Professional Documents

Culture Documents

Image2014 01 24 102121

Image2014 01 24 102121

Uploaded by

Alexandre Jusis Blanco0 ratings0% found this document useful (0 votes)

4 views70 pagesjkl

Original Title

image2014-01-24-102121

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentjkl

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views70 pagesImage2014 01 24 102121

Image2014 01 24 102121

Uploaded by

Alexandre Jusis Blancojkl

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 70

Xylem Water Solutions AB (the Company) was previously named ITT Water &

Wastewater AB. The name change took place in November 2011. This is document is

(i) a document that relates to a product of the Company phased out prior to the name

change; or (ii) an old version of documentation relating to a product that is still being

produced by the Company but which document was published prior to the 1st of

January 2012 . This document may therefore still be marked "ITT". Xylem Water

Solutions AB is no longer an ITT company and the fact that "ITT" may appear on this

document shall not be interpreted as a reference by the Company to "ITT" in the

Company’s current business activities. Any use or reference to “ITT” by you is strictly

prohibited. In no event will we be liable for any incidental, indirect, consequential,

punitive or special damages of any kind, or any other damages whatsoever, including,

without limitation, those resulting from loss of profit, loss of contracts, loss of reputation,

goodwill, data, information, income, anticipated savings or business relationships for any

use by you of “ITT”. This disclaimer notice shall be interpreted and governed by Swedish

Jaw, and any disputes in relation to it are subject to the jurisdiction of the courts in Sweden

/f you do not agree to these terms and conditions you should not print this document and

immediately stop accessing it.

xylem

Let's Solve Water

End of Disclaimer text.

xylem

Let's Solve Water

Sirt

Water & Wastewater

Parts List

Flygt 3127.090/170/181/890

eer

Engineered for life

Parts List

Flygt 3127.090/170/181/890

Overview

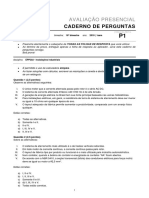

Table of Contents ‘This publication contains the following topics:

Topic

Preface...

Practical information :

Data plate interpretation .

Product denomination

Order parts.

Motor Parts: .

Explosion-procf..

Standard ....ececnn ne

Grinder, Explosion-proof,

Grinder, Standard

List.

Hydraulic Parts.

List... :

Parts for Service...

Parts List. Fiygt 3127.0907170/181/090 3

Pans Lit, Fiygt 3127 090/170/101/890

Purpose

Recipient

Contact

Reference

Preface

‘The purpose of this document is to give the reader information about parts and accessories

for the product.

‘The document is intended for TT

+ customers

+ service personne!

+ sales personnel

For more information

+ contact your ITT representative

+ visit htp:/hwww.ittwww.comy

More information about the product is available at http:/webservices ittwww.com/tpil,

Pans List, Fiat 3127,090/170/101/890 5

Overview

Table of This chapter contains the following topics:

Contents

Topic

Data plate interpretation

Data plate ...

Approval plate...

Product denomination.

Order parts...

Pans List, Fiygt 3127.090/170/161/000

Roan

Data plate interpretation

Introduction The ITT product is aways provided with data plates:

+ The general data plate is used on all products.

* The approval plate is added to all explosion proof products,

Data plate

The product may only be ‘operated within the parameters stated on the data plate.

Illustration This is an illustration of a general data plate,

3 2 *

24

23

2

2

20

FH 2 tats ee 18

Field This table shows the fields on the general data plate, and which information each field

description contains.

Field Description Field Description

1 Curve code/Propeller code 13 Rated current.

2 Serial number 14 Rated speed

3 Product number 15, Maximum submergence

4 | Country of ergin 18 | Direction of rotation:

+ LeLer

+ R= Right

‘Adtional information 17 | Duty cass ;

Phase; type of current, 48. | Duty factor

frequency -

Rated votage 19 | Product weight

Thermal protection 20 Locked rotor code letter

E Thermal class 21 | Power factor

Pars Ust, Fygt 3127 o90/170/1@17890

Field | Description Field Description

10 _| Rated shaft power 22 _| Maximal ambient temperature

14__| Intemational standard 23 _| Read installation Manual

12 | Degree of protection 24 | Notified body (only for

EN-approved Ex-products)

Approval plate

‘The approval is shown on the approval plate.

FM approved

version

Illustration This is an illustration of an approval plate for the FM approved product version.

1

Wax Operating Temp] 1

Explosion proof for use ia

Class |. Div t. grp C and D

Dust ignition proof for use in ‘APPROVED

lO Class f. Div 1. grp E, F and 6 °

Suitable for use in Class ll. Div 1. Hazardous Locations

f 7 Ambien: limits

00 AN WHILE ENERGIZED

CONNECT THERMAL CONTACTS

2

Field ‘This table shows the fields on the approval plate, and which information each field contains.

description Field Description

1 _| Temperature class

2__| Maximum ambient temperature

EN approved

version

Illustration ‘This is an illustration of an approval plate for the EN approved product version.

C Pans List, Fiygt 3127.090/170/181/890

Field

description

This table shows the fields on the approval plate.

Field Description Field Description

A__| Approval 1 | input power

B_ | Approval authority + Approval J | Rated speed “|

Number |

C__| Approval for Class 4 K__ | Controller |

D_| Approved drive unit | Additional information |

E | stalitme M___| Max. ambient temperature

F _| Starting current / Rated current | _N | Serial number

G | Dutyclass 0 | ATEX marking |

H | Duty factor = = |

Pats List, Fiygt 3127.090/170/181/000

>roduct denomination

iales

lenomination

*roduct code

‘The product's identity is built up of the Sales Code (four digit) and two letters indicating

hydraulic end and type of installation

This is an example of a sales denomination.

NP 3085,

123

Table: This table explains what the letters and the numbers in the sales code stand for.

Code Position Gives information about the...

1 hydraulic part

2 installation mode

[ sales code

In each range the product's identity, Product Code, is made up of seven digits.

This is an example of a product code.

NP 3085.183

ve

‘Table: This table explains what the product code is made up of:

Code position Gives information about the ..

sales denomination

2 version |

° Parts List, Fiygt 3127.090/170/1817800

‘Serial number The serial number is used for identification of an individual pump/mixer.

- ~ This is an example of a serial number.

NP 3085.183 - 951 0163

TTT

1 234

Table: This table explains what the serial number is made up of:

Product code position Gives information about the ... |

1 Product code |

2 production year ]

3 production cycle

4 unning number |

Pants List, Fiygt 3127.090/170/181/090 "

Order parts

Order

Requirements

Qualification

of personnel

Specially

approved

products

When ordering spare parts, state serial number of the product, spare part number and

quantity,

Genuine ITT parts must always be used for repairs if the product is to fulfil requirements

and obtain official approval.

Only ITT or ITT-authorized service personnel may undertake repair work on Ex-approved

products.

‘Spare parts marked with 0 after the part number are subject to dimensional accuracy

inspection.

2 Pats Lit, Fiygt 3127.090/170/181/090

Motor Parts

Overview

Table of This chapter contains the following topics:

Contents

To

Explosion-proof

Standard...

