Professional Documents

Culture Documents

Mechanical Properties of Alloy Steel - GBT 17107-1997 PDF

Mechanical Properties of Alloy Steel - GBT 17107-1997 PDF

Uploaded by

AM0%(1)0% found this document useful (1 vote)

505 views4 pagesOriginal Title

Mechanical properties of alloy steel - GBT 17107-1997.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0%(1)0% found this document useful (1 vote)

505 views4 pagesMechanical Properties of Alloy Steel - GBT 17107-1997 PDF

Mechanical Properties of Alloy Steel - GBT 17107-1997 PDF

Uploaded by

AMCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

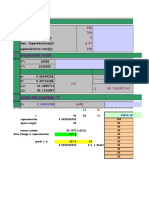

Table 4.

Mechanical properties of alloy steel (Chinese standard: GB/T 17107-1997) 1/4

Mechanical properties

Heat Dimension Tensile strength Yield point Elongation Reduction Absorption Brinell

Chinese symbol (ISO)

treatment (e.g.length) (N/m) (N/m) (%) of area (%) energy (J) Hardness

thermal 100 685 440 15 50 - -

30Mn2 28Mn6

refining 100300 635 410 16 45 - -

normalizing+ 100 620 315 18 45 - 207241

35Mn2 36Mn6 tempering 100300 580 295 18 43 23 207241

thermal 100 745 590 16 50 47 229269

refining 100300 690 490 16 45 47 229269

normalizing+ 100 690 355 16 38 - 187241

45Mn2 42Mn6 tempering 100300 670 335 15 35 - 187241

600 470 265 15 30 39 -

20SiMn - normalizing+ 600900 450 255 14 30 39 -

tempering 9001200 440 245 14 30 39 -

300 490 275 14 30 27 -

normalizing+ 300500 470 265 13 28 23 -

20SiMn - tempering 500750 440 245 11 24 19 -

7501000 410 225 10 22 19 -

100 785 510 15 45 47 229286

35SiMn - thermal 100300 735 440 14 35 39 271265

refining 300400 685 390 13 30 35 215255

400500 635 375 11 28 31 196255

100 785 510 15 45 31 229286

42SiMn - thermal 100200 735 460 14 35 23 217269

refining 200300 685 440 13 30 23 217255

300500 635 375 10 28 20 196255

thermal 100 835 540 15 40 39 229286

50SiMn - refining 100200 735 490 15 35 39 217269

200300 685 440 14 30 31 207255

300 500 305 14 40 39 -

20MnMo - thermal 300500 470 275 14 40 39 -

refining 300 500 305 14 32 31 -

300500 470 275 13 30 31 -

thermal 100300 635 490 15 45 47 187229

20MnMoNb -

refining 300500 590 440 15 45 47 187229

thermal 500800 490 345 15 45 39 -

20MnMoNb - refining 100300 610 430 12 32 31 -

300500 570 400 12 30 24 -

thermal 100300 765 590 12 40 31 241286

42MnMoV - refining 300500 705 540 12 35 23 229269

500800 635 490 12 35 23 217241

thermal 100300 885 735 12 40 31 269302

50SiMnMoV - refining 300500 885 635 12 38 31 255286

500800 835 610 12 35 23 241286

thermal 100200 865 685 14 40 31 269302

37SiMn2MoV - refining 200400 815 635 14 40 31 241286

400600 765 590 14 40 31 229269

normalizing+ 100 390 195 26 50 39 111156

15Cr tempering 100300 390 195 23 45 35 111156

normalizing+ 100 430 215 19 40 31 123179

20Cr 20Cr4 tempering 100300 430 215 18 35 31 123167

thermal 100 470 275 20 40 35 137179

refining 100300 470 245 19 40 31 137197

30Cr 34Cr4 therm.ref. 100 615 395 17 40 43 187229

35Cr 34Cr4 therm.ref. 100300 615 395 15 35 39 187229

100 735 540 15 45 39 241286

40Cr 41Cr4 thermal 100300 685 490 14 45 31 241286

refining 300500 685 440 10 35 23 229269

500800 590 345 8 30 16 217255

thermal 100 835 540 10 40 - 241286

50Cr -

refining 100300 785 490 10 40 - 241286

normalizing+ 100 440 275 20 50 55 159

12CrMo -

tempering 100300 440 275 20 45 55 159

quenching 100 440 275 20 - 55 116179

15CrMo - + 100300 440 275 20 - 55 116179

tempering 300500 430 255 19 - 47 116179

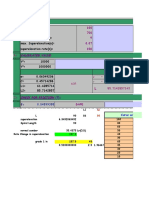

Table 4. Mechanical properties of alloy steel (Chinese standard: GB/T 17107-1997) 2/4

