Professional Documents

Culture Documents

Methods and Compositions For Decontamina PDF

Methods and Compositions For Decontamina PDF

Uploaded by

Derrick Kimani0 ratings0% found this document useful (0 votes)

11 views13 pagesOriginal Title

Methods_and_compositions_for_decontamina.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views13 pagesMethods and Compositions For Decontamina PDF

Methods and Compositions For Decontamina PDF

Uploaded by

Derrick KimaniCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 13

us) United States

2) Patent Application Publication co) Pub. No.: US 2007/0048175 Al

oy

6)

ay

@

@)

Tichy et al.

METHODS AND COMPOSITIONS Fi

DECONTAMINATING SURFACES E

OR

:XPOSED

‘TO CHEMICAL ANDIOR BIOLOGICAL

WARFARE COMPOUNDS,

aryl J. Tiehy, Orem, UT (U

Jarson, Alpine, UT (US)

G.

Comespondenee Address:

US); Brian

‘THORPE NORTH & WESTERN, LLP.

8180 SOUTH 700

AST, SUITE 200,

SANDY, DT 84070 (US)

Appl. No S10,133

Filed: Aug. 24, 2006

Related Us

Application Data

Continuation-in-part of application No.

filed on Feb. 24, 2006

Continuation-in-part of application No.

filed on Feb, 24, 2006

Continuation-in-part of application No

filed on Feb. 24, 2006

Continuation-in-part of application No

filed on Feb. 24, 2006

11361,836,

112361,837,

11361,841

117361,665,

U!

SS 200700481751

(43) Pub. Date: Mar. 1, 2007

(60) Provisional aplication No, 60/656,723, fled on Feb.

25, 2008. Provisional application No. 6016S6,723

filed on Feb, 25, 2005, Provisional application No,

601686,723, fled on Feb. 25, 2005, Provisional appli-

cation No, 60/656,723, file on Feb, 25, 2005

Publication Classification

(1) Insc.

AGIL 2/18 (2006.01)

(2) USC 42228

on ABSTRACT

‘The present invention is drawn to methods and compositions

for use in partially or fully decontaminating surfaces which

have boon contaminated with chemical or biological warfare

‘gens. The invention includes contacting the contaminated

strlace with a composition capable of ameliorating. the

egtive effets cased by the warfare agent, In one embodi-

‘ment, the composition includes an aqueous vehicle of water

‘and. Trom 0.001 wt % {0 40.0 wt % of a peroxygen.

Additionally, the composition ean include from 0.001 ppm

4 50,000 ppin by weight ofa transition metal based on the

‘aqueous vehicle content. Optionally, an alcohol can be

‘included in the composition, In one embodiment, the ran-

sition metal canbe in the fomn ofa colloidal transition metal,

seh as colloidal silver.

US 2007/0048175 Al

METHODS AND COMPOSITIONS FOR

DECONTAMINATING SURFACES EXPOSED TO.

(CHEMICAL AND/OR BIOLOGICAL WARFARE,

‘COMPOUNDS,

[0001] The present application isa continuation-in-part of

US. patent application Ser. Nos. 11/¥61,836, 11/361,841;

11/361,837; and 11/361,668, each of which was fled on Feb,

24, 2006, and each of which claims the benefit of US.

Provisional Patent Application No. 6/656,723, fled o

25, 2008,

FIELD OF THE INVENTION

{0002} The present invention is drawn to methods and

‘compositions for use in decontaminating surfaces contami

nated with chemical and/or biological warfare agents,

BACKGROUND OF THE INVENTION

{0003} Biological and chemical warfare agents are potent

Killing tools. Although they were banned by the Biological

Weapons Convention of 1972 and the Chemical Weapons

‘Convention of 1998, both chemical and biological weapons

remain a legitimate and viable test against people and

‘countries throughout the world. As such, the need exists for

‘an fast and ellective means for deconlaminating surfaces

‘contaminated with biological and/or chemical agents

SUMMARY OF THE INVENTION

[0004] Ichas been recognized that it would be desirable to

provide a method! and an associated decontaminating com

Position which would be effective against biological andor

‘chomical warfare agents. In accordance with ths, a method.

Tor decontaminating a surface contaminated with 2 chemical

‘oF biological warfare agent ean comprise contacting said

furfice with an effective amount of a composition, The

‘composition inclides an aqueous vehicle with water and

fiom 0.001 wt 9% to 40.0 wt % of a peroxygen, The

‘composition further includes fom 0.001 ppm to 50.000 pp

by weight ofa transition metal or alloy thereof based on the

aqueous vehicle content,

[0005] Additional features and advantages of the iaven-

tion will be apparent from the detailed description that

follows, which illustrates, by way of example, features ofthe

DETAILED DESCRIPTION OF THE

PREFERRED EMBODIMENT(S)

[0006] Reference will now be made to the exemplary

‘embodiments, and specific language will be used herein t0

‘describe the same, It will nevertheless be understood that no

Timitation of the scope of the invention is thereby intended.