Grinder, Explosion -proof

Grinder, Standard

List:

Parts Uist, Fygt 3127 0907011817800 8

Explosion-proof

3127.090/095

“ Pans Uist, Fiyat 3127. 0907170118890

Standard

3127.181/185

aot

Pas List, Fir 3127.090/170/101/090

Grinder, Explosion-proof

3127.890

oreee

*) Intended for 64217xx

16 Parts List, Fiygt 3127.0907170/181/890

Grinder, Standard

3127.170

Pars List, Ft 3127.090/70/181/890

List

8

Pans Uist, Fiygt 3127.090/170/181/800

| Qtyrversion

Pos.No | Part.No Denomination Bese

1 477 11 01 Lifting handle Ja fa [aa

2 83.03.23 Hex. socket hd screw J2|2|2 2]

M10x25-A4-70 |

3 6306800 —_| Data plate USE 6306801 AS j2 22 |2]

‘SPARE PART | | |

6 83.0258 Hex socket hd screw \2 2]

MSX12-A4-70

8 | 2782900 | Earthing plate 1 1

9 | 82.20 88 Drive screw 4X5-A2-70 ols |6 6

10 443.6300 Stator housing Standard 1|4

19 443 53 05 (EX) | Stator housing Exversion 1 1

" 83.03 30 Hex socket hd screw aiala4

M10X60-A4-70

13 6307600 _ Plate HOT WATER PRODUCT 1

13 6563422 | Caution plate a] |

14 6306300 | Certificate plate EX 2] | jz]

14 6307000 | Certificate plate FM APPROVED 2) | |2]

15 5502100 | Connection plate (FLS+CLS) ata] |

15 5502200 | Connection plate (FLS) afa]a fa]

\15 5502300 . | Connection plate (CLS) fafa

15 6577900 | Connection plate SCREENED 1 1

CABLE |

15 6988200 | Connection plate | afa}a]a

18 6988400 | Connection plate 12 leads Ja fafa fa

15 6891600 | Connection plate Scotch paper nr 256 a] ja

15 7270300 | Connection plate T1T2 1

fie |ee7497 | o-rng239.5x57 NBR jaja fala

16 82 60 86 O-ring 239.3X5.7 FPM | 1]

7 83 32 36 Ball bearing 6207,35X72X17 Ja}ajala

18 4435905 | Shaft unit For motor 21-12-4 | \4

18 443.5906 | Shaft unit For motor 21-10-4 | 1

18 4436002 | Shaft unit For motor 21-11-2 1

18 443 66 04 (EX) | Shaft unit For motor 21-12-4 1

\18 443 66 05 (EX) | Shaft unit For motor 21-10-4 1 |

18 443 67 02 (EX) | Shaft unit For motor 21-11-2 1

18 5089104 | Shaftunit 21-11-2 For motor 21-11-2 } |a

18 508.9105 | Shaft unit 21-11-2;1-FAS For motor 21-11-2, t-phase ja

18 508 92 04 (EX) | Shaft unit For motor 21-11-2 }} di

Pars Lit, Fiygt 3127 090/170/181/000

Pos. No | Part. No Denomination - g858

18 508 92 05 (EX) | Shaft unit For motor 21-11-2, 1-phase ] 1

19 309 44 12 (EX) | Stator 21-12-4a 3. phase, 60Hz, 440V - \4

460VYSER/220V - 230VY/I

‘-phase, 60Hz, 220V - 240V,

19 309 44 28 (EX) | Stator 21-12-44 3- phase, 50Hz, 190-200VD. 3 | 1

Phase, 60Hz, 200-220VD, |

19 309 44 29 (EX) | Stator 21-12-44 3- phase, 60Hz, 380VY/220- 1

230vD

19 309 44 30 (EX) | Stator 21-12-44 3 phase, 60Hz, 380V D. 1 1

19 309.44 32 (EX) | Stator 21-12-44 3 phase, 50Hz, 348- 350v¥/ | 1 fl

200 - 208V D. 3- phase, 60Hz,

400V ¥ / 230 - 240 D.

19 309 44 34 (EX) | Stator 21-12-4a 3: phase, 50Hz, 380-400VY/ 4 1]

220 - 230V D. 3- phase, 60Hz,

440 - 460V Y / 260V D.

19 309.44 38 (EX) | Stator 21-12-44 3- phase, 50Hz, 660-690VY/ 1 1

380 - 415V D. 3- phase, 60Hz,

440 - 460V 0

19 309 44 40 (EX) | Stator 21-12-42 3-phase, SOHz, 400VD. 3- phase, 1 1

60Hz, 400V D. |

19 309.44 44 (EX) | Stator 21-12-44 3- phase, S0Hz,400-440vD, | 4 1

19 309 44 50 (EX) | Stator 21-12-4a 3 phase, 50Hz, 500V D. 3- phase, | 1 1

60Hz, 575V D.

19 309 44 52 (EX) | Stator 21-12-44 3 phase, 60Hz, 575-600VD. 1 1

19 309 49 01 Stator 21-11-28 3- phase, 50Hz, 400V YY /230vD. | 1 | 4 |: {4

193094902 | stator 21-11-20 3 phase, sone, 690v¥ ra0ov0. | 1/4 | 4 I

19 309 49 12 (EX) | Stator 21-11-22 3 phase, 60Hz, 440-460V Yser. 1) 1 4 | 4

| 1 200-230WY1I. |

19 309.49 28 (EX) | Stator 21-11-28 3. phase, S0Hz, 190-2000. 1 |4 11/4 |

Phase, 60Hz, 200 - 220V D. |

19 | 30949.29(€x) Stator 21-11-28 3 phase, 60H, SB0VY 1220-1 4 44

230V D. |

19 309 49 30 (EX) | Stator 21-11-24 3- phase, 60Hz, 380V D. jt fa la |a

19 309 49 34 (EX) | Stator 21-11-24 3 phase, 50Hz, 380VY/220V 1/1 4 4

| D. 3 phase, 60Hz, 440- 460vY_|

1 260V D.

19 309 49:38 (EX) | Stator 21-11-24 3: phase, SoHz, 66OVY/380VD./1 /1 1 1

3- phase, 60Hz, 440 - 460V D,

19 309 49 40 (EX) | Stator 21-11-24 3-phase, S0Hz, 400VD.3-phase,|1|1 1 1

60H, 400V D

19 308 49 44 (EX) | Stator 21-11-2a 3 phase, S0Hz, 400-44ovD. 4/1/11

‘S-phase, 60Hz, 480V D. |

19 309 49 50(EX) | Stator 21-11-28 3- phase, SOHz, 500VD. 3-phase,|1 1 | 1 | 1

| 60H, 578V D. |

}19 309 49 52 (EX) | Stator 21-11-28 3 phase, 60Hz,575-600VD | 1 1 14

19 4266301 | Stator 21-10-44 3: phase, S0Hz,680VY/4o0vD.|1 1

Pos. No Part.No | Denomination ZE58

19 4266302 | Stator 21-10-4a 3 phase, S0Hz, 400vY/2s0v0.[1 | [1 |

19 426.63 12 (EX) | Stator 21-10-4a 3: phase, 6OHz, 440-460V Yeer. 1) 1

1220 - 230V Vil |

19 426 63 28 (EX) | Stator 21-10-4a 3: phase, SoHz, 190-200V0.3 1 | 1

phase, 60Hz, 200-220V0.

19 | 4266334 (EX)| Stator 21-10-44 3 phase, S0Hz, 380VY/220V. 1) 1

D. 3- phase, 60Hz, 440-460 Y

1 260V D. |

19 | 4266338 (EX)| Stator 21-10-48 3:phase, SoHz, 660VY/380V0. 1) 1

3: phase, 60Hz, 440-4600.

19 | 42663 40 (EX) | Stator 21-10-4a 3- phase, S0Hz, 400V D. 3- phase, 1

BoHz, 400v D | |

19 426 63 44 (EX) | Stator 21-10-40 3. phase, 50Hz, 400-440VD.3- 1 | | 4

phase, 60Hz, 460V D.