Mechanical properties

Heat Dimension Tensile strength Yield point Elongation Reduction Absorption Brinell

Chinese symbol (ISO)

treatment (e.g.length) (N/m) (N/m) (%) of area (%) energy (J) Hardness

thermal 1740 780 600 14 55 - -

25CrMo - refining 40100 690 450 15 60 - -

100160 640 400 16 60 - -

thermal 100 620 410 16 40 49 196240

30CrMo 1 2

refining 100300 590 390 15 40 44 196240

100 735 540 15 45 47 207269

35CrMo 34Cr4 thermal 100300 685 490 15 40 39 207269

refining 300500 635 440 15 35 31 207269

500800 590 390 12 30 23 -

thermal 100300 635 440 11 30 27 -

35CrMo 34Cr4 refining 300500 590 390 10 24 24 -

500800 540 345 9 20 20 -

100 900 650 12 50 - -

thermal 100160 800 550 13 50 - -

42CrMo 42CrMo4 refining 160250 750 500 14 55 - -

250500 690 460 15 - - -

500750 590 390 16 - - -

100 900 700 12 50 - -

thermal 100160 850 650 13 50 - -

50CrMo - refining 160250 800 550 14 50 - -

250500 740 540 14 - - -

500750 690 490 15 - - -

100300 765 590 15 40 47 -

34CrMo1 - thermal 300500 705 540 15 40 39 -

refining 500750 665 490 14 35 31 -

7501000 635 440 13 35 31 -

case hardening+ 30 780 590 10 40 - -

16CrMn - quenching+

tempering 3063 640 440 11 40 - -

case hardening+ 30 980 680 8 35 - -

20CrMn 20MnCr5 quenching+

tempering 3063 790 540 10 35 - -

20CrMnTi - therm.ref. 100 615 395 17 45 47 -

case hardening+ 30 1080 785 7 40 - -

20CrMnMo - quenching+

30100 835 490 15 40 31 -

tempering

thermal 100300 785 590 14 45 43 207269

35CrMnMo - refining 300500 735 540 13 40 39 207269

500800 685 490 12 35 31 207269

100 885 735 12 40 39 -

40CrMnMo - thermal 100250 835 640 12 30 39 -

refining 250400 785 530 12 40 31 -

400500 735 480 12 35 23 -

100 900 785 13 40 39 277331

100300 880 735 13 40 39 225302

20CrMnMoB - thermal 300500 835 685 13 40 39 241286

refining 500800 785 635 13 40 39 241286

100300 845 735 12 35 39 269302

300600 805 685 12 35 39 255286

thermal 100300 880 715 12 40 31 225302

30CrMn2MoB - refining 300500 835 665 12 40 31 225302

500800 785 615 12 40 31 241286

thermal 100300 830 685 14 45 59 255302

32Cr2MnMo - refining 300500 785 635 12 40 49 255302

500750 735 590 12 35 30 241286

30CrMnSi - thermal 100 735 590 12 35 35 235293

refining 100300 685 460 13 35 35 228269

35CrMnSi - thermal 100 785 640 12 35 31 241293

refining 100300 685 540 12 35 31 223269

12CrMoV - normalizing+ 100 470 245 22 48 39 143179

tempering 100300 430 215 20 40 39 123167

Table 4. Mechanical properties of alloy steel (Chinese standard: GB/T 17107-1997) 3/4

Mechanical properties

Heat Dimension Tensile strength Yield point Elongation Reduction Absorption Brinell

