Professional Documents

Culture Documents

Deutz 1

Uploaded by

Miguel Ruivo Almeida100%(1)100% found this document useful (1 vote)

275 views256 pagesTBD616 Marine Diesel

Original Title

Deutz_1

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTBD616 Marine Diesel

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

275 views256 pagesDeutz 1

Uploaded by

Miguel Ruivo AlmeidaTBD616 Marine Diesel

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 256

Operating Instructions

TBD 616 OEM

gine Number: feels eslee| |=] 6)

‘Ploase enter your engine number ero. This wil help us to serve

fo pats ae aftersalos so

Wo resorve the ight to make technical altrations tothe drawings

the particule in thie donsmentation package, if this should

bosom necessary to Improve the engines. Reprints end duphcs

on of any ind elchor in whale orn pat, quire our witon per

0299 8561 en.

io

¢

TBD 616 OEM

“This documentation intended forthe folowing engine

© Boone pe I uO

© bentxton I

(e/=/3)e [8]

© sytem name foo

ots Dw

© Spent a wn!

© conminionsn: §— (T] 0

Plosse enter the relevant data. This will make it easier for us to lp you in questions InvoWing

repairs, spate parts and aftr eales service in general

"This dooms

‘ie jl i enring out

‘tes loge

a Nera exa0

Patani

(Chapter 0- Page 4 senzoanen tain

package sto be presontod to the Service Partner responsible very time 8 ser

Di

0 Introduction

(© ease 9d all tha information conned in this manual, ad flow the

Instructions carefuty. You wil avid accident, retain tie manufacturer's

waranty, an wil be abot ue a fy functional and operational engine.

© This engine has been tui soley fr the purpose appropriate the scope

cof delvory concemed, as defined by the equipment manufacturer

(etendea Use) Any eter use shall be ensued 3s not intended. The

‘manufac shal not be lable for any damage resulting thereto ll

‘ks tmolved shall be bore sly by the user

(The tr intended use” shal ako nclode compliance wh the operating,

Imaintonance and repair conditions specified by the manvlacturer. The

‘engine ray be used, maiained and repaed nly by persons who are

tear wah the work concerned and whe Rave bes propery nfermed of

the lke wove

1 Mako sue that theso operating instructions are available to everyone

invelvedin operating, maliaring. and rparing tho engine, and that they

havea understood the conn,

(© Non-compliance with these operating insbuctons may result in engine

‘mafunction and even damage or injury o persons; the manufacturer wil

‘accep no ably i sch cases.

‘© Proper maintonance and repair work depends onthe avaabiy of al req

Use equipment tools nd specs Implements, a of whch must be In

portet condition

(© Engine pons Ike sprigs, brackas, east holing rings, et, Invove

Incresed ck af muy i et handed propery

(© Tho relovantacciontprovrton regulations and cher generally recon

rizod ues relating to safety engineering and health and sey at work

‘musta be compos with.

(© Naxiized costtflency,retabaty and long etme

cngial pas rom DEUTZ AG are used

‘© Engine pars must corespond tothe ntonded use nthe overt of mo

‘cation werk, erly parts approved by the manufacurr for the purpose

concemed may be uses. Unauthorized ehanges tothe engine wal pre

hie ay Kbily of he manutaeturr for esutlant damage

sured only

Introduction

m-sized and large engines

Please read all.

Chapter 0 Page S

Introduction

Careful when the en-

gine fs running!

chapter 0- Pages

Medium-sized and large engines a

‘cat out maintenance or epi fobs only when he engine a stadt

you emove ay protective features, t Bom back n postin af completing

Your werk. Aways wear Ughfiing cating you are worting onthe engine

‘aie rain,

Safety

‘You wi find this syn next toa safety nsbucion. Folow these

rmetiuous. Pass on all safety instructions to your operating stat

1 well In edtion, comply wih the statutory general safety and

‘ecient prevention puto appying Your unt.

Instration

‘You wl od this symbol net to instructions o general nature

Fotow thse insttions careful

Asbestos

Tote nas und spew iPr

EE) Saar masse

Introduction

A Medium-sized and large engines

DEUTZ

‘boar customer, Forword

‘The engines ofthe DEUTZ brand have boon developed fora broad spectrum

of appears. A comprehensive rango of fren variants ensues tal spe

‘ka requirements can ba met forthe indivi case inveves.

Your engine has boen enupped fo sl you aun pareusrnstalaton, and

econ nt ala ho devees at components described in these operat

ing wstctons wil actualy be ted your engine

bie 0 make t easier for you fo ed th operating and mantonanes ic:

tions you need for your own partculr angie.

lags read this manual bear you slat up Your engine, and allow the ope

‘ing and maintenance msticions mates

"you have any questions, just tn touch with us, and we willbe pleased to

‘answer ham fr You

Yours snceroly,

DeUTZ AG

‘ae the culmination of ong years wit esearch and development work. DEUTZ engines

‘The in-depth know-how thes acquired In congncton with high sandards of

quay 5 your gurantee for engines manufactured for log ei, igh el

‘tity and ow ool eoneumion. And ofcourse, singe eel een

‘ment tendnes are met 35 wel

aro crucial factors in ensuring that your engine salstactorly meets the Care and maintenance

‘equrementsIneved. Complance withthe spoctied mainicnance ntevals

‘and meticulous perfomance of eave and maininance work aro therfore

‘bsoltly essential. Spec atortion must be pad o anymore erica ope

Sng conditions Seviatng fom te nom,

Inthe event of matfncions cr i'you need spare pas, ease contact one of DEUTE Service

‘ur responsible server agentes. Ou Yained and quali staf wil sure

fact prolessonarectfcalon of any damage using erga pat

(Original pars fom OEUTZ AG have always boon manuactred to the very

latest state-oFtneart

‘You wild etais of cur atersles service atthe 6nd of these operating

incructons

oom seqzrom.n comm chapter 0- Page 7

Introduction

Medium-sized and large engines A

pete

“This page intentional blank,

Chapter 0- Page

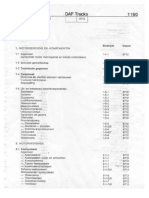

Contents

A TBD 616 Marine

peUTz

Contents

0 Introduction

Please ead a os

‘Carel when te engin sunning! co

Fonwor, a

DEUTZ engines a

(Care and maintenance a

DEUT2 Serie or

1 User Guide

ener “4

equations. 4

Safety Regulations / Res fr Accent Prevetion a

Rules fo elisposa. “2

operating Instructions and Werkshop Manual 2

Job cards “4

Spares. 6

2 Description

“Typo and designations, a

Type designation uM

Rating pate. a

Postion on he gine | es)

Figure rating plate. 22

Designation ofthe engine ses, cyndr and drecon of rtaton 23

Direction ofrtaton 23

Engine igus. a

Lo sie, 2

Fight si, as

Dave side 26

‘Sucre and unto, 7

Crankcase. 2

Crankcasebieding (aco), 28

Crank ive and valve ve. 210

Whoo ave 212

ass compensation shaft (V8 engines on) 213

‘vinden. 216

Sruct Bas

Valve conta. 245

charging 246

‘Schematic gram ofthe charge a creut (ith gud cooled charge i ca0e1)

28

‘Schema ingram ofthe charge ace (aa charge ar cooler)... 249

Exhaust gas system 220

Exhaust system wih the DEUTZ PEARL Syston, 220

Surge charging 220

Fuel system 221

Contents

TBD 616 Marine aN

DeUTzZ

Eriasions

Injecton

Fuel pio syste.

Fuebppe system V8 engine

Feel pipe sytem V12 engine

Feet pipe sytem V 16 engine

‘Speed requis.

Electronic speed governing systems.

Lube ol esto.

Soong system

‘Schematc representation of to dua cee casing

‘stan

tone engine convoerEMR2

Use ond ttre

‘System tanctions

CConfigraton and paramstrzaton.

