Professional Documents

Culture Documents

Acid Gas Sweetening

Uploaded by

Immanuel Agapao0 ratings0% found this document useful (0 votes)

17 views12 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views12 pagesAcid Gas Sweetening

Uploaded by

Immanuel AgapaoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

Gl Acid Gas Sweetening with DEA

G1i.1 Process Description

In this example, a typical acid gas treating facility is simulated. A water-saturated natural

gas stream is fed to an amine contactor. For this example, Diethanolamine (DEA) at a

strength of 28 wt in water is used as the absorbing medium. The contactor consists of20,

real stages. The tich amine is flashed from the contactor pressure of 1000 psia to 90 psia

before it enters the rich/lean amine exchanger, where itis heated to the regenerator feed

temperature of 200 F The regenerator also consists of 20 real stages. Acid gas is rejected

from the regenerator at 120 F, while the lean amine is produced at approximately 260 F

‘The lean amine is cooled and recycled back to the contactor.

EE

Recommended amine strength ranges:

Eas

‘Amine we

MEA 15:20

DEA E55

TEA, MOEA 35-50

DGA eS

Figure G1.2

cas 10 SrasToR

‘There are two basic steps in this process simulat

1. Setup - The Component list includes C1 through C7 as well as N2,

(C02, H2S, 1120 and DEA.

2. Steady State Simulation - The case will consist of an absorber

scrubbing the inlet gas using DEA solution, which will be

regenerated in a distillation column. Sweet gas will leave the top

whereas the bottom stream wil be sent to a regenerator column,

An analysis on both the SWEET GAS and the ACID GAS will be

performed to satisfy the specified criterion.

Pci eros)

Input Area,

‘Temperature 5 F

Pressure 905 pala

Liquid Voiume Flow | 190 USGPIA

Water foie Frac. | 0.720

DEA Mole Frac. 0.280

eon tr er

G1.2 Setup

‘The Amines property package is required to run this example problem,

This isa D.B. Robinson proprietary property package thet predicts the

behaviour of amine-hydrocarbon-water systems. The components to

bbe selected are N2, CO2, H2S, Cl, C2, C3, I-C4, n-C4, -C5, n-C5, C6, C7,

#20, and DEA,

Clone the Field unit set. Change the default units for the Liquid Volume

Flow to USGPM and the Molar Flow to MMSCED.

G1.3 Steady State

Simulation

‘The following major steps will be taken to setup this case in steady

state:

1. Installing the DEA Contractor - A 20 stage absorber column will be

used to serub the SOUR GAS with DEA solution DEA TO CONT).

‘The SWEET GAS will leave from the tower from the top whereas the

pollutant rich liquid will be flashed before entering.

REGENERATOR,

2, Regenerating the DEA - The liquid stream from the absorber will

be regenerated in a 18 stage distillation column. The ACID GAS will,

be rejected from the top and the regenerated DEA will be send back

to the DEA CONTACTOR,

G1.3.1__ Installing the DEA

CONTACTOR

Feed Streams

Before the amine contactor can be calculated, an estimate of the lean

‘amine feed (DEA TO CONT) and the inlet gas stream (SOUR GAS) must

be provided. The stream specifications are shown here. The DEA TO

CONT values will be updated once the recycle operation is installed and

thas been calculated

a EEE

rere uo)

Input Area [Ente

“Temperature T2000F WL

Pressure 7000,0000 psia

[Motarriow | 25 NISCFO

N2MoleFrac. | 00016

COR ole Fac. O08

HS Molo Frac. oor

1 Mole Frac. 0.9892

CE Mote Frac 0.0389

3 Mole Frac. 0.0088

TGA Mole Frac. 00088

G4 Mole Frac. 0.0028)

165 Molo Frac. og

OB Mole Frac. 2.0072

‘08 Molo Frac. DooT8

GT Mole Frac. 0.0072

H20 ole Fret 0.005

‘DEA Mole Fra. 0.000

Any free water carried with the gas is first removed in a separator

operation (V-100):

Eran!