Chinese symbol (ISO)

treatment (e.g.length) (N/m) (N/m) (%) of area (%) energy (J) Hardness

100 440 245 19 50 39 123167

12Cr1MoV - normalizing+ 100300 430 215 19 48 39 123167

tempering 300500 430 215 18 40 35 123167

500800 430 215 16 35 31 123167

thermal 100300 735 590 16 - 47 -

24CrMoV -

refining 300500 685 540 16 - 47 -

thermal 100200 880 745 12 40 47 -

35CrMoV -

refining 200240 860 705 12 35 47 -

thermal 150 830 735 15 50 47 219277

30Cr2MoV - refining 150250 735 590 16 50 47 219277

250500 635 440 16 50 47 219277

thermal 100 835 735 15 50 47 269302

28Cr2Mo1V - refining 100300 735 635 15 40 47 269302

300500 685 565 14 35 47 269302

100 735 590 14 45 47 223277

40CrNi SNC236 thermal 100300 685 540 13 40 39 207262

refining 300500 635 440 13 35 39 197235

500800 615 395 11 30 31 187229

80 980 835 12 55 78 -

quenching+ 80100 980 835 11 50 74 -

40CrNiMo - tempering 100150 980 835 10 45 70 -

150250 980 835 9 40 66 -

thermal 100300 785 640 12 38 39 241293

refining 300500 685 540 12 33 35 207262

100 850 735 15 45 55 277321

34CrNi1Mo - thermal 100300 765 635 14 40 47 262311

refining 300500 685 540 14 35 39 235277

500800 635 490 14 32 31 212248

100 900 785 14 40 55 269341

34CrNi3Mo - thermal 100300 850 735 14 38 47 262321

refining 300500 805 685 13 35 39 241302

500800 755 590 12 32 32 241302

case hardening+ 30 880 640 9 40 - -

15Cr2Ni2 - quenching+

3063 780 540 10 40 - -

tempering

thermal

20Cr2Ni4 -

refining

15 1175 1080 10 45 62 -

case hardening+ 30 1080 790 8 35 - -

17Cr2Ni2Mo - quenching+

3063 980 690 8 35 - -

tempering

100 1100 900 10 45 - -

thermal 100160 1000 800 11 50 - -

30Cr2Ni2Mo - refining 160250 900 700 12 50 - -

250500 830 635 12 - - -

5001000 780 590 12 - - -

thermal 100 1000 800 11 50 - -

34Cr2Ni2Mo - refining 100160 900 700 12 55 - -

160250 800 600 13 55 - -

thermal 250500 740 540 14 - - -

34Cr2Ni2Mo -

refining 5001000 690 490 15 - - -

thermal 100300 685 585 15 60 110 190240

15CrNiMoV -

refining 300500 635 535 14 55 100 190240

100 900 785 14 40 47 269321

34CrNi3MoV - thermal 100300 855 735 14 38 39 248311

refining 300500 805 685 13 33 31 235293

500800 735 590 12 30 31 212262

100 900 785 13 40 47 269321

37CrNi3MoV - thermal 100300 855 735 12 38 39 248311

refining 300500 805 685 11 33 31 235293

500800 735 590 10 30 31 212262

Table 4. Mechanical properties of alloy steel (Chinese standard: GB/T 17107-1997) 4/4

Mechanical properties

Heat Dimension Tensile strength Yield point Elongation Reduction Absorption Brinell

Chinese symbol (ISO)

treatment (e.g.length) (N/m) (N/m) (%) of area (%) energy (J) Hardness

100300 1000 870 12 45 70 -

24Cr2Ni4MoV - thermal 300500 950 850 13 50 70 -

refining 500750 900 800 15 50 65 -

7501000 850 750 15 50 65 -

80 1180 835 10 45 78 -

18Cr2Ni4W - quenching+ 80100 1180 835 9 40 74 -

tempering 100150 1180 835 8 35 70 -

150250 1180 835 7 30 66 -

You might also like

- Horizontal Curve Excel SheetDocument9 pagesHorizontal Curve Excel Sheetrjg_vijayNo ratings yet

- ProjectDocument11 pagesProjectusman_usaf100% (1)

- How Can Europeans Benefit From An Innovative Approach To Offshore Wind Farm Lifecycle and Supply ChainDocument23 pagesHow Can Europeans Benefit From An Innovative Approach To Offshore Wind Farm Lifecycle and Supply ChainAna Maria LaraNo ratings yet

- Yale-NUS College Faculty Handbook-Updated Oct 2016Document61 pagesYale-NUS College Faculty Handbook-Updated Oct 2016Drnuzhat Fatema100% (2)