19 426 63 60 (EX) | Stator 21-10-44 3-phase, S0Hz, S00VD.3-phase,|1 | | 1

SoHz, 575V D.

19 426 63 52 (EX) | Stator 21-10-44 3-phase, 60Hz, §75-600VD. 1) 1

19 426 63 55 (EX) | Stator 21-10-4a 2: phase, S0Hz, 550V 0 Ja} fa

19 509 04 72 (EX) | Stator 21-11-29 tephase, 60Hz, 220-250. 1) |

2 83.4559 | Cable tie 200X2.4 PAGIS -55+105 Jafa]afa

23 941723, Motor cable SCREEN 9X2.5MM2_ Max 70°C(158"F)(13.6) -14.9mm |?

FOB

|

23 9417 24 Motor cable SCREEN Max 70°0(158°F)(18.1) 18.8 |

6X2.5MM2#2X1.5 FGB |

23 94.1781 Motor cable SCREEN Screened SUBCAB. Max |: *

S3X2.5+3K2.5/344X1 70°C(158°F)(187) -20mm |

23 94 20.42 Motor cable 462.5 MM2 Max 70°C(158°F)(12)-14mm | * | *

00=125-13.5 MM |

23 942043 Motor cable 4G4 MM2.OD=16-17 Max 7O°C(158°F)(16)-17mm =| [* | *

MM |

23 942054 | Motor cable SUBC7G.2.5MM2 182-162 “|e

23 942059 | Motor cable 4G2.5+2X1.5 M2 Max 70°C(158°F)(17)-18mm = |* |* + +

op=17-48 |

23 94.20 60 Motor cable 4G4+2K1.5MM2 920-22 cae aa

0D=20-22 MM |

2 94 20 60 Motor cable 7G4+2X1.5MM2 Max 70°C(158°F) + |e ts |e

0D=22-26 MM |

2 |erz0e2 | eorenble 7622x152 ez020 f+ [+ |-

00-20-23 |

23 942102 | Motor cable 14AWG/7 OD=18-20 918-20 eel

MM

23 9421 04 Motor cable *2AWG/T 0D=20-22 Subeab 12AWGI7 3.31mm* ae

uM (20-22mm)

23 942108 | Motor cable 1AWG/S.2-1-GC Subcab 10AWGI9-2-1-GC steeds

0D=20-22MM

Ponts List, Fiyot 3127.0900170/181/800

5.26mm? (20.3-22.3mm).

Qtyiversion

Pos. No_| Part. No | Denomination —__ le-e-s

23 94.21 08 Motor cable BAWGI3-2-1-GC Max 7O°C(158"F) Tee

(0D=27-29 MM

241 | 397 81 00 (EX) | Gland screw FOR CABLE ENTRY (10)- 20 mm 1/4

241 | 6421701 (EX) | Entrance flange atada|a

243 | 9303.48 Hex.socket hd screw 2|2|2\2

M12x40-A4-70 |

248 | 821761 Cutting screw TAPTITE-M6X 12 3|3|3

247 | 83.4296 Cable lug 2.5-6 MM2:M6 \2}2l2

247 83 43 36 Cable lug 6.1-10 MM2:M6 | 1 1

247 | 83.43.45 Cable lug 1-2.5 MM2MB Jaa 2a

[247 | 83.4348 Cable lug Uninsulated | 2/2

248 | 83.4423 Closed end splice 5.1-10.6(AWG 2/2 |2 I2

18-8) L=38,

248 | 83.4424 Closed end splice 3-6(AWG 12-10) ata |a fe

Lat

249 | 827463 O-ring 49.5X3 NBR t]atada

25 4435000 | Entrance cover 20-32 mm {4

25 | 443.5003 (EX) | Entrance cover a | |

25 4435100 | Entrance cover 40-20 mm |} |afa}

6 83.04 45 Hex socket hd serew jaa fala

MaX35-A4-60 |

a7 27479 O-ring 129.53 NBR afa fala

ar #28098, O-ring 128.5X3 FEM \1

2e1 | asss21 “Terminal clamp 6} lel6

282 | 835330 Terminal clamp eieie 6

283 |835322 End plate APPA - 11796 a] fala

24 — | 93 53.22 End plate APPA - 11796 vfafa fa

288 | 83.5331 End support 35X15 22 |2l2

207 | 443.6800 | Rail 35x15 t fafa fa

288 | 7220000 —_| Marking plate 22 |2|2

289 | 4271300 Matking tape t]afaa

§289 © |4717701 | Marking stip 2] |2

30 | $368600 | El.ead through unit, a] |a

30 | 7348900 | Eltead through unit lafata la

1 | 439.44 01 (EX) | Screw M14X1.25 3 \3

32 5960700 | Square washer 3 \s

33 82 17 64 Cutting screw TAPTITE-M6X20 7 7

34 82 50 60 ‘Sealing washer DUBO NR 301 3|3]3|3

35 4435700 | Sleeve 435mm | 1

ae gee exe oe ||):

[35 |aas.s702 | sleeve 63.5mm | 1

Pants List, Fygt 3127.090/170/161/890

a

Qtyversion

Pos. No | Part. No Denomination ges8

gre 8

36 504 76 06 Cable unit Jifa

37 504 78 07 Cable unit Ja jajaja

38 5188902 _| Leakage detect unit (FLS) Ja fafa la

39 5051200 _| Leakage detect unit (CLS30) } |afa

| 40 443.5510 | Bearing holder ) laa

| 40 443.55 11 | Bearing holder EX.VERSION 1 1

| 40 4435512 _| Bearing holder STANDARD 1 |4

VERSION

| at 833017 Ball bearing 35X80X34.9 Jala fala

42 827815 (O-ring 78X4 NBR afafa ya

|42 827918 (O-ring 784 FPM \1

43 6144900 | Bearing cover afafals

| 44 8937003 | Mechanical seal WCCRWCCR- ja 1

| TYPEO. |

44 593 7006 Mechanical seal WCCRIAL203, | a]a fafa

45 83.0323 Hex.socket hd screw | 5

M10X25-A4-70 |

45 83.03 48 Hex.socket hd screw 5/5/55

M12x40-A4-70

45 |a30351 | Hex socket hd screw a) ia

M12K55-84-70 |

46 518.0000 | Ci housing bottom Option | Ja

485180001 | of nousing botom Option js

46 | 604 47.00 Oil housing bottom ‘Standard aiijais

46 604 4701 | Oil housing bottom 1

47 | 443.4900 | Sleeve afafala

ws [e27295 | ong 102K3 Fem ae

48 82 73 90 ‘O-ring 19.2X3 NBR 2i2|2

49 4282217 _| Inspection screw j2 |2 |2

53 429.2104 Mechanical seal RSIC/RSIC- 4 1

TYPE!

