Professional Documents

Culture Documents

Modular Unit Doubles Gasoline Output PTQ Technology in Action Feature

Uploaded by

SYedZYnAleCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Modular Unit Doubles Gasoline Output PTQ Technology in Action Feature

Uploaded by

SYedZYnAleCopyright:

Available Formats

Technology in Action

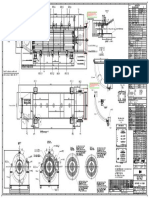

Modular unit doubles gasoline output limited resources. Built under controlled conditions in

fabrication shops and fully inspected prior to shipment,

the modules are designed to reduce installation time

Over the past eight years, Pakistan has increased its and can result in earlier start-up, further improving

level of petroleum imports to meet growing domestic project economics.

demand for gasoline. To reduce its new-found depen- In addition, Honeywell Process Solutions and UOP

dence on imports, Pakistan Refinery Limited (PRL) Process Information and Control teams worked

needed a way to boost the production of gasoline from together to execute the process control system for the

its refinery, and selected Honeywell UOPs Penex unit, which was critical to its successful operation. In

process. By converting light naphtha to isomerate, the addition to licensing and modular equipment, UOP

Penex process produces high octane gasoline blending provided PRL with catalysts, adsorbents, engineering,

components for the production of cleaner fuels with technical support, and a drier regeneration control

reduced emissions. system (DRCS) for extended catalyst life for the unit.

Working with PRL, UOP provided a detailed design The DRCS worked seamlessly with the existing

for the Penex unit, doubling PRLs monthly output of Honeywell distributed control system. Both systems

high quality gasoline to 24 000 tonnes. The unit was were built on Honeywells Experion PKS platform,

built and delivered as a modular solution, greatly which uses a unified automation system and advanced

simplifying the construction phase and reducing inter- software applications to increase operator productivity

ruption to refinery operations. and profitability. Process graphics were tailored to

Equipment specifications were developed using PRLs plant, and both systems were delivered on time

UOPs Schedule A, basic engineering design. Using a and ready for start-up with the unit.

3D model, UOP engineers worked with PRL to visual- UOP, A Honeywell Company

ise the plant and review the designs throughout the For more information: info@uop.com

project to ensure that it met PRLs processing objectives.

The modules were fabricated in the United Arab

Emirates, and were fully inspected before delivery to

the site. The modules shipped in November 2014, only LINKS

12 months after the order was placed. Within two

weeks of their arrival, the first module was bolted to its More articles from: UOP

foundation at PRLs site. UOP personnel were on-site to More articles from the following categories:

supervise installation and commission the unit. Blending

This modular equipment is ideal for many remote Catalysts & Additives

locations, short project timelines and regions with

www.digitalrefining.com/article/1001177 PTQ Q4 2015 1

You might also like

- UOP 300-E-03 D Shell Side Nozzle Load Flange Rating As Per Code Case 2901 CalculationsDocument12 pagesUOP 300-E-03 D Shell Side Nozzle Load Flange Rating As Per Code Case 2901 CalculationsSYedZYnAle100% (1)

- Saudization PlanningDocument4 pagesSaudization PlanningSYedZYnAle100% (1)

- For Pressure Vessels and Columns (Bidding Stage)Document2 pagesFor Pressure Vessels and Columns (Bidding Stage)SYedZYnAleNo ratings yet

- 100 E02eDocument12 pages100 E02eSYedZYnAleNo ratings yet

- PV Elite: Input Echo, Leg & Lug Item 1, Description: Trunnion 1-2Document15 pagesPV Elite: Input Echo, Leg & Lug Item 1, Description: Trunnion 1-2SYedZYnAleNo ratings yet

- Allowable loads on pressure vessel nozzlesDocument1 pageAllowable loads on pressure vessel nozzlesSYedZYnAleNo ratings yet

- Nozzel LoadDocument6 pagesNozzel LoadSYedZYnAleNo ratings yet

- ASME PTB 10 2015 Guide For ASME Section VIII Division 1 Stamp Holders 1 PDFDocument111 pagesASME PTB 10 2015 Guide For ASME Section VIII Division 1 Stamp Holders 1 PDFmarcoNo ratings yet

- AMETank Product BrochureDocument6 pagesAMETank Product BrochureSYedZYnAleNo ratings yet

- QG20 Career 20 FairDocument7 pagesQG20 Career 20 FairKarthik ChockkalingamNo ratings yet

- Rams Is Organization ChartDocument1 pageRams Is Organization ChartSYedZYnAleNo ratings yet

- Threaded Half CouplingDocument1 pageThreaded Half CouplingwhngomjNo ratings yet

- Form 4Document5 pagesForm 4SYedZYnAleNo ratings yet

- PC Version Help Manual V2Document5 pagesPC Version Help Manual V2Alyani KornerNo ratings yet

- Resignation LetterDocument1 pageResignation LetterSYedZYnAleNo ratings yet

- Data Overview - Sr. Project EngineerDocument1 pageData Overview - Sr. Project EngineerSYedZYnAleNo ratings yet

- Standard Drawing For Stationary Equipment (1) - 2Document76 pagesStandard Drawing For Stationary Equipment (1) - 2SYedZYnAleNo ratings yet

- Body Flange To Be Replaced by Dished Head As Mentioned in DOCUMENT MISA-1836-001-V - 1 AND MISA-1836-001-V - 2Document1 pageBody Flange To Be Replaced by Dished Head As Mentioned in DOCUMENT MISA-1836-001-V - 1 AND MISA-1836-001-V - 2SYedZYnAleNo ratings yet

- Common Liquid and Gas DataDocument2 pagesCommon Liquid and Gas Dataabhi_mohit2005No ratings yet

- CEPCI June 2017 IssueDocument1 pageCEPCI June 2017 IssueEsteban Wong Muñoz97% (31)

- Net Positive Suction Head or NPSHDocument4 pagesNet Positive Suction Head or NPSHsateesh chandNo ratings yet

- Version 5.10 CAESAR II Applications GuideDocument302 pagesVersion 5.10 CAESAR II Applications GuideBin XiangNo ratings yet

- Tank Calc - Api650Document90 pagesTank Calc - Api650kamleshyadavmoney100% (3)

- Descon Engineering Corporate Presentation 2016Document23 pagesDescon Engineering Corporate Presentation 2016SYedZYnAle100% (1)

- ATM Tank Calc (Converted)Document5 pagesATM Tank Calc (Converted)rahul84803No ratings yet

- VD-SRU-V-004-100-Rev ADocument51 pagesVD-SRU-V-004-100-Rev ASYedZYnAleNo ratings yet

- American Structural ShapesDocument16 pagesAmerican Structural ShapesSYedZYnAleNo ratings yet

- Structural Design of Steel Bins - Gerard XavierDocument77 pagesStructural Design of Steel Bins - Gerard XavierNicolas Valle100% (9)

- Introduction Computer NetworkingDocument42 pagesIntroduction Computer NetworkingAtul SinghNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- K220 Accessories BrochureDocument6 pagesK220 Accessories Brochurehh8g9y6ggcNo ratings yet

- Chapter 14: Redundant Arithmetic: Keshab K. ParhiDocument21 pagesChapter 14: Redundant Arithmetic: Keshab K. ParhiInJune YeoNo ratings yet

- LPDocument5 pagesLPHeizyl ann VelascoNo ratings yet

- Vedic Maths - India's Approach To Calculating!Document4 pagesVedic Maths - India's Approach To Calculating!padmanaban_cse100% (2)

- Get Lucky LetraDocument1 pageGet Lucky LetraDante Jhonatan Kamt GarciaNo ratings yet

- Adaboost With Totally Corrective Updates For Fast Face DetectionDocument6 pagesAdaboost With Totally Corrective Updates For Fast Face DetectionNguyen Quoc TrieuNo ratings yet

- Internship Reflection PaperDocument8 pagesInternship Reflection Paperapi-622170417No ratings yet

- Quadratic SDocument22 pagesQuadratic SShawn ShibuNo ratings yet

- Surveying - Mcqs On Unit I - SJMDocument6 pagesSurveying - Mcqs On Unit I - SJMKalyani ingole100% (1)

- Cryptography and Network Security": Sir Syed University of Engineering & TechnologyDocument5 pagesCryptography and Network Security": Sir Syed University of Engineering & TechnologySehar KhanNo ratings yet

- Certificate of Incorporation Phlips India LimitedDocument1 pageCertificate of Incorporation Phlips India LimitedRam AgarwalNo ratings yet

- Creative Commons Attribution-Noncommercial-Share Alike 3.0 LicenseDocument4 pagesCreative Commons Attribution-Noncommercial-Share Alike 3.0 LicenseAnindito W WicaksonoNo ratings yet

- DLP 6 LO2 Safe Disposal of Tools and MaterialsDocument13 pagesDLP 6 LO2 Safe Disposal of Tools and MaterialsReybeth Tahud Hamili - Matus100% (2)

- D Series: Instruction ManualDocument2 pagesD Series: Instruction ManualMartin del ValleNo ratings yet

- Engine Parts Location GuideDocument4 pagesEngine Parts Location GuidevarenziaNo ratings yet

- Analyzing an Anti-Smoking Poster Using a Formalist ApproachDocument20 pagesAnalyzing an Anti-Smoking Poster Using a Formalist ApproachAlphred Jann NaparanNo ratings yet

- A4931 DatasheetDocument12 pagesA4931 DatasheetDiego HernandezNo ratings yet

- Cycle1 Parta GettingtoknowyourstudentsDocument7 pagesCycle1 Parta Gettingtoknowyourstudentsapi-295073409No ratings yet

- Management Science PDFDocument131 pagesManagement Science PDFAngela Lei SanJuan BucadNo ratings yet

- Professional Industrial Engineering Program: Technical EnglishDocument15 pagesProfessional Industrial Engineering Program: Technical EnglishFabio fernandezNo ratings yet

- 1 National Workshop For Sustainable Built Environment South - South PartnershipDocument14 pages1 National Workshop For Sustainable Built Environment South - South PartnershipRajendra KunwarNo ratings yet

- Circuit Breaker GTSDocument31 pagesCircuit Breaker GTScpandey01_688066930No ratings yet

- Abdul Jabbar (Mechanical Engineer) AGROFEED KSADocument4 pagesAbdul Jabbar (Mechanical Engineer) AGROFEED KSAftimum1No ratings yet

- Call Log ReportDocument44 pagesCall Log ReportHun JhayNo ratings yet

- Iso 19108Document56 pagesIso 19108AzzahraNo ratings yet

- IAS Mains Electrical Engineering 1994Document10 pagesIAS Mains Electrical Engineering 1994rameshaarya99No ratings yet

- In2it: A System For Measurement of B-Haemoglobin A1c Manufactured by BIO-RADDocument63 pagesIn2it: A System For Measurement of B-Haemoglobin A1c Manufactured by BIO-RADiq_dianaNo ratings yet

- EPFO Declaration FormDocument4 pagesEPFO Declaration FormSiddharth PednekarNo ratings yet

- Well Plan Release NotesDocument28 pagesWell Plan Release Notesahmed_497959294No ratings yet

- RD 5000 CalibracionDocument5 pagesRD 5000 Calibracionfran reyNo ratings yet