- Steel grade 12Х1МФDocument6 pagesSteel grade 12Х1МФHussien AlsadyNo ratings yet

- Von MisesDocument4 pagesVon Misesmohanad tariqNo ratings yet

- Resistance To Pitting and Crevice CorrosionDocument6 pagesResistance To Pitting and Crevice CorrosionsuiafwgehjdfNo ratings yet

- DIWA 373: Weldable Fine Grained Steel For Higher Temperature ServiceDocument4 pagesDIWA 373: Weldable Fine Grained Steel For Higher Temperature ServiceRam KadamNo ratings yet

- Consteel Catalogue PLATES ChequeredPlatesDocument3 pagesConsteel Catalogue PLATES ChequeredPlatesrichard richNo ratings yet

- Tugas Uji Tarik FixDocument15 pagesTugas Uji Tarik FixANDINTA MUDA YUSUFNo ratings yet

- Sa283c Stress-Strain CurveDocument7 pagesSa283c Stress-Strain CurveAnonymous AtAGVssJNo ratings yet

- Bus Bar Selection Chart AluminiumDocument1 pageBus Bar Selection Chart AluminiumJit0% (1)

- P355GHDocument1 pageP355GHCommercial MarocNo ratings yet

- Boiling PointDocument3 pagesBoiling PointrusyadNo ratings yet

- Alloy Machining: NickelDocument2 pagesAlloy Machining: Nickeljoko setiawanNo ratings yet

- Tgsno2 Geofisikainversi FatimahNurkhalifahDocument2 pagesTgsno2 Geofisikainversi FatimahNurkhalifahSisilia ElisNo ratings yet

- Radiation ValuesDocument12 pagesRadiation ValuesSameer AmjadNo ratings yet

- Tabela API 6ADocument2 pagesTabela API 6AFeromont KvalitetNo ratings yet

- Quality 39nicrmo3: Lucefin GroupDocument2 pagesQuality 39nicrmo3: Lucefin Groupmarko9292No ratings yet

- P MaterialDocument18 pagesP MaterialANDINTA MUDA YUSUFNo ratings yet

- Temp Diff EUDocument3 pagesTemp Diff EUSreeraja SreevilasanNo ratings yet

- Hardy Cross Method Solved ExampleDocument4 pagesHardy Cross Method Solved ExamplejajajajNo ratings yet

- 42 CR Mo 4Document2 pages42 CR Mo 4ElMacheteDelHuesoNo ratings yet

- Busbar Selection ChartDocument4 pagesBusbar Selection ChartArvind KumawatNo ratings yet

- 39NiCrMo3 PDFDocument2 pages39NiCrMo3 PDFAmy GriffinNo ratings yet

- Alla France ASTM ThermometerDocument3 pagesAlla France ASTM ThermometerPutut WindujatiNo ratings yet

- Brightbar Sae1018 2021Document2 pagesBrightbar Sae1018 2021Mike HeisenbergNo ratings yet

- Rumus CCI 4737Document5 pagesRumus CCI 4737Eko NbsNo ratings yet

- − sin θ − cos θ + sinθ + cosθ = ¨ cos θ − sin θ − cosθ + sinθ = 0Document1 page− sin θ − cos θ + sinθ + cosθ = ¨ cos θ − sin θ − cosθ + sinθ = 0Muhammad FauziNo ratings yet

- Calibration of Thermocouple and RTD: For Platinum: Alpha 0.00385. Reference Temperature 100 CentigradeDocument3 pagesCalibration of Thermocouple and RTD: For Platinum: Alpha 0.00385. Reference Temperature 100 CentigradeBharath kumarNo ratings yet

- 34 CR Mo 4Document2 pages34 CR Mo 4ceca nikolicNo ratings yet

- Pavsp: 200 F (X) - 0.359129697x 2 + 37.2815284848x - 810.0475454545Document6 pagesPavsp: 200 F (X) - 0.359129697x 2 + 37.2815284848x - 810.0475454545Oscar FernandoNo ratings yet

- GB 5310 Seamless Boiler Pipe SpecificationDocument1 pageGB 5310 Seamless Boiler Pipe SpecificationMujib DerusNo ratings yet

