Professional Documents

Culture Documents

Asme 31.8 2

Asme 31.8 2

Uploaded by

sri99870 ratings0% found this document useful (0