Professional Documents

Culture Documents

Aalco Datasheet ST ST BS en

Uploaded by

SH1961Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aalco Datasheet ST ST BS en

Uploaded by

SH1961Copyright:

Available Formats

H62 - EN

H62

Steels for pressure vessels and

boilers

The fundamental property of steels for pressure vessels is their ability to

withstand high pressures at different temperatures.

Properties

Steels for pressure vessels and boilers differ from carbon and manganese structural steels by their high

resistance to pressure at all temperatures (ambient, low or high).

Advantages

The fundamental property of steels for pressure vessels is their ability to withstand high pressures at

different temperatures. They present good weldability and impact, and are suitable for normalising and stress

relief annealing (both treatments neutralise the consecutive local hardening of welding).

Applications

Steels for pressure vessels are mainly used to manufacture boilers, drums, pressure or steam piping,

industrial thermal vessels and heat exchangers. These steels are suitable for mechanical forming and

welding.

Recommendations for use

Options available after previous agreement for the different groups of grades:

ASTM A204

Reduced sulphur content

PWHT on test specimens

Charpy Impact test

High temperature tensile test

ASTM A285

Product delivered normalised

PWHT on test specimens

Bending test

Copper content between 0.20 and 0.35%

ASTM A515

Vacuum degassing

Austenitic grain size

Product analysis

PWHT on test specimens

http://www.fcs.arcelor.com/prd_web/new_web_details.pl?code=H62&langlist=EN&color=67b2b7 (1 12)07/06/2006 10:03:01

H62 - EN

Charpy Impact test

High temperature tensile test

Ultrasonic inspection

Bending test

ASTM A516

Vacuum degassing

Austenitic grain size

Product analysis

PWHT on test specimens

Charpy Impact test

High temperature tensile test

Ultrasonic inspection

Bending test

ASTM A537

Vacuum degassing

Product analysis

PWHT on test specimens

Charpy Impact test

High temperature tensile test

Ultrasonic inspection

Bending test

Brand correspondence

Steels with specified properties at elevated temperatures (EN 10028-2:2003)

EN 10028-2:2003 EN 10207:1997 EN 10028-3:2003 ASTM JIS G3115 EN 10207:1991

P235GH AFCS P235GH - - A285 gr.C/A414 gr.C SPV 24 -

P265GH AFCS P265GH - - A414 gr.E -

P295GH AFCS P295GH - - A299/A414 gr.F - -

P355GH AFCS P355GH - - A414 gr.G SPV 36 -

16 Mo 3 AFCS 16 Mo 3 - - A204-B - -

A387-11-2/A387-12-

13 Cr Mo 4-5 AFCS 13 Cr Mo 4-5 - - - -

2

Steels for simple pressure vessels (EN 10207:1997)

EN 10028-2:2003 EN 10207:1997 EN 10028-3:2003 ASTM JIS G3115 EN 10207:1991

P235S AFCS - P235S - - - SPH235

P265S AFCS - P265S - - - SPH265

P275SL AFCS - P275SL - - - SPHL275

Weldable fine grain steels, normalised (EN 10028-3:2003)

EN 10028-2:2003 EN 10207:1997 EN 10028-3:2003 ASTM JIS G3115 EN 10207:1991

P275NH AFCS - - P275NH - - -

P275NL1 AFCS - - P275NL1 - - -

P275NL2 AFCS - - P275NL2 - - -

http://www.fcs.arcelor.com/prd_web/new_web_details.pl?code=H62&langlist=EN&color=67b2b7 (2 12)07/06/2006 10:03:01

H62 - EN

P355N AFCS - - P355N A737 gr.B - -

P355NH AFCS - - P355NH A737 gr.B - -

P355NL1 AFCS - - P355NL1 - -

P355NL2 AFCS - - P355NL2 - - -

P460NH AFCS - - P460NH A737 gr.C - -

P460NL1 AFCS - - P460NL1 - - -

P460NL2 AFCS - - P460NL2 - - -

Dimensions

For dimensions offered, see Table A in data sheet H99.

