Professional Documents

Culture Documents

Wire Ropes and Their Uses

Uploaded by

livslx0 ratings0% found this document useful (0 votes)

7 views12 pagesinspection, maintenance and certification of wire ropes

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentinspection, maintenance and certification of wire ropes

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views12 pagesWire Ropes and Their Uses

Uploaded by

livslxinspection, maintenance and certification of wire ropes

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

ic

Se

esac ear cary

peo his special issue of Signal wil cover

certfation and handing requirements ofeach

Useful sources of erence nung inter

conventions and standards, are provided on the

back page

SIGNALS

Wire construction Source: Cortex

6x36WS.IWAC

Worington Seale Wie

Source:N Thompson

Wire Construction

Before discussing the use and maintenance of

Ship's wires it is useful to understand. how

Wire ope sabia from stands of

ual wies. The configuration oft

m selected grades of steel to predetermine

Dhyscl properties and sizes. A number offnshed

comer atten to form a stand, The

si

of suitably fabricated strands a

tof the finished wire

ition to properties such s material strenath

‘minimum beating load and co

and the number of

8x36 construction denotes 6-strand rope, with

strand having 36 wes.

1 centre of the wire may

‘rane wires on ships are commonly configued wth

core (WSC)

dependent wire ropecore(WRC) or wiestand

sed to a fibre core

ing, such a8 14/7 & 7/7,

ve arrangements ofthe strand

ravens

andor ies

arranged to sive dif

known as Fille, Seale

Filler (F)~ Characterized by the small spacer

wires that ie inthe gaps between strands ofthe

inner ayer to help positon and support the outer

layer they provide crush sistance and lel,

Seale (S) ~ Characterised by having eaually

sized wires in the outer ayer with the some number

of wifrm but sar sized wiresin the ne layer

round a central core wire. The arrengement

provides goad abrasion resistance but less fatigue

Warrington (W) -Characterised by having one of

its wite layers made up of an arrangement of

altematly large and small wires. This arrangement

provides good flexibly and strength but lesser

abrasion esistance.

The notation WS, for examal

wire rope

suchas 6x36

patterns are wed

Continued page 2

INSIDE:

puns

os

Peete

can nih

Eee

coat

a

creme

Pea

WIRE CONSTRUCTION

Wire rope lay

Thehelicor spr ofthe wires and strands in a rope

ishonas he ay and there re several asic ype.

Fight hand eguerloy

Aight ond Langsioy

Lefthandreguorioy

Lefthand ang'sioy|

Regular (ordinary) ly - This denotes open which

the wires are twisted in one direction, and the

strands the oppsite direction to form the rope.

The individual wires appear to run oughly parallel

to the centre line ofthe rope. Due to the aifference

indirection between the wires and strand, regular

lay ropes ae ess ily to un-twistoknk Regular

loy ropes ae alzo less subject to failure fom

crushing and cstortion because of the shorter

lenath of exposed outer wires.

Lang's ly This the opposite to regularly -the

wires and strands spiral inthe same erection and

appear torn ata diagonal tothe centre in ofthe

rope. Due ta the longer length of exposed outer

wires, Lang’ lay ropes have greater flexibility and

Bbrason resistance than do regular lay ropes.

Greater care, however, must be exercised in

handing and spooling Langs lay ropes. These ropes

are more ley to twist kink nd eush than regular

iy ropes.

Regular lays the most common form of wire rope

for cranes and usually furnished for all rope

plications unless others specif.

Thelay-length isthe near aatance a single stand

tvtends in making one complete turnaround the

rage. Lay-tength is measured in a straight line

paallel to the centre line of the rope, nat by

Faloning the pth ofthe stand,

Strength

Te responsibility for determining the minimum

strength of a wte rope used in a given system ets

with the manufacture ofthe machine, appliance or

lifting equipment. AS art ofthis proces, they

should have taken into account any relevant

regulations or codes of practice governing the

design of the rope ~ often refered to as the

coffcient of utilisation ~ and other Factors that

Wire construction (continued)

‘migtnfuence the desig, These include the design

ofthe sheaves and drums, he shape ofthe groove

profiles and corespending radius, the dum pitch,

land the angle of fee all of which have an effect

‘nope performance

‘Once the strength (ferred to. 25. minimum

breaking fore or minimum breaking oad) has been

determined its then necessary to consider which

type of ape wil be most suitable. Forinstance, des

ited tobe rotation resistant, havea good fatigue

performance, ot be able to withstand particular

typescf abuse or arduous conditions?

Resistance to rotation

Some applications require use ofl ratation or

rotation resistant rope, Examples would be ifebost

fall wires, and main and aur hist crane wires

‘Suh ropes are often refered to as muti-strand

ropes Sit oreight strand rope constructions are ine

for ow lifting heights r those with multiple als

but the mast common choice to misimise load

rotation on a single part system, block ation, or

‘abling” ono multi-part eeving system, are low

rotation ropes.

When foade, steel wire ropes generate ‘torque It

both ends of rope are Fixe, or turn if one ena

Isunresrsines, The torque or turn generated wil

increase asthe load applied increases, and the

Aegree to which tis happens wl be influenced by

the construction of the rope. The tendency for any

rope to tum will be greater a5 the helt of

lift increases, In 2 multi-part reeving syster, he

tendency forthe rope o eal wll increase as the

Spacing between the pats ofthe rope decreases

Selection of the correct rope will help to prevent

cabling’ and rotation of the os.

Some wites have been designed to minimise

problems associated th cabling and lsd rotation

‘As a general rule, however, ia rotation resistant

‘ope is ot needed then it should not be sed six

‘or eight strand rae wl always be more robust and

better able to withstand excessive let angle and

suse than thelemorecompex counterparts

Fatigue resistance

‘The rope’ ftiqu resistances aso an important

facta. Stel wire ropes wil suffer from fatigue

ven working around a sheave or drum. Therate of

eteroratonsintuenced by te umber of sheaves

inthe sytem, the tareteraf the sesves and um

nd the lating conditions. fatigue resistance is

an sau, then its wise to select a rope containing

Sirall wires, sch a5 6 x 26 0S (14/78 7/711), 28

opposed toa rope containing larger wires suchas 2

6 19 (/0/1, whichis more resstan to wear.