53 5490701 | Mechanical seal WCCRWCCR- | 1

TYPET |

[53 [5037003 | Mechanical seal wecRWECR- a fa fala

TYPE O

54 5917900 | Insert ring | | fa

87 827429 | O-ring 179.1X8.4 NBR ) | fa

87 8274.38 (O-ring 249.1%8.4 NBR 1 1

58 4361000 Ring a] fa

75 607063 —_| Parallel key SMS 2306- 1 la

| | BHOX7H11 x45

2

Pans List, Fiygt 3127.090/170/181/800

QtyNersion |

Pos.No | PartNo | Denomination —__ - Be8s8

75 5077500 | Parallel key [a

162 | 930077 Shrink hose ID 6.4 To be used together with screened | + =

cable

166 | 6538500 | Connection plate Tlead cable end afata ja

166 | 6871400 | Connection piate 6-lead cablo end a] |

169 | 6674000 | Sticker 2|2}2|2

215 | s24061 Plain washer (10)-22 MM 1\4

215 | e24oa1 Plain washer (14)-20 MM

215 | 82.40.82 Plain washer (20)-32 MM alala

216 84.17 90 Seal sleeve (10}-12 MM \4

216 | 41791 Seal sleeve (12)-14 MM 1/4

216 | e4 1792 Seal sleeve (14)-16 MM 1|4

216 | 841793 Seal sleeve (16)-18 MM 1/4

216 | a4 1794 Seal sleeve (18)-20 MM ata] |

216 84 18.00 Seal sleeve (14)-17 MM 2) | [2]

216 | 84 1801 ‘Seal sleeve (17)-20 MM 2 2|

216 | 841802 ‘Seal sleeve (20)-23 MM 2 |2 2 \2

216 | 84 1803, Seal sleeve (23)-26 MM 2 |2 |2 |2]

216 | ea t8.04 Seal sleeve (26)-29 MM 2 |2 2/2

216 | sat805 Seal sleeve (29)-32 MM j2|2}2]e

217 | 678.5812 (EX) | Cable clip (10)-12 MM 1

217 | 6785814 (Ex) | Cable clip (12)-14 MM af4

217 | 678.58 16 (EX) | Cable clip (14)-16 MM. 1|4

217 | 67868 18 (EX) | Cable clip (16)-18 MM 14

217 | 678 58 20(EX) | Cable ciip (18)-20 MM a|4

218 | 8979802 | Ring afafa la

s12 | 827295 O-ring 19.23 FEM Extra O-rings for Insp. serews 4] |

912 | 827390 O-ring 19.23 NBR Extra O-rings forinsp. screws 4/4 | 44

12 | 827479 O-ring 129.5X3 NBR Extra O-rings for Entrance cover 4 ]1 4 1

912 82 8098 O-ting 129.5x3 FPM Extra O-rings for Entrance cover ja

1

FPM

Parts Uist, Fiygt 9127.090/1 70817800

Overview

Table of

Contents

Hydraulic Parts

This chapter contains the following topics:

Topic

oir.

Pump Housing .

LL Instaltation

CMT a

clu

50/60 Hz

60 Hz

GLHG En

NUT ence

Pump Housi

LL instalation

N_MT.

NOHT

NISH

DP MT.

DP HT.

Fo.

Plu

List

24 Parts List. Fit 3127,090/170/1817800

c_LT

Pump Housing

“LT” low head. Curve: 410, 411, 412, 441, 442

C_3127LT

22s

Pats Uist, Frat 3127.090/17a/181/890

LL Installation

“LT" low head. Curve: 410, 411, 412

Lt 3127

2 Pas List, Fig 3127.090/170/181/800

C_MT

“MT" medium head. Curve: 430, 431, 432, 435, 434

C_ 3127 MT

Pans Ust, Ft 3127.090/170/181/890

a

c_HT

50/60 Hz

“HT" high head. Curve: 250, 480, 481, 483, 484, 485

C_ 3127 HT

8 Parts Uist, Fig! 3127.0907170/181/800,

sora

60 Hz

“HT” hight head. Curve: 462, 463

C3127 HT

sor

Pans List, Fiyat 3127.090/170N181/890

c_HS

“HT” high head. Curve: 466, 468

HS 3127 HT

sane

ey ars List, Avot 3127.090/170"181/890

Pump Housing

“LT” low head. Curve: 420, 421, 422

N_ 3127 LT

sot

Parts Usl, Ft 3127 090/1707¥817090 ai

LL Installation

“LT* low head. Curve: 420, 421, 422

NL 3127 LT

22 aut List, Fly 3127.090/170/181/090

N_MT

“MT” medium head. Curve: 437, 438, 439

N_ 3127 MT

i

89

Parts List, Fiygt 3127 09001 70/181/090 23

N_HT

“HT” high head. Curve: 486, 487, 488, 469

N_ 3127 HT

1“ Pans Lit, Fiygt 3127.090/170/181/800

091

“SH” super high head. Curve: 245, 246, 247, 248, 249

N_3127 SH

suo

Pans List, Fiyat 3127 090 7a/V81/890

DP MT

"+MT* medium head. Curve: 400, 404, 470, 471, 472

DP 3127 MT

nes

26 Pants List, Fiygt 3127.090/170/181/800

DP HT

“HT” high head. Curve: 205, 206, 207,278, 276, 277 : a

D_3127 HT

Parts Ust, Fiygt 3127 090/170/181/890 a7

F_LT

wT" fow head, Gurve: 490, 491, 492, (499 (Cutting knife))

F_3127LT

Cutting knife

201

Pas Lis, Ft 3127, 090/170/181/890

P_LT

“LT" low head. Curve: 494

PL 3127

1907 70/N81/290

Fier 3127.05

List

ans List, iyo 9127.0907170/161/890

Hz, S-phase |

Tatyrversion |

Pos. No | Part. No Denomination eess

£883

| ;

60 | 3797904 _| Plain washer 124X172X11 mt 1

60 3797905 _| Plain washer 162X172X11 1 1

63 4394100 | Sleeve a] 4

64 3090300 | Impeller Medium head "MT", Curve 430, 1 1

| 50 Hz, S-phase |

64 | 3090500 | Impeller Medium head "MT", Cuve 43, 11

50 Hz, S-phase |

3090900 | Impeller Medium head "MT", Curve 433, 1 1

50/60 He, 1-phase / S-phase |

64 3091100 ‘| Impeller Medium head "MT", Curve 434, | 1 1

50/60 Hz, 1-phase / 3-phase

cs 3091300 | Impeller High head "HT", Curve 250,50 |1 | |1

Hz, S-phase

6 339.8900 | Impeller Heavy duty, HD "HT", Curve 466, | 1 A

50 Hz, S-phase |

64 339.9000 | Impeller Heavy duty, HD "HT", Curve 468, 1] ]

| 50/60 Hz, 3-phase | |

64 391 36 00 Impeller Low head "LT", Curve 441, 50 Hz, | 1 1 |

Siphase |

64 4296300 | Impeller Medium head "MT", D-impeller, | 1 1

Curve 470, 50 Hz, S-phase |

64 428.6301 | Torque flow impeller Medium head "MT", D-impeller, | 4 1]

Curve 471, 50 Hz, 3-phase |

64 429.6308 —_| Impeller Medium head "MT", D-impelier, | 1 1| |

Curve 472, 50/60 Hz, 2-phase |

4296330 Impeller HARDENED CASTIRON Medium head "MT", O-impelier, | 4 1

Curve 400, 50 Hz, 3-phase. | | |

84 4296331 | Impeller HARDENED CASTIRON Medium head "MT", D-impeller, | 1 1

Curve 401, 50 Hz, 3-phase. |

Cy 4301100 | Impeller High head "HT", Curve 463,601 1

Hz, t-phase / phase | |

64 430 12 00 Impeller High head "HT", Curve 462,60 1 4 |

Hz, 1-phase / 3-phase |

64 4301400 | Impetier Low head "LT", Curve 442, 50/60 | 1 1]