Diagnostic possi,

3 Operation

irk pre o commissioning.

General

Operating medi.

‘Coolant

Coolant ive

Fu

Lticant

Montoting

Stoner system,

Room entation,

Commissioning

‘Starting the engine

“Montring operation

‘Shutting down,

4 Expendables

Gone ears

Wirreny

Prodct election

Miata,

Fa.

Engine ube ol

Engine coolant

‘ary mater.

‘Seslns and securing agents

Gluing agents.

Luicants

Other ausliary material

Contents - Page 2 onze 202m e010

A TBD 616 Marine

DEUTZ

Contents

Maintenance

‘Continuous supervision.

Maintenance sched

‘General

Selection snd suc.

Deutz maintenance and savice schedule.

Specie maintenance scheduio performance group At

‘Operating hourindopendont maintenance work

Defnion of activites nthe maintenance schcul

‘Operating hour dependent malnienance work

‘Overview of operating hou-independent maintenance work (coy orn)

(vera of operating hour-sependentmalnenance work (copy fe).

‘Spectle maintenance schedule perormance grup A2

(Operating hourndependent maintonanco wok.

Defotion of actives inthe maninance schedule

(Operating hour dependent maitenance work

Cverviow of operating heurindopendont maininance work (copy form)

(Overvilwof apraing our dependnt maintenance work (copy orn.

_Specfe maintenance schedule porormance group B

‘Operating hourindopendent aitonance work

Dafirion of aciis inthe matenance senedue.

‘Operating hour dependent maininance work

‘Overiw of eperatinghourndependontmintonance work (coy fm)

‘Ovoriw of operating nour dependent mntenance work (coy form)

Specie malnienance schedule perfomance proun

‘Operating oursndependentmainienance work

Defriton of actites nthe maintenance sehesle

(Operating Row dependent maintenance work

COveriew of parting hourindopendent maininance work (copy form)

Cverviow of operating howr-dependent mainkenance work (copy orn).

Tools for maintenance werk upto E40.

‘Standard cl ht.

‘Smal oo

Lge oot

Tool kt supplement

eat kt supplement

Turing device

\-bot tension measuring nsturent

“eats or mainonance work om E50.

6 Troubleshooting

Fut table

7 Conservation

conservation,

8 Technical particulars

General engine data

513

54

545

55

518

549

521

522

523

531

53

535

sa

537

ey

m

uM

Contents - Page 3

Contents

TBD 616 Marine

Basie data

contol data

Ignition sequence

Dimensions.

Wiis.

Operating data

Fling volumes.

Tempraturos.

Pressures.

Emission dat

‘Sta of pumping

‘Tagnteningspoctetions for maintenance work up t0 E40

‘Tightening spectieations fr maintenance work fom E50.

9 Job Cards

Explanation of symbols,

Overviws

‘ranged aiphabetealy

‘ange by Job Card Numbers,

10 Other instructions

Index

Service

We move your word

DEUTZ AG - at your sence

Sales & Service Indo.

ePIC

Seminar program

Contents - Page & exces 2

Senvon!

Serioe

Service

Services

Service

A Engines and systems

DEUTZ

4 User Guide

‘Tho mainenance and service work prescabed Inthe operating inswuctons

and the werkhop manval mst be performed on schedule arin fl

‘The maintenance and sence personel must have the nocessary technical

nowledge 1 perform tho werk. Safty and potacton dovios whieh may

have tobe removed dung maienance and srvice work mst be replaced

sienvards

“The rules forthe prevention of accidents and the safety regulations

rust be observed at lltnes during maintenance and service work

Please also observe the special safety regulations forthe various ser-

‘ice groups which are sted in detail as job ards in the jb cards chap-

{also chapter 1" Safely Regulations. | Rules for Accident

Prevention).

‘The maintenance and sence inervals ae Sted in the maintenance and

erie schedules. Tees a0 provide fomation abo ho work tobe et

‘The ob cards provide teh hits or erorming the work

Detaled safety instructions havo been compiled for various service

‘rou in the form of job cards, these precede the job cards af the

rospective service groups

‘The legally prescribed rules for accident prevention (available from the

appropriate associations or technical publishers) must be observed.

‘These depend on the instalation site, the made of operation and the

‘operating and auxiliary mocia being used.

‘Spocal safely measures dependent on the respective work are spec-

fied and highlighted in the work description,

it generally applies among other things:

© for personnel

Only instucted personnel may operate or maintain the engine

Unauthorised persons may not enter the engine room.

Wear tight fiting clothing and ear protectors in the engine room

vinen engines are runing,

Only omploy quaifed personnel for repalrs or service work.

{© forthe engine room:

Eneure adaquate feth alr and ventilation (de nt cover vena:

tion sha),

Provide fist i kits and suitable fr extinguishers. Check the fe

Ting and proper functioning regulary

COniy store inflammable materials in the engine room which are

necessary fr operating the syst,

‘Smoking and naked light are prohibited inthe engine room,

User Guide

General

A

Regulations.

Safety Regulations /

Rules for Accident P

vention

Chapter 1 - Page t

User Guide

Rules for disposal

Operating Instruc-

tions and Workshop

Manual

Chapter 1 - Page 2

Engines and systems A

UTE

© for operation and maintenance of theo

~ Only stat the engine when al safety devices have been fied and

tho turing gear has been removed. Make sure thee Is no-one In

the danger zon

= Only perform cleaning, maintenance and ropar work when the

‘engine Is switched of and socured against starting up-

‘The work descibed in the operating instructions and workshop manvsi

necessitates the renewal of pals snd expendsbles arong other thos.

Aiepoeod of The ewnese responsible forth

Disposal incudes recycing and disposal of pars exgendablos whereby

reoyeing has prot.

‘The deals of dposel ans supersion are govemed by regional rational

and inlerstional laws and decrees which the plant ounarsFesponsible fr

‘beeing,

‘The service documentations died into the operating sucions and the

workshop mania fora ustr-riented organisation othe information cortont

‘The Operating instructions contain a general description as wel 3s is

tions forthe necessary malntonance and srvice work whch can be pe.

formed by a vained operator

‘contains the folowing chapters

0 troduction

Contents

1 User guido

2 escgtin (description ofthe engine and components)

3 Operation (operating he engin)

‘4 Expendables(operaing media specications and ailary mate

as)

Maltenance

“Troutleshootng

Conservation (conservation ofthe engine)

Technical particulars

Job card in do of job card numbers)

‘Sundry ether tutions (i not inthe appends or seperate folders)

nde

Serica

User Guide

A Engines and systems

DEUTZ

‘The Workshop Mana assumes knowode of the content of th operating

insructos, this apples especialy to the safety regulations. Mnorrepats

‘and emergency messures on components re deste when raqure a

(tener eft and aperopistly quali personnel

Itcontain the chapters

0 traduction

Contents

1 User guide

24 See operating instructions

5 Tools for service

6.7 Sco operating insiructons

8 Technical preva

8 Job cards (in order of jb card numbers)

10 Sundy oer instuctens i notin the append or separate folders)

‘Service

ows sotaotns ena in chapter 1-Page 3

User Guide

Engines and systems A

petre

Job cards

“The Job cards ae dvd nto Jo cards ofthe eperating instructions, 9. 1

Workshop manual, 29. 4-5

(© Please see Figure 1-1 fr explanations ofthe numbing.

{© The structure of he od cards shown in Figuro 1-2.

1 and job cards ofthe

(Cpe ot dncumentation

Te eter the font sigiles ie ype of documentation involved

‘3B = Operating newuctons

W= Winston Manual

CGovecalremarks /cosscatepny te] 8 Lube all system

{Gyndornead 9 Coolant eytom

De mechanism 10° Compreseodar system

Crankcase {4 Montoing stom

Engine contol $2 Other companonts

Governar 43° Eloctcal ycom

Exhaust gas system / Charging

~The subsystems are alstngushod by mainenance groups.

* Genera val

30 Cros subsystem or Safety Regulations

+ System parameters o general checks

<

* Counting por subsystem (omponen)

"Yara jbs pr subsystom (comenent)

{version siferences

B 3-3-3

chapter 1 -Page 4 seman im 20.

A Engines and systems

User Guide

Fie 12 Wambo e

41 DEUTZ Senco, publisher ofthe sence dacumen-

faton 2

2 Engine ype or system °

3 Number ofthe ob era 10

4 Tie ofthe ot car "

5 Tools, sts, spares ane references 2

8 Salty instructions 8

7 Sub-beadigs

bout tho job card please always sate he ene “Ey

‘ype the ston 2 the nunc of he jo adhe page rumbor he

of sue 13 or alematively tho dentfeaton numberof the ob card

Flows

Comer rotes

Work seauence

Page number

donation numberof he job card

Dato of sue of hej card

User Guide

Spares ‘Spares are avalable rom DEUTZ Serie. You wild it of spares in the

Spare parisst othe engine a the sytem. You wil rd futher information in

Chapibr Sevice athe and ofthe operating ntti.

Chapter 4 - Page 6 e200 fm oo

TBD 616 OEM

Description

2 Description

‘The engines inthis series ae wate cooled four-stroke dese! engines whieh

can be usod for various powertrain.

‘See aso rating pat (Fig 1

wenden

Turbocharger 1

charge aircon

BD ow v

Nocofenders

‘Te rating plate is Fo to he engine, The engine number is punched ad

sional

Flows 21 Peston na pn deo nara on eghs oaros)

‘Type and designa-

tions

‘Type designation

Rating plate

Position on the engine

‘chapter 2- Page

Description

Figure rating pate

TBD 616 OEM A

ad 2) iV Anal rA\c) Pree

7.8.0

14

16

18

20,24,22

‘chapter 2-Page2

Engine type designation

Year of manutsctire

Engine number

Perlrmance cde aecorting to DIN ISO 3046 Pat 7

‘nor pected after he poremance cod fhe avaiable

Performance ie retried toa cara time Searing to special

manufacturer speseations soe 1,18

"Numoic valu ofthe perfermance in kW

Engine speed in rm

Timo liniting of he valbe performance inhours (h)

Helgi above sea teva (condos at instalition ste)

‘i prssure in mbar (contions at instaliion sts)

aura xl ener "(xno inate

Folavehumiy Fn %(condtion at instalation site)

‘Al heer 0° (cles estat te)

[Numoricvalve of an auiary device in kW (GH)

Description

A TBD 616 OEM

DEUTZ

Designation ofthe engine sides, cylinder and cretion of rotation

‘The four sides ofthe engine normaly cary the folowing designations in practic (soe Figure 23)

“The designation use nhs operating manuals Nghighted respect n bold pit end corresponds lth

DIN IS0 1204

wd

@e/a|o!

alee /

> |

[pre 23 Geipaioncl te egies ad os

Engine sides

1 Drive se Flywhoal,cuch side

2 Lot sido yn side A

2 Free side End, damper, hid pump, etch epposte side

4 Right side oyinder site 8

ylinder numbering

‘counted and label frm the dive side,

Direction of rotation

Leokng toward the dive sige in aticlockwise recon “hand alain”

00 sore sno Chapter 2-Page 3

Description

TBD 616 OEM A

Engine figures

Left side

(42) (11) (10,

1 Charge a coor 1 otpan

2 Suetion aiintake er 8 Rotary cunt atorator

3 Grankcase blood valve 8 Coolant pump ofthe charge ak aoler

“4 Exhavet ga turbocharger cylinder side A 10. Rotary vibration dampor

5 Heatinsuaton dadding PEARL exaust ppe 11 Coolant pump engine cookrgcreut

6 Ster 12 Mover or anacnng me en

fan the cagonely opposite

chapter 2- Page 4 otzont nn eo

Description

A TBD 616 OEM

pevré

Right sido

4 beat nara 5 Lube ol ier

2 Fue iter 8 Fuet hand pump

3. Lube ol cooker 7 Heat insulation lading PEARL exhavst pipe

4 Oapati Exhaust gos turbocharger oynder se 8

oi sexzeotoe 0m Chapter 2- Pages

Description

TBD 616 OEM A

Drive side

Figse2e tape aoe

41 Fiywhost

2 Flywheet housing

Holder for atlaching th engine (sacond holder onthe agony oppose sie)

‘Chapter 2-Page S oz nn e010

Description

TBD 616 OEM

Structure and function

crankcase

“Tho crankease ls mada fram a special alloyed casting. Torsional stongt, breaking ength and casing

Uightness which enabie ow weight and compacnoss distnguish ts manvtacuring mes. The sido was

fol the crankcase are pulled dw below the conor ofthe cranks and therefore quaraniee addtional to.

‘Sonal eng. The cinder angle of 60" enatios a ncrow design which s dmandod many applications,

‘201 searootoen col Chapter 2- Page?

Description

TBD 616 OEM A

DEUTZ

Crankcase bleeding (Racor)

Fumes are produced nthe crankcase during engine operation. To potst the envronmet these fumes ae

not alowes to escape ino the atmosphere but are fed ito a closed rankcacoblacdng syst. In this

‘ankcase beeing system the ilo exons imprint uncon.

‘The fumes foing ito the er tst pass the pressure conto valve which is mounted central in the top

pat ofthe ter system. Aer pasing the iter element the prio esd gases are fe othe Seton Baw

betwen the sucton anak fer and he turbocnarge

‘The pressure reguistor consis fm capheagm valve loaded bath sdes Wt cantos the crankcase presire

wheat the same time vacuum presses rom the sucon intake estar see tan fper lint Pulsatng

‘An optical indeatr slants ine to change he fier element.

‘The exchangeable and recyclable itr element cons of a mio glas bre structure lh a iter etect up

{00.3 ym Ths can be changed without tools dv o quick change caches. The tered ol parties collec ik

‘th sump of th iter easing and ae fed back int th al crcl bya tune

‘Aloe valve prevents oa geting in ough the reir ne, The leurs on exceeding ho pressure citer:

{ce between the ile and eraricase or a engine lands.

Optical insicatr or dve change ot element

Quick elease ctenes

itor op with integrated pressure regulator

Powder-coated metal housing

iter element

Fund seating ring

Fund ating rng

Foor inset

chapter 2- Page 8 01700102 00m 010

Description

A TBD 616 OEM

DEUTZ

“This crankcase bleeding system achleves that

{© the-engine om and system are nc contamintod by ol ues,

{© the smal te ined vcnty is reduced,

{© covronmentlpotuon i reduce,

‘© charge ai cooler, uboehargr and it valves are beter protected againt sling

orto] 2

>

® ge ©} ©

1 Suckedinaie

Suction arin fier

“Turbocharger

Exnaust gos

Charge i cooler

Engine

Line for tumes to hee system

Une fr iter fumes into the ston ne

Fit

Return to the of pan

eo sweaotoncomn chapter 2- Pages

Description

TBD 616 OEM A

pete

Crank drive and vale dive

‘The crank tive comprises crankshaft con rd, piston rotary vibration damper andthe Nhe

‘Te drop forged crankshaft is hung in mulayerboarings in the crankcase 7. Ever bearing cover is

secured by fur suds, Muay bearings ofr greater baton security and emergency runing prope

tos. The shat and crank jonas and the core sraces of he axa Dearings me Incuvely hardones

The counterweight 0 screwed to ho crank wods seve to dspat he ira mass ct and reve the

‘ankshat bearing, The cary vibeation damper and he ywheel ensure smooth running of the engi th

thor stucur cakulated exactly for every appacain.

‘The double Thank con rods 2 are givied at an angl. Ths lows removal ofthe piston with con rod up

trvough te ander iors In con roo un on te ranks neuter Sears. Anes pessoa tthe

Upper can rod aye mn which the piston bok 4 is mounted on a eating bearing,

“Tho pistons 6 are cast rom a ightwoight mea. The piston gs 5 (rapeze ring, mine ing and @narow

land ran ol conto ring) are in cast soe beams. The pstons ae supplied wih cooking be ol ough a

spray nozzle 6. Tho ube of flows trough the cooing chants of he piston base where Lams Nea.

‘The oynerinors 3 aro made by a spn casing locrique. Special emphasis is placed en honing inthe r=

thar processing. The cross ging angle ested during Ponng f asymmetial expaneo toe demand

forlow llconsumplon and optima canines. The ender hers touch he crankcase and ae guided

colar al hep and baton.

“The use of wet indents enabl fast and lw cos exchange of a ylnder unt,

Chapter 2- Page 10 orator ‘eo

Description

TBD 616 OEM B

1 Crankshat

6 Piston

2 Contos 7 crankcase

3 Cylndor ner 8 Ol nection nozzie

4 Piston ot 9 Countorweights of the cranksha

5 Pistoncings

or soxzotee 0m Chapter 2- Page 11

Description

TBD 616 OEM A

Whee dive

“The whee! dive serves for engine contol and eeving fsub-components

Engine contol unit

The tooted whee! 6 onthe crankshalt vs the toathed wheel 3 on the camshat

‘Sub-components

“Tne toothed whoo 3. onthe cama dives the injection pump ia toothed whoo! haute pumps ae

alsched tothe engine, toothed wheel 210, these are ven by toothed whoo 1

‘The ube ol pump 7 is dven by toethed whoo 6 on ho crankshaft

compressor i sald on the engin, oohed wheel 4, tis even ty the itermedate whe! ven by

toctned whee 6 on he crankehas,

“The coolant pum, tathed wheal 9 is driven bythe intermediate whee 8, dven by toad whe! 6 onthe

crankshat

Gear wheels:

1 njeton pup 6 Crankshat

2 Hydrale ume 7 Lube ot pump

3 Camshan 8 lormediato whoo!

4 Compressor 9 Coolant pump

5 Inermadiate whee! 10 Hyaraue pump

‘Chapter? Page 12 002004040 010

Description

WN TBD 616 OEM

peurz

‘Mass compensation haf (V8 engines ony)

Because ofthe number of eyndors a mass compensation shaft must ran as wel inorder tobe abe to

‘active low-vbrtion runing of he engine. The macs compensation sha ls cin ty 9 separate whee

‘hve onthe drive ide

1 Crankshat

2 Mass compensation shat

3. Inlermedite whee!

eo secesntee com Ccraptor2 Page 12

Description

TBD 616 OEM

Cylinder noad

structure

“The onder heads are made ofa special alloyed casing tk tho crankcase. One since cyader head is

Inet per eyinder The single eyndr head Ean ba changed vry ack thanks (0s excelent access.

‘ity and opimzed design.

“The channel guide is basod onthe oss curent principle, The eylnder heads ae supped wth charge air

irom ine Vecnamber vate charge a pipe. Tho vo net channels 2 and 3 have ferent manifolds nthe

(hinder beads They ae dvidad to fling channel 2 and a tals channol3. The shape these ensixes &

‘hangs ar fow ino the combustion chamber which considerably mproves the mb formation, The oust

hanelst end onthe respective ate of tho engine In he exhaust system m whe Me exNBust gas

energy srt st but recycled

Figs fos sug fae nd oe conn Ce

Chapter 2-Page 14 2200400 00

Description

1 TBD 616 OEM

Valve contot

“The cyndechoads are mu-valve heads, Le Wo ne valves per cinder provide for optimum ling and two

‘let ‘vates fr lat exhaust gus Gacharge, The high heat poo! vaves are fn the possod-n and hs

‘sai repacoabo vaio seal ngs. The valves ae contol by a preven valve bridge achnque. The vahe

bridge corr operates wth ver low Wear and & extemely martonance- tingly.

4. Camshan 5 Toggle lover lek

2 Pietoppet 5 Valve bridges

3 Tappet rods 7 Outletvanes

4 Rocker am 8 inlet vatves|

20103 >onoonto nom lor 2- Page 15,

Description

TBD 616 OEM A

pEurz

Charging

‘Tae engine eaiope witha biturbocharger and optionally witha iqui-cooled charge ar cooler. The bi

lurbocnarger system shares one row of oyndors each. Theatre one oxtaust urbocharorsnstalled pr

‘ow of ender. The advantage of being equppod wi the Bturbo i nthe response Boho reno thing,

‘Asma exhaust turbocharger bus up the necessary chaige a greseure na short time. On he one hans

the whole engine outputs aval, en heather hand the pial lsc smoke is vitualyekminted,

Figwe2 6 Stennis hare arp Ugascona pe ara

41. Charge air cooler '5 Exhaust gas turin fhe trbecharger

2 ite 8 Heat insulation cadsing

3 Ar-sucton take pipe 7 Eshaus! pe (DEUTZ PEARL® Syston)

44 Turbocharger compressor 8 Charge st ine

Charge ar heated by the turbocharger

(Coo intake a and charge ar cooled by the charge a cooker

HIRE ot exrcust gases

‘chaptor2- Page 16 otzo0t02 00m 010

-

Description

TBD 616 OEM

Finwe 26 Sin ako a pa (a cama)

1 Charge a housing '5 Exhaust gas turbine oftheturbocharger

2 nei 6 Heat insulation clading

8A suction take pipe 7 Exhaust pipe (OEUTZ PEARL® System)

44 Turbocharger compressor 8 Charge ane

TEE Cage a nested by he twdocharger

(Coo intake ai and charge air cooled by te charge a cooker

TENE Hot exhaust nasos

e010 01200400001 chapter 2- Page 17

Description

TBD 616 OEM A

ee pers

Schematic diagram ofthe charge air eitcut with quid-colad charge air cooler)

1 Exhaust gas txtine of theturbochargercyinder sd A

2. Compressor turtine ofthe turbocharger cylinder sie A

3 ‘Suction intake air cynde ie A

4 Charge ai pipe cylinder side A

5. OEUTZ PEARL exhaust pipe cylinder side A

8 Charge ar ip cylinder side A

7 yinder needs cynder side A

8 Charge ar cooler

8 Cyander nese ead ide 8

10 Charge ir pipe cynder ste B

‘11 DEUTZ PEARL® exhaust pip cylinder side 8

12 Charge a pipe cyter sie 8

43 Sucton lake ar oye ide 8

4 Compressor utine of to turbocharger eyinder sida 8

16 Exhaust gas discharge cynde side 8

17 Exhaust gas discharge oyinder side A

‘Chapter 2-Page 18, 12000-6900 20109

Description

A TBD 616 OEM

DEUTZ

A

Rn 10 8 8 one

"igus 2h al ar ar ur igh

41 Exhaust gas turin of the turbocharger yinder side A

2. Compressor tute of he turbockarger eying sie A

3 Suction take ar cyinder ide A

44 Charge ai pipe onder sido A

5 DEUTZ PEARL® exhaust pipe onder side A

8 Charge ai pipe cylinder side A

7 Cylinder heads eyner sce A

{8 Oyler hoods cyngor side 8

9 Charge ai ppe cyander side

40. DEUTZ PEARL exhaust pipe cinder side

11 Charge a pipe cyinder side B

12 Suction nske a cynder side 8

48 Compressor tubing ofthe titocharger cinder se 8

“Exhaust gas turbine of the tubocharoe ylnder side B

46 Exnaust gos clacherpe cyinder side A

oom onto <0 tm chapter? - Page 19

Description

TBD 616 OEM A

Exhaust gas system

Exhaust system with the DEUTZ PEARL System

The 12 and 16cnder engines aro equipped withthe DEUTZ PEARL® system patented by DEUTZ, The

DEUTZ PEARL® system alows a more eflecivewikzaton ofthe exhaust gas energy by sect shaping and

Joning of the exsaist pe eomenis. This gonerates backup nthe two trbochargersresuting na ghar

{turbocharger partormance

‘The PEARL exhaust pipe clement 1 are connected to compensators 2. They ake care of not nt the sm

le connection betwoon te PEARL exhaust pipe elements but ako compensa te hal siesses which

‘ccur during he warm-up phase, operation and afr shuting down the engine.

The PEARL exhaust gas elrents are surrounded bya hetproot housing

Fe 2:1 OEVTZ PEARL Sytem

‘Surge charging

‘The VB engine i equipped wth a surge charging exhaust gas system. The gases enle the exhaust pipe

according othe ote of gion. The resulting pressure waves er combined go thal sige charging takes

‘ace on he turbocharge

chapter 2- Page 20, orm0240 0m 0100

Description

A TBD 616 OEM

DEUTZ ee

Fuel system

Emissions

‘8: Tuo system with charge a cooing, ross curent cySndar head wih ws channel pistons, mulihake

Injection nozls in connection with he high-pressure jection sytem, DEUTZ PEAR® System allcompe

nents which contribu fo the progressive emission behav ofthe engine are adacted to eachother wth

absolute accuracy. lhe bmi valve specications are complod wih as esi,

Injection

‘The engines are equpped with a high pressure injction stam, The eh and twehe- Feetpipo,suppy 0 seis ijacton pump

HEEEEE £21 :po, ctu trom sts injection pump

Chapter 2- Page 24 swaxeotoencotm ‘oor

A TBD 616 OEM

pEUTZ

‘Tho task of speed governing systems Iso Inuence the fue Supt othe

‘engin by adjusting the jection pump contro, n such away ha the per

formance requred from te engine Is cbtained whist mainlaing a pr-se

‘constant or variable speed

‘wo slecvonic governing systems are avaiable forthe engines of the

‘TAD 616 O2M series

Heinzmann actuator S16 2080-0? wh EMR? (gta)

GAC (analog)

‘The oloning apples or sped govarring Syste:

(© The specd governing systems ae st accarding lo the requirements and

pplication of te engine

(© Sotings, bookings and seas of tho speed govring systems may not be

‘hanged or removed. inthe event of manipulations tothe governing 5

tems, he warranty and qatar ae voided,

1 ITnow sotings become necessary due lo repairs or changes in the appl

cation condos, thse may only be done by auhoczed personne

In thor basic design the eeconle speed governing syst const of the

‘otowng components

Magnetic tequency pick-up

Conta! device, analog or cg

Aesuator

= Satin wansmiter

‘The magnetic tequency pick-up records the acta value ofthe sped onthe

ring goa fhe fyi! and passes ion othe contol davies, In the contol

‘ovieo, whieh can be an analog er agtal design, the actual valve is com

pared fo tho solpi Into case of devtions tne cont devew sends the

ommandto the actuator to adjust he injection pump convo bar Tho ac

ter sends a rele sinal ofthe contal bar poston ot convo device

Description

‘Speed regulation

_Etectrnic speed govern-

ing systems

chapter 2- Page 25

Description

TBD 616 OEM A

‘Actuators

Heinzmann actustor

(nthe neal shaft ofthe actuator sa mut-pole permanent magnet. Oppost the permanent magnets

‘body on wich s mounted @ working col. the working col conducts, forue overs fone drecton, he

‘evereal ofthe current provides toque mth oppose deco,

‘Th lover tached to the intra shaft connected othe ection pump contol rd wi the hp of & soe

al conection stent bs rears the lary mation ofthe ternal shat ansterrc drcty as aipear

‘movement othe cool 0

“The stn of the contol cuout shafts deleted using a non-contact method by a retun system mounted

femiy onthe shat andthe passed oth coil dove

(On reaching the stp, current maton is inplemnted ater approx 20 seconds, which reduces he actsior

ture sich anentent hat no damage sufered bythe acuta

Emergency sop possible wih an addin sop lve.

41 nection pure 5 Working cal

2 Adaptor pato 5 Stoplover

5. Retun system 7 Contorod tion (aduscle)

4 Connection to injcton pup cont rod

Cchaptor2-Page 26 1200400 20100

Description

TBD 616 OEM

GAC actuator

‘The GAC actstoris use 10 reasure tho fuel Injctionvelume The cifferenca beteen the noninal and

‘cual speeds converted ino a votage signal forthe electepostonng magnets nthe actuator which ses

the conta tar fhe njecton pup by to onl dave. In ths way he fel oka constant inreased

6 reduced depending on the oad requirement at constant speed. The actuator fs mounted det on the

inecton pun.

“The actuator operates nea the eouback ofthe con bar poston lakes place witht contac.

Emergency sp spossibe with an acstioal stop lever,

Injection pump

Sop over

Connector sug, in GAC (sg)

‘lectomagnetc chamber (encapsulated)

‘Connectr plug. a GAC (tal)

Fastening stip

‘Upper chamber, n ube ot ect

Injection pump contr rod

Connecting plate

‘0% 220040 0m chapter? - Page 27

Description

TBD 616 OEM A

Frequency piek-up

“The magnetic teauancy pick-up is into on he cve si. produces electrical pulses ropetonalto the

peed ne ring gear on tho feet by sampling the oot ofthe ng gear, which move past the Fequoncy

‘edcup, and ransmis these pues Io te contro vice.

“The number of instal raquency pick-ups doped onthe speed governing system Uses

Fie 2.7 Fria pcb ran ae ERE)

4+ Frequency pickup

22 Starter sng gear on fywhes!

Chapter 2- Page 28, senaotoencolm ‘oo%e

Description

A TBD 616 OEM

DEUTZ

Setpoint potentiometer

“The seting ofthe setpoint speed can be implemented by a Setgant potaometar,curant or vag signals

or adjust ned vals.

Control devices

“Tho cont dovcw monitors the various input signals, wg. he actual vale of the spee, the current sing

of ho set pone transite and tho soting of tho actuator. nthe case of deviations fom the setpoint, he

tzid device sends te command othe actuate Lo adsl he incon pump contol ber and hus dp the

‘valble fo! volume,

Eloctonic engin contoler DEUTZ EMR2

Cont dvi for GAC sped governing syst (analog)

Etoctronic engine controller EMR2

‘The electronic engine contalr EMRIs equpped wth an een microprocessor and an intemal contvoler

‘rogram. Changes othe setings ae made bya PChaptop wih a special connecting cate andthe apie

fat softare and may ony be performed by authorized parson

Furthr information about the elcrnic engine conve EMR2 canbe found Inthe secon "Electronic

‘gine contol EMR”

‘Control device for GAC speed governing system (analog)

This speed governing sytem isan elctoric analog governor, itis st wih he poontonetrs and sitches

con the con deen

0102 senate encom ‘haptor2-Page 28

Description

tem: Name:

1 OVERSPEED

2 CILEADCIRCUIT

(C2 SOFTCOUPLING

3 RESET

4 Test

5 OVERSPEED

6 sTaBLTY

7 GAN

8 SPEED

°

10 me

+1 DROGP

32 STARTING FUEL

13 SPEEDRAMPING

TBD 616 OEM A

Function:

Indicator LED for overspeed

Swch fr adional damping

Swth or resonance wbration suppression

verspecd reset button

(Overopeed test btn, reduces the switching pointy 10 %

Seting of evrspoed

Seting te stongth

Seting the sensitivity

Seting th ated speed

Brgo or capacitor fr ingroving tbity

Seting the lowing speed

Setting the Pfacor

Solin the fe stating volume

‘Selig the sa ram to minimize the smoke devebpnent

[C5> _Setings on tie contol unt may onl be made by authored personnal

Cchaptor2- Page 30,

Description

A TBD 616 OEM

pevTz

Luo oi system

The lube all rece fon of he components which rub apnint each aber and das pas Neat kom the

‘bing postions and he stn. Am ef ube aon the yao sraces soporte ang efecto the

ston rings. The ibe al also susponds contamination an vansports tothe the ube eile,

‘The lube ol pump sucks the ube ol fom to ol panand feed though he lube ol one and he lube ot

fer it he ubretion circa ofthe gin,

‘The ube ol resure inthe engine cu ss bya ibe ot prossure ruling vane. The bypass valve

Insalled inthe ube ol cooler to avoid he flow of ibe ol belng nterupted na eal lan, The overpressure

valve opens when the ibe ot pressures suffelety high and lows the sup be oto ow back the

Cooting system

“The ceca ney inthe fel s converted into heat energy ding combustion. The engine can ony party

convert this into mechanical nergy. Tho emaning hea esipated many wih the exhaust gas ad Io

coolant,

‘The engine operates wih 2 duakcut cooling, Lea high temperature cul and a ow lempeature cout

‘The combustion chanber wals ae coled by te nigh temperate cut. The cool fed trough the

coolant chambers between the crankcase and the eyinder Ines. From tha the colt i fod fvough

bores in the crantoaso othe eylnder heads. Channels inthe eye head fed the cola to the oor ef

tho eyinder head and the valve soa. The coolant emerges om he cylinder heads an ed noth col.

ant mane tothe thermostats negated inte charge be,

‘The charge ai cooler is cole byte low temperature ckcuit. Depending onthe version as avatar ora

!ar coclng, Inthe akvater version a second coolant pum dtves another cooing ceo whien cool the

‘charge arin the cargo a cook In the ak charge aircoaling, tne charge a cot system precedes.

‘oon om 404 Cchaptor2-Page 31

Description

TBD 616 OEM

As

Fre. coagon wan ae ae)

41ischarge of hot colant tothe coler 7 Temperature sensor

2 Thermostat hosing Suction lake of cooled coslnt othe charge

ar cooler

Coolant pump and inet ofthe coolant in cyl 9 Coalant pump (coting excl charge a cooler)

er ke

4 Sisto iniake of ool coolant tothe engine {0 Charge ar calor

5 Inet of coolant to ender sie A” 11 Discharge hot coolant ar charge alr cooler

{Coolant overtlow af cynder heads

[ERIE Coot crest for coning tne eynders and cyinder heads

Contant cet ofthe aiater charge air cocer

Description

A TBD 616 OEM

ee

Fae 50g os ea)

1 Discharge o hot cctant tothe cooler 5 lt coolant ood sito "A"

2 Thexmosiatnousing 5 oolant overt of eye heads

3 Coolant pump andre ofthe coolant ia cyn- 7 Tempertue sensor

‘er side 2"

4 Suction intake of cooled coolant fo the engine

[ERE Coote crcut for cooing te eynders and cyinder heads

‘ore eozntofm ‘hapter2 - Page 32

Description

TBD 616 OEM pn

‘Schematic representation ofthe dua-ciruit cooling

"igse 251 Gang nem store(or wan)

“Te dua-ccut cooling sytem s shown inthe stir vetelon nth que nthe aversion the ems

6,10 and 1 ae omits. The charge a cole thn precades nth aa version,

Chapter 2- Page 34 soroont nce 20109

Description

A TBD 616 OEM

Turbocnarger

Extaust pipe

(charge ai ino

Pipe rm the coolant pump tthe engine

‘Thamoetat

Charge a cooker avai)

Coolant pump (ow temperate cut)

Engine inertace

9 Pipes tothe cooler angio cooking)

40 Pipes om the cole (charge ar ccting)

11 Pipes othe cooler (charge ar cooling)

12 Pipos kom the cooler (engine cooing)

13 Coolant pump (high temperate cc)

14 Shortsreut ne

15 Lube ol cooler

16 Pipe kom ibe ol cole to the engine

Labeling of coolant

cont

meee cold and warm mixed

=== worm and warmicold mixed

oe nat ed

20000 sora etm Chapter 2- Page 36,

Description

TBD 616 OEM ra

Starter

Chapter 2- Page 36

‘The engine s started by an elctic or preumaic starr depending on the

‘The stator 1 has the Job of acolrating the engin crnkshat to nition

speed. On reaching this speed the compression fomperaie inthe cinders

has heated upto ignition temperate ofthe ects fue

Description

j TBD 616 OEM

Electronic engine controler EMR2

Use and structure

‘The electronic engine conterEMR2 serves for speed governing of DEUTE diesel engines,

‘The EMR? basicaly consists of sensors, the contol device andthe actuator The tala onthe engine

ide and the system side are comected to the EMR2 contol dvio by sopra cable erneeses

ide instalations

Figs 912082 ego ae ais (ar THD BEV)

4 Engine 6 Sensor lube otvet

2 Cable amess engine -EMR2 contol deuce 7 Sensor coolant tamperatue

3 Actuator and connection fer eable hamess 8 Frequency pickup

4 Stop magnet 9. Sensor lube of pressure

5 Sensor charge ar temperature 10 Sensor crankcase pressure and safety eutout

(Nor)

Description

TBD 616 OEM a

pete

‘System side installations

= EMR2 conta device

= Powersupply

‘Speed potenlomster cepointgoneratr)

= Diagnst interface CAN but

= Fautlame

+ Diagnostic buston

‘amin ames fer overspood, ibe al pressure, lube of leve coolant enperatre

= Sieh fc factor, speod

= Engine stop

ews 22 cl cores

‘EMR? contro! device

connection for engine so cable hares

Feoanecton fr sytom side cable hamess

Function

“Te sensors mount onthe engine supy the conto device elas wit athe reevant la.

“According tothe information abou tha momentary conn of tho engine andthe pests (setpoint genera

tor fr speed, ste} the ENR? dries the acustr which adjusts the njecton pu cont fed and this

fact he fel volume according to the power requrement. The actuator sends a etun signal ofthe ine

tion pump cont! od positon oe convo deve

“The EMR? is equipped wi safely devices and measures in hardware and software b ensue emergency

‘operation functions.

“The gion switch cuts othe pawer to he EMR? 0 shut dwn he engine. A sulcenty tong sping inthe

{cluatr pulse myocton pun con bar othe 20 positon nthe powerless slat, Aone and indc-

‘Pendent of ths the us supply ntortuped by shut magnets.

chapter 2- Page 38 e022 2010

Description

TBD 616 OEM

‘ystom functions

‘The EMR? ofre a wid raga of functions which canbe acvated by an spplicaton seated contguraton

and allocation ofthe inputs and outputs I erabos a signal exchange bath between tho engine and EMR2

{va the engine side plo) and between tne system and EMRZ (athe system se Pug

‘The functions of the EER2 rele tothe speed govern, volume eson (Wel ejection), mantering, system

and devi unions and communication and dagnostc nleraces,

Serpe EMR2 Saree

‘oo

Ctr rertre Sena

(Chae reo) enm

(etree (scan

(specs Seoiso Sn

Scoot

Stop nrg) =

Steatnpemne) ay

Schone eo

coca

Darian

a ‘aor or)

‘Sx

e010 0020128 00m ‘chapter 2-Page 39

Description

TBD 616 OEM A

pEUTZ

Selected systom functions are descebed bit blow.

Spwed governing system

Dierant versions of he speed governor ae posible depending onthe appcaton 0.9, speed governor,

fiaod speed goverer.

Ihe posse to protect the engine agalst overspeed wih the EMR2,

Setpoint preset

“Tne setpoint preset can be made fr example bya tga potentiometer, a voltage sgl or vid an inte

face

| constant or soeed dependent P fetar can be set depending en the application. In adn, switching

between ta P factors cr between constant and speed-dependon Pfc can be proud a.

Engine starstop

‘As s0on a the cool device detects the lat speed, the Ijction pump cont! ba is leased fer staring

‘The power othe EMR2 must be cut of wth the ey operated sw fo shut down he expe. The actuator

{hon pul the injection pump cao bart the sop pation, Additonaly ar dependent a hs, he fl

‘pp lterpted by shut magnets.

“Te engine may alo ba shut down by an err into EMR, e.9, exceeding ox droping blow fied meas

tre value Its

Displaystoutputs (monitoring function)

Dillernt signals can be played and up though th conl devie ouput, eau lamp, sped,

‘waning signals or coolant tomparative, lube ol press, tube ol ve.

“The ful amp must be mountad by the custome in a wel vile place onthe este. serves fo rough

3

oars.

= Protubcate for at fast 2 minutes ator an engine standst of « 3

{© Check the ube ove again, up othe top mark i ncessary.

© heck he power supply othe engine martoring system bat)

© ‘Suton on engine montering stom

Compressed at starter system

€ Fitter sir tank wit stare compressor or earbor dx (CO) Kom

prassurend vaesl fo 90 bar nd dan wae.

Filing the starter ar tank with oxyas

Eloctric starter systom

{© Check the power supply othe manitor bation)

{© Check the connecting cabo for croc olay, ght Mand good cots

{© Snitch on the room venation to evacuate racaton haat anol vapour.

“The room venta ao Nas the jb a supplying to engine wah com-

bution ait sucks nom he stor room,

TBD 616 OEM

Operation

‘There is a danger of fir, Backtring oF explosion dus to igniting oF

Uunbuoned fuel nthe exhaust system which could ease damage,

‘Theretore the following notes must be observed.

“There may bea danger of backing, fr o explosion

{© in to caso of voluminous and lon, horizontal lid exhaust systems

{© ator sting and ajustment work onthe ful system with ing peed

apd succession ad col exhaust poe

er hea mires

inthe case of nsuficlenty bled fe! ines.

eee

‘Ar longer pauses in operation cot engin) partarm werk according to

‘haptor Commissioning

‘Open the coolant and felts. Switch on the pup if avaiable

Remove the turning gear (tached).

‘Switch on engine moniering systom

Setlow engine speed

‘Sart engine onthe engine montxng system

‘Slowly increas the speed anlad ater ulin up the lie ol pressive

‘Do ot warm up engines nding speed witout oad

During engine operation, check whether the data eplayed by the engine

‘montring sytom are wid ho specfed parameters.

(© Avoid sting down rom ul ba.

{et the engine run for about another 5 minues at increased idle spend

witout gears beers shuting down fo avid heat uling Up a ender

liners and ender neads as well as coking onthe extn rbocharger.

{© Shutdown engine onthe engine montring sytem.

{© Lt ne coolant pump assembly run fo 3 few minutes more ar shuting

1 tho engine is shut down for ong, lose the cola and fel aps ans

the starter ap avalabe

Commissioning

A

State the engine

“ell

Monitoring operation

‘Shutting down

chapter 2- Page 7

TBD 616 OEM A

pete

“This page intentional blank,

Chapter 3 -Page 8 soz nom eo

Diesel Engines

4 Expendables

I unsuitable expendables ae used, ot cannot be documented thatthe

‘xpondablesusod conform to requirments, ne warranty wit be accepted by

{he engine's manufacirr for touble‘fee operation. This also apps for,

Inadequate care and maintenance ofthe engines and he expendaties,

Punt he tga mime of perils sunlahie natonaly ant nematonay

{hd the wide varey of quates Involved, plus coniinual grovemns 26

ols imposible for us to check asta produts and namo Dem, and

_2ccoringly we cannot accept any respons fr hese products.

‘Tho suppy ofthe expendable concerned bears sole responsibilty forgo

bay consent qualy ofthe products namod hero, ad in th case of prod

ts not rare additonal fr compliance wh the spect requirments

forte expendabies and ter operational reabity This shall so apply In

{he event hat the prdueer coneemed proves the products naried nee.

“Te expendbles named hee (vfeence products) ae onl a slecton fom

corn producers and ther produc. Other expendables not sted here may

‘a0 be use, provided they conform othe roqurerens involved, Ls. are at

leat ecuivaant in ers fa ereria. The expendabies named inthis spect

‘eatin shal be used as reterene prods for pxpaes of comparison The

‘xpandabies suppers involves can supply ber requis ‘formation, and

‘should als cont the suai of hor pals covespondinghy

Mixing diferent expondabo types together, 9. derent ube os weh esch

‘other eileen coolant adv wth each ater may leas fo malfunctions.

In ovary such caso, bole any miking perfrmed, permission must be

‘obtained rom the suppl ofthe products volved, wo shal the Boar ho

‘esperstly for ary such mixing. Ths shal aso poly to puting any tater,

‘eaves inthe oxpendaties,

500 Tecnica! Creular TR 0199-00-2080.

00 Tecnica! Cheula TR 0199-00-2000.

900 Tecnica! Cheular TR 019899-2001

Expendables

General remarks.

Wrrenty

Mixa

Fuel

Engine tube oi

Engine coolant

Cchaptor4- Pago +

Expendables

Chapter 4-Page2

Diesel Engines

‘This page ntetionaly et blank

A

Medium-sized and large engines

‘Auxiliary materials

Sealants and securing agents

= Observe storage stably, an, gvon onthe package!

= Upon transport. storage and csposing ofthe abovementioned ems, cbsowe Chapter 1, Rogult-

ons ofthe operating manual no acorn informations given on ho package

Expendables

[ears aeiaes [i [Scars ad [aacternice [aomeatonramaee

ton spectetone

foevTa rat —|Seaiva Jovan a2 | tan cna, acy Reni, | Sag gh od oe

Potesco lsc marr |wsnte

aeuTzowae [Saas |ivoreraara [Stan eaoaone vaca atin | Sagat ih and we

Jeveteascto|atng ssi tng gy 66 | eter

arureanae — [emoan — |ivorer oar |ises painted int oan |S re Pa Pe

voroseor |eenore svn hon porary

eaureowss [ore omy ape many

BrUTzow ss — [Seasraapce |rvaiems [amet ete ango-anymn |Sasraacieaig ot

renner eh ta as ma

BEUTZGW ss |Seaxra ance |vaieom [anerbe ovrtte sgb-omnan [Site dala ot

sn xceg noe nah sgh

BEUTZDWeT — [Srosba meen |FVGIO00R lanai wranfea twcmomen [Sen ac earod

en exc eae ste

tengo ge seco ae

nzsuresnaaeang gon meseonact [ering ait or

tener cen, en tr,

teegetoerticttenese wan pes]

chapter 4- Pages

Expendables

Medium-sized and large engines

A

DEuTZ

[iowa oan Yio Snare ma [otaiincs [eplssonexonlen

to ‘ecto

BETEGWe — [Sarraaeme FveKoHE [aamncsonrete geearenen [ane pina ap waat

Son nen nsngnygen| mac 2

ose mada ecos sre

loryarssn nage asc se

DEUTZGWe [Seas |vaionGR mweiesaereteorecoroonen [Sang taaar win

ental won xc oon, |g wih fo O10

a a ee

eter eau ee

pg rg eae

enna —|araet [vom Iae |secsioetee nye cmmes [aroma etal

essen ty ec

aruTzoae — [Smoae | VCI=GHO sw sane shgeconpnet

orn, tons acre,

acarzawe line [vee [ort ene nanan [Saractawans ge

trae evoctu hoes, |seong sean

TEUTZDWG —|Secung spew | FVOTGORGHE [Ammo sarentee sgl omeat| ar

ona en gon, | Pr

eanzowTe owas meicsverctn sieconoown_ [Shara lseainge

Ireaum term stern ee

faeorzcT —|Beaseoapea [ev eTen =e — [inert ckeitesdcanpeen_| Sea nd alg

Ingrsrengh meson vcs ompow|pisvoto ags who

BeuTzawT2—|eeamaoawe [PVeI@ ORE [nmcte enn angerwet | Sa wat

chapter 4- Page

Expendables

Medium-sized and large engines

Gluing agent

[ster aesiona- [ype [characteristics [Apatcaton examples

focuTzx + [gaan |ivorerass | mosanernt pny bed wat

Foo 208 J's andasc lesa sion ts cae)

tenes a 506 ra sun pone

[ecuTzm > [Faeroe Jive mmawoccs, |

Foo 2000 laps 1, [sna bem eater

Jung open otUTz tenchacinw [orca ta

Lubrleants

ati Fempeatie[appienton ani

cevizse —[ivoveiorsr [2c a0 | pyterrsing teen and wearerarnattin acs Goer

DeuT2ss ——fivowierss [Secwe0e | eaybrreanhg itn awe Gorin enon mb

DEUTES!—_[ivowetarss [arc «57 [tower roarg angen who eon |

Paso str rw npn cer 620°C) eect

es Cnt ata nebo pn

TacuTze ——fivoreraras [Sew HOC |Fer Pept cain fn a ear th

etn teareg penne nd er ener Wie rene

eure fivowiarar [20m WO” |fe Pept natin cf in a ebamhge ih

entra ene nd wnpres esi

co faNsie [SOC WO |enenon gastrin anon being, se a a

ana srg utes Forum rng apres coe TD

sexe 0m Chapter 4- Page 5

Expendables

Medium-sized and large engines A

‘tne auxliary mat

‘Below you wl nd reference let forthe used auxitry matrls wth which the est ess have been

‘ctived. Equivalent products canals be used: Ws e950, the supplier must assure essay of the

product forthe appcaton,

= When using the pods indeted below, tho folowing references of he manufacturer must abso-

hey be obeorve

Salty eterences

+ Personal protecton equipment

+ Disposal as directed

chapter 4- Page 6 exact 80im 010

Expendables

Medium-sized and large engines

[reson [nicion a

|Oetergent [or enge components [P3 co leaner (id) ese. Merkel KGAA

foamaae soa ms ean

[Gotonencrrer Anes ACEO (aaa |e Dem Arad

rename cngsyaen [PST Ripe)

Pn owe

Recon poms)

icone is)

sara owen

oer un

Tomes war ats) ana [Pa TH

tesa

lara) macnn at

[eran ane [econ 8248 pau en vec Git

[econ tia or Hons.

aon lh

rin

oe ae Daron acoo ooh sare es al

or tare

20% o1z000 00m Chapter 4-Page 7

Expendables

Medium-sized and large engines

Preise [Ropieatn Pott ane

[owe |avar toe senor

crn) arse

[vane gem: ar ye

5% teal a Sh)

to en

oes [ewes 25 as tae

[Neeresanon ras dneminson orang [aganni ht We VD i Me

se ster Dcvteeemmne eis i 09 cam

eso ar aang acon Gv pose a on

Gein war eto icaaimeees ie ere Gro

oneness)

chapter 4-Poge®

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Parts Catalogue DI 16 Marine EnginesDocument745 pagesParts Catalogue DI 16 Marine EnginesMiguel Ruivo Almeida89% (9)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Daf 1160 User ManualDocument80 pagesDaf 1160 User ManualMiguel Ruivo Almeida0% (1)

- Parts Catalogue DI13 Marine EnginesDocument567 pagesParts Catalogue DI13 Marine EnginesMiguel Ruivo Almeida100% (4)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Deutz ManualDocument76 pagesDeutz Manualdim4erema60% (5)

- CENTA - Compact Seal - Assembly & Operating ManualDocument20 pagesCENTA - Compact Seal - Assembly & Operating ManualMiguel Ruivo AlmeidaNo ratings yet

- DF4 5 6Document60 pagesDF4 5 6Miguel Ruivo Almeida0% (1)

- MA Vitotronic333 MW1S NL 5858 163Document260 pagesMA Vitotronic333 MW1S NL 5858 163Miguel Ruivo AlmeidaNo ratings yet

- Air Conditioning Principles and Systems An Energy Approach (4th Edition)Document544 pagesAir Conditioning Principles and Systems An Energy Approach (4th Edition)Ira Martiani84% (19)

- DF4 5 6 MedidasDocument2 pagesDF4 5 6 MedidasMiguel Ruivo AlmeidaNo ratings yet

- Alfa Laval Pump Handbook PDFDocument257 pagesAlfa Laval Pump Handbook PDFkashifwarsiNo ratings yet

- MSC-Circ.1165 Agua Nebulizada PDFDocument5 pagesMSC-Circ.1165 Agua Nebulizada PDFLeviatan McblueNo ratings yet

- Comapsystems - Com - Id-Bf - Operator Guide r2Document40 pagesComapsystems - Com - Id-Bf - Operator Guide r2Miguel Ruivo AlmeidaNo ratings yet

- Grundfosliterature 970920 PDFDocument36 pagesGrundfosliterature 970920 PDFMiguel Ruivo AlmeidaNo ratings yet

- Ships Electrical SystemDocument224 pagesShips Electrical SystemMiguel Ruivo Almeida100% (5)

- Id Dcu Marine 2.2.2Document168 pagesId Dcu Marine 2.2.2Miguel Ruivo AlmeidaNo ratings yet

- The Machine 5hown Here 15 Without Guard5 For Pre5Entati PurpoDocument4 pagesThe Machine 5hown Here 15 Without Guard5 For Pre5Entati PurpoMiguel Ruivo AlmeidaNo ratings yet

- 06-2 Rinke Prospectus R-EFM (En)Document8 pages06-2 Rinke Prospectus R-EFM (En)Miguel Ruivo AlmeidaNo ratings yet

- CENTA - Assembly and Operating InstructionsDocument18 pagesCENTA - Assembly and Operating InstructionsMiguel Ruivo Almeida100% (1)

- The 12 Volt Doctor's Practical Handbook Fo - Edgar J. BeynDocument243 pagesThe 12 Volt Doctor's Practical Handbook Fo - Edgar J. BeynseadlexNo ratings yet

- Operators Manual DI13MDocument71 pagesOperators Manual DI13MMiguel Ruivo AlmeidaNo ratings yet

- Source Changeover SystemDocument116 pagesSource Changeover SystemMelissa HolmesNo ratings yet

- Pagina 14-38 (Manual Boxcoolers)Document26 pagesPagina 14-38 (Manual Boxcoolers)Miguel Ruivo AlmeidaNo ratings yet

- Calandras HidraulicasDocument19 pagesCalandras HidraulicasMiguel Ruivo AlmeidaNo ratings yet

- Blue Guide - 2014 - en PDFDocument134 pagesBlue Guide - 2014 - en PDFjasonNo ratings yet

- Quaderno 2 enDocument180 pagesQuaderno 2 enkitofanecoNo ratings yet

- LNG Glossary FinalDocument93 pagesLNG Glossary FinalSander Laust100% (1)

- Air Conditioning Principles and Systems An Energy Approach (4th Edition)Document544 pagesAir Conditioning Principles and Systems An Energy Approach (4th Edition)Ira Martiani84% (19)

- Idronics 9 0Document88 pagesIdronics 9 0Lee ChorneyNo ratings yet

- Alfa Laval Pump Handbook PDFDocument257 pagesAlfa Laval Pump Handbook PDFkashifwarsiNo ratings yet