Additonal resistance to atgue canbe achieved by

selecting 9 wire rope with a smoother surface than

standard rope. Thisimproves roe 1oSheave contact

leasing to reduced wear on both rope an sheave

‘An increased cross-sectional steel area. and

improved interne contact also ensures that the

rope wil operate with omer internal tres evel

‘Thisultmately resus in greaterbendingfatioe life

‘nd long-term lower operating costs

Wire pe on aocent rum fpscon couse

pointcontactondacelerated wear

Compoctedouterstandswilleduce abrasion |

troughimproved contactconditions.

Resistance fo weor ‘Source Certex

Resistance to abrasive wear

‘Aarasive wear cn take pace beteen ir rope and

sheave, and betwen wite ope and drum, ut the

greatest cause of abrasion Is often through

‘ntererenc’ atthe drum. abrasions determined

to bea major factor in rope deteriaration then a

wire ope with relatively large outer wires should

beseecte,

‘tan’ oy structure, hen the ditecton of lay of

the wires inthe tr sans he sane as that of

the outer stands inthe ope, aso has better wear

characterises than a regular ay rape ~ when the

{irecton ofa ofthe wires in the outer stands in

theoppsite Breton tthe af the outerstrands

intherope

Crush resistance ropes

In multi-layer coling applications, where there is

more than one layer of rope on the érum, itis

tssentl to instal she rope with some back tension.

This should be between 295 and 108 of the

minimum breaking force of the wite rope. this is

hot achieved, rin applications where high peessure

‘on the underlying rope i inevitable - such as a

boom hast rpe ralsng 2 oom from the horizontal

Dostion ~ then severe crushing damage can be

‘caused to the underlying layers Use of steel core

as opposed to fibre core wll hep this situation,

land for this reason stel core ropes are always

recommended for crane use. ditional resstance’s

offered by wies which have high steel fil-fector

and these rapes are also recommended fr multi-

layer coling operations where crushing on lower

layersis ineitabe

It should also be noted tata Lana's ay ope resists

interference atthe dum beter than a regular ay.

Corrosion resistance ropes

When the wire rope is tobe used in 2 comosive

envionment = which applies broacly acass the

maine environment thena galvanized coating my

‘be recommended and where moisturecan penetrate

‘the rope and attack the core, plastic impregnation

‘could be considered. In order o minimise the eects

of eosin itis important to slecta wie ope with

= suitable manufacturing lbrcat This should bee

plied regulary while the ropes inser:

a

~»

SRP TT

ROUTINE INSPECTION

’ Routine Inspection

The time interval and extent of inspection and

intenance for wites will vary. depending

documented by the manufacturer an incorporate

repent office

rt ofa continuous races of inspection for

age, the

wire rope shouldbe

signs of genera

general condition of al

monitored on a daly bass when in use. All wires

ian by a resposile

person before work commences and on completion

Jer nvoranc if socksosding is thought to Rave

ire ropes are stored on drums, considera

the timescale and logistics that wil be involved

cludes

vith planning

‘Although wies of si or eght strand constuction

ands, ts the super provided by the ore whi

maintains the wires efficiency and performance

of any inspection regime and may be cared out bya

The sagram

exibited a minimum amount ofcorsion, with ao

GP broken wires and limited wear, The rope pated

Periodic Examination

By cond

of therope incu

iting heavier nada oad,

ates the rate of fatigue damage tothe

must be

including the fequency of inspection,

rie to rect this Rate ofeceurence of broken

onition of wre. These are commonly refered to

Period examination shouldbe carried out by @

m « er50n and will involve the complete

nd the ves

150 43

eile

ag Stat

rework for an examination and many

determining how often they shouldbe caved ou.

how often it suse, referred to a the number of

Internal Examination

Some specialized tols are required to carr out an

ternal examination, These nelude

+ AT neele(e Nat spike wit rounded edges) ora

fed scremdrver for displacing outer

+ Tape measure for measuring lay length

+ Chatkelectricians tape for marking any areas

that equi further examination

+ Cleaning materials solvent fr removing debris

‘The examination should concentrate on evidence of

ake wits internal abrasion ction, the degree

of eonesion ad intra vrei

‘lamps approximately 100mm ~ 200mm apart

of causing permanent damage. The stands can

tbe manipulated with the probe to facitate

‘nce the examination complete, desing can be

ont the cre. At 2 pint of termination one clan

will usualy be suc

must be recorded and compares tothe

discard

‘Source: Certex

Examining ropes running over sheaves

he lengths of rope running aver sheaves are the

most heavily worked pats of the ope and the

"

The rope MUST NOT

Discard

Stress, abrasion, bending, crushing and coresion

tae the most common Sources of damage to wires.

Henever rotation, vibration cabling and elongation

may also oceur under certain circumstances.

These can in extreme cases lead to catastrophic

ire au

A detalied external examination should compare

‘the wire agains the dscord criteria foreach typeof

‘ite. These eriteria are determined in consultation

‘sith the manufacturer and include

+ Number of broken wires ~ The number of

permissible broken wires til depend on the

funtion of the wire and wl include the ate of

breakage occurence and grouping of broken

wires For example single ayer 67 ice core

wireropeused fora carga wie snow be diced

12 or more wires ae visibly broken ina length

equialentto diameters

‘Fractured strands ~Astrandthathas completely

feactted will quite the wire tobe discard

+ Decrease in elasticity ~ This can be quite

aifficlt to detect and it may be necessary to

consult 2 wite specislist if i is suspected

Warning sign can include a reduetion inthe

diameter of the rope, elongation of the ly

length, signs of compression between strands

‘long with the appearance offne brown ponder,

and an inereas inthe stiffness ofthe wie

Although broken strands maybe absent fom 2

wie that has a reduction in elasticity this

‘The lifespan of any wire will depend to gre!

featent on the way that it is maintained on

board. The technical nature of wire manufacture

‘demanes that planned maintenance programmes

bbe developes in collaboration with che

manufacturer before the wite is supplied to

the vessel, Where lubrication or drssing of the

wire is required this shoulé be applied prior to

the wires installation on board and reapplied at

pre-determined intenals. determined by the

‘manufacture. Lubricants may need tobe workes

| into the core of the rope during application if they

| areto sere thee intended purpose

If cleaning of the wie is required before lubrication

care mus be taken to ensure substances used are

‘compatible with the components ofthe wire and

lubricants tobe used

Changes to operating practices and environmental

conditions will requite planned mainterance

programmes tobe fll and aticipatory to ensure

the continued safe operation of wires an board

DISCARD CRITERIA J MAINTENANCE AND RECORDS

Criteria

condition cam lea to catastophic wire allure

‘and should result in the immediate removal of

‘the wire from servi.