Hz, 3-phase

64 4301500 | Impeller Medium head "MT, Curve 432, [1 || 1

50/60 Hz, 3-phase |

6 4353100 | Impeller unit Low head "LT", Curve 490, 50 Hz, \

S-phase |

64 4353101 | Impeller unit Low head "LT", Curve 491, 50/60 | 1

Hz, 3-phase |

i epee inet oe scat ||

Pos..No | Part. No | Denomination er —lg ere

64 439.0900 | impeller High head "HT", Curve 480, 50 | 1 1] I

Hz, 3-phase |

64 4391200 | impelier igh head "HT", Curve 481, 50/60 | 1 1

Hz, S-phase

64 4391400 | impeller High head “HT”, Curve 483, 50/60 | 1 1

Hz, S-phase ) |

64 438.1600 | impetier High head "HT", Curve 484, 50/60 | 1 |

Hz, 1-phase / 3-phase |

64 4391800 | impelier High head "HT", Curve 485, 50/60 | 1 1

Hz, t-phase / 3-phase | | |

441.9000 | impetier Low head LT", Curve 410, 50Hz,| | 4 |

S-phase

64 4413001 | Impelter Low head "LT", Curve 411, 50/60 \a

Hz, S-phase

4419002 | Impetier Low head “LT”, Curve 412, 50/60 1

Hz, 1-phase / 3-phase

4865400 | impeller D=170 MM Low head "LT", Grinder, Cuve || 4

210, 50 Hz, 3-phase

64 486 54.09 Impeller D=159 MM Low head "LT™ , Grinder, } ja |

Curve 212, 216, 60 Hz,

‘-phase / 3-phase. High head | |

"HT'Curve266, 60H2, 1-phase/3. |

phase | |

64 4965411 | Impeller 0=170 MM High head "HT", Grinder, Curve | | 4 \t |

262, 60 Hz, 3-phase

66 535.0900 | impeller High head "HT", Grinder, Curve 1] fa

252, 50 Hz, 3-phase

64 5896400 | Impeller High head "HT", impeller, cuve 1) 4

275, 50 Hz, 3-phase |

64 5096401 | Impetier High head "HT", D-impeller, Curve | 1 +| |

276, 50 Hz, 3-phase |

64 5896402 | Impeller High head "HT", D-impeller, Curve | 4 1|

277, 50 Hz, S-phase

6 5896430 | Impeller HARDENED CAST IRON. High head “HT, D-impelier, Curve | 1 Jay]

205, 50 Hz, 3-phase. |

66 5896431 | Impeller HARDENED CAST IRON High head “HT*, D-impeller, Curve | 1 1

208, 50 Hz, 3-phase |

589 64 32 Impeller HARDENED CAST IRON High head "HT", D-impeller, Curve 1 Ht |

207, 50 Hz, 3-phase. | |

6083300 | Impeller High head "HT", Grinder, Curve a] fa]

255, 50 Hz, 3-phase |

64 6309200 | Propeller Low head "LT", Propeller, Curve | 4 1] |

494, 50 Hz, 3-phase |

64 6852800 | Impeller unit Low head "LT", Curve 493, 50 Hz, jo} |

S-phase

Pars Ust. Fat 3127 090 70/81/8090

“

| QtyVersion

Pos. No | Part. No | Denomination - = ge 58)

64 7162500 | Impeller DIA. 220 ‘Low head “LT, N-impeller, Curve | 1 1] |

420 | Medium head "MT" Curve

437, 50 Hz, S-phase

6 7162518 | Impeller DIA. 202 Low head"LT*, N-impeller, Curve }1 || 4

421 | Medium head "MT" Curve

438, 50/60 Hz, 3-phase

6 7162532 Impeller DIA. 188 Low head "LT", N-impeller, Curve | 1 1

422 / Medium head "MT" Curve

439, 50/60 Hz, 3-phase, 60 Hz,

a2 |

64 7162603 | Impelier DIA. 255 High head "HT" N-impelier, uve 1] 1) |

486, 50 Hz, 3-phase

64 7162623 | Impeller DIA. 235 High head "HT" N-impelier, Curve ]1 | | 1

487, 50/60 Hz, S-phase

64 7162643 | Impeller DIA. 215 High head "HT" N-impeller, Curve | 4 1

488, 50/60 Hz, S-phase |

64 716 26 63 Impeller DIA. 195 High head "HT" N-impeller, Curve | 1 1 | i}

4489, 50/60 Hz, S-phase, 60 Hz,

‘trphase |

64 7193800 | Impeller ‘Super high head "SH" N-impeller, 1 1

Curve 245, 50 Hz, 3-phase

6s 7193807 | Impelier ‘Super high head "SH" N-impoller, | 1 1

‘uide pin, Curve 246, 50 Hz,

Sephase

64 7193816 | impetier ‘Super high head "SH" Nimpeller, | 1 1} |

guide pin, Curve 247, 50/60 Hz,

S-phase |

4 719.3825 | impeller Super high head "SH" N-impeller, | 4 1

guide pin, Curve 248, 50/60 Hz,

S-phase

64 7193834 | Impeller Super high head "SH" Nimpeller, [1 || 4 |

guide pin, Curve 249, 50/60 Hz, |

3.phase |

65 631.9900 | Plain washer 1 1

66 486 4700 | Cutter whee! ae| al

86 532.0000 | Cutter wheel 1 1]

67 3092520 | Pump housing Medium head "MT" DN 150, 1 | 1

Undriled. For flush valve

to ANSI B16.1:-89; tab.5, EN |

eae, |

87 3092604 | Pump housing High head "HT" DN 80, drilled acc. | 1 |

to:Conversion unit 3038400

67 3092620 | Pump housing High head "HT" ON 80, undriled. | 4 1

For fush valve |

er 3092630 | Pump housing ‘Super high head "SH"DN80, 1) |) |

| undriled ) | |

Pans List, Fat 2127.090/170/181/680

Pos. No. | Part. No Denomination ae oe

67 309 26 61 Pump housing High head "HT", Super high head |1 | | 4

"SH" DN 80, drilled to EN 1092-2

tab. 9 |

87 3082722 | Pump housing Low head "LT* DN 150, undrilied | 4 1

67 3082726 | Pump housing Low head "LT" DN 150, drited to | 4 | 4) |

EN 1092-2 tab. 9, ANSI B16.1-89; |

tab

87 3095805 | Pump housing High head "HT" DN 100, drilled to | 1 1

ANSI 816.1:-89;tab1.5 |

er 3095920 | Pump housing High head "HT" DN 100, undriled. | 1 1| |

For fush valve |

or 3095921 | Pump housing High head "HT" DN 100, driled to | 4 1

EN 1092-2 tab. 9. Prepared for ' | |

flush valve

67 339.8800 | Pump housing High head "HT" DN 100, undriled. | 1 1

Heavy duty version

67 3967300 | Diffuser coat. Low head "LT" DN 600, Propetier | 4 | | 4

version. "LL"

67 4264405 | Pump housing Medium head "MT" DN 100, driled | 1

to ANSI B16.1-89; tab.5

67 | 4264620 | Pump housing Mesium nead "MT ON 100, 0) |

undfilled |

67 426.4422 | Pump housing Medium head "MT" DN 100, died | 4 1

to EN 1092.2 tab. 9 | |

67 4296000 | Pump housing Medium head "MT" ON 100, 1 1] |

undriled. D-version

67 | 4296020 | Pump housing Mesum head "MON 100, ||

Lndriled. Propared for fush valve, |

D-version | |

7 4296031 | Pump housing Medium head "MT" DN 100, 1 1

Lndriled. Hardened cast iron.

