Professional Documents

Culture Documents

Standard Head

Uploaded by

Cool Like0 ratings0% found this document useful (0 votes)

6 views1 pageStandar Bowl Front

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentStandar Bowl Front

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pageStandard Head

Uploaded by

Cool LikeStandar Bowl Front

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

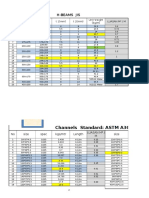

Either (A) or

OP “5s slit

EL ete [ ests ra

[=1=s3 [24s]

2] S68 ~ 418

z2~+4]-2~+6 |

se that the inside diameter is less than 600mm and the thicksess is less than 6mm,

the torelance of out side circumference is + 6mm and that of inside diameter is + 2mm,

1 Standard length of outside circumference ia(D + 20)m, where 93.1816

2 Average of inside diameters

17.2 17.3

eundness (Wax Dia= Ming bia) 97, (Shape) Deviation)

C [Mes 0.890 |

(let [Max 0.5950

Notes 1)

undness of head not included in the

applicable range of JIS standard shall be

ot more than 1.0%D,

Where a value of t/D is 0.008 and under,

the reinforcement may be required

17-4 17.5

Tolerance of Height 57 Tolerance of Welding Bevel

0 + 18D Mind) re OO

— ee

Note 1) Where a value of /D is 0.008 and |—SaeS-F2St* ————_— =. |

ander, the feinforcement may be Rowginess of | Gas Gating’ ever S05” Grinding: over 70S

17.6 77

Tardif anthem) Aceeotable standard of surface defects

ore than Se ‘The surface shall be visually smooth and surface detects sbove 025mm depth shalt be ans

ceptable, Cracks produced by material defects or forming shall also be unacceptable

Acceptable Standard of Lamination

Length of each lamination Permissible Quantity per 3m

‘onder 10mm [ ~_Not restricted

Tom and over, unde Max. 4 #1

25mm and over _ Not Permissible

Note #1. Lamination ger 30mm shall not exceed 3 at aggregating area

17.8

(oe 7

(1) In case the material is supplied from

omer, we are not responsible for any aonconformance

produced by material properties such as laminations et,

21 When head are Surmed ty step-pressing af Cold Press Method. Circunferentil shock: mark may

be produced,

‘The gap betwen surface and gage at the shock-mark shall be not more than 2mm.

3) In calewiating the tolerance of roundness, height and shape deviation, she nurerical value below

the fiestplace of decimals shall be omited

(4) In case of head beat-ireoted after forming, tolerance of circumberence oF inside diamotar). is in

sccordaner with JIS BR247,

-~ MONICA!

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Data Flange AnsiDocument10 pagesData Flange AnsiCool LikeNo ratings yet

- Pipe Dimensions: Nominal Pipe Size Pipe Schedule No. Pipe Outside Diameter Pipe Inside Diameter Wall ThicknessDocument2 pagesPipe Dimensions: Nominal Pipe Size Pipe Schedule No. Pipe Outside Diameter Pipe Inside Diameter Wall ThicknessCool LikeNo ratings yet

- H-Beams Jis: Size (MM) HXB (MM) T 1 (MM) T 2 (MM) Unit Weight (KG/M) Luasan M / MDocument20 pagesH-Beams Jis: Size (MM) HXB (MM) T 1 (MM) T 2 (MM) Unit Weight (KG/M) Luasan M / MCool LikeNo ratings yet

- Gantry CraneDocument2 pagesGantry CraneCool LikeNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)