- Chapter 5. Control Valve Selection: Cast Carbon Steel (ASTM A216 Grade WCC) - WCC Is The Most PopDocument8 pagesChapter 5. Control Valve Selection: Cast Carbon Steel (ASTM A216 Grade WCC) - WCC Is The Most PopRedzaNo ratings yet

- Horizontal Curve Excel SheetDocument9 pagesHorizontal Curve Excel SheetTarunNo ratings yet

- Bakir BaralarDocument1 pageBakir BaralarFurkan TopcuNo ratings yet

- Okada Top SeriesDocument2 pagesOkada Top SeriessinanNo ratings yet

- Katalog Komposisi Lengkap New VersionDocument8 pagesKatalog Komposisi Lengkap New VersionSontani PurnamaNo ratings yet

- Normal Distribution Excel ExampleDocument16 pagesNormal Distribution Excel ExamplehaffaNo ratings yet

- 41Cr4 Chemical PDFDocument2 pages41Cr4 Chemical PDFGayathriRajasekaranNo ratings yet

- Δ X Δ Y Δ X Δ Y: Calculation Of Closed Traverse (Bowditch Method)Document8 pagesΔ X Δ Y Δ X Δ Y: Calculation Of Closed Traverse (Bowditch Method)Erlita KusumasariNo ratings yet

- Steel Grade Diameter Tensile Strength (RM) YIE Point (RP0.2) Elongation (A5) Hardness Impact Test (J at - 20°C)Document1 pageSteel Grade Diameter Tensile Strength (RM) YIE Point (RP0.2) Elongation (A5) Hardness Impact Test (J at - 20°C)Kuya Fabio VidalNo ratings yet

- Macizo RocosoDocument8 pagesMacizo RocosoCristobal De La GuardaNo ratings yet

- UntitledDocument11 pagesUntitledksarawanNo ratings yet

- 46S20PB - 46SPb20-Nr 1 0757-ENGDocument1 page46S20PB - 46SPb20-Nr 1 0757-ENGVipul SharmaNo ratings yet

- CR XP Hit Dice Hit Points XP Armor Class XP Attack Bonus XP Avg Damage XP Level Max XPDocument1 pageCR XP Hit Dice Hit Points XP Armor Class XP Attack Bonus XP Avg Damage XP Level Max XPMike DonovanNo ratings yet

- !en 10025Document1 page!en 10025Nguyen Quy DuongNo ratings yet

- Singly Reinforced (ACI) : UnderDocument16 pagesSingly Reinforced (ACI) : UnderWilfredoEnghoyNo ratings yet

- TemperatureDocument2 pagesTemperatureramy thaerNo ratings yet

- Tugas 5 PartikulatDocument6 pagesTugas 5 PartikulatTabina Amanda Aurelia SuryaNo ratings yet

- Toque WrenchDocument7 pagesToque WrenchMohammed SibghatullaNo ratings yet

- Jamito - Activity DataDocument36 pagesJamito - Activity DataClarence CaparasNo ratings yet

- Hedonic 1Document262 pagesHedonic 1KaiWenNgNo ratings yet

- Table Busbar ArusDocument2 pagesTable Busbar ArusFreddy Suhartono100% (3)

- 070m20 En3a BlackDocument3 pages070m20 En3a BlackmitternpdNo ratings yet

- Thalachrome Se 500: High Corrosion ResistanceDocument1 pageThalachrome Se 500: High Corrosion ResistancethyskieNo ratings yet

- Volume Per KM S1-4Document15 pagesVolume Per KM S1-4dinal031No ratings yet

- TENDON PROFILE - BAYUG BRIDGE ZMS - TYPE IV - Span 21Document1 pageTENDON PROFILE - BAYUG BRIDGE ZMS - TYPE IV - Span 21vfmagallanesNo ratings yet

- Excel de InterracionesDocument3 pagesExcel de InterracionesrudyNo ratings yet

- Diagram AsDocument11 pagesDiagram AsJhon MagañoNo ratings yet

- EPDM Double Spheres Rubber JointDocument1 pageEPDM Double Spheres Rubber JointMô hình Motion ChanelNo ratings yet

- Westport Electrical Corporation Case Study AnlysisDocument4 pagesWestport Electrical Corporation Case Study AnlysisMilanPadariyaNo ratings yet