Deversion. Prepared for fush

valve |

er 4353206 | Pump housing Low head "LT" DN 150, driled to | 1

ANSI B16.1:-89; tabl.5, EN 1092-2 |

tabs

67 4651405 | Pump housing High head "HT* DN 100, driled to 1 1

ANSI B16. 1-89; tab.5 |

67 4651422 | Pump housing High head "HT" ON 100, undriled. 1 | 4 ||

Prepared for lush valve | |

87 4851424 | Pump housing High head "HT" DN 100, dried to | af ofa} |

EN 1092-2 tab. 9. Prepared for

flush valve |

67 508 65 00 Pump housing Low head "LT" DN 50, Vertical | | 1

outlet. Grinder-version,

H-installation,

Parts Uist. Fat 3127 090/170/181/800

6

‘Qty/Version

Pos. No | Part. No Denomination = ——|g- e238

67 ‘508 65 01 Pump housing Low head "LT" DN 60, Horizontal | [1 1

outlet. Grinder-version.

Pinstalation. |

67 508.6600 | Pump housing High head "HT" DN 50, 1 1

Vertcal outlet. Grinder-version.

installation

67 508.6601 | Pump housing High head "HT" DN 50, ji 1

Horizontal outlet. Grinder-version. |

P.installation |

67 5896300 | Pump housing High head "HT" DN 80, D-version | 1 1) |

67 689.6330 | Pump housing High head "HT" DN 80, D-version. | 1 1

Hardened cast iron |

67 608 34.00 | Pump housing High head "HT" DN 50, Ai 1]

Grinder-version. H-nsiallation |

67 608 3401 | Pump housing High head "HT" DN 50, 1 |

Grinder-version. P-installation

67 608 3402 | Pump housing High heed "HT" DN 50, a{ ja

Grinder-version. H-installation |

67 608 34.03 | Pump housing High head "HT" DN 50, a 1

Grinder-version. P-installation

67 6309300 _ Diffuser uncoated Low head "LT" DN 600, PLversion 1/1

68 486.4200 | Cutting ring Curve 210, 212 1 1]

68 486.4201 | Cutting ring Curve 216 1 1

68 5086700 | Cutting ring Curve 252, 262 1 1

68 5086701 | Cutting ring Curve 266 1 1

69 83.0273 Hex socket hd screw 3 3

MEX12-A4-70

70 82.357 lain washer A4-A170 1 a| |

70 82.38 00 Plain washer STAINLESS STEEL 1 1] |

AS |

70 3381301 | Plain washer Curve: 400, 401, 205-207, A 1

410-412, 430-436, 441-442,

250, 462-463, 470-472, 275-277, |

480.481, 48-485 |

70 4039404 | Ring 1

70 496.4300 | Sleeve Curve: 210-212, 216, 252, 255, 1 1

262, 266

n 3435300 | Square nut HS-version a) 4

2 83.03 51 Hex socket hd screw Nimpeller; LT, MT, HT 1 1]

M12X55-A4-70 |

R 83.03 58 Hex socket hd screw M12X100 A4 1 1

70

R 83.04 56 Hex.socket hd screw ur aT J [af fa

M10X35-A4-60

2 844254 Hex socket hd screw MC6S D; MT, HT. G; LT, MT, HT \4 1|

12X40-2343, id |

“ Pans List, Fit 3127 090/170/161/890

QtyWersion |

Pos. No. Part.No | Denomination — =, —le-e-z 2

72 438.5700 | Hex socket hd screw SOCKET T Tt] ]

HEAD SCREW SPEC. |

B 3035000 | Ring Rubber. HT 462-483 a} fa]

Fy 3082900 | Wear ring Rubber. MT 430-435 a] fa

3 3093400 | Wear ring Rubber. HT 250, 480-485 +) 4

73 3093600 | Ring compl Rubber UT 410-412, a4tage x) | 4

73 314.8800 | Ring Brass. HT 462-463 a] ia

73314802 | Ring Aluminium bronze. MT-4s0495 | | 64 | |

73 3148803 | Ring Aluminium bronze, LT 410-412, 4 | | 4

441-442

13 3148804 | Ring Brass. HT 250, 480-485 a] fa

3 4875200 | Wear ring Brass. MT 436 a] ofa

nm 6309500 | Ring Stainless steel. PL 494 1] ja

72 [98200 | Sietn cover care: 452485 1| |r]

79 339.9400 | suction cover Curve: 466-468 1] fa

79 680.3400 Insert ring Cure: 437 - 439 a] fa

79 6803500 | Insert ring Curve: 420-422 1] fa

79 682.4900 | Insert ring Curve: 486 - 489 a] fa] |

79 7254000 | Insert ring Cune: 245 - 249 ja] fa

20 81.4905 | Hexagon head screw 4] ja] |

M12X25-84-70 | |

80 830455 | Hex-socket hd screw e| |s

MI2XT10-A4-80 | |

82 827501 O-ring 279.3X5.7 NBR 1 1] |

83 4296700 | Square nut 4] ia

84 4296600 | Using D=100mm +) 4

84 5262000 | Seal ring D= 80mm ty fel

86 3965500 | Pump housing cover 1|

88 | 7193900 | insert ring laf fa

ar 809529 | stus Mt2x35-42-70 F-version 3| |

87 8097 40 ‘Stud 12X35-A4-70 2 2| |

er 84.94 94 Stud 12X80-4-70 ja) la

88 82.23.35 Hexagon nut M12-A4-70 je] je

88 82.2729 Lock nut Mi2-A4-70 | 3|

89 296.6200 | Washer 0.3 MM NUT, MT, HT, LL Ja] |4

89 2986201 | Washer 1.5 MM NUT, MT, HT, LL a] i4

88 2986202 | Washer T, MT, HT, LL Jz 2] |

a9 3347100 | Adjustment washer FLT; thickness = 0.3 mm | ar

89 3347101 | Adjustment washer FUT: thickness = 1.5 mm | [| |

1 827905 ——_| O-ring 10X5 NBR ja

Parts Uist. Fig? 3127.090/1 7071817890

Pos. No Part. No Denomination - ges3

gr28

[ss 339.9200 | Wear protect. compl. intended for HS Curve 466,468 1 | [1 |

94 9283.41 Gering 1 1

95 630 9400 | Bell mouth 1 1

124 83.03.23 Hex.socket hd screw j2| |2

MI0X25-A4-70 |

122 433 56.00 Cover 1 1]

423 | 6479900 —_| Gasket Rubber-bonded aramid fibre 1

123 | 6479901 | Gasket FPM af ofa

201 | 6838300 | Cutting knife fd

4

ans List, Fst 3127.090/170/181/690

Overview

Table of This chapter contains the following topics:

Contents

Topic

CPINP...... 48

CsINS...

Pans Ust, Fyat 3127.090/170/181/890 a

CP/NP

CP, FP, NP 3127

Discharge connection as accessories, see www.ittwww.com for further information,

sores

46 Pants List, Fiygt $127.090/170/181/890

CSINS

CS, FS, NS 3127

0253

Parts List, Ft 3127.090/170/181/800

CTINT

CT, FT, NT 3127

50 Pans Lis, Fiygt 3727.090/170/161/800

sore

CZINZ

CZ, FZ, NZ 3127

0670

Pats List, Fhgt 9127.090/170/181/800

DP MT

DP 3127 MT a

Discharge connection as accessories, see www.ittwww.com for further information.

ores

82 Pants List, Fiygt 3127 090/170/1817000

DP HT

DP3127HT

Discharge connection as accessories, see www.ittwww.com for further information.