Alterations and furher modifications of the inventive fea-

tures illustrated herein, and additional applications of the

principles of the inventions as illustrated herein, which

‘would occur to one skilled in the relevant art and having.

possession of this disclosure, are tobe considered within the

cope of the invention. Its also to be understood that the

terminology used herein is used for the purpose of deserib-

ing particular embodiments only. The terms are n0t intended

to be limiting unless specified as such

[0007] It must be noted that, as used in this specification

‘and the appended claims, the singular forms “a.™an,” and,

“the” include plural referents unlese the content clearly

dictates otherwise

Mar. 1, 2007

[0008] The term “decontaminate” does not require that

complete decontamination occur. In other words, partial

decontamination to complete decontamination ar included

Whenever the term "deconiaminate,™Jecontaninating,

“decontamination,” ee. is used. Further, the use ofthe term

disinfect.“ disinfoting, disinfection,” or the like, is used

‘0 include not only fighting infection of virus, bacteria, or

other living organisms that may be used for biological

‘warfare, but also includes decontamination of surfaces that

fare exposed to harmful chemicals often used in chemical

‘warfare, such as by oxidation of the chemical. Aga

complete disinfection i not required for disinfection to

‘occur: Generally, though sanitizers, strilants and disinfec-

tants are used for the same purpose, ie. 1 Kill bacteria

andr vinses, et, sterilant composition exhibits a greater

all evel compared to a disinfectant, which in tur has

better Kill level than a sanitizer. This being stated, most

applications require only sanitizer or disinfectant levels

bacteria/vrus reduction, though otber applications benefit

considerably from the use of steriants. Fore

the present application the term “disinfectant” is used gen-

enlly to reer to each of sanitizers, disinfectants, and ster

ilants unless the context clearly dictates otherwise,

[0009] The term “solution” is also used throughout the

specification to describe the liquid compositions of the

present invention. However, as these “solutions” include

colloidal transition metals, these compositions ean also be

Ueseribed as dispersions or suspensions. As the continuous

phase is typically a solution, and the transition metal is

present as a colloid, for convenience, these composit

‘ill typically be refered to as “solutions” herein

[0010] The term “substantially free” when used with

epard 1o the compositions ofthe present invention refers to

the total absence of or near foal absence of a specific

‘compound or composition. For example, when s compos

tion is sid to be substantially free of aldehydes, there are

either no aldehydes in the composition or only trace amounts

of aldehydes in the composition.

0011] The term “peoxygen” refer: 10 any compound

containing a dioxygen (OO) bond. Dioxygen bands, par

ticularly bwalent OO bonds, are readily cleavable thereby

allowing compounds containing them {0 act as powerful

‘oxidizers, Non-limiting examples of elses of peroxygen

compounds include peracid, peracid sls, and peroxides,

suc as hydrogen peroxide.

[0012] ‘The tem “biological warfare agent” and “hiologi-

«al weapon” are interchangeable and refer fo any biological

‘onganim or toxin that are often used as a weapon of war oF

{errorism to kill, injre, or incapacitate. Similarly, she terms

“chemical warfare agent” or “chemical weapos refers to

chemical agents which have toxic properties and ean be used

in war of temorism to kil, injure, or incapacitate.

[0013] Concentrations, dimensions, amounts, and other

seal data may be presented herein in a range format

Is tobe understood that such range format is used merely

or convenience and brevity and should be interpreted

flexibly to inelude not only the numerical values explicitly

recited as the limits ofthe range, but also to ince all the

individual numeri values or sub-ranges encompassed

‘within that range as if each merical Value and sub-range

is explicitly recited, For example, 2 weight ratio minge of

about 1 wt % to about 20 wt % should be interpreted to

US 2007/0048175 Al

Include not only the explicitly recited Iimits of 1 wt 9% and

out 20 wt %, but also to include individual weights suck

‘as 2.90%, 11 w1%, 14 WU %, and sub-ranges seh a8 101

% wo 20 wi %, 5 Wi % to 15 WI% ee

[0014] In accordance with this, the present invention pro-

vides a method for decontaminating surfaces contaminated

With biological andor chemical weapons, ‘The method

‘involves contocting the coataminated surface with a com-

position comprising an aqueous vehicle, ineluding water and

from 0.01 wt % f0 300 wt % of a peroxygen. Addtionaly,

trom 0.001 ppm to 30,000 ppm by weight of a transition

mital based on the aqueous vehicle content can also be

present.