- Dwnload Full Technology in Action Complete 12th Edition Evans Test Bank PDFDocument35 pagesDwnload Full Technology in Action Complete 12th Edition Evans Test Bank PDFeloisabroomheadfxs100% (9)

- GP-18!07!01 Welding ProceduresDocument21 pagesGP-18!07!01 Welding ProceduresFrancesco AvogadroNo ratings yet

- Latihan Uas Bahasa InggrisDocument9 pagesLatihan Uas Bahasa InggrisAlzeyma Novita SariNo ratings yet

- Final Exam Switching AnswersDocument11 pagesFinal Exam Switching AnswersAfridi AteeqNo ratings yet

- Science Mixed MCQsDocument14 pagesScience Mixed MCQsFarooq ShahNo ratings yet

- Hearts of Iron 2 CheatsDocument2 pagesHearts of Iron 2 CheatsWasim KhanNo ratings yet

- VNX - Su Fiesta BRM B299 2008.75Document485 pagesVNX - Su Fiesta BRM B299 2008.75rukford1100% (5)

- Sweet Nechako Honey TearsheetsDocument20 pagesSweet Nechako Honey TearsheetsdmalikbpdigitalNo ratings yet

- Cambridge IGCSE (9-1) : English As A Second Language 0993/31Document8 pagesCambridge IGCSE (9-1) : English As A Second Language 0993/31Tshegofatso SaliNo ratings yet

- Pltu Process OverviewDocument1 pagePltu Process OverviewDimasQiNo ratings yet

- Self AwarenessDocument4 pagesSelf AwarenessNamita BhattNo ratings yet

- Digital Integrated Circuits: Week 3 Melik YAZICIDocument44 pagesDigital Integrated Circuits: Week 3 Melik YAZICIboubiidNo ratings yet

- EC2 Ch03aDocument15 pagesEC2 Ch03asunilarunaNo ratings yet

- Industry CPD: Modelling Buildings For Seismic AnalysisDocument4 pagesIndustry CPD: Modelling Buildings For Seismic Analysisshare4learnNo ratings yet

- Nomenclatura Aeronáutica: Prof. Felipe BernardDocument26 pagesNomenclatura Aeronáutica: Prof. Felipe Bernarddaniel felipe rangel patiñoNo ratings yet

- Answer: CDocument4 pagesAnswer: CwendychenNo ratings yet

- Reff UNE-EN 1264Document8 pagesReff UNE-EN 1264Miguel CastroNo ratings yet

- English SolutionsDocument16 pagesEnglish Solutionsganesh pathakNo ratings yet

- Prelim FinalDocument18 pagesPrelim FinalCaren PacomiosNo ratings yet

- Analisis Probabilistik Bahaya Gempa Pada Bendungan WadaslintangDocument12 pagesAnalisis Probabilistik Bahaya Gempa Pada Bendungan WadaslintangTegas Shidik PermanaNo ratings yet

- Strategy Formulation For An Expansion Strategy - BlaBlaCar - Middle East - Aboud KhederchahDocument4 pagesStrategy Formulation For An Expansion Strategy - BlaBlaCar - Middle East - Aboud KhederchahaboudgkNo ratings yet

- Cyber Abcs PosterDocument1 pageCyber Abcs PosterFendy AriwinandaNo ratings yet

- Black Box" Model For DC-fed Trains Equipped With VSI Traction Drives and Three-Phase Induction MotorsDocument19 pagesBlack Box" Model For DC-fed Trains Equipped With VSI Traction Drives and Three-Phase Induction MotorsCPiresNo ratings yet

- Technical Reference For Hydrogen Compatibility of MaterialsDocument292 pagesTechnical Reference For Hydrogen Compatibility of Materialsstem86No ratings yet

- Units 1-7 Review Test: Listen To The Conversation. Then Listen Again and Circle The Correct AnswersDocument10 pagesUnits 1-7 Review Test: Listen To The Conversation. Then Listen Again and Circle The Correct AnswersDanilo Echeverri CarmonaNo ratings yet

- Part ONE GPRS (Gas and Pressure Reduction Station)Document2 pagesPart ONE GPRS (Gas and Pressure Reduction Station)DangolNo ratings yet