Tab puRATea [Ents

Feed SOUR GAS

Design Vapour Oatet GAS TO

{Connections GONTACTOR

Uquid Ont FAK

‘Design [Parameters} | Pressure dep Opal

DEA Contactor

Before installing the column, select Preferences from the HYSYS Tools

‘menu. On the Simulation tab, ensure that the Use Input Experts check

box is selected (checked), then Close the view.

e110

ee

‘The contactor can now be simulated. An Absorber column operation is

installed with the specifications shown below. The Amines property

package requires that real trays be assumed in the contactor and

regenerator operations but in order to mode! this, component specific

efficiencies are required for 12S and CO2 on a tray by tray basis. These

proprietary efficiency calculations are provided in the column as part

Of the Amines package. Tray dimensions must be supplied to enable

this feature.

Es Geen

[age si hen af tmput Areas oy ca Entry oe eeines|

No.of Stages 20

“Top Siago net) | DEA TOCONT

ease Bottom Siage inet | GAS 70

ConTacTOR

‘Ova Vapour Outlets) | SWEET GAS

Bottoms Liquid Outlet] RICH DEA

Topo 385 psa

Pressure Profile

Bottoms 1000 psia

"Temperature ‘Top Temperaturen) | 100

Estimates Bottom Temperatures | 160F

For the Contactor, itis recommended that the program calculate the

efficiencies using the Tray Dimensions shown in Figure G1.4. These

parameters enable component specific efficiencies to be calculated by

estimating height of liquid on the tray and the residence time of vapour

in the liquid. These values can be supplied on the Tray Sections page,

‘ating tab, in the Column property view.

oun

es

rte

Using this information, the component specific tray efficiencies can be

calculated. Run the Column, and once it has converged move to the

Efficiencies page on the Parameters tab. Click on the Component radio

‘button and make note of the efficiency values for CO2 and H2S on each

tray. HYSYS provides the component tray efficiencies but allows you to

specify the desired efficiences,

‘The Stream RICH DEA from the absorber is directed to Valve VIV-100,

where the pressure is reduced to 90 psia, which is close to the

regenerator operating pressure.

‘Gases which are flashed off from Rich DEA are removed using the rich

amine flash tank (FLASH TK) which is installed as a Separator

operation.

on

Tableagey | inputArea | Ent rabTeage) | WRpULAER

Tae Talat RICH DEA inet | DEA TO FLASH

{Cormections) | Outlet DEATOFLASH | | Design ™

™ {Connections} | VapourOullet__| FLASHY

oak Pressure (DEA | 80 Tiquid Outlet | RIGHTOUR

Worksheet | TO FLASH TK) -

{Conaitionst | jpsiay

G1.

2 Regenerating the DEA

The Regenerator

‘The stream RICH TO LIR is heated to 200 F (REGEN FEED) in the lean!

rich exchanger (E-100) prior to entering the regenerator (which is

represented by a distillation column). Heat is applied to break the

‘amine-acid gas bonds, thereby permitting the DEA to be recycled to the

contactor.

Pee caicaey

|afatateace) Sys esis] AMUNAreR TEE

Tube Sia

ecgn conection) | Bese Onl REGEN FEED

Shel Sie REGEN STIS

Shel Side Oulet TEANFROMUR

; Tubeside Dela P TOpat

Design [Parameters] | Sheiside Delta P 10 psi

‘Worksheet Temperature (REGEN | 200F

{onettions} FEED)

‘The amine regenerator is modelled as a distillation column. There are

20 real stages - 18 stages in the Tray Section plus @ Reboiler and

Condenser.

ore

Peer n lacie)

Input Area on

No. of Stages 16

Feed Streams (Stage) _| REGENFEED(®) |

‘Condenser Type FullRefx

Connections ‘Ovid Vapour GIO GAS

Botoms Liquid REGENBTINS

Reboler Duly RELRG

Condenser Duly ‘CONDG.

Condenser Pressure | 275 pela

Prossure Profile Cond Delta P 25 pst

Reboller Pres. 315 psi

For this tower, the component efficiencies will be setup to be constant

at 0.40 for H2S and 0.15 for CO2, The efficiencies of the condenser and

reboiler must remain at 1.0, so enter the efficiencies for stages 1-18

only. To set the new efficiencies press the Reset H2S CO2 button, and

then type the new efficiencies into the matrix. Specify a Damping

Factor of 0.40 on the Solver page, Parameters tab, to provide faster,

‘more stable convergence.

sTab rage] ti

Condenser 10

Parameters Reboier 10

{Eficiences) TIS 15002 _| 0.15

TISw TTS HS | 0.80

Paramotors [Solver|_| Damping Factor 040

Add a new column specification called Reboiler Duty vie the Specs

page of the Design tab, as well as set the default specification s shown

below and delete the Refiux Rate and Buus Prod Rate specification

from the Column Specification list in the Column property view.

