperature distribution in the

wall and inthe adjoining water.

(63 Ins particular application involving airflow over a heated

surface, the baundary layer temperature distribution may

be approximated as

where y isthe distance nommal tothe surface and the

Prandti number, Pr = eyulk = 027, is @ dimension

less fluid propery. If Ty = 400%, 7, = 300K, and

Jy = S000 m?, what isthe surface heat ux?

Heat Transfer Coefficients

(6A For laminar flow over a flat plate, the local heat trans-

fer coefficient h, is known to vary 98 x°°, where x is

the distance from the leading edge (x = 0) of the

plate. What is the ratio of the average coefficient

Detnecen the leading edge and some location x on the

plate tothe local coefficient at 2?

(65 For laminar fie convection fom & heated vertical sr-

face, the lol convection eoeficient may be expressed

ash, = Cx, where A, is the coefficient at a distance x

from the leading edge ofthe surface and the quantity C,

which depends on te uid propsts is independent of

2 Obtain a expesion forthe ratio, where his the

average coeicent between the lading edge (= 0) and

{he locaton. Skee the vaziation of hand, with.

66 A circular, bot gas jet ot Tx is diected normal to &

circular plate that has radius r, and is maintained at a

vuiform temperature T,, Gas flow over the plate is

axisymmetric, causing the local convection coefficient

to bave radial dependence ofthe form h(r) = a + Br,

‘where a,b, and n are constants. Determine the rate of

heat transfer to the plate, expressing your resale in tems

(of Toy Ty Fee yb, and

6.7 Parallel flow of atmospheric air over @ flat plate of

length L = 3 m is disrupted by an anray of stationary

rods placed inthe flow path over the plate

ABS 9 Dedede

8 HO oO

1

u. i

Latoaory messreméns ofthe le onveeton cet

Feieat ot the sce ofthe plat are mmc fr pre-

sibel yalue of V snd 7, > To. Tho resits ae

Censied by tn expesion ofthe form by = 07 =

1DiGe~ 2 wre hes it of Wi? Kandi

in mots, Bratt the average convection coeficent

Fy foc the entre plate ad the ao Fi at he aig

alle low vera fat pate of fength L'=

ature T, = 90°C, However, obstacles placed in the low

intensify mixing with increasing distance x from the

leading edge, and the spatial variation of temperatures

390

620

621

623

Chapter 6 = Introduction to Convection

‘The surface area of the blade may be assumed to be

rectly proportional to its characteristic length.

Experimental measurements of the convection beat trans-

fe coeticient for «square bar in cross low yielded the

following values:

B= S0Win?

Fm 40Win?

when

‘Assusme tha the functional form ofthe Nusselt number

Js Bu = C Re" Pr', where C, mt, and n are constants.

(@) What will be the convection heat transfer oo-

efficient for a similar bar with L = 1m when

V= 15 mis?

() What will be the convection heat ensfer coefficient

foc a similar bar with L = I m when V= 30 mis?

(©) Would your results be the same if the side of the

ber, rather than its diagonal, were used as the char

acteristic length?

[Experimental results for heat transfer over a fat plate

‘with an extremely rough surface were found to be oor

related by an expression ofthe form.

Mu, = 0.0429 Pe

where Mi, isthe local value ofthe Nusselt number ata

position x measured from the leading edge of the plate.

Obtain an expression for the ratio of the average heat

transfer coefficient ft the local coefficient hy.

(Consider condition for which «fluid wit a fre steam

velocity of V = 1 avs flows over a surfsce with a char-

acteristic length of L = 1 m, providing an average con-

veetion heat transfer coefficient of = 100 Wim? K.

Calculate the dimensionless parameters Nii, Ress Pr,

and jg forthe following uid: ir, engine oil, mereury,

and water. Assume the fluids tobe at 300 K.

Por flow over a flat plate of length Z, the local heat

transfer coefficient A is known to vary asx", where x

is the distance from the leading edge ofthe plate. What

is tho ratio ofthe average Nasselt number for the entire

plate (i) tothe leal Nusselt number atx = L (M4)?

