Professional Documents

Culture Documents

Work Instructions For Blasting Painting

Uploaded by

ananda_beloshe750 ratings0% found this document useful (0 votes)

355 views2 pagesWork Instructions for Blasting Painting

Original Title

Work Instructions for Blasting Painting

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWork Instructions for Blasting Painting

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

355 views2 pagesWork Instructions For Blasting Painting

Uploaded by

ananda_beloshe75Work Instructions for Blasting Painting

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

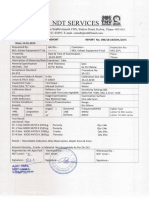

INDUSTRY Department | Q A Page No. | | of 2

PPE at |

it i i in R

Cut tbe EE Title Work instruction for Blasting & Painting Revision | 0

RefNo. | QAWI2S Date | 16.11.17

TITLE : Work instruction for Blasting & Painting

ACTIVITIES

Step 1 = Protection of machined surface

| i) Pre-machined surfaces, drilled & tapped holes must be covered before blasting &

painting.

Step 2 - Blasting

i) CMI FPE requirement is to maintain surface finish as per Sa 2¥ (ISO 8501-1) & surface

profile of (Rz) 40-60 j To achieve these requirements, contractor shall select

appropriate specification of grits and maintain proper blasting pressure.

il) Visual inspection for Sa 2% by comparator & blasting profile by profile by profile gauge.

iii) Photographs of all blasted components to be submitted to CMI FPE,

i) _ After blasting, the primer coat shall be applied within 4 hours to avoid new formation of

rust. (in rainy season primer coat shall be followed within 2 hours after blasting. If

surface is not hot, ie. temp. is above 50°C)

ii) Ensure surface is completely dry.

iii) Ifrequired, dry the surface by hot air to remove moisture.

iv) Apply primer to achieve total DFT as per painting specification. (Ref, CMI Painting

Specifications }

v) Ensure surface is completely dry & then check DFT.

vi) Adhesion test to be carried out for each lot,

vii) _ Photographs of adhesion test to be submitted to CMI PE.

(P-7.0)

|

|

ij petal Department | QA Page No. | 2 of 2

CAPR Maen Title Work instruetion for Blasting & Painting Revision [o_|

RefNo. | QAAWI2S Date | 16.11.17

Al tion of Paint

i) Ensure surface is completely dry.

ii) Ifrequired, dry the surface by hot air to remove moisture.

iii) Apply first coat of paint to achieve DFT as per painting specification.

iv) Allow to dry as per paint specification requirement by CMI FPE before application of

second coat.

v) Ensure surface is completely dry & then check DFT. |

vi) Apply second coat of paint to achieve DFT as per painting specification.

vii) Allow to dry as per paint specification requirement by CMI FPE after second coat.

viii) Ensure surface is completely dry & then check DFT.

ix) Adhesion test to be carried out for each lot.

x) Photographs of adhesion test to be submitted to CMI FPE.

i) Suitable rust preventive to be applied on drilling, tapping & machined surface.

Effectiveness of rust preventive must be for minimum 6 months.

Step 6 ~ Preservation of pain!

i) Painted surface must be packed by stretch film. (Please refer Purchase Order for more

details).

ii) Stretch film thickness must be minimum 50 p.

iii) Ensure that moisture or water should not entrap during packing. Overlap of stretch film

must be minimum 40%. Ensure that stretch film wraps are stick to each other. Supplier

to ensure that there is no opening between the stretch wraps.

Notes: 1) All above information (Step 1 to 6) to be provided in VIR. (in CMI FPE paint

certificate format No. QA/FO/36, latest revision)

2) Make for primer & paint shalll be used as per CMI FPE recommendation.

