Professional Documents

Culture Documents

KRD-8 06.08.2017

KRD-8 06.08.2017

Uploaded by

SE EST0 ratings0% found this document useful (0 votes)

20 views3 pagesear

Original Title

KRD-8_06.08.2017

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentear

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views3 pagesKRD-8 06.08.2017

KRD-8 06.08.2017

Uploaded by

SE ESTear

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

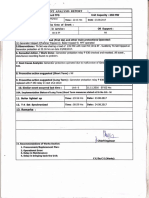

EVENT ANALYSIS REPORT

_|

UNITNO :8 _ |TPS: Koradi ‘Unit Capacity : 660 MW

: Time 00:05|ate#- 06.08.2037 No

1. *HO Code: Station Code: T004 Tire [Of days from last synchronization: 10 Days

jand 6 Hours

‘Operating conditions at the time of Event :.

—_—toad MW ‘Coal_cycles In service ‘Oil Support

144 MW D wl

3. Nature of Event : Set withdrawn for attending various shutdown works.

Ia. Name of First Up, Main Protections & protection on which GCB tripped:

1) MFT operated (Loss of flame). 2) Turbine trip. 3) Gen.Protection trip alarm appeared. 4) Lock out relay 86 GA 1/2 operated.

IS A) Observations :- While withdrawing unit, only one coal cycle was in service without oll suppor and coal flow was 28}

|TPH CV was 4000. Due to high CV of coal , BID Lock at 150 MW due to ecostezming & load was not reduced to minimum .

Hence hand trip nat done due to high load and Boiler failed on loss of flame

[5 B) Remedial Action/Work done :- Work done by BM section: As per the attached sheet.

[6. Root Cause Analysis :- Set withdrawn (planned outage) for attending various shutdown works.

7. Preventive action suggested (Short Term) = As per the atiacne

8. Preventive action suggested (Long Term!

19. Similar event occurred last tim

10. Boiler lighted up Time- 12:39 Hrs Date — 12.08.2017

111. T-A Set Synchronized Time - 21:08 Hrs Date ~ 12.08.2017

[12. Remarks : Work done by EMT section: 06.08.2017. Ai & (iz are covered with polythene for Boiler

washing activity.

107.08.2017:- ID Fan outlet damper control box mounted end trial take

IMOBFP,

108.08.2017:- # P/M of FD fan-A&B, GT R,Y,B & UT 182, common

IC.w.182. # C&r TPS panel 220v OC source 182 checking, con

supply voltage is observed and contactor deenergised. Therefore to avoid tripping both sources are kept on source 1. # H.P.

heater 6A & 7A MOV actuator replaced, L.P. cleanup blow down MOV attended. # ESP pass A,B,D & E FRP rod inspection

carried out, 6 Nos. rod found damage & is replaced by new. # P/M of Gene: p rings, 4 Nos. brushes replaced.

J09.08.2017:- # P/M of soot blowers 207, 243 & 264. # 220v battery bi lis are replaced. # Boller feed pump

I/L MOV attended. # 220v battery charger P/M done. # P/M of ‘Seal air fan A & B done. # Seal air fen A

lf 1D fan 8A found abnormal sound in motor replaced with spa Slip ring polarity interchanged.

10.08,2017:- # Ventilator V/v was replaced with modified MOV & trial taken. # P/M of TDBFP A&B, A.CAOP 1 & 2, AC. EOP

Jdone, L.P. & H.P. Vacuur pump done.

11.08,2017:- # ECP panel 220V D.C. supervision relay 80 A & 80 B found fauity replaced by new. # ESP pass F field no, 3 HT

side insulator is changed. # All LRSB tral is taken. # P/M of 220v DC charge” & settings checked.

32.08.2017:- # P/M of RAPH A & B done, # Two Lc

ISG/TG charger and settings checked.

|Work done by TM section: 1) Condenser fil test for vacuur

preventive maintenance done. 4) TD- B governing done. 5) All CEP preventive

leakage attended. 7) 24 mtr clean up MIV gland leakage attended. 8) DMC\\

replacement done. 10) Ventilator V/v shaft replacement done. 11)

leakage attended. 13) HPH orifice modification done (Vent line).

intenance of CEP-A&C, ID fan A&B,

trol panel, P.R.V & Buckholz relay, A.C.W. 1,

During changeover interruption in

tenance done. 6) CRH pegging MOV gland

np overhaul done. 9) SCCW fitter

2 PM cone, 12) Clean up line safety V/V

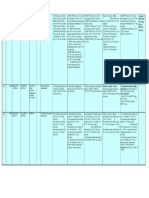

‘Surpjam 4q papuany|

‘Surpjom £q papuany|

aiquoridde yoy pasejdas 1ayse9|

aiqeandde oN -panejdas

io}

wio] 3u0y

SuonepuoUTUOIoy

‘uop {yom SuIysHY apts 49}BA YC 494009 a

‘uop 30M juouDse} dau pnp A/a a

‘uop om Bupsou aeyeay

‘uop 0m auEeda NENW = FOP AIA HSL

2uop pow wwDsej das puBID 1OF NA HSC

au0p 10M,

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- NTPS - Highlights and Records For FY 2017-18Document2 pagesNTPS - Highlights and Records For FY 2017-18SE ESTNo ratings yet

- All India Nov-17Document2 pagesAll India Nov-17SE ESTNo ratings yet

- BTL Index Nov2017Document4 pagesBTL Index Nov2017SE ESTNo ratings yet

- Station Capacity (MW) Rank PLF (%) : Central Central CentralDocument2 pagesStation Capacity (MW) Rank PLF (%) : Central Central CentralSE ESTNo ratings yet

- Compiled by EST-HO MumbaiDocument47 pagesCompiled by EST-HO MumbaiSE ESTNo ratings yet

- Sop Chlorine and Ammonia GasesDocument3 pagesSop Chlorine and Ammonia GasesSE ESTNo ratings yet

- Event Analysis: TPS: Unit - Date: Operating Coal SeruiceDocument1 pageEvent Analysis: TPS: Unit - Date: Operating Coal SeruiceSE ESTNo ratings yet

- BTL 500MW U4 Updated 06072017Document1 pageBTL 500MW U4 Updated 06072017SE ESTNo ratings yet

- Sept 17 New DataDocument8 pagesSept 17 New DataSE ESTNo ratings yet

- At Of: Eyent Analysis NewlarliDocument1 pageAt Of: Eyent Analysis NewlarliSE ESTNo ratings yet

- PRS-4 16.12.2015Document1 pagePRS-4 16.12.2015SE ESTNo ratings yet