Fax laminar boundary layer flow over a lat plate with air

20°C and 1 etm, eae thermal boundary layer thickness.

5, is approximately 13% larger than the velocity bound-

ary layer thickness 8, Determine te ratio 8/5, if the fluid

is ethylene alycol under the same flow conditions

625 etch the vacation ofthe velocity and thermal tous

ay layer thickness with distance from the leng

tae ofa lat pate forthe laminar ow of ai, was

npine oi, and mercary. Fr each case assome 2 may

$id temperatire of 300K

6.26 Forced sta T= 25°C and V = 10 ms 4819 cot

slecroaic elements on 8 cirt board. One sich ele

tenis «chip, 4mm by 4mm, leested. 120mm foe

the leading edge of the boa. Experiments hoe

revealed that ow over the oad is disturbed by te

tlements and tht convection heat transfer i corel

by an expression ofthe form

o.04Red* pri?

Estimate the surface temperature ofthe chip if tis di

Sipating 30 mW.

a

Beat

220 ne

627 Consider the electronic elements that are cooled by

{oreed convection in Problem 6:25. The cooling system

is designed and tested at sea level (F * 1 stm), but the

circuit board is sold toa customer in Mexico City, wth

an elevation of 2250 m and stmospheric pressure of

165 kPa,

(@) Estimate the surface temperature of the chip

located 120 mm from the leading edge of the board

when the board is operated in Mexioo City. The

dependence of vatious thermophysical properties

‘upon pressure is ncted in Problem 6.17,

(©) Itis highly desirable for the chip operating temper

ature to be independent ofthe location ofthe cus

tomer. What air velocity is required for operation

in Mexico City if the chip temperature is to be the

same as at sea level?

[EBB] consi te chip o thee boad of Probie 626

To entre able operation ot ented periods,

chip tempera sould ot eneed 85°C, Asami

valu of feed alr Tz = 25 and aplcty

othe preset bea ant conelan, opt snd

plate maximum alwabl cp power tpn P-

fe aurcon ot velo for 12 V2 25.

Ship surlce bos er emissivity of 0.80 andthe bos

imounid in pe enlouehove walls re at 2°,

hat sth effet of alton on he PV pet?

6.29 A major conttibutor to product defects in electronic

‘modules relates to stresses induced duxing thermal

® Probleme

going (itermitent heating and cooling). For example,

fh circuit cards having active and passive components

with materials of differest thermal expansion coeffi

Uyents, thermal stresses aze the peincipal source of fail

the i component joints, such as soldered and wired

oecions. Although concer is generally for fatigue

failure resalting from numerous excursions daring the

life of a produc, it is possible to identify defective

joints by performing accelerated thermal stress tests

wet ee tefore the product is released 10 the customer. In such

eet By Be = cases itis important to achieve rp thermal eyling to

1

saninize disruptions to production schedules.

'A manfactacer of cenit carés wishes to develop

sn apparazus for saposing rapid thermal transients on

the cards by subjecting thom 19 forced convection char-

tecezed by a relation ofthe form Ni, C Re Pr,

where m= 08 and n= 033. Hovever, she does not

now whether to vee air Ge 0026 Wim>K, y=

16X10"? m's, Pr = O71) or edilectic Liquid (k =

(0064 Winn K, » = 10°# a, Pr= 25) a6 the work

ing fluid. Assuming equivalent air nd ligud velocities

and validity of the lumped capacitance model forthe

omponent, obtain a quanttave estimate of the ratio.

of te thea ime constants forthe two ftids, What

fd provides the faster therm response?

‘To asess the efficacy of different liquids for cooling an

abject of given sie and shape by forced convection, itis

convenient to introduce a figure of ment, F, which com-

tines the infloonce of al pertinent fluid properties onthe

convection coefficient. If te Nusselt number is governed

by aa expression ofthe form, Nu,~ RefPr', obtain the

corresponding relationship between Fy and the fluid

wopeties, For representative valves of m = 0.80 and

2=033, caloulate values of Fy for air (k= 0026

Win-K, v= 16 X 10°? mis, Pr= 0.71), water Qe=

0.600 Wim: K, y= 10" mils, Pr = 5.0), and a diel.

ttc liquid = 0.064 Wim -K, v= 10°® mls, Pr = 25).