Parts List, Fygt 3127. 090/17a/181/090

FJ

FS3427 LT

2s

Py Pans Lis, Fiygt 3727, 090/170/181/800

FS

Fs3i27iT : _

0ase

Pars List, Fygt 3127.090/17a/81/890

HS

HS 3127 HT

ass

88 Pants List, Fiygt 3127.000/170/181/000

LU/NL

LUNL, 3127000

MP

MP 3127.170/890

Pans List, gt 3127.0907170/781/800

MF

MF 3127.170/890

41

i

110.

112-

‘nea

Pars List, Fiygt 3127.090/170/181/090 59

PE

"PL 3127

aio7e

oo Pans List, Fygt 3127.090/170/181/850

List

Pots List, Frat 3127.090/170/181/890

Pos. No | Part. No Denomination

61 3808100 | Sliding bracket

8 4049001 | Sting bracket unit

Cl 4640600 | Sliding bracket FP °LT"; BP "HT";

DP"

61 4640601 | Sliding bracket Prepared for flushvalve execution

61 5214800 _| Sliding bracket DP "MT"

et 5896500 | Sliding bracket oP -HT

62 e141 at Hexagon head screw

M16X40-A4-70 |

62 81 49.32 Hexagon head screw a} la)

M16x45.A4-70 |

62 83.04 53 Hex socket hd screw a2

M12X45-A4-80 |

7 814181 Hexagon head screw 4

M16x40.44-70

" 814912 Hexagon head screw 4) 14

M12x35.44-70 |

96 404 $1 00 Discharge con.stat, Optional. F-version 1 |

96 486 55 00 Discharge connection INOUT High head "HT" DN 50, ISO G2A 1 1]

50/50 MM Inner. Grinder-version |

96 486.5501 | Discharge connection IOUT High head "HT" DN 50, 2-11 4/2 1 1]

| 50/50 MM NPT. Grinder.version |

%6 6199500 Discharge con stat. INOUT 50/50 Low/High head "UT-HT" DN 50 tf taf

Mau "MP", ISO G2A inner. Top 50 and |

Top 65 |

96 6199501 | Discharge con.stat. IN]OUT 50/50 Lowitiigh head “LT-HT" DN 50 1] fa

wn "MP", 2-11 1/2 NPT inner. Top 50 | |

and Top 65

o7 | 84.34 38 Hexagon head screw 4| a

M20x120-A2-70 |

98 823526 Plain washer 20-A2-A-170 a} fa

99 8223.38 Hexagon nut M20-A4-70 4 |

99 822362 Hexagon nut M20-A2-70 4 |

101 6697700 | Guide bracket unit SS Grinder-version a] fa

102 | 2598204 —_| Discharge connection MediumHigh head "MT-HT" ON | 4 1]

100 |

102 | 2596405 | Discharge connection Medium/High head "MT-HT" ON | 4 1] I

100, Thread : 4-8NPSM Outer |

102 |2598408 —_| Discharge connection MediumiHigh head-wT-HT on [4 }-~)4 |

100, Thread ISO Ga Outer | |

102 | 2855700 _| Discharge connection Low/Medium head "LT-MT"Dn 4 1

150

Qty/Version

Parts List, Fit 3127 08001 70/t81/800

Pos. No | Part. No | Denomination _ -t-o-€

102 3093100 | Discharge connection LowMedum head "UT-MT Dn |t | |t |

4180, Thread: 6-8NPSM Outer

toz | 3003101 | bischarge conection Medium head "MT? ON 150, 1 | 1 |

Thread : ISO GEA Outer |

102 3098000 _| Discharge connection 8° Low head "LT* DN 200 a] fa

toz | 3100301 —_| Discharge connection High head "HT" ON 75 1} |

to2 | 3408800 —_| Discharge connection High head "HT" DN 100 a) fa

102 | 3408900 | Discharge connection High head "HT* DN 100, Thread: 1 | 1 |

4-8 NPSM Outer |

102 340 89 01 Discharge connection High head "HT" DN 100, Thread: 1) | 1 |

180 G4a Outer | |

102 | 3855203 | Discharge connection 38NPSM High head "HT"ON75,Thread: | | 1 |

3:8 NPSM Outer |

402 | 3855204 —_| Discharge connection ISOG3_—-High/Super High head "HT-SH” 1 || 1

| DN 75, Thread : ISO G3 Outer. |

Quick Coupling. |

102 |391.4200 | Discharge connection Low head “LT” DN 100, Manure 1|

Angled 90 dgr. |

102 | 391.4300 | Discharge connection Low head “LT” DN 100, Manure, 1

Thread : 4-6 NPSM Outer

102 | 4047100 | Discharge connection Low head *LT* DN 100, Manure 1

aon |

103 | 814935 | Hexagon head screw a] fa

| M16x60-A4-70 |

103 [814995 | Hexagon head screw at fal |

MI6X65-A4-70

103 [814960 —_| Hexagon head screw 8] |e

M20X70-A4-70

103 | 843434 | Hexagon head screw 2

M20X80-A2-70

403 90.3254 —_| Locking liquid LOCTITE 601 a

104 | 82.3526 | Plain washer 20-A2-A-170 | 2|

104 92.3578 Plain washer 16-A4-A-170 \4 4|

104 823730 _| Pain washer TBRSB-20-200 | 2

HV-FZB |

104 | 93.0453 | Hexsocket hd screw 2

Mt2X45-A4-80

}106 | a22335 | Hexagon nut M12-A4-70 2] |2

10s | 822337 | Hexagon nut M16-A4-70 a} |4

10s |622398 | Hexagon nut M20-A4-70 Ja] |e

105 | 823577 —_| Plain washer A4-A170 | 2

107 2598300 —_| Gasket 4° * a| fa

107 | 2956400 | Gasket 6° e 1| |

407 3100500 | Gasket s a] ja

QtyNersion

Pos.No_| Part. No___| Denomination - = ge-=-2

107 339.8700 | Gasket 4, HD 1] EF ] |

103 | 436.8400 | Stand unit SINS; HT fy fad]

108 436 94 01 Stand unit CSINS; LTIMT Ja]ofa

110 | 3080500 | stud Me 3) 3

a 83 1828 Coupiing part 6" 6 4

+11 |8318.46 | Coupling part DN 75 G3" INNER Ja] fa

| storz |

jan 831934 | Coupling part DN 110 G4" INNER a] |

STORZ |

im" 831836 | Coupling part DN 150 GSB INNER a] fal |

STORZ

at 83.9249 | Coupling 532-132 ALENCO-EGNELL 32-132 a] ja

jan 5054301 | Nipple NPT 2 NPT 2 a] fa

112 | 8344800 | Foot complete MF-version js] |s

13, 814158 Hexagon head screw | |2

M12x45-A2-70

13 | 822338, Hexagon nut M20-A4-70 2

114 | 4996900 | Guide ring unit 1

116 | 4161301 | Plate 1) Ja

18 | 823877 Plain washer A4-A170 4) fa

118 | 82.3578 Plain washer 16-A4-A-170 a} ja)

125 | 3067000 | Puller screw compl. M16X285. imp, PL-prop a] da]

109 |

125 | 4385800 | Hexagon head screw M16X218—F-imp. +| Ja

109 |

126 © | 4952700 | Clip. MP a] fa

127 | 495 26 00 Clip Mp 1 1

128 | 815859 Hexagon head screw a] fa

MBX65-A4-70 |

|120 | 822332 Hexagon nut M8-A4-70 a] fa

130 | 823574 | Plain washer 8-A4-170 a{ ja

132 | 827417 | O-ring 124.X5.7-NBR a] |a

(132 [827486 O-ring 164.3X5.7 NBR fo

192 | 82.7488 O-ring 174.3X5.7 NBR a] ia

133 303 72 00 ‘Suction connection STATIONARY High head "HT" DN 100, undrilled 1 \1