[0015] I s noted thatthe lower end of the range of the

peroxyigen can be mosified to 0.01 wt %, 048 wt, and 0-1

‘wt % andor the upper end ofthe range can be modified to

301%, 20 wt % oF 10 6 % in accordance with specific

‘embodiments of the present invention. Further, the concen

tration ofthe metal content, ineuing ionic andor colloidal

mictal content, can also be modified to 10 ppm by weight at

the lower end ofthe range, and/or to 20,000 ppm or 10.000

pm by weight atthe upper end of the range. As these anges

ate merely exemplary, one skilled in the art could modify

these ranges for a particular application, considering such

things as the type of alcohol (polyhydrie, food grade,

mixtures, etc.) the type of peroxygen (peroxide, peracid

‘combination of poroxidelperaci, ct.) and the type of metal

Gonie, colloidal, alloy, et). For example, in treating @

hhuman for exposure to biological or chemical agents, lover

‘amounts of peracid may be used s0 as tb be within safe

parameters, Whereas when decostaminating terra firma,

‘ilies, or equipment, higher concentrations of the peracid

may be useable (closer to the 40 wt %). Altemativey. if

hydrogen peroxide is use asthe peroxygen compound, thea

1 broader range of the material may be useable fora wider

range of applications

[W016] The aqueous vehicle can optionally ince other

ingredients, sich as organic co-solvents. In particular, co

im alcohols ca be present Is noted that i a alcohol is

present it ean be present at from 0.08 wr % 10 40 WU,

the lower end othe range ofthe alcool being mod

10.0008 wt 8% oF 0.1 wt 8% and the upper end of the range

being modifiable to 20, 9% oF 10 Wr 6 In selecting he ype

‘of aleool that an be used for example, leas ineading

‘lnhatc sleohols and other carbon-cotsining alee

having fom Ito 24 carbons (C,-C alcoho) can be waed

eis to be noted tht "C,-C,), alcohol” does ast necessarily

imply only straight chain saturated aliphatic alcohols, as

‘olhcr carbon containing aleobals can also be used Within

this definition inching rancho aliphatic alcohols alicy-

lie aleahos, aromatic alcohols, unsaturated aleobls, as

‘vel as subsite alpha ley, aromatic, and wns

Ute sleaols, ete. In one embeadiment, the aliphtie aco:

hols ean be Cyto, sleobols including methaool ethane,

propanol and isopropanol, butanols, and pentanol, doe to

their availabilty and lower boiling points. This being stated,

polyydee alcohols can also be used ellectivly in enhanc:

ing thedisinfctant and sterilnt potency of the compositions

‘of the present invention, as wel as provide some degree of

skied sailiztion. Examples of poly sleohols which

fem be wsed inthe present invention iaclude BUL are not

Timited to ethylene give (cthane-I.2ol) glycerin (or

ulyoerl, propane-1234riol), and propane1 20). Other

Mar. 1, 2007

on-aliphatic alcohols may also be used including but not

Timid to phenols and substituted phenols, erucylaleobel,

ricinolyl alcohol, arachidyl alcohol, capryl aloo, eapric

alcohol, bebensl alcobol, lauryl alcoho! (1-dodeeano)

‘myrsiylaleobol (J-teiradecano), cetyl (or palityl) aleohol

(F-hoxadecano),steayl alcohol (I-oetadecanol),isosteary!