Mechanical properties

Steels with specified properties at elevated temperatures (EN 10028-2:2003)

Thickness Re Rm A 5.65So KV KV 0 KV - KV - KV - A 2 A 8

Direction 20C 20C 40C 50C

(mm) (MPa) (MPa) (%) C (J) (%) (%)

(J) (J) (J) (J)

5 - 16 235

16 - 40 225 360 -

P235GH AFCS T 24 40 34 27 - - - -

40 - 60 215 480

60 - 80 200

5 - 16 265

16 - 40 255 410 -

P265GH AFCS T 22 40 34 27 - - - -

40 - 60 245 530

60 - 80 215

5 - 16 295

16 - 40 290 460 -

P295GH AFCS T 21 40 34 27 - - - -

40 - 60 285 580

60 - 80 260

5 - 16 355

510 -

16 - 40 345

650

P355GH AFCS T 40 - 60 335 20 40 34 27 - - - -

490 -

60 - 80 315

630

5 - 16 275

440 -

16 - 40 270

590

16 Mo 3 AFCS T 40 - 60 260 22 31 - - - - - -

430 -

60 - 80 240

560

440 -

L 60 - 80 - - - - - - - - -

590

5 - 16 300 450 -

13 Cr Mo 4-5 AFCS 31

http://www.fcs.arcelor.com/prd_web/new_web_details.pl?code=H62&langlist=EN&color=67b2b7 (3 12)07/06/2006 10:03:01

H62 - EN

T 16 - 60 290 600 19 - - - - - -

440 -

60 - 80 270 27

590

All mechanical properties are guaranteed in the normalised condition.

For 13 Cr Mo 4-5 grades, the mechanical properties are guaranteed in the normalised and tempered

condition.

Steels for simple pressure vessels (EN 10207:1997)

Thickness Re Rm A 5.65So KV KV 0 KV - KV - KV - A 2 A 8

Direction 20C 20C 40C 50C

(mm) (MPa) (MPa) (%) C (J) (%) (%)

(J) (J) (J) (J)

5 - 40 26

L - - - - 28 - - - -

40 - 60 25

P235S AFCS 5 - 16 235

360 - 24

T 16 - 40 225 - - - - - - -

480

40 - 60 215 23

L 5 - 60 - - 22 - - 28 - - - -

5 - 16 265

P265S AFCS 410 -

T 16 - 40 255 20 - - - - - - -

530

40 - 60 245

L 5 - 60 - - 24 - - - - 28 - -

5 - 16 275

P275SL AFCS 390 -

T 16 - 40 265 22 - - - - - - -

510

40 - 60 255

Weldable fine grain steels, normalised (EN 10028-3:2003)

Thickness Re Rm A 5.65So KV KV 0 KV - KV - KV - A 2 A 8

Direction 20C 20C 40C 50C

(mm) (MPa) (MPa) (%) C (J) (%) (%)

(J) (J) (J) (J)

L 5 - 40 - - - 75 65 45 - - - -

5 - 16 275

390 -

16 - 40 265 24

P275NH AFCS 510

T 40 - 60 255 50 40 30 - - - -

370 -

60 - 80 235 23

490

L 5 - 40 - - - 63 55 47 34 27 - -

5 - 16 275

390 -

16 - 40 265 24

P275NL1 AFCS 510

T 40 - 60 255 45 40 35 27 - - -

370 -

60 - 80 235 23

490

L 5 - 40 - - - 85 75 55 45 42 - -

5 - 16 275

390 -

16 - 40 265 24

P275NL2 AFCS 510

T 40 - 60 255 70 60 40 30 27 - -

370 -

60 - 80 235 23

490

L 5 - 40 - - - 75 65 45 - - - -

http://www.fcs.arcelor.com/prd_web/new_web_details.pl?code=H62&langlist=EN&color=67b2b7 (4 12)07/06/2006 10:03:01