138 | 3087201 | Suction connection STATIONARY High head "HT" DN 100, driled to (4 | | 4

EN 1092-2 tab9 | | |

133 3037205 | Suction connection High head "HT" DN 100, driledto 4 | 1

| ANSI B16.1 1-88:tab 5 |

133 | 303.8500 —_| Suction connection STATIONARY . Medium head "MT"DN 150, 1 | 4

| i undriled |

Parts List, Fiygt 3127 090701817090

o

PartNo Denomination ee oe

3038506 | Suction connection STATIONARY Medium head "MT" DN 150, driled | 1 1

te EN 1092-2 tab.9 and ANSI

B16.1-89;2b.5

183 | 309.4600 | Suction connection Low head "LT" DN 200, undrilled | 4 1

193 | 308.4806 | Suction connection Low head "LT" DN 200, driled to | 1 1

EN 1092.2 tab. 8 and ANSI B16.1;

tab

| 133 309 46 07 ‘Suction connection Low head "LT" DN 200, driledto 1 0/4

EN 1092-2 tab.9 |

11331 ].814906 | Hexagon head screw a] ja] |

| M12X30-A4-70 |

1331 | 3038700 | Cleaning door Intended for MT 1 1

| 133.4 | 308.4800 | Cleaning door Intended for LT 1 1] |

1332 | 3037600 | cleaning door Intended for HT a| fa} |

133.2 | 303 88.00 Gasket Intended for LT/MT 1 a]

133.3 | 814181 Hexagon head screw a] jaf f

| M16x40-A4-70 |

[1333 |3037700 | Gasket Intended for HT 14

194 | 8543015 | Starter START 351-400-B-532-14 \4 1

[isin [cst antolll |e! soerostoseea's Ale

Pant List, Fygt 3127 090/170/181/800

Parts for Service

Pants List, Fit 3127.090/170/181790

List

Pos. No | Part. No Denomination

800 | 80.3233 (Ovting kits 8127.080,170,180,880

800 | 8032 74 | O-ring kits

| 3127.090/180F,0,SUPHT

808 =| 618.8915 | Impeller kit “LT” Curve 210, 50Hz, 3-phase 1 1

808 =| 618.8916 —_| Impeller kit “HT” Curve 252, 50Hz, 3-phase 1 1

808 6188917 | Impeller kit “HT" Curve 262, 60Hz, 3-phase 1 1

808 = 618.8918 | Impeller kit. CHT" LT" Curve 266/216, 60Hz,| | 1 1

‘-pase / 3-phase

808 649 30 00 N-pump kit CURVE:420 "LT™ \4 \4

808 © 6493001 | N-pump kit CURVE:421 "LT* 1 1

808 649 3002 N-pump kit CURVE:422 "LT" \4 1

808 650 06 00 N-pump kit CURVE:437 "MT" \4 1

808 | 6500601 | Nepump kit CURVE:438 "MT Hi 1

808 | 6500602 —_| N-pump kit CURVE:439 "MT fi 1

808 | 663.3000 | N-pump kit CURVE:486 "HT" 1 1 |

808 | 663.3001 | N-pump kit CURVE:487 “HT” Al 1

808 | 6633002 N-pump kit CURVE:488 "HT ja 1

808 | 6633003 N-pump kit CURVE:489 "HT" a} fa

900 601.8909 | Basic repair kit 3127.090,180 Incl. mechanical seals a] ia

WCCRIWCCR

$00 | 6018910 Basic repair kit 3127.090,180 Incl. mechanical seals 1 1

WCCRIWCCR, O-rings kit | |

3127090180 F, OSUP.HT |

900 | 6931900 | Basic repair kt Incl._mechanical seals a}a fata]

WCCRIWCCR, WCCRIA203.

O-rings kit 3127.090, 170, 180,

890

900 | 6931901 | Basic repair kit Incl. mechanical seals a] fal

WCCRIWCCR, WCCR/AZ203.

‘O-rings kit 3127.090/180 F, D

‘SUP. HT | |

900 6931902 | Basic repair kit Incl. mechanical seals RSICIRSIC, \4

WCCRIAI203. O-rings kit

3127.090, 170, 180, 890

900 | 6931903 | Basic repair kit Incl. mechanical seals RSICIRSIC,| [1 |4 1

WCCRIAI203. O-rings kit

3127.090/180, F, D, SUPHT

sor |e01752 | on "20 tire" 2|2f2l2

904 [4369700 | Mounting tool fafa fafa

6 Pans List, Fit 3127, 090/970/1817890

i os

What can ITT Water & Wastewater do for you?

Integrated solutions for fluid handling are ofered by ITT Water & Wastewater 2s a world leader in trans

port and treatment of wastewater, We provide a complete range of water, wastewaler and drainage

Bumps, equipment for monitoring and control, units for primary and secondary biological treatment,

products for fitrtion and disinfection, and related services. ITT Water & Wastewater, headquartered in

‘Sweden, operates in some 140 countries across the world, with own plants in Europe, China and North

‘and South America, The company is whelly owned by the ITT Corporation of White Plains, New York,

supplier of advanced technology products and services.

%

ree SANITAIRE: WEDECO @uoroww

Visit our Web site for the latest version of this document and more information

‘wel 5

bservices.ittwww.com/tpi

IT Water & Wastewater AB Visting adress: Tel, +45-8-475 60 00

SE-174 87 Sundbybers Gesalvagen 33 Fax $46-8-475 69 00

Swesen Sundberg

Swesen

© ITT Wiater & Wastewater AB. The original instruction is in English

‘Ai non-Engish Insitutions are translations of the anginal instruction.

"397426, 7.0_en.US, 2011-03 GPL.S127

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- EngProd - 2014 - EPP302 - Instalacoes Industriais - P6 - GabaritoDocument4 pagesEngProd - 2014 - EPP302 - Instalacoes Industriais - P6 - GabaritoAlexandre Jusis BlancoNo ratings yet

- EngProd 2014 EPP302 - Instalacoes Industriais P3 GabaritoDocument4 pagesEngProd 2014 EPP302 - Instalacoes Industriais P3 GabaritoAlexandre Jusis BlancoNo ratings yet

- Corrosao EnsaiosDocument75 pagesCorrosao EnsaiosAlexandre Jusis BlancoNo ratings yet

- EngProd - 2014 - EPP302 - Instalacoes Industriais - P1 - GabaritoDocument4 pagesEngProd - 2014 - EPP302 - Instalacoes Industriais - P1 - GabaritoAlexandre Jusis BlancoNo ratings yet

- (K-05) MC-3902.01-8211-175-QCI-001 - Memorial de Cálculo PDFDocument133 pages(K-05) MC-3902.01-8211-175-QCI-001 - Memorial de Cálculo PDFAlexandre Jusis BlancoNo ratings yet

- High Temperature Tensile and Strain Hardening Behaviour of Aa5052/9 Vol. %ZRB Insitu CompositeDocument7 pagesHigh Temperature Tensile and Strain Hardening Behaviour of Aa5052/9 Vol. %ZRB Insitu CompositeAlexandre Jusis BlancoNo ratings yet

- Relatório de ArDocument4 pagesRelatório de ArAlexandre Jusis BlancoNo ratings yet

- MateriaisDocument8 pagesMateriaisAlexandre Jusis BlancoNo ratings yet

- 18 04 Palestras Tribologia Profa MCristinaMFariasDocument93 pages18 04 Palestras Tribologia Profa MCristinaMFariasAlexandre Jusis BlancoNo ratings yet