‘The T Top and Reboiler Duty specifications should be Active; the

Reflux Ratio and Ovhd Vap Rate should be set as Estimates only.

ees

stage

Spec Valve

Name Reboier Day

Energy Stream ROLRQ

Spec Value 1.3607 stun L |[-te 7

Desires) | Se Converse

Flow Basis Moise

Spec Velue os

Nome [ona vapRae |

Deaw ACID GAS

Flow Basis Mole

Spee Vave 2.0MMSCEO

‘The reboiler duty is based on the guidelines provided below, which

should provide an acceptable H2S and CO2 loading in the lean amine,

Recommended Steam Rates

Beemer)

ee rc

Primary Amine (e.g.MEA) | 0.60

‘Secondary Amine (e.g. DEA) | 1.00

Tertiary Amine (og. MOEA) | 1.20

DGA 730

Water make-up is necessary, since water will be lost in the absorber and

regenerator overhead streams. A MIXER operation combines the lean

‘amine from the regenerator with a water make-up. These streams mix

at the same pressure. Define the composition of MAKEUP 120 as,

being all water, and specify its temperature to be 70°F Specify its

flowrate and pressure to be 2.195 USGPM and 21.5 psia, respectively.

ors

Ger

LE(¢o

[prabtragel se | : E

THAKEUP 20

{Gonections] LEAN FROM UR

Sata DEATO GOL

Design Paranal | ASsurment | Lovett

“perature WAREUP | 70F

Heo)

Workshoet Frese WAREUS | BIS pe

[Conditions] a0}

Tig Wal Faw GER | SSSLSGE

WAKEUP H2O) Tone too GP"

Wortahost 2 Wass Frc is

Teompostiont | (maxeuP H20)

Cooler E-101 cools the lean DEA on its way to the main pump. Pump P-

100 transfers the regenerated DEA to the Contactor. A recycle is

installed in the Flowsheet between the Pump and the Contactor.

Eeeatonn)

— inet DEA TO PI DEA TO COOL.

Qesign n

‘Outi A rae

Teaetionsy LOutet DEA TO RECY Pesiee tions) [Suet DEATO PUMP.

Eneray PUNPO Energy Steam | COOLER

Worksheet Temperature] | 95 De Pressure Drop | Spsi

[Conditions _| (OEATORECY) (Parameters)

‘The Coolerand the Pump Use a Set operation (SET-1) to maintain the pressure of streamt DEA TO

‘operations will remain

Unconverged until tne Set

‘operation has been installed.

RECY to be5 psi lower than the pressure of the gas feed to the absorber

‘Torget DEA TO RECY

Connections "Target Variable Pressure

Sous GASTO

CONTACTOR

Taplin 7

Parameters

OFfsei =

ors

eines Seu

{At this point the recycle inlet stream is fully defined, ond a Recycle

operation is installed with stream DEA TO RECY as the inlet and DEA

‘TO CONT s the outlet. The lean amine stream, which was originally

estimated, will be replaced with the new, calculated lean amine stream

and the contactor and regenerator will be run until the recycle loop

converges, To ensure an accurate solution, reduce the sensitivities for

Flow and Composition to 0.10 from 10.0,

a Pa0e) rInputAre ER

oes Food DEA TO RECY

Prodeek DEATO CONT

rameters ow oo

Troterancs} [composts [0s

G1.4 Simulation Analysis

“The incoming sour gas contained 4.1% CO2 and 1.7% H2S. For the inlet

‘gas flowrate of 25 MMSCFD, a circulating solution of approximately 28,

‘wt. DEA in water removes virtually all of the H2S and most of the CO2.