H62 - EN

5 - 16 355 490 -

P355N AFCS 16 - 40 345 22

T 630

50 40 30 - - - -

40 - 60 335

470 -

60 - 80 315 21

610

L 5 - 40 - - - 75 65 45 - - - -

5 - 16 355

490 -

16 - 40 345 22

P355NH AFCS 630

T 40 - 60 335 50 40 30 - - - -

470 -

60 - 80 315 21

610

L 5 - 40 - - - 63 55 47 34 27 - -

5 - 16 355

490 -

16 - 40 345 22

P355NL1 AFCS 630

T 40 - 60 335 45 40 35 27 - - -

470 -

60 - 80 315 21

610

L 5 - 40 - - - 85 75 55 45 42 - -

5 - 16 355

490 -

16 - 40 345 22

P355NL2 AFCS 630

T 40 - 60 335 70 60 40 30 27 - -

470 -

60 - 80 315 21

610

L 5 - 40 - - - 75 65 45 - - - -

5 - 16 460

570 -

16 - 40 445

P460NH AFCS 720

T 40 - 60 430 17 50 40 30 - - - -

540 -

60 - 80 400

710

L 5 - 40 - - - 63 55 47 34 27 - -

5 - 16 460

570 -

16 - 40 445

P460NL1 AFCS 720

T 40 - 60 430 17 45 40 35 27 - - -

540 -

60 - 80 400

710

L 5 - 40 - - - 85 75 55 45 42 - -

5 - 16 460

570 -

16 - 40 445

P460NL2 AFCS 720

T 40 - 60 430 17 70 60 40 30 27 - -

540 -

60 - 80 400

710

All mechanical properties are guaranteed in the normalised condition.

Pressure vessel plates, Molybdenum alloyed steel (ASTM A204)

Thickness Re Rm A 5.65So KV KV 0 KV - KV - KV - A 2 A 8

Direction 20C 20C 40C 50C

(mm) (MPa) (MPa) (%) C (J) (%) (%)

(J) (J) (J) (J)

450 -

A204 gr.A AFCS T 5 - 80 255 - - - - - - 23 19

585

http://www.fcs.arcelor.com/prd_web/new_web_details.pl?code=H62&langlist=EN&color=67b2b7 (5 12)07/06/2006 10:03:01

H62 - EN

485 -

A204 gr.B AFCS T 5 - 80 275 - - - - - - 21 17

620

515 -

A204 gr.C AFCS T 5 - 80 295 - - - - - - 20 16

655

Pressure vessel plates, in carbon steel, low and intermediate tensile strength (ASTM A285)

Thickness Re Rm A 5.65So KV KV 0 KV - KV - KV - A 2 A8

Direction 20C 20C 40C 50C

(mm) (MPa) (MPa) (%) C (J) (%) (%)

(J) (J) (J) (J)

310 -

A285 gr.A AFCS T 5 - 80 165 - - - - - - 30 27

450

345 -

A285 gr.B AFCS T 5 - 80 185 - - - - - - 28 25

485

380 -

A285 gr.C AFCS T 5 - 80 205 - - - - - - 27 23

515

Pressure vessel plates, in carbon steel, for intermediate and high service temperatures (ASTM

A515)

Thickness Re Rm A 5.65So KV KV 0 KV - KV - KV - A 2 A 8

Direction 20C 20C 40C 50C

(mm) (MPa) (MPa) (%) C (J) (%) (%)

(J) (J) (J) (J)

415 -

A515 gr.60 AFCS T 5 - 80 220 - - - - - - 25 21

550

450 -

A515 gr.65 AFCS T 5 - 80 240 - - - - - - 23 19

585

485 -

A515 gr.70 AFCS T 5 - 80 260 - - - - - - 21 17

620

Pressure vessel plates, in carbon steel, for intermediate and low temperatures (ASTM A516)

Thickness Re Rm A 5.65So KV KV 0 KV - KV - KV - A 2 A8

Direction 20C 20C 40C 50C

(mm) (MPa) (MPa) (%) C (J) (%) (%)

(J) (J) (J) (J)

380 -

A516 gr.55 AFCS T 5 - 80 205 - - - - - - 27 23

515

415 -

A516 gr.60 AFCS T 5 - 80 220 - - - - - - 25 21

550

450 -

A516 gr.65 AFCS T 5 - 80 240 - - - - - - 23 19

585

485 -

A516 gr.70 AFCS T 5 - 80 260 - - - - - - 21 17

620

Pressure vessel plates, heat treated, in carbon-manganese-silicon steel (ASTM A537)

Thickness Re Rm A 5.65So KV KV 0 KV - KV - KV - A 2 A 8

Direction 20C 20C 40C 50C

(mm) (MPa) (MPa) (%) C (J) (%) (%)

(J) (J) (J) (J)