“What fluid isthe most effctive cooling agent?

Gases aze often used instead of liquids to cool electron-

{es in avionics applications because of weight consider

ations. The cooling systems are often closed so that

coolants other than air may be used. Gases with high

‘figures of met (se Problem 6.30) are desired. For rep-

resentative values of m = 0.85 end n = 0.33 in the

expression of Problem 6.30, determine the figures of

391

6.32 The defroster of an automobile functions by discharg-

ing warm air on the inner surface ofthe windshield. To

prevent condensation of water vapor on the surface, the

temperature ofthe sir andthe surface convection coe

cient (7. ) must be large enough to maintain a sa-

face temperature Tz that is st least as high 2s the

ewpoint (ys Ti

Consider windshield of Fength 1 = 800 mm and

thickness = 6mm and diving conditions for which

the vehicle moves at a velocty of ¥= 7Omph in

ambient ac at. = ~15°C. From laboratory expec

tenis performed on s model ofthe vehicle, the aver:

tage convection cefficeat onthe outer surface of the

‘winded is known tobe conelated by an expression

of the form Mi; = 0030 Reb" PP, where Re,

Viv. Properties of the ambient air mey be approx

imited a8, k= 0005 Wim-K, v = 125x10™* ms

and Pr= OI. IfTyp= 10°C and Ta, = 50°C, what

isthe smoalest valve of Fy equied to prevent cnden-

sation onthe ier surface?

633 A microscale detector monitors @ steady flow (L_ =

PC, V = 10 ms) of ai forthe possible presence of

Small, hazardous particule matter thet may be sus

pended inthe room The sensor is heated to a sighly

higher temperature inorder to induce a chemical reaction

associated with cerain substances of interest hat might

impinge onthe sensor's scsive surface, Te active surface

produoes an electric cueat if such surface reactions

focur the else coent is then sen tan alarm. To

‘maximize the aioe head's surface erea and in tum the

probebilty of expering ad detecting apace, the sen-

Sor head is designed with a very complex shape. The

wale ofthe average heat transfer coefficient associated

with the heated sensor must he known so that the

require electial poner othe sensor canbe deter

rect for air, pure helium, pure xenon (& = 0.006

Wim + K, y= 24.14 % 10°F N + afm), and an ideal

He-Xe mixture containing 0.75 mole fraction of helium

(= 00713 Wim + K, w= 2595 % 10-6 N- sm).

‘Evaluate properties at 300 K and atmospheric pressure.

For monatomic gases such as helium and xenon and.

their mixtures, the specific beat at constant pressure is

ell described by the relation ¢, = (S/2)BRMt, 4

Particulates

BTV

‘Consider a sensor with a characteristic dimension of

'80 jm, A seale model ofthe sensor is placed in a

15% 10, for what values of Re, would the total Beat

‘anser be independent of orientation?

infec cll stacks, it sdesinble oops unde cond

Je Rt promote uniform surface trperatres fr the

Som ote membranes This i espocally true in high-

cletoane fuel cols where Wie membrane is coo.

temnd of brite ceramic material. Electrochemical

sertjons in the eleewolytic membranes genera ther-

‘err enesy, wile gases lowing above and telow the

cool it. The stack designer may specify OP

REF bottom Bows thet are in the same, opposite, ot

Sxogonal directions. A preliminary stad ofthe effect,

amie relative How dixections is conducted whereby 4

6 mt % 150 mom thin sheet of mate, producing &

‘itor heat x of 100 Wn, i cole (top and bot

any by ar with & free steam temperature and velocity

of 25°C and 2 mi, respectively.

(@) Determine the minimam and maxima loss mem

rane temperatures for top and bottoms Hows tha re

in the same, opposite, and orthogonal Asn

‘ie

(a) Consider an L = 1 mlong, w = 0.1 m wide sola cell

‘hat is placed on az insulated surface. Determine the

silicon temperate and the electric power produced

by the solar cel for an air veloity of 4 mo parallel

to the long diecton, with sir and sorroundings tem

peratures of 25°C. The solr iradiation is 100 Win.