+ External and internal corrosion ~ External

corrosion is easier to detect than internal

Diseolovration will be accompanied by an

apparent slakness between wires, whic is

result of reduction nthe cross-sectional area

‘of the wire. Coresion can rapidly accelerate

fatigue damage by causing surface deformation

hich canleadtostescracking

the discard criteria may nh:

1 Heat damage

+ ate of permancr elongation

‘+ Reduction in tensile strength

+ Length of sevice

+ Number offe-cyeles,

+ Broken wiresat termination pins

+ Redution’n ameter.

In addition to these considerations 2 detailed

‘examination ofthe wire will be required here has

been a prolonged pei f inactivity ora change to

the characteristics ofthe loading and discharge

pattern ofthe ese

Evidence of broken wites should vigger a more

aggressive inspection regime, grouping of broken

strands may indicate inherent wean the work

procedure for the particular wire affected and

should be monitored closely if not removed

Maintenance and

Examination records

Detaled records of examinations must be

‘maintained, this wil allow those responsible to

identity patterns of

Information can then be ued in conjuntion with

eamage occurence. This

the anticipated cycles of work to determine

expected deterioration prior tothe nest scheduled

inspection. On detecting damage which exceeds

that predicted inthe maintenance record, a re-

evaluation ofthe life expectancy ofthe ire will

bbe requited and this should be followed by

an inspection ofall other associated machinery

inorder to establish the source of the accel

crated damage. International standard 150 4309

contains examples of rope examination records

for both individual inspections and_ running

records. Details should include:

+ Number f visible broken wires

+ Measurement of reduction in diameter

from service. Once broken wites nave been

identified i important that they be removed

without further damage being done to the

wit or injury to crew Pliers may be used to work

the broken wire back and forward until it

beaks close tothe stand. Nondestructive testing

Wil greatly assist wice Inspection in applications

Where there is an increases isk of internal

wire damage.

destructive testing is employed, initial eeference

In circumstances where non-

ra must be determined as soon as posible after

the wires installation to allow subsequent

comparisons tobe made

Records”

+ Degree of abasion

+ Degree ofcorosion.

+ Degree ofdamage and deformation

+ Location of Damage and an overal assssmen

of wire condition

‘The degre of deterioration may be asseseed on 3

percentage basis:

igh

40% = medium

20%

ane = high

r= very igh

1008 = isc

Storage

en not in use, wires shouldbe stored in ey

conditions or there protected fram chemicals

and sibstanes that may harm their protective

eesing read corsion

ACCOMMODATION LADDERS

“Accommodation Ladders

r

Accommodation lacers are the mast commonly

Used means of acces to ships. On vessels that have

iarge freeboard, they may fll the rleof genera

access when in port and facilitate pilot boerdng

and disembarking at the beginning and end of

passage, They are generally located en the main

feck, constructed in a composite fashion wich

collapsible hand cils and platform. Ths allows

space when the veselisonpasage

The complex nature ofthis semi-permanent design

may eause problems. Removable stanchions and

hinged components are often damaged by excessive

wear uring therigging and dsmanting proces.

5 of International Labour Organization

(io) Convention

adequate, sae, propery installed and secure

However, the leek of specific guidance making

reference to periodic inspection of accommodation

laders inthe existing regulations contained in

chapter 1 ofthe International Convention forthe

Safety of Life at Sea SOLAS) equations 7 and &

detailed planned maintenance regime

Construction of accommodation

ladder wire

The stowage location of ladders on high freeboard

ure them tobe lowered significant

distance ta the vesse’s shell dor acces. Tis ean

require large amounts of wire tobe spooled on

winen drums, Wire used fortis purpose must be

compact, have a small diameter and be flexible

ough to rotate around the multiple sheave

configurations associated with these ladders

Strands constructed of 36 wires give good Melty

ile maintaining shape and geometry with an

independent wire rope core. This reduces the effet

of compression and cush damage

Crossecton of 361/7AC Source: Cert

‘occommodation adder wie

Principal causes of damage

+ Corrosion - Storage onthe main deck exposes

contamination. The smal diameter of wite

require its the effectiveness of internal core

lubrication and weakens the wires esitance to

Abrasion - Damage often occurs a a esl of

pulley and sheave seizure, wires canbe damaged

ad kinked during rigging and dismantling, Poor

supervision of adders landed on the quay may

result bights of wire being expose to quay

and cush damage,

+ Cutting in = This occurs when rope buries itself

under tension ina wire that hasbeen spools

poorly underneath. I nt monitored clase this

an la 0 jamming causing counter rotation,

Crushing ~ Uneven spooling can result in

crossed wires onthe drum ~ under load this can

result crush damage. This may also accu to

exposed ire whien have become snagged or

sipped onthe quaside

* Fatigue ~ The rate of fatigue damage is

accelerated by frequent bending ofthe wire

while under load ~ tight nips round smal

diameter pulleys and kinking damage during

rigging ace examples. The rate of fatigue is

accelerates by por lubrication and exposure to

‘orosion damage

Care and handling

The complex nature of ladder contruction requ

that the rigging process be supervised by a

responsible officer. During ths process 2 careful

inspection should be conductes to ensute each

component ofthe adr free from damage fit for

purpose, secure and sultably lubricated. The

supervising affcer shoud inspec the wie fr signs

ae shouldbe taken to

of damage and fatigue

ensure» suitable amount of ack tension is applied

during spooling. This wll reduce te kelihoed of

the wich

Most adders are designed to ret on the quayside

and pivot atthe point of attachment tothe ship's

hull Ths can resultina significant concentration of

leasing ste, often compounded by movement of

the vstel onthe berth, Supervision ofthe vessel's

access can monitor the extent ofthis movement and

prevent the ladder becoming overoaded when arge

groups reassembled waiting to board or disembark

This is particulary important when the vessel is at

anchor and the adders entirely suspended from the

wire and davitarcngement. Tere have been 2

number of fatal accidents under these

circumstances with suspension wires. parting,

rapping ladders into the water Sigs ingesting

‘maximum loading should be attached to the ladder

both atthe top an bottom toads on the capacity

oftheladder atany onetime.