‘The sweetened gas leaving the DEA contactor is shown to the left. The

conventional pipeline ges specifications is no more than 2.0 vol.% CO2

and 4 ppm (volume) H2S; the sweet gas produced easily meets these

criteria,

G1.5 Calculating Lean and

Rich Loadings

Concentrations of acid gas components in an amine stream are

typically expressed in terms of loading of the amine - defined as moles

pour 7.000

“Temparatore FT 35.205

Pressure [psi 9950

Wolar Flow (MMSCFD] 23.425

‘Mass Flow (Bini) 48595,

ig Volume Flow (USGPM)_| 200.7

Feat Flow (Btu) SoTeOT

T2 Mole Fras ‘O00T707

Ca Malo Frac e.000826

HS Mole Fac. 0.000000,

Ci Mole Frac 0.926748

Caio Fe. ‘ooaTeTt

3 Mole Fac. 0.008820,

104 Mole Frac 0.002775

104 Mole Fre. 0.003095

165 Mole Frac. 0.00148

‘CS Mole Frac. o.00T28t

ACS Mole Fras. o.00182%

C7 Mole Frac. 0.007684

20 Mole Frac. 0.000885)

DEA Mole Frac 7.000000

of the particular acid gas divided by moles of the circulatingamine, The

Spreadsheet in HYSYS is well-suited for this calculation, Not only can

the loading be directly calculated and displayed, but it can be

incorporated into the simulation to provide a "control point” for

optimizing the amine simulation, Also for convenience, the CO2 and

H2S volume compositions for the Sweet Gas stream are calculated.

our

poe EE

‘The following variables were used for the loading calculations.

‘The following formulas will produce the desired calculations,

eae =

‘coz 125 ‘The acid ges loadings can be compared to values recommended by D.B.

MEADGA [05 036 Robinson, shown to the right.

DEA 0a 030

TEAMDEA | 0.30 020

ore

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- BookDocument2 pagesBookImmanuel AgapaoNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Production of Lipopeptide Antibiotic Iturin A Using Soybean Curd Residue Cultivated With Bacillus Subtilis in Solid-StaDocument7 pagesProduction of Lipopeptide Antibiotic Iturin A Using Soybean Curd Residue Cultivated With Bacillus Subtilis in Solid-StaImmanuel AgapaoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Soybean Carbohydrate As Fermentation Feedstock For Production of Biofuels and Value-Added Chemicals PDFDocument12 pagesSoybean Carbohydrate As Fermentation Feedstock For Production of Biofuels and Value-Added Chemicals PDFImmanuel AgapaoNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- BiomolDocument13 pagesBiomolImmanuel AgapaoNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Production of Lipopeptide Antibiotic Iturin A Using Soybean Curd Residue Cultivated With Bacillus Subtilis in Solid-StaDocument7 pagesProduction of Lipopeptide Antibiotic Iturin A Using Soybean Curd Residue Cultivated With Bacillus Subtilis in Solid-StaImmanuel AgapaoNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- PengantarminyakbumiDocument13 pagesPengantarminyakbumiImmanuel AgapaoNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

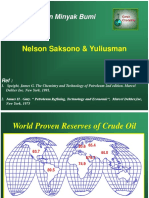

- Nelson Saksono & Yuliusman: Pengolahan Minyak BumiDocument13 pagesNelson Saksono & Yuliusman: Pengolahan Minyak BumiImmanuel AgapaoNo ratings yet

- Nelson Saksono & Yuliusman: Pengolahan Minyak BumiDocument13 pagesNelson Saksono & Yuliusman: Pengolahan Minyak BumiImmanuel AgapaoNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Nelson Saksono & Yuliusman: Pengolahan Minyak BumiDocument13 pagesNelson Saksono & Yuliusman: Pengolahan Minyak BumiImmanuel AgapaoNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- PastryDocument1 pagePastryImmanuel AgapaoNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- PengantarminyakbumiDocument13 pagesPengantarminyakbumiImmanuel AgapaoNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Antoine EqDocument4 pagesAntoine EqImmanuel AgapaoNo ratings yet

- Tabel KonversiDocument2 pagesTabel KonversiImmanuel AgapaoNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Production Facilities Glossary TermsDocument19 pagesProduction Facilities Glossary TermsImmanuel AgapaoNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Balance ConceptDocument27 pagesBalance ConceptImmanuel AgapaoNo ratings yet

- Tabel KonversiDocument2 pagesTabel KonversiImmanuel AgapaoNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Role of Algae in Phytoremediation of Heavy MetalsDocument8 pagesThe Role of Algae in Phytoremediation of Heavy MetalsImmanuel AgapaoNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)