‘The boundary layer is tripped to a turbulent condi-

tion atthe leeding edge ofthe panel.

() Repost part (a), except now the pane is cess

pau is shoes side paallel to the air low, thet is,

=O mendw = 1m,

{6 Pot the elecrie power output and the silicon fem:

perature versus ar velocity over the range 0S Me =

{0 mus for the L = 0.1 mandw = L mise

719 Concentration of sunlight ona photovoliaio eels ie

Geaued since the concentrating miors and lenses are

fess expensive than the photovoltaic materia. Consider

the solar photovoltaic cell of Problem 7.18, 8 100 mm *

100 mm photovoltaic cll is iradiated with concentrated

olor energy. Since the concentrating lens is glass,

Speovbo 10% ofthe iragiation instead of the top surface

st solar cell asin Problem 7.18. The remaining re

‘iaton is selected frm the system (7%) otis absorbed

{hte silicon Semiconductor material ofthe photovoltaic

‘Ri (83%). The photovoltaic ce is cooked by sit

‘irectee parallel to is top and bottom surfaces, The air

temperature and velocity are 28°C and § a, respon:

frely, and the botiom surfce is coated with & hish-

cmasvity pain, #5 = 095.

Solar adiation

Pook e|

SEe 1-300 nm

= Seo Prblen 7.18,

gg = 250

(@) Deermine the elec power produced bythe poto-

‘ofa eell and the silicon temperate fora square

TGncontating Tens With Digg = 400mm, stich

Focuses the iaiation falling on the lens t0 the

ipnaller acea of the photovoltaic cell, Assume the

25°C and dots not

Roun les me

aan eating ee oft pbeovolic marl

[Bbonerine te cles power out of he po.

pee and te sce temperature OVE he

Tege 100 ma Le = 600 ma

na0 The root of & refigeted tack compartment is of

Te et Cretetn conitng of yer of ane

Chapter 7 # External Flow

at

ethane ington (= Sm & = 0026 Win)

sramehed between unm ay peels = Stan

sre tgo Wins). The lengh nd wth of thereat ae

PP Jom ana W = 35 my respesively, and the temper

1 re ott naer surface eT, = ~10°C. Conse on

Jiuows for which the muck is moving a speed of

ioe kavis he at comperste is To= 32°C, an te

iat mtn is Gp = 750 Wir, Pubes ow may

eatomed over the ssi length of the oo

(4) Focequivalent values of the solar absorptivity andthe

tenianvity of the outer surface (as 6 = 05), et

toate te average erperanare T, of the ote sures

‘What isthe comsponding heat lod impoeed on te

refrigeration systems?

(o) A special finish (a5= 015, = 98) may

fpplod to the ovter surface. What effect woul

Such an application bave on the surface temper

ture and the heat Lood

(© If, with ag= 2 =O, the roof is not insulated

(0), what are the comesponding values of the

surface temperatare an the heat load?

‘The top surface of a heated compartment consists of

‘ery smooth (A) and highly roughened (B) potions and

the surface is placed in an atmospheric airstream. i he

mtorest of Minimizing total convection heat taster

from the surface, wich orientation, (1) or 2), is ee

ened? IF T,= 300°C, To = 20°C, and te = 20 te

fanatis the convection heat transfer from the entice

face fortis orientation?

462

istance L between two rollecs ata velocity V. In this

problem, we consider cooling of an aluatinom alloy

(2024-16) by an air stream moving at a velocity ta in

counter flow over the tap surface ofthe sheet. A turbu-

lence promoter is used to provide turbulent boundary

layer development over the entice surfece.