Maintenance and inspection

Aan inspection bya responsible person should take

Blac rior tothe preparation ofthe ladder for use

and subsequent to dismanting. This shoul include

vies ll moving parts nd printsfstachment The

‘out ata time interval which hasbeen determined

appropriate bythe Flag State séminisration and

shoud rete the Frequency of use

If no guidance sprovied by te Flag State it may

be prudent to adopt. 2s a minimum, te Frequency

(of examination for the pilot hoist and

Equipmen

Cerificate Storage onthe main deck exposes the

each survey for the ship's Safe

wire and winching mechanism to the

extremes of enranments damage possible, wire

shouldbe removed from winch drums before the

vessel embarks on a long ocean voyage, If this

is impractical, maintenance procedures should

incorporate particularly aggressive lubrication

regimes to compensate and suitable protective

coverings should be used when the ladder i no

Discard eriteri should take account of the high

levels of corrosion associated with this application

LIFEBOAT WIRES

Lifeoat systems have been subject 0 seat del

Of scrutiny an investigation recently following

cident during statutory dls nd maintenance

procedures

Several independent investigations have been

Carried out by Fag State administrations another

organisations, including the UX Maritime and

Coastguard Agency (MCA) and Marine Accident

Investigation Branch IMAIB). Ther conclusions

orcut rat although casaton may not be direct

linked to fall wire fatigue its integral role in the

overall function ofthe system demands that those

involved withthe maintenance, inspection and

operation of ifeboat systems fully understand the

complet of the design and the contribution of

each component

Tricing pennants, gripe wires and hanging-off

pendants are subject to similar sources of fatigue

and misuse sal wires and must nate overooked

during inspection and maintenance programmes

Tein penrants in particular have been deified

by several esearch projects asbeng subjected to

increasing levels of misuse by orl supervised

‘ren members who overioad nem during dis by

lowering boats ta point where the weight ofthe

bets mosty transfered fom the fal wire to he

ttcing pennant. This dangerous practice ca ea to

slack fll wires, trcing neat failure and the

potential forthe consequential failure ofthe entire

davit structure. These risks highlight the importance

ofa resporsbe officer supervising lactis thet

involve movement af the boat ana maintenance

activity conducted by ship's crew. Robust rk

procedures must precede all

‘examination ane maintenance work.

Construction

Fall wires ae required tobe both eb arstabie

in order to withstand the shocking ane

rotation that can be present during lowering and

recovery, this equites larger sumber of smal!

ameter wires within he structure of the rpe Fall

ives maybe certificated to remain in sence for up

{ove yeas Lubrication and the corosio estat

‘quay ofits orsruction ae therefore very important.

‘ras section af 2x7 RC

low rotaionsteleore

Ieboat fot wire

Lifeboat Wires

Principal causes of damage

+ Conrosion~Fersstentexpsue ie eiarmental

extremes attach the constuction ofl wires.

“Wisi compounded by rested access tong

lenaths of wire spooled on winch drums

protittng penetrating dressing and lbricaton

+ Abrasion ~ Seized davit sheaves and poor ope

teas wil aceerate the extent of damage to the

lager numberof exsese wires associated ith

thistyp of ope.

+ Crushing High freeboar esses with laroe

amount of fll wire can suter from eutingin™

uring bad spooling with low back texsion

resistance increasing the lieihood of crush

damage

+ Jamming - Uneven movement f devi and fl

‘wires ca eed to slack wire ad bight forming

between sheaves, unchecked this can result in

salient and sppage of tefl wre the

sheave blocks jamming fall wites between

‘heave and dit seuctue

Care and handling

The accident investigations refered to earer

{stablised that many ofthe inedents associated

sit feboats ive alls, sheaves, blocks cing

pennants and rie arrangements

Davit alignment relies on the precise tensioning of

fal wie. During lowering and recovery operations

fue diligence must be exercised to ensure even

spooling on winch des. Smooth opertion of the

wine controls necessary to avoid sharp juddering

‘movement ofthe dts ana boat. Sheoves ae aften

seat anges the than vertical Sippage of wire off

sheave blocks may resut in the wire jamming

bese the sheave and chet late

Crew members should be made aware of the

angers associated with lonering the boat to

embarkation level beyand the pont of weight

transfer from fall wie toting pennant, Larger

apc ifeoats that are bowsed-in alongside the

vest close tothe davit head produce fal wie

angles that are increasingly removed from the

vera. This produces nereasing large horizontal

Suspended iteboat

With he iteboatin ths position

thereisnoloedon the fli so he

tricingpennontsond doit ams

apport the ene meant the

ifebootunaiged

‘moments and transfers unacceptable loads on to

both the dai arm and cing pennant.

Maintenance and inspection

AL ifeboat wes are requied ob ispectes

rely ons iesiate eadiness and monthly

toesut they ae maintained in gos order SOLAS

chapter eulatin 2 ques wires tobe tue

tod frend atintenal no exceeding 30 months

and replaced at nteraenot exceeding years

"ubjet tothe conto ofthe we An akeratve

arrangement eaves the need for end-or-nding

if wires are inspect requnty and renewed at

intena not exceesing four yer, subec to wire

condition

Moret miotenance nd servicing guidlines

than reo velable have een prompted by

{helnternationl Martie Organization (10) i

the annex to IMO crear MSCICre 206. This

ince:

+ Rekae ga ncn esting proces for on

leadmetanm

+ Davittinitsnitehes sheaves ition of

roving pars.