3) Every 6 months, ProceMs vflidation report must be-provided for blasting & painting by

contractor. : Ng

as Den a7 Ae

ir Ugale Shridhar Sulebhavi Vaman Urunkar = Pravat’Mahapatra

(HOD Qa) (HOD Projects) (HOD Purchase) —(HOD Plant)

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Pictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsDocument24 pagesPictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsBellana SirishNo ratings yet

- CRN 3493990263Document3 pagesCRN 3493990263ananda_beloshe75No ratings yet

- Quality Certificate for SAIL Discharging Door AssemblyDocument1 pageQuality Certificate for SAIL Discharging Door Assemblyananda_beloshe75No ratings yet

- Weekly Report-NovDocument8 pagesWeekly Report-Novananda_beloshe75No ratings yet

- Purchase Orders for Engineering EquipmentDocument122 pagesPurchase Orders for Engineering Equipmentananda_beloshe75No ratings yet

- Synergia Inspected List-23.5.2019Document1 pageSynergia Inspected List-23.5.2019ananda_beloshe75No ratings yet

- Comparison EN8D - IS 2062Document1 pageComparison EN8D - IS 2062ananda_beloshe75No ratings yet

- Macro Requirement As Per CodeDocument3 pagesMacro Requirement As Per Codeananda_beloshe75No ratings yet

- Quality Certificate for SAIL Discharging Door AssemblyDocument1 pageQuality Certificate for SAIL Discharging Door Assemblyananda_beloshe75No ratings yet

- Standard Working Procedure - System 1Document6 pagesStandard Working Procedure - System 1ananda_beloshe75No ratings yet

- Dissimilar Metal Weldability Concepts Alber SadekDocument45 pagesDissimilar Metal Weldability Concepts Alber SadekMohammad AliNo ratings yet

- Dissimilar Metal WeldabilityDocument1 pageDissimilar Metal Weldabilityananda_beloshe75No ratings yet

- Letter To Elca - 16 - 17 NewDocument89 pagesLetter To Elca - 16 - 17 Newananda_beloshe75No ratings yet

- ISH Check List - EK288Document1 pageISH Check List - EK288ananda_beloshe75No ratings yet

- C Channel Length Extension WeldingDocument1 pageC Channel Length Extension Weldingananda_beloshe75No ratings yet

- Steelwork Preparation S 2 EepvDocument6 pagesSteelwork Preparation S 2 Eepvananda_beloshe75No ratings yet

- Comparison EN8D - Is 2062Document1 pageComparison EN8D - Is 2062ananda_beloshe75No ratings yet

- Digital Lab OvenDocument3 pagesDigital Lab Ovenananda_beloshe75No ratings yet

- ASTM A106 Seamless Carbon Steel Pipe For High Temperature Service PDFDocument9 pagesASTM A106 Seamless Carbon Steel Pipe For High Temperature Service PDFsingaravelan narayanasamyNo ratings yet

- Testrep - Lock NutDocument2 pagesTestrep - Lock Nutananda_beloshe75No ratings yet

- Preferred Tol and FitsDocument9 pagesPreferred Tol and Fitsananda_beloshe75No ratings yet

- COC - Entry and Exit Saddle Assembly.Document2 pagesCOC - Entry and Exit Saddle Assembly.ananda_beloshe75No ratings yet

- Is 13311.2.1992 PDFDocument12 pagesIs 13311.2.1992 PDFTayyab AnwarNo ratings yet

- TC For AVM WasherDocument4 pagesTC For AVM Washerananda_beloshe75No ratings yet

- Journal International SDLC 15 HalDocument15 pagesJournal International SDLC 15 HalAmandhaEarlyNo ratings yet

- Status Report of Saddle AsslyDocument2 pagesStatus Report of Saddle Asslyananda_beloshe75No ratings yet

- 55 Ni CR Mo V7Document1 page55 Ni CR Mo V7ananda_beloshe75No ratings yet

- Guarantee Certificate For SRDocument1 pageGuarantee Certificate For SRananda_beloshe75No ratings yet

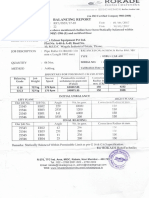

- Balancing ReportDocument2 pagesBalancing Reportananda_beloshe75No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)