Aiaminu alloy

po2as

(8) By applying conservation of energy toa differential

control surface of length de, which either moves

with the sheet or Is stationary and through which

the sheet passes, derive a differential equation that

fgovems the temperature distribution along the

sheet, Because of the low emissivity of the elu-

‘minurn, radiation effects may be negleted, Express

‘your result in terms of the velocity, thickness, and

propetias of the sheet (¥, 8, p, cp, the local con-

‘ection eoeficent h, associated ‘with the counter

flow, and the air temperature, For a known temper-

tare of the sheet (7) atthe onset of ecoling and &

negligible effect of the sheet velocity on boundary

layer development, solve the equation to obtain an

‘expression forthe outlet temperanste

() For = 2mm, V=0.10m/s,L=5m,W= 1m,

4, = 20/5, T, = 20°C, and T;= 300°C, what is

the outlet temperature T,?

In the production of sheet metals or plastics, it is eas

tomary to cool the material before it Feaves the produc-

tion process for storage or shipment to the customer,

‘Typically, the procese ie continuous, with a sheet of

thickness 3 and width W cools as it wansits the distance

[L between two rollers ata velocity ¥. In this problem,

‘we consider cooling of plain carbon steel by an air

stream moving at velocity usin cross flow over the top

tnd bottom surfaces of the shee. A turbulence promoter

5s used to provide turbulent boundary layer development

‘over the entire surfece.

{@) By applying conservation of energy ta differential

contol surface of length dx, which either moves

withthe sheet or is stationary and through which

the sheet posses, and assuming uniform sheet

temperature in the diection of air flow, derive a

differential equation that goveras the temperature

Chapter 7 2 Baternal Flow

“urate

pono

istrbution, T[2), along the sheet. Consider be

sffecs of radiation, a8 well at comvetion, ad

xpress your result in terms of the velocity, thik

pees, and properties ofthe bec (VB, ye

‘average convection coefficient hy associated with

the eres ow, andthe environmental temperate,

Cah

(b) Neglecting radiation, obtain «closed form slut

tothe forgsing equation. For8 = 3mm, V= 0.0

‘ta = 20 ms, To = 20,

fda shee tempecatare of 7, 500°C a eons

SF cooling, what isthe ove temperate 7.2

‘sume aneligible effext ofthe sheet velocity en

boundary ayer development inthe dzetion of er

flow. The deasity and specific beat ofthe steel ae

850 kgf? and ¢, = 620 Jikg~K, while proper.

fer of ti a may be taken tobe = 0048 Wit K

15 10% miss, Pr = 0.68,

[Daccountng forthe effects of raison, with =

070 and Tye = 20°C, namely integrate the it

fereal equation derived in part () fo determine

the temperature ofthe sheet at = 10m. Expl

the effet of Von the temperate distbuion

along the est

“727 A steel stip emerges from the bot rol section of a sel

rill at a speed of 20 m/s and temperanre of 1200 Ki

length and thickness are L= 100m snd 8 = 0003,

respectively, and its density and specific heat are 7900

kp? and 640 kg, respectively.

inset ,

Sqmy

129

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Rangkuman SCMDocument14 pagesRangkuman SCMJecky Mitra SainiNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Couch Roll Paper MachineDocument4 pagesCouch Roll Paper MachineJecky Mitra SainiNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Fourier Series PDFDocument7 pagesFourier Series PDFJecky Mitra SainiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Sustain 23 PDFDocument48 pagesSustain 23 PDFJecky Mitra SainiNo ratings yet

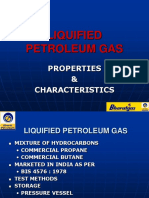

- LPG Properties Bharat PetroleumDocument19 pagesLPG Properties Bharat PetroleumJecky Mitra SainiNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 4 Boiler PDFDocument103 pages4 Boiler PDFHexa JoGle100% (9)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 02 - FuelDocument26 pages02 - FuelRivky Haris RizaldyNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Curriculum VitaeDocument2 pagesCurriculum VitaeJecky Mitra SainiNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Bernoulli and Torricelli Theorem Basics.Document49 pagesBernoulli and Torricelli Theorem Basics.shubhamcholeNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Jadwal KuliahDocument1 pageJadwal KuliahJecky Mitra SainiNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Jurnal InternasionalDocument21 pagesJurnal InternasionalJecky Mitra SainiNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Jurnal Internasional 2Document9 pagesJurnal Internasional 2Jecky Mitra SainiNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- App FDocument3 pagesApp FAhmed EldalyNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)