Professional Documents

Culture Documents

ECR Burner With Control System

Uploaded by

nagagop930100%(1)100% found this document useful (1 vote)

333 views4 pagesburner

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentburner

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

333 views4 pagesECR Burner With Control System

Uploaded by

nagagop930burner

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

ae DORBES

ECR Burner with Control System

For automation, efficiency and operational control

&

Energy Conservation | Environment | Process Efficiency www forbesmarshall.com

¥W FORBES

Bo tanseace

ECR Burner

with Control

System

‘The ECR (Electronic Compound

Regulation) burner operation,

efficiency monitoring and control

system from Forbes Marshall is the

smartest offering in burners. This

innovative product provides end to

end solutions for monitoring and

controlling boilers to the optimum

efficiency, at any load and at any

time.

The ECR burner system is equipped

with a user friendly touch screen

display which enhances the usability

of the system. The system also

provides modbus output, which

enables alll boiler data to be

displayed and logged onto the

connected computer using

proprietary software.

HMI Display Panel

The New and Innovative ECR System

Air / Fuel ratio control and setting - The ECR bumer control system has

separate servo motors for air / oll modulation and an electro-pneumatic

system for gas modulation. This innovative feature allows precise air to fuel

ratio setting throughout the modulation range thereby ensuring best

efficiency at any load and at any time.

Precise oil temperature control - The PLC based controller with accurate

temperature helps achieve this, thereby ensuring more precise and uniform

oil temperature. This results in reduced unburnts and incomplete

‘combustion losses and hence consistent efficiency.

‘Smooth start up for gas firing - For bumers with rating > 1500 kW, pilot

gas train helps achieve this, which results in smooth establishment of flame.

Valve proving system - Valve proving system (VPS) ensures checking

leakages within gas solenoid valves at every start up. This results in safe

‘operation on gas firing,

Safety solenoid valve - Presence of safety solenoid valve for oil firing

ensures circulation of oil in external oll circuit til the start of the purging cycle.

This further minimises the risk of oll leakage inside the furnace in case of a

malfunction,

Pressure switches - High pressure switches for oll supply and return line

ensue that oll pressure never exceeds the set value. This sets the limit for

maximum pressure and subsequently sets the maximum limit for cil flow

available for combustion. Also, for gas fing, pressure switches ensure the

‘operating band for low and high gas pressure control in the gas line.

Ratio controller for gas - inbuilt gas to air ratio control enables gas

multiblock to maintain uniform combustion performance throughout the

operating range.

Easy maintenance - Periodic maintenance of combustion head is very easy

and the oil diffuser plate once inserted into the combustion head ensures that,

the flame is centered. Also in case of dual fuel burner, oil hydraulic lance

along with diffuser plate can be easily removed and refitted without any

interference with the gas header.

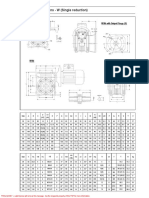

Hinge design - The burner comes with a hinge design that needs only one

person to open the door to access components inside the combustion head

for regular maintenance.

Burner with Electronic Compound Regulation

The stepless modulating bumer has the latest technology of air to fuel ratio control mechanism by electronic compound.

regulation, through independent servo motors for air and oil modulation

This eliminates the old ratio control technology of mechanical compound regulation which has a single servo motor with

mechanical linkages.

fos [Pose Jeo | 3 oe fe Be [ie oom [4 Be [SR

wee [Foo ae [= es Bee, [mew

fore HEF wees, | sxe [Gy Bett: [ah Bex [fe Bee [A me

Be [Oc [EBB [i Bee [— Banne|— Sdnne| & SAME

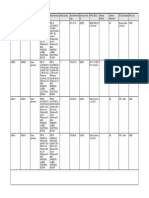

Advantages of Electronic Compound Regulation over Mechanical Linkage Type

Sr.No. | Electronic Compound Regulation Mechanical Compound Regulation

1 Independent servo motors for al and air precise | Single servo motor - poor precision in control

control

2 Control through electronic signal pulse - high Contra through mechanical inkage - poor

repeatability. Each pulse motor receives a signal | _repeatablity due to mechanical hysteresis

from the PLC and load controler.

3 Online display of air and fuel dampers possible. Display of air and fuel dampers pasion not

As pulse motors are connected by cans toa PLC. | possible. The exact position of air and fuel can't

‘exact position of air and fuel at any time is displayed| _ be known.

onthe PLC

4 Burner tuning and settings - user friendly operating ‘Bumer tuning and settings - very cumbersome to

and display device set due to mechanical linkages

5 Burner fault detection - available dreclly rough | Burner Taull detection - not avalable directly

digital manager

5 Total interface with computer Computer interlacing not possible

7 Toad controler programme inbuilt in PLG and no | Load regulator To be connected separately and

separate controller required wired to the sequence controler

Customer Reference List

Customer Capacity Fuel

‘Alwar Dairy 8TPH Furnace Oil

‘Amneal Pharmaceuticals Ltd STPH Furnace Oil, Natural Gas

Cadila Healthcare Ltd 2.8TPH HSD, Natural Gas

DIC Fine Chemicals Pvt Lid 2.8TPH HSD, Natural Gas

Dr. Reddy's Laboratories 6TPH Furnace Oil

Eisai Pharmaceuticals India Pvt Ltd 3TPH Furnace Oil

Fermenta Biotech Ltd 21PH Furnace Oil, Natural Gas

Hindustan Unilever Ltd 8 TPH Furnace Oil

Hitech Engineers 2TPH LDO

Hindustan Petroleum Corporation Lid 6.3TPH LDO|

Kohler India 3.5TPH HSD, Natural Gas

Madhur Dairy 2.8TPH Furnace Oil, Natural Gas

Meghmani Industries Ltd STPH Furnace Oil, Natural Gas

Mukand Bekaert Wire Ind Pvt Lid 3TPH Furnace Oil

Orbit Resorts Pvt Ltd 2.8TPH HSD, Natural Gas

Pharmalab India Pvt Ltd 21PH Natural Gas|

Rallis India Ltd 3.5TPH Furnace Oil, Natural Gas

Reliance Industries Ltd 3.5TPH HSD, Natural Gas

Remi Metals Gujarat Ltd 2TPH Furnace Oil, Natural Gas

Sandoz Pvt Lid 3TPH Furnace Oil, Natural Gas

Supreme Petrochem Ltd 6.3TPH Furnace Oil, Natural Gas

Symbiotec Pharmalab Pvt Lid 2TPH LDO, Natural Gas

Tata Bluescope 40TPH LPG

Tata CRM STPH LPG

‘TEVA Pharmaceutical Ind Ltd 3.5TPH Furnace Oil

‘The Akshaya Patra Foundation 2TPH Furnace Oil, Natural Gas

Vidya Dairy 3TPH Furnace Oil, Natural Gas

PY FORBES Opp 106th Milestone 85, Phase I, Chakan In Area A-34/35, MIDC H Block

Arid

Forbes Marval

Krohn Marshall

Forbes Marsnalaccs

Code intematonal

oes Sole

oes Vyncke

Forbes Maral Slam Systems

Bombay Poona Road

Kasarwad, Pune 411 034

INDIA

Tel = 81(0)20.27148695, 38858555

Fax" 91(0}20-27147413

Sawardan, Chakan, Tal, Khoo

Dist Pune - 410 60%. INDIA

Tol: 91(0}2135-393400

Email: seg@yorbesmarshall.com, comido@orbesmarshallcom

A contents he

impr, Pune- 11 018. INDIA

Tel" 94(0)20-27442020, 39857199

Fax: 91(0}20-77442040

www forbesmarshall.com

othe proportyofFrbos Marshall Private Limite FMP) and having protection under the lleva

Property rights. Aryroaducen, ditbon of dilosure who pr wren penises prohbod. nfermaton nhs

ffocumert sbjoct to change witout noteo.

Doce FBLA SR-02081V8, 20

You might also like

- Torsion SpringsDocument4 pagesTorsion Springsnagagop930No ratings yet

- Fan Installation GuideDocument45 pagesFan Installation Guidenagagop930100% (2)

- Asme Ix QW PDFDocument183 pagesAsme Ix QW PDFAnonymous 4e7GNjzGW100% (4)

- Torsion Spring Design InfoDocument3 pagesTorsion Spring Design Infoashish19851No ratings yet

- Caleb Catalogue Intcirclip Metric PDFDocument3 pagesCaleb Catalogue Intcirclip Metric PDFnagagop930No ratings yet

- Ribbon BlendersDocument1 pageRibbon Blendersnagagop930No ratings yet

- CD 4060Document10 pagesCD 4060ahocine2011No ratings yet

- MVS-SVE Chapter10 PDFDocument52 pagesMVS-SVE Chapter10 PDFnagagop930No ratings yet

- Abacus CalculationDocument4 pagesAbacus Calculationnagagop930No ratings yet

- Food Safety 2Document5 pagesFood Safety 2api-3709624No ratings yet

- Mounting Dimensions - W (Single Reduction) : WSM With Output Flange (V) WSDDocument1 pageMounting Dimensions - W (Single Reduction) : WSM With Output Flange (V) WSDnagagop930No ratings yet

- Bridges PDFDocument6 pagesBridges PDFnagagop930No ratings yet

- DmpstyleDocument1 pageDmpstylenagagop930No ratings yet

- Steam Generator Receipt RecordsDocument9 pagesSteam Generator Receipt Recordsnagagop930No ratings yet

- Ad7793 DatasheetDocument18 pagesAd7793 Datasheetnagagop930No ratings yet

- 12 BSP FittingsDocument17 pages12 BSP Fittingsparag7676100% (1)

- Aosong Electronics Co.,LtdDocument10 pagesAosong Electronics Co.,Ltdnagagop930No ratings yet

- Dsa00402039 PDFDocument1 pageDsa00402039 PDFnagagop930No ratings yet

- Dsa00402040 PDFDocument1 pageDsa00402040 PDFnagagop930No ratings yet

- Heater Calculation1Document23 pagesHeater Calculation1nagagop930No ratings yet

- Kern Method Heat ExchangerDocument30 pagesKern Method Heat ExchangerCS100% (3)

- Dsa00402040 PDFDocument1 pageDsa00402040 PDFnagagop930No ratings yet

- 13501Document2 pages13501nagagop930No ratings yet

- Aosong Electronics Co.,LtdDocument10 pagesAosong Electronics Co.,Ltdnagagop930No ratings yet

- Technical Data: Relative Humidity SensorDocument4 pagesTechnical Data: Relative Humidity Sensorandresromero80No ratings yet

- Manuale-GB - 1261 R4Document54 pagesManuale-GB - 1261 R4manoj983@gmail.comNo ratings yet

- Heat Exchanger Handbook - Heat Exchangers PDFDocument66 pagesHeat Exchanger Handbook - Heat Exchangers PDFhonghai_dl100% (3)

- The Fundamentals of Heat ExchangersDocument4 pagesThe Fundamentals of Heat ExchangersJojie-Ann AlabarcaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)