+ Winch power suply, convols and braking

arrangement

(On vessels that are exempt fom the Iauneing

reirement seid innterationalCrwenton

forthe Setey of Life at Sea (SOLA) ene

regulation 19, planned maintenance schedules

Should tate acount of periods of inactivity.

Discussion wth manufacturers should determine

sual dressings and labia to reflec hese

Reports and records

Detailed records of inspection and maintenance

work must be maintained and signed by the

maintenance companys representative, ship's

raster and those involved in conducting the

maintenance programme. When repairs and

Servicing have been completed a. statement

confirming that ifebost arangements remain fi

for purpose sould be issued by the manufacturer’

representative oinviual cette by them

ELEVATOR WIRES

"Elevator Wires

Elevators orl havebeen used on merchant veses

for many years. The wires used to operate them are

refered to as ‘host rope’ and commonly have

Numer of Visible Broken Wires

Single Layer Ropes with ibe Core Operating in Cast kon or Stee Sheaves

Ciera flere cor an af Sorta Tapas psec caine vin s

Construction. Wies are nomal“p-frmed Skekeopetovesanoyihe | Okcadopesinmeitey

‘theres hat nnn wea prt ompetepenon

not adversely change the geometry ofthe rope. Conation Gass6x19FC | Casexi9FC | Casexi9RC | Cisaxi9FC

Aroenwiesrndomiy| Moretan 2 | warethan1s | Morethan2# | Moe than20

Germataronae | propel” | perpely | pereecoy” | peronciey |

{oo |

Bren ies Moetané | wort | Moret 5 | oe than io

| beaming inone | peropeay? | peropeloy | pevopelny” | peopel

| Srwouterstons | |

Cossreionetxisdeet —— Sowce Cotes apcentwatenuies | 4 4 | woretana | Moreton

aaron inane outer sand |

Ap teseorie

Both regu ay and Lang iy are sed in oit_—_| Vey beats Spa pest || eum | Masties 10) Mert

rope construction. Each has quite different Lehane eon

avantages. Regularly is easier to handle and wl

luemor resilient to rshing damage Lanta th

‘enteral wires being expsed toa longer sy length

reduces wear more effectively than ordinary lay

thus improving the wires fatigue life. Whichever

construction method is selected, i is important

that it be mainaineéthraughout the operation of

the elevate

Te fibre core, which may be natural sisal or

synthetic polypropylene, is impregnated with

lubricant during manutacture to ensure a gradual

felease during the operation of the wire. Tis

facitatee mechanical movement between inaivual

vires during bending anda offers some protection

Against corrosion. Rate of lubricant release is

critical, too quick and the wire wl slip on the

sheaves, too iw and abrasion damage will eu.

Combination wir constuction ules high tensile

wite inthe inner strands where thei harder mare

brittle construction cn be protected by softer more

raleable low tensile strands on the exterior.

Wihicrever wires selected its construction must be

‘compatible withthe materi used to manufsture

the sheave configuration,

Ses lifting ropes must share identical properties

throughout thei length particularly ther stretch

characterises under loa, Manufacturers must

therefore ensure that pairs of rope are taken rom

the same production ngth

Principal causes of damage

‘+ Fatigue ~ Felt is avitl component ina

hoist rope, continual bending and compression

coversheave blacks wil pemeate throughout the

lifespan of the rope, which, depending on

‘warking condition rama between 3 and 8

years. Weta fatigue wil produce spontaneous

{racks that spread along the ength ofthe wire

unt fracture

Abrasion ~ rsufcen ubriant wil sult n

cacessive internal wear inown 35 feting

corrosion. Individual wires rub. together

producing an appearance iia to rust damage.

Thiscan lead to premature ise ofthe rope

+ Steteh- tight sscrepancesin diameter and

etastic properties ofa particular wie can result

“Thelength of one rope lays approximately equivalent to 6x4

(whered's the nominsl ope dzmeter]

Tobie ofaiscorderiteraforsuspensionropes,

‘ovemor ropes and compensating ropes

inone ofa pir of hast ropes stretching lightly

‘more than theater, of traveling more quickly

‘though the rope cycle. Without a compensation

‘mechanism inthe lit operation this an lead to

slippage onthe sheave during use and affect the

rection properties of the sheave and wite

combination. Elastic stetch could commonly

amount to about ém for every 10 metres of

trove, permanent stretch ean aecount for as

much as 40mm pee 10 metres of length when 2

wireisnew this isa symptom of bedg in and

wil occur very quik further stretch by a5

much as GOmm per 10 metre length isnot

Uncommon avers number of years

Maintenance and inspection

Inspection intenals for hoist wires wil be

dependant on ca administration and Fg State

teguatin. Subject ta the numberof rope cles,

industry best practice recommends 8 cael

cxamination aS monhy tena The extensive

benging hich ost ropes experience demands

careful assessment of fatigue rack on india

wire stands. ispectons shoul ako leude

termination points and the means fatachent 0

thecarand eunterneght Sheaves re designed to

be softer than the wie and wil she slivers 8

resultofropesippage reset the case mustbe

invested rug

High operating temperatures, traction, fst ne

speeds and small bending rats al reduce the

efficiency of tubicatin,Adtoal biation

during the operational ite ofthe wie wllcean and

iaitain traction, penetrate nto the wie tng

to repel mostue and recuce abrasion damage.

Small amounts applies fequenty ll radce the

best results. Lbatng compounds must be

approved by the manufactures. Shave groves

Should exhibit a sigh sponge ite texture tthe

Source: Utond scolator

Industry Assocation LEA)

{ouch when the wires wel ubrieated. the ger

remains ry, the ope requires bration. Governor

ropes should nat be lubricated afterinstallaton.

Inadition to sscard criteria applicable tal wie

ropes the following require particular attention:

+ Surface eardamage to exterior wires caused by

sheave action and slippage.

‘Inequality in tension between pied ropes.

‘+ Excessive stretching, tis canbe monitored by

the countereight bottom overnun dimensions

‘Inequality in wire diameter throughout the

length ofthe rope.

‘+ xtealevdenc of nteralreting orosion

tn the absence of any national regulations or

instrvetions fom the equipment manufacture the

lpove table provides a general guide to broken wire

ddscard citer

A propery qualified competent person inspecting

the wire must le aware ofthe posible increase in

internal damage f operating sheaves ar construed

‘om mater other than cast ron orstee

Care and handling

Theres it handing of hoist apes once instal

homeve they arewlnerable to gamage fom sharp

edges and corners ring transportation and

shiping Ropes must be protected fom wet

damage, uit and heat. ubiarts ean soften

in strong sunlight ard ep from the wires. The

‘ethos of urreeing must ensure there 0 kink

damage and na contamination ofthe wire, pling

‘the rope ove sharp edges during installation cn

praace ore which can de-stabiieits stir

Some manufactrers mark the op a maior he

amount of twisting ding instalation, excessive

{wsting can apy reduce the fe expectancy of

ist ire an ma require conection.

ito

HOIST WIRES

Mechanical

Pilot Hoists

Pilot hosts were orginally introduced to assist

lt to board shins with lage freeboard as an

alternative to the ace

modation and pit ade

combination. Although pilots nave sometimes

ions about their effectiveness,

they ate stil in use and their safe operation is.

describes in detail in Intemational Maritime

(Organization (IMO) Resolution A889(2)- Pl

raster Arengements adopted bythe MO in

Flot host are sometimes semi-pertabe, in which

ase they requite careful assembly under else

slowing suficient time for rigging

and testing before the vessel is due to arive at the

Construction

Hoist wires are required tobe made from flexibe

steel wire rope whichis resistan to the corrosive

joperties in the marine environment. The

construction wil be very similar to that o

Similar sources of damage and fatigue.

=

Sure: Certer

WC pot hit wie

Care and handling

Fiat hoists consist of a moveable plot ladder

section hosted or lowered from 2 su

embarkation position, The necesity for two

fentof one of the wires parting, however wires

‘must be spooled carefully to maintain horizontal

aration on the winch drums Thi ensures »

iaximum resistance to twisting and improves the

concem of pilots

Great care must be exerised during Ii

lowering to ensure freedom of ovement ofa

ies, saves and winch drums. Confined spaces at

conventional plo ladder be placed adjacent and

accesible ot is immetiatty available should the

Maintenance and inspection

Te International Convention forthe Safety of ie

at Sea (SOLAS) chapter 1, regulations 7 and 8

tr intermediate survey and at each

ot the shin’ Sofety Equipment Certieate.

shouldbe supe

by obo spe

responsible officer before and after each use and

‘xamined atime intervals that both manufactures

sider appropriate. Analysis

te installation st of te averoad

required the the dint

wastage and trimming of the hoist wires

uring the life-span othe wie arst care must be

‘aximum freeboard extension of the hoi

hile maintaining a minimum o thee turns onthe

vine drum,

ofthe roles

tobe ited othe platform section

fhe hist f hese llr seize ican increase the

fatigue damage Power failure safety mechanisms

and brake stranger

lowering

from the vesses access. In the event of power

$s. should be tested during @

(eof the hoist ta distance of metres

failure a manual method of recovery should

avilable and must be ited in such a fashion that

hen itis engaged the power Supply to the

imtarzed winch is cisengage.

MOORING WIRES

“Mooring Wires

Wire failure continues to feature a 2 causative

‘actor in acident investigations int incidents that

‘occur during mooring operations. These ar almost

alwaysserious ad sometimes atl, Each mooring

operation requires careful planning to ensure that 2

safe working environment for the crew can be

‘maintained while reducing the mately sources

offatique and stress damage tthe wire.

Environmental exposure, abrasion damage and

shock-loading al pla a part in accelerating wire

fatigue. Significant loads can be experienced

unexpectedly during any berthing manoeuste

Incidents of this type wil frequently expose

weakness within the structure ofthe rope and

accelerate fatigue to the point of wie failure

Designing a mooring wire with sufficiently robust

‘qualities to withstand these external fores con be

particularly challenging often a technical solution

‘one source of fatigue may nate compatible with

‘the requirements demanded by the application

Maintenance regimes must therefore be designed

to maintain the lexbilty and subsequent fe span

of the wire, while inspection programmes should

erable ships crew to identity symptoms of Fatigue

early in order tO protect the crew from the

consequences of wie flue

Construction

Ropes that are constructed with wires of larger

diameter will be less vulnerable to coresion

damage, This chractristic i also desirable for

abrasion resistance properties However to large 8

Aiameter of wice wil produce a less flexible ope

and reduce resistance to fatigue damage

Compromise i therefore equted to produce a wire

thatcan satisfy the demands of mooring operations

and also be suitably lubricated to protect it from

corrosion. Wires that may be exposed to crushing

damage benefit fom a wire core and equal ay

construction, this wll produce a mare robust shape

‘hats ssl to deform unde peessut. typical

rooting wire construction consists of ixstrand of

36 wires with an independent wire core (6x36

IWRC). Mocrng wires canbe supplied from ast

35 10mm to ove 1mm diameter

Resistance to shock-oading can be difficult for 8

‘manufacturer to include inthe design ofa rope

Sometimes lengthof nylon mltilaitraneifites

2 the working end ofthe mooring wit to absoro

‘most ofthis shock Fiting a aylon tal which as 2

lower breaking strain than the wire, alo ensures

that the cheaper and easier to replace tal parts

before the wire when seeidental overoading

takes place

Principal causes of damage

' Conosion -Thisis common cause of wire rope

failure. Mooring wires located on drums a the

fentremities of the vessel can be subject to

extensive environmental exposure

+ Cutting in This occurs when wire ope buries

itself under tension in a wire that has been

spooled poory underneath it causing counter

rotation during terthing and kink damage. If

undetected by erew members tis wl not only

seriously damage the wire and wine, but could

result in serious injury othe cre

Crushing - This can seriously damage the

structure of the rope by separating strands

hich will change the geometry of the rope

reducing te breaking strain sgnifcant,

Abrasion ~ Some sources of abrasion damage

are unavoidable - stevedores repeatedly

fragging the wite over quaysde knuces will

produce progressive wearin every mooring Wie

Preventable abrasion damage accuts when

wire is led through poorly maintained leads

which have become seizeé or have uneven

comoded surfaces,

Fatigue —The extent ofa wire’ lesilty shouls

be discussed with the manufacturer prior to

purchase Frequent excessive bending o the wie

while under load wll produce fatigue eamage,

Which wil be acelerated i the wie is being

used beyond its design specification. Careful

consideration should be given to. the

characterises of the wie when od wire being

replaced by nem Before ordering new wie those

responsible nee to ensure thatthe diameter of

the lle leads and pedestal alles on board are

‘ompatbiewith he construction af the wie and

‘the manufactur’ recommendation.

Care and handling

Haneling of mooring wire ropes is 2 hazardous

activity and all those involved should receive

propriate instruction on the dangers and

precautions requ oeduce thers of ij.

‘raining should include the limitations of use and

posible causes and consequences of poor handing

and insufficient maintenance. Topics could include

‘butrot be limited te

‘+ voiding sharp angles in mooring srangements.

* Correct use of leads and pedestal ler

‘voiding snap-back ones.

+ Danger ofboken strands.

‘Hazards of lubricansin contact with skin,

+ Precautions required when working with single

srr, spit drum and dum ends.

Wires tres on rus.

Mooring operations are no different to anyother

hazardous activity onboard the vessel and requiea

risk assessment to be cari out as pat of the

‘iting and preparation process. The raring plan

should be discussed with all those who will be

Involved to establish the most appropriate leads and

roles tobe used foreach wie

Maintenance and inspection

Because af the exposed location of mooring wires

and their vulnerability to fatigue damage, strict

maintenance and lubrication senedues must be

maintained to prevent carrion Wires should be

removed from winch drums for detailed

‘examination at a time interval based on the

manufacturers recommendations andthe wire’s

siscard criteria. The wire should be cleaned with

products compatible with the wire, intended

lubricant and approves ty the wite's manufacture.

During cleaning crew members must be aware of

‘the possiblity of broken wire and wear appropriate

hand protection. very broken wie detected should

be brought to the attention ofthe supervising

officer. Wire manufacturers will stipulate the

Permissible maximum numberof broken standsin

given wire enath

‘Ageneral rule of thumb for mooring wires would be

breakage in 108 of te vse strands in any length

of wireequal to lamers

this number is exceeded then the wite should be

condemned and removed from service. Once

‘leaned and examined, damage to the wire must be

recorded in planned maintenance records and

compared tothe manufacturers discard rtera and

previous damage notes, This is also an ideo!

opportunity to inspect the end fiting ofthe wire to

the drum and check method of attachment. When

the responsibeoficer is satisfied with the wire’s

condition it can be treated with the approved

lubrednt and greased if requires. Care must be

taken to ensure that the lubricant penetrates

between the surface wies and int the central core

ofthe rope. During re-spooing crew must ensure

sufficient back tension is maintained this wil not

only protec the wie fom crushing damage but wil

help prevent cutting in and kink damage during

future se

Routine external examination shoud be incorporated

inte pre-artival and departure checks in acordance

with the vessels safety management system:

‘Ai feads, rollers and contact surfaces must be

‘maintained to ensure they ae kept smooth and

‘ree rom signs of cortsion this will reduce

likey Sources fabasion damage

Pedestal and fiend roler bearing surfaces

shoul be kept lbrcated.

Maintenance of back tension during operation

and poling fo inspection must be maintained

+ ‘Amore detailed examination should take place

after any shoetloading or unusual event. Those

involved should compare the condition of the

wire to the manufacturer's recommended

Aiseard criteria and should check for signs of

elongation and bid-caing

CARGO WIRES

Cargo wires are used in cranes, gantres and othe

cargo ling ap

sed for other lifting operations such as stores

ce, Similar wires wl so be

anes and engine room ganties. The

spy tall such wires used n cargo and other iting

Sirens

the tensile forces imposed on them bythe design of

appropriate

factor of safety, Applicable safety factors forthe

re ropes are se outin the design requirement for

vanes and other lifting appliances by various

‘sasifiation societies andar primarily based on

3 safe working load (SW of the equipment. For

ship's cranes ot other lifting appliances rated

between 20 and 60 tonnes (SIL), the required

braking strength ofthe wie ofthe order of four

Fo five times the maximum signed duty load in

servic. Thisaplies to iting aa ling Wrst

forcesin which alter depending upon te cietation

ofthe crane, ban the dymamic influences during

operation

Construction

The most common wire construction for nite ropes

on ship's anes iting appliances isthe single

ayer wire rope corresponding, 3s the name

suggests, single ayer of strands helieally wound

srounda cove. Other typesare manufactured suchas

rotation resistant’ or ‘muli-strang” in which @

number of layers of strands are contra-helclly

the rotational tendency and torgue

inthe rope under terslon These ope canals

compacted strands in whieh the inividual wires

are not round but shaped to provide @ greater

rece the contac pressure

Defects and damage

ntemational_ standard 150.4909 provides 2

| comprehensive isting of, and photographs, showing

‘number of defects that ean oceur on crane or

iting appliance wire ropes, Obvious defects such

kinks and basket deformation n which the external

shape af the wire rope changes shouldbe able to be

identified relatively quick External corosi

Should alsa be obvious during inspection.

Wire ropes shouldbe frequently checked closely f

other damage and defects, suchas indication of

wear (fitting of wires) ane broken wires in the

strands. Te extent of broken wires na give eng

‘and grouping of wire beaks real factors tha ees

tobe considered when judg criteria for allowing

the rope to continue in sevice. Tables in standards

set out the eelevantcfteria although there are

differences between the

and standards under the regulatory

inthis regard

ee

Cargo Wir

Probably the most common defect within wire ope

inwhich eursory examination of greased rope can

often ovrooks wear. This is shown by fiateing of

the round wie elements learcan be acelerted ty

defective (non-otatng) sheaves with the rope

abreding around it orf the wie ope diameter i

larger than, an not matched, othe sheaves. Too

small diameter sheaves can als result in excessve

bending ofthe rope. Eventually, Patening ofthe

wires reduces the load beating ctoss-secton of

individual wires, which can lead to wire fractures.

Wear can also initiate fatigue From a maintenance

and safety perspective of wire rope, regular

inspection and ubrication of sheaves in accordance

with the manuf

res instructions. should

be flowed

Wire facture caused Source:WThompson

byexcessive wear

Fatigue crocs

Source:NThampson

oO

far are shown inthe two figures on

et In one ican be sen by the naked eye that

excessive wear. The scanning electron microscope

photograph in the other shows two rack fronts

propagating frm the fltteneé portion ofthe wire

hough fatigue that ordinarily may not be vibe to

he raked ye

According to 80 4209, 2795 reduction in nominal

rope ameter warrants discard ofthe rope evenfno

Whichever guideline document is used to judge

conton ofa wire open use onboard a esses

wire ropes should be consieredconsumabe ems,

Care and handling

There iso set pei forthe expected lifetime o

rapes. Homever in practice 2 survey cycle period of

five years would bea typical maximum ifetime fo

crane or lifting appliance wire ropes. OF course,

depending on the duty of the crane o lifting

appliance ad sil of operators,

particualy prone to external abrasion o crushing

‘damage Such damage can occur ina single even

and possibly resulting in relatively new wie to

‘wie, similar toa chai, sonly

strong sits weakest pint.

Inspection and maintenance

Regular bua inspection, ideally before and after

‘operations handling cargo, should be ered ut on

bord to check For damage and defects Measurement

of the rope diameter (scribed from the

surrounding the entire rope) shoulé be made and

recorded regulary to monitor wear partulary

Crane and other iting apolances and ther loose

9 nludng wie ropes ae subjet to annual and

diate yearly surveys. at which hey are also

prooflad tested bythe clasfiation society Details

‘ofthe surveysare recorded the vessels Reisterof

Ling Appliances and Cargo Handling Gear

‘Adocumentary record af wie ropes in us onthe

‘rane or lifting appliances, their identification,

appropriate est cetficates ang dates of renewal

(> should be maintained onboard. When wires are

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Shipping in Arctic Waters, A Comparison of The Northeast, Northwest and Trans Polar PassagesDocument435 pagesShipping in Arctic Waters, A Comparison of The Northeast, Northwest and Trans Polar Passageslivslx100% (1)

- Panamax Cargo Hold Cleaning Manual Rev01Document22 pagesPanamax Cargo Hold Cleaning Manual Rev01livslx100% (2)

- Power Supply Repair PDFDocument4 pagesPower Supply Repair PDFAbdul Basit AminNo ratings yet

- Mpi Mru Guide For The En62305 En60364-6 StandardsDocument48 pagesMpi Mru Guide For The En62305 En60364-6 StandardsChristine BuchananNo ratings yet

- Fluke 17b Multimeter SchematicsDocument1 pageFluke 17b Multimeter Schematicslivslx100% (1)

- Radio Electronics November 1991 PDFDocument188 pagesRadio Electronics November 1991 PDFlivslx100% (1)

- Survey and Examination of Ships' Lifting AppliancesDocument24 pagesSurvey and Examination of Ships' Lifting Applianceshpss77100% (1)

- 11 Normal Vs AbnormalCombustionDocument4 pages11 Normal Vs AbnormalCombustionDhananjay BaviskarNo ratings yet

- Poor Man 1GHzDocument3 pagesPoor Man 1GHzmuddogNo ratings yet

- Attiny2313 ESR SchematicDocument1 pageAttiny2313 ESR SchematiclivslxNo ratings yet

- JASON Version 0.99: Just Another Ship-Owner Name:-)Document7 pagesJASON Version 0.99: Just Another Ship-Owner Name:-)Apollos_80No ratings yet

- Fluke 17b Multimeter Schematics PDFDocument1 pageFluke 17b Multimeter Schematics PDFlivslxNo ratings yet

- Interfacing 555 TimersDocument4 pagesInterfacing 555 TimerslivslxNo ratings yet

- Troubleshooting OPAMPs and OtherDocument11 pagesTroubleshooting OPAMPs and OtherlivslxNo ratings yet

- Single Supply Op Amp DesignDocument2 pagesSingle Supply Op Amp DesignlivslxNo ratings yet

- Simple Overload Circuit Protects DC PSUDocument1 pageSimple Overload Circuit Protects DC PSUlivslxNo ratings yet

- Designing Oscillators OpAmpDocument5 pagesDesigning Oscillators OpAmplivslxNo ratings yet

- MIC-10K1 Insulation TesterDocument68 pagesMIC-10K1 Insulation TesterlivslxNo ratings yet

- LKZ 1500Document48 pagesLKZ 1500livslxNo ratings yet

- Dissassembling and Patching Hardware - (Malestrom)Document90 pagesDissassembling and Patching Hardware - (Malestrom)diwankumaniNo ratings yet

- Sonel MMR-620Document40 pagesSonel MMR-620livslxNo ratings yet

- GSM / GPRS Wireless Module: Design Guide Rev. 0.1 December. 2003Document23 pagesGSM / GPRS Wireless Module: Design Guide Rev. 0.1 December. 2003livslxNo ratings yet

- MMR-650 MilliohmeterDocument72 pagesMMR-650 MilliohmeterlivslxNo ratings yet

- Sonel MZC-304 User's ManualDocument44 pagesSonel MZC-304 User's ManuallivslxNo ratings yet

- Archivi Audiofilofine Crowhurst Cooper 1956 High Fidelity Circuit DesignDocument304 pagesArchivi Audiofilofine Crowhurst Cooper 1956 High Fidelity Circuit DesignGastrolio ErmeteNo ratings yet

- Ordering Safety SignsDocument14 pagesOrdering Safety SignslivslxNo ratings yet

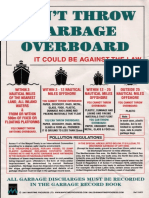

- Garbage RegulationDocument1 pageGarbage RegulationlivslxNo ratings yet

- COLREG-A Good PracticeDocument5 pagesCOLREG-A Good PracticelivslxNo ratings yet