450 -

L 65 - 80 310 - - - - - - - -

585

485 -

A537 cl.1 AFCS 5 - 65 345

620

T - - - - - - 22 18

450 -

65 - 80 310

585

http://www.fcs.arcelor.com/prd_web/new_web_details.pl?code=H62&langlist=EN&color=67b2b7 (6 12)07/06/2006 10:03:01

H62 - EN

Mechanical characteristics at high temperature

Steels with specified properties at elevated temperatures (EN 10028-2:2003)

Steel grade Thickness (mm) 50C 100C 150C 200C 250C 300C 350C 400C 450C 500C

5 < t 16 227 214 198 182 167 153 142 133

16 < t 40 218 205 190 174 160 147 136 128

P235GH AFCS

40 < t 60 208 196 181 167 153 140 130 122

60 < t 80 193 182 169 155 142 130 121 114

5 < t 16 256 241 223 205 188 173 160 150

16 < t 40 247 232 215 197 181 166 154 145

P265GH AFCS

40 < t 60 237 223 206 190 174 160 148 139

60 < t 80 208 196 181 167 153 140 130 122

- -

5 < t 16 285 268 249 228 209 192 178 167

16 < t 40 280 264 244 225 206 189 175 165

P295GH AFCS

40 < t 60 276 259 240 221 202 186 172 162

60 < t 80 251 237 219 201 184 170 157 148

5 < t 16 343 323 299 275 252 232 214 202

16 < t 40 334 314 291 267 245 225 208 196

P355GH AFCS

40 < t 60 324 305 282 259 238 219 202 190

60 < t 80 305 287 265 244 224 206 190 179

5 < t 16 273 264 250 233 213 194 175 159 147 141

16 < t 40 268 259 245 228 209 190 172 156 145 139

16 Mo 3 AFCS

40 < t 60 258 250 236 220 202 183 165 150 139 134

60 < t 80 238 230 218 203 186 169 153 139 129 123

5 < t 16 294 285 269 252 234 216 200 186 175 164

13 Cr Mo 4-5 AFCS 16 < t 60 285 275 260 243 226 209 194 180 169 159

60 < t 80 265 256 242 227 210 195 180 168 157 148

Steels for simple pressure vessels (EN 10207:1997)

Steel grade Thickness (mm) 50C 100C 150C 200C 250C 300C 350C 400C 450C 500C

P235S AFCS 5 < t 60 171 162 153 135 117

P265S AFCS 5 < t 60 194 185 158 140

- - - - -

5 < t 40 221 203 176

P275SL AFCS 159 132

40 < t 60 212 194

Weldable fine grain steels, normalised (EN 10028-3:2003)

Steel grade Thickness (mm) 50C 100C 150C 200C 250C 300C 350C 400C 450C 500C

5 < t 16 266 250 232 213 195 179 166 156

16 < t 40 256 241 223 205 188 173 160 150

P275NH AFCS

40 < t 60 247 232 215 197 181 166 154 145

60 < t 80 227 214 198 182 167 153 142 133

5 < t 16 343 323 299 275 252 232 214 202

16 < t 40 334 314 291 267 245 225 208 196

P355NH AFCS - -

40 < t 60 324 305 282 259 238 219 202 190

60 < t 80 305 287 265 244 224 206 190 179

5 < t 16 445 419 388 356 326 300 278 261

http://www.fcs.arcelor.com/prd_web/new_web_details.pl?code=H62&langlist=EN&color=67b2b7 (7 12)07/06/2006 10:03:01

H62 - EN

16 < t 40 430 405 375 345 316 290 269 253

P460NH AFCS

40 < t 60 416 391 362 333 305 281 260 244

60 < t 80 387 364 337 310 284 261 242 227

Chemical properties

Steels with specified properties at elevated temperatures (EN 10028-2:2003)

Ni+Cr

Thickness C Mn Si Al Cu Cr Ni Mo Nb V Ti Ceq +Cu

P (%) S (%) N (%)

(mm) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) +Mo

(%)

0.60

< < < < > < < < < < < < < <

P235GH AFCS 5 - 80 - -

0.16 0.025 0.015 0.35 0.020 0.30 0.30 0.30 0.08 0.020 0.02 0.03 0.012 0.70

1.20

0.80

< < < < > < < < < < < < < <

P265GH AFCS 5 - 80 - -

0.20 0.025 0.015 0.40 0.020 0.30 0.30 0.30 0.08 0.020 0.02 0.03 0.012 0.70

1.40

0.08 0.90

< < < > < < < < < < < < <

P295GH AFCS 5 - 80 - - -

0.025 0.015 0.40 0.020 0.30 0.30 0.30 0.08 0.020 0.02 0.03 0.012 0.70

0.20 1.50

0.10 1.10

< < < > < < < < < < < < <

P355GH AFCS 5 - 80 - - -

0.025 0.015 0.60 0.020 0.30 0.30 0.30 0.08 0.020 0.02 0.03 0.012 0.70

0.22 1.70

0.12 0.40 0.25

< < < < < < <

16 Mo 3 AFCS 5 - 80 - - - - - - - - -

0.025 0.010 0.35 0.30 0.30 0.30 0.012

0.20 0.90 0.35

0.08 0.40 0.70 0.40

< < < < <

13 Cr Mo 4-5 AFCS 5 - 80 - - - - - - - - - - -

0.025 0.010 0.35 0.30 0.012

0.18 1.00 1.15 0.60

The above chemical properties are based on cast analysis data.

Steels for simple pressure vessels (EN 10207:1997)

Ni+Cr

Thickness C Mn Si Al Cu Cr Ni Mo Nb V Ti Ceq +Cu

P (%) S (%) N (%)

(mm) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) +Mo

(%)

0.40

< < < < >

P235S AFCS 5 - 80 - - - - - - - - - - -

0.16 0.035 0.030 0.35 0.020

1.20

0.50

< < < < >

P265S AFCS 5 - 80 - - - - - - - - - - -

0.20 0.035 0.030 0.40 0.020

1.50

0.50

< < < < >

P275SL AFCS 5 - 80 - - - - - - - - - - -

0.16 0.030 0.025 0.40 0.020

1.50

The above chemical properties are based on cast analysis data.

http://www.fcs.arcelor.com/prd_web/new_web_details.pl?code=H62&langlist=EN&color=67b2b7 (8 12)07/06/2006 10:03:02

H62 - EN

Weldable fine grain steels, normalised (EN 10028-3:2003)

Ni+Cr

Thickness C Mn Si Al Cu Cr Ni Mo Nb V Ti Ceq +Cu

P (%) S (%) N (%)

(mm) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) +Mo

(%)

0.80

< < < < > < < < < < < < < <

P275NH AFCS 5 - 80 - -

0.16 0.025 0.015 0.40 0.020 0.30 0.30 0.50 0.08 0.050 0.05 0.03 0.012 0.40

1.50

0.80

< < < < > < < < < < < < < <

P275NL1 AFCS 5 - 80 - -

0.16 0.025 0.015 0.40 0.020 0.30 0.30 0.50 0.08 0.050 0.05 0.03 0.012 0.40

1.50

0.80

< < < < > < < < < < < < < <

P275NL2 AFCS 5 - 80 - -

0.16 0.020 0.010 0.40 0.020 0.30 0.30 0.50 0.08 0.050 0.05 0.03 0.012 0.40

1.50

<

5 - 60 1.10

< < < < > < < < < < < < < 0.43

P355N AFCS - -

0.18 0.025 0.015 0.50 0.020 0.30 0.30 0.50 0.08 0.050 0.10 0.03 0.012 <

60 - 80 1.70

0.45

<

5 - 60 1.10

< < < < > < < < < < < < < 0.43

P355NH AFCS - -

0.18 0.025 0.015 0.50 0.020 0.30 0.30 0.50 0.08 0.050 0.10 0.03 0.012 <

60 - 80 1.70

0.45

<

5 - 60 1.10

< < < < > < < < < < < < < 0.43

P355NL1 AFCS - -

0.18 0.025 0.015 0.50 0.020 0.30 0.30 0.50 0.08 0.050 0.10 0.03 0.012 <

60 - 80 1.70

0.45

<

5 - 60 1.10

< < < < > < < < < < < < < 0.43

P355NL2 AFCS - -

0.18 0.020 0.010 0.50 0.020 0.30 0.30 0.50 0.08 0.050 0.10 0.03 0.012 <

60 - 80 1.70

0.45

1.10 <

5 - 60 < < < < > < < < < < < < <

P460NH AFCS - 0.53 -

0.20 0.025 0.015 0.60 0.020 0.70 0.30 0.80 0.10 0.050 0.20 0.03 0.025

60 - 80 1.70 -

1.10 <

5 - 60 < < < < > < < < < < < < <

P460NL1 AFCS - 0.53 -

0.20 0.025 0.015 0.60 0.020 0.70 0.30 0.80 0.10 0.050 0.20 0.03 0.025

60 - 80 1.70 -

1.10 <

5 - 60 < < < < > < < < < < < < <

P460NL2 AFCS - 0.53 -

0.20 0.020 0.010 0.60 0.020 0.70 0.30 0.80 0.10 0.050 0.20 0.03 0.025

60 - 80 1.70 -

The above chemical properties are based on cast analysis data.

Carbon equivalent is guaranteed only if specified on ordering.

Cr+Cu+Mo 0.45

For P275...AFCS grades, Nb+Ti+V 0.05

For P355...AFCS grades, Nb+Ti+V 0.12

For P460...AFCS grades, Nb+Ti+V 0.22

Pressure vessel plates, Molybdenum alloyed steel (ASTM A204)

Ni+Cr

Thickness C Mn Si Al Cu Cr Ni Mo Nb V Ti Ceq +Cu

http://www.fcs.arcelor.com/prd_web/new_web_details.pl?code=H62&langlist=EN&color=67b2b7 (9 12)07/06/2006 10:03:02

H62 - EN

(mm) (%) (%) P (%) S (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) N (%) (%) +Mo

(%)

<

5 - 25

0.18

0.15 0.45

< < < <

A204 gr.A AFCS 25 - 50 - - - - - - - - - - - -

0.21 0.90 0.035 0.035

0.40 0.60

<

50 - 80

0.23

<

5 - 25

0.20

0.15 0.45

< < < <

A204 gr.B AFCS 25 - 50 - - - - - - - - - - - -

0.23 0.90 0.035 0.035

0.40 0.60

<

50 - 80

0.25

<

5 - 25

0.23

0.15 0.45

< < < <

A204 gr.C AFCS 25 - 50 - - - - - - - - - - - -

0.26 0.90 0.035 0.035

0.40 0.60

<

50 - 80

0.28

Pressure vessel plates, in carbon steel, low and intermediate tensile strength (ASTM A285)

Ni+Cr

Thickness C Mn Si Al Cu Cr Ni Mo Nb V Ti Ceq +Cu

P (%) S (%) N (%)

(mm) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) +Mo

(%)

< < < <

A285 gr.A AFCS 5 - 80 - - - - - - - - - - - -

0.17 0.90 0.035 0.035

< < < <

A285 gr.B AFCS 5 - 80 - - - - - - - - - - - -

0.22 0.90 0.035 0.035

< < < <

A285 gr.C AFCS 5 - 80 - - - - - - - - - - - -

0.28 0.90 0.035 0.035

Pressure vessel plates, in carbon steel, for intermediate and high service temperatures (ASTM

A515)

Ni+Cr

Thickness C Mn Si Al Cu Cr Ni Mo Nb V Ti Ceq +Cu

P (%) S (%) N (%)

(mm) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) +Mo

(%)

<

5 - 25

0.24

0.15

< < < <

A515 gr.60 AFCS 25 - 50 - - - - - - - - - - - -

0.27 0.90 0.035 0.035

0.40

<

50 - 80

0.29

<

5 - 25

0.28

0.15

< < < <

A515 gr.65 AFCS 25 - 50 - - - - - - - - - - - -

0.31 0.90 0.035 0.035

0.40

<

50 - 80

0.33

<

http://www.fcs.arcelor.com/prd_web/new_web_details.pl?code=H62&langlist=EN&color=67b2b7 (10 12)07/06/2006 10:03:02

H62 - EN

5 - 25 0.31

0.15

A515 gr.70 AFCS < < < <

25 - 50 - - - - - - - - - - - -

0.33 1.20 0.035 0.035 0.40

<

50 - 80

0.35

Pressure vessel plates, in carbon steel, for intermediate and low temperatures (ASTM A516)

Ni+Cr

Thickness C Mn Si Al Cu Cr Ni Mo Nb V Ti Ceq +Cu

P (%) S (%) N (%)

(mm) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) +Mo

(%)

0.60

5 - 12.5 < -

0.18 0.90

0.15

12.5 - 25 < <

A516 gr.55 AFCS - - - - - - - - - - - -

< 0.60 0.035 0.035

25 - 50 0.40

0.20 -

< 1.20

50 - 80

0.22

0.60

5 - 12.5 < -

0.21 0.90

0.15

12.5 - 25 < <

A516 gr.60 AFCS - - - - - - - - - - - -

< 0.85 0.035 0.035

25 - 50 0.40

0.23 -

< 1.20

50 - 80

0.25

<

5 - 25

0.24

0.85 0.15

< < <

A516 gr.65 AFCS 25 - 50 - - - - - - - - - - - - -

0.26 0.035 0.035

1.20 0.40

<

50 - 80

0.28

<

5 - 25

0.27

0.85 0.15

< < <

A516 gr.70 AFCS 25 - 50 - - - - - - - - - - - - -

0.28 0.035 0.035

1.20 0.40

<

50 - 80

0.30

Pressure vessel plates, heat treated, in carbon-manganese-silicon steel (ASTM A537)

Ni+Cr

Thickness C Mn Si Al Cu Cr Ni Mo Nb V Ti Ceq +Cu

P (%) S (%) N (%)

(mm) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) (%) +Mo

(%)

0.70

5 - 40 -

0.15

< 1.35 < < < < < <

A537 cl.1 AFCS - - - - - - - -

0.24 1.00 0.035 0.035 0.35 0.25 0.25 0.08

0.50

40 - 80 -

1.60

http://www.fcs.arcelor.com/prd_web/new_web_details.pl?code=H62&langlist=EN&color=67b2b7 (11 12)07/06/2006 10:03:02

H62 - EN

Request for information: fcs.technical.assistance@arcelor.com

All information in the Arcelor FCS Commercial catalogue is for the purposes of information only. Arcelor FCS

Commercial reserves the right to change its product range at any time without prior notice.

-- Last update: 2006-5-5 --

http://www.fcs.arcelor.com/prd_web/new_web_details.pl?code=H62&langlist=EN&color=67b2b7 (12 12)07/06/2006 10:03:02

You might also like

- 444 StainlessDocument4 pages444 StainlessSH1961No ratings yet

- Non Ferrous MaterialsDocument8 pagesNon Ferrous MaterialsSH1961No ratings yet

- Chloride SCC of 316 SSTDocument5 pagesChloride SCC of 316 SSTSH1961100% (1)

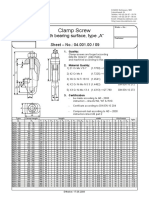

- Vba Edelmann Clamp FastenersDocument2 pagesVba Edelmann Clamp FastenersSH1961No ratings yet

- Non Returne ValvesDocument22 pagesNon Returne ValvesSH1961No ratings yet

- Pipe Symbols For Isometric DrawingsDocument3 pagesPipe Symbols For Isometric DrawingsSH1961No ratings yet

- Tightening TorquesDocument4 pagesTightening Torquesflanker76No ratings yet

- Chlorides Stainless ResistanceDocument1 pageChlorides Stainless ResistanceHRK65No ratings yet

- Lumi GlassDocument1 pageLumi GlassSH1961No ratings yet

- Gaskets - Graphite PDFDocument4 pagesGaskets - Graphite PDFSH1961No ratings yet

- Algoma Steel Sheet PDFDocument10 pagesAlgoma Steel Sheet PDFSH1961No ratings yet

- Corrosion Resistance ofDocument44 pagesCorrosion Resistance ofalkem7No ratings yet

- Velan High Pressure Steam Trapping Brochure PDFDocument8 pagesVelan High Pressure Steam Trapping Brochure PDFSH1961No ratings yet

- Stainless Steels and Their PropertiesDocument45 pagesStainless Steels and Their PropertiesSH1961No ratings yet

- Complete CatalogDocument52 pagesComplete CatalogrbsaylorsNo ratings yet

- Bolt Tightening-Torques PDFDocument4 pagesBolt Tightening-Torques PDFSH1961100% (2)

- Bolt Tightening Torques PDFDocument3 pagesBolt Tightening Torques PDFSH1961100% (3)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Economies of Scale FinalDocument33 pagesEconomies of Scale FinalNikhil KasatNo ratings yet

- Literature Resources For Chemical Process Industries (Advances in Chemistry Series 010)Document578 pagesLiterature Resources For Chemical Process Industries (Advances in Chemistry Series 010)Rian PuspitasariNo ratings yet

- Manufacturing Process Assignment 1Document10 pagesManufacturing Process Assignment 1abhishek chibNo ratings yet

- Corporate Profile: Kintetsu World Express South AfricaDocument11 pagesCorporate Profile: Kintetsu World Express South Africalospepes19No ratings yet

- Case Study DELHAIZE ZELLIK ENG PDFDocument2 pagesCase Study DELHAIZE ZELLIK ENG PDFhonghai_dlNo ratings yet

- QuestionnaireDocument4 pagesQuestionnaireAnish Thomas100% (1)

- Duragrout: Non-Shrink Cementitious GroutDocument3 pagesDuragrout: Non-Shrink Cementitious GroutJohan ConradieNo ratings yet

- 679 02 Fenner Chain DrivesDocument32 pages679 02 Fenner Chain Drivesparag76760% (1)

- AllaboutDocument13 pagesAllaboutRohan JindalNo ratings yet

- Elastomer For Heavy Engineering ApplicationsDocument23 pagesElastomer For Heavy Engineering Applicationsalwil144548No ratings yet

- Economic Structure of IndiaDocument22 pagesEconomic Structure of IndiaShreedhar DeshmukhNo ratings yet

- GLACIER LAr Tank Design (Deliverable 2.2)Document76 pagesGLACIER LAr Tank Design (Deliverable 2.2)atiqulaNo ratings yet

- Standard and InterchangeDocument25 pagesStandard and InterchangeBibin Baby100% (1)

- AHU CasingDocument3 pagesAHU Casingmirali74No ratings yet

- A618 PDFDocument4 pagesA618 PDFSadashiva sahooNo ratings yet

- National Open University of NigeriaDocument106 pagesNational Open University of NigeriaAromasodun Omobolanle IswatNo ratings yet

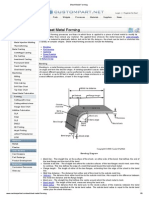

- Sheet Metal Forming PDFDocument9 pagesSheet Metal Forming PDFRakhesh Manchi100% (1)

- A3 Civil WorksDocument28 pagesA3 Civil WorksNonsoufo ezeNo ratings yet

- Ultra Thin WhitetoppingDocument36 pagesUltra Thin WhitetoppingAnil Kumsr T B100% (1)

- 1602Document6 pages1602umair186No ratings yet

- Mechanical Design Manual FastenerDocument68 pagesMechanical Design Manual FastenerRuben VidalNo ratings yet

- Rumusan 3Document42 pagesRumusan 3Den limboongNo ratings yet

- Powder Production Methods: - Mechanical Crushing and Grinding - Mechanical AlloyingDocument14 pagesPowder Production Methods: - Mechanical Crushing and Grinding - Mechanical AlloyingSalvador Tinoco VRsNo ratings yet

- Jessica Shuangji Model 75-90 Ps Foam Food Box Production Line - 600x1000mm Forming Area - 2017Document23 pagesJessica Shuangji Model 75-90 Ps Foam Food Box Production Line - 600x1000mm Forming Area - 2017sachpatiNo ratings yet

- Solid-State Recycling of Aluminium Alloy Swarf Through Cold Profile Extrusion and Cold RollingDocument42 pagesSolid-State Recycling of Aluminium Alloy Swarf Through Cold Profile Extrusion and Cold RollingthaivinhtuyNo ratings yet

- Electronic Product Development - Manufacturing Cost Estimation PDFDocument21 pagesElectronic Product Development - Manufacturing Cost Estimation PDFDhanus KodiNo ratings yet

- Introduction To Welding - 1 GCDocument66 pagesIntroduction To Welding - 1 GCkr_abhijeet72356587No ratings yet

- Thesis-Vdattani-Study On Waste Management From Indian Perspective FinalDocument84 pagesThesis-Vdattani-Study On Waste Management From Indian Perspective FinalAnjnaKandariNo ratings yet

- Bulgaria MSWDocument16 pagesBulgaria MSWAndrei IoanNo ratings yet

- Bucket Elevator Project ReportDocument104 pagesBucket Elevator Project ReportTanvi Khurana100% (2)