Alcohol, oleyl alcohol (cs-9-oetadecen-I-o), palmitoteyl

aleolol, linoleyl alcohol (92, 12Z-octadecadien-I-ol),

clay! sleoho! (E-octadecen-|-o),eladotinoley! alcohol

(OE, 12E-vctadecatien-1-0), linolenyl aleobol (9Z, 122,

15Z-octadecatrien-10l), elaidolinolenyl alechol (9E, 12E,

15-E-octadecatrien-I-o)), combinations thereof and the Tike

[0017] In some embodiments, for practical considerations,

vethanol, ethanol, and denatured aleolols (mixtures of

cthuol and smaller amounts of methanol, and optionally,

‘minute amounts of henzene, Ketones, acetates, ete.) can

often be prefered for use because of their avilability and

cost, Glycerol is also preferable for use in some embodi-

sens, Ifthe desire is 19 provide a food grade composition

as may be desirable for mucosal, ski, of alimentary canal

‘application, thea alcohols ean be selected that satisfy this

requirement, AS these ranges are merely exemplary, one

stilled in the art could modify these ranges for a particular

application, considering such things as whether alcohol

selected for use is polyhydric, whether the aleohol is food

rade, mixtures of aleohols, ete

[0018] | Reyarding the tansition metal, in accordance with

the embodiments ofthe present invention the metal can be

inn form (¢ a metal salt) andor colloidal form. Inone

specific embodiment, the transition metal can be in a sub-

meron form (Le. dispersion of less than I wm metal colloidal

panicles). However, larger colloidal transition metal par-

ticles can also be used in contin applications, Typical

transition mals that are desirable for we inchude Group VI

to Group XI transition metas, and! more preferably, can

include Group X to Group XI transition metals. Alloys

‘including atleast one metal from the Group VI to Group XT

metals can also be used. Its recognized that any of these

metals will ypiclly be oxidized othe corresponding cation

in the presence of pemxyzen, However, with colloidal

metal, typically, the surface is usually more susceptible 10

such oxidation. Further, when colloidal metals are dispersed

{na colloidal solution, there is often an amount of the metal

in ionie or salt fonn that is also present in the suspension

solution. For example, colloidal silver may inchude a certain

percentage of a silver salt or ionic silver in solution, eg.

10% t0 99% by wight of meta content can be ionic based

fon the total metal content, This being slated, certain pre-

{erred metals for se in accordance with embodiments ofthe

present invention are ruthenium, rhodium, osmium, iridium.

palladium, platinam, copper, god, silver, alloys thereof, and

‘xturesthereo?. Silvers offen the most preferred, depend

‘ng on the application, the levels of kill that are desired oF

required, the type of pathogen being tameted, the subsirate

that is being cleaned, ete. Any of these embodiments ean

also benefit from the use of alloys. For Example, certain

‘combinations of metals in an alloy may provide an accep

able Kill Tevel for a specific pathogen, and also provide

‘benefits that are rolated more to secondary consideration,

such as solution stability, substrate to be cleaned, et

Preferred examples of transition metal alloys for use in the

present invention include but are not limite to coppersilver

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Sirius Times 2006 ModifiedDocument30 pagesSirius Times 2006 ModifiedDerrick Kimani100% (5)

- The Gospel Witness of The Stars: 2Nd ComingDocument1 pageThe Gospel Witness of The Stars: 2Nd ComingDerrick KimaniNo ratings yet

- The Petrolist - DIY - How To Make A BuzzcoilDocument4 pagesThe Petrolist - DIY - How To Make A BuzzcoilDerrick KimaniNo ratings yet

- A Perpetual Motion Machine - Bold, Alan, 1943 - London, 1969 - London - Chatto and Windus - Hogarth Press - 9780701114855 - Anna's ArchiveDocument72 pagesA Perpetual Motion Machine - Bold, Alan, 1943 - London, 1969 - London - Chatto and Windus - Hogarth Press - 9780701114855 - Anna's ArchiveDerrick KimaniNo ratings yet

- Flavor Water For About $20 - FacebookDocument6 pagesFlavor Water For About $20 - FacebookDerrick KimaniNo ratings yet

- Books - TheOldScientistDocument9 pagesBooks - TheOldScientistDerrick KimaniNo ratings yet

- Indian Forest ActDocument9 pagesIndian Forest ActDerrick KimaniNo ratings yet

- Cyclos PRO Prices: Classification Number of Users Turnover Initial Fee Yearly FeeDocument1 pageCyclos PRO Prices: Classification Number of Users Turnover Initial Fee Yearly FeeDerrick KimaniNo ratings yet

- The Banishing Ritual of The Hexagram: y H W HDocument4 pagesThe Banishing Ritual of The Hexagram: y H W HDerrick KimaniNo ratings yet

- Science PDFDocument32 pagesScience PDFDerrick KimaniNo ratings yet

- SECTION 1 - Instructions To The Individual and State-Licensed PhysicianDocument9 pagesSECTION 1 - Instructions To The Individual and State-Licensed PhysicianDerrick KimaniNo ratings yet

- Group Statement: Charles Mbiko 0725673458Document3 pagesGroup Statement: Charles Mbiko 0725673458Derrick KimaniNo ratings yet

- M-PESA Certificate Troubleshooting Guide PDFDocument3 pagesM-PESA Certificate Troubleshooting Guide PDFDerrick KimaniNo ratings yet

- SpeechDocument8 pagesSpeechDerrick KimaniNo ratings yet

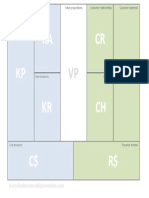

- KA CR CS CH: Key Partnerships Key Activities Value Propositions Customer Relationships Customer SegmentsDocument1 pageKA CR CS CH: Key Partnerships Key Activities Value Propositions Customer Relationships Customer SegmentsDerrick KimaniNo ratings yet

- Silver Colloids - Scientific Information On Colloidal Silver PDFDocument1 pageSilver Colloids - Scientific Information On Colloidal Silver PDFDerrick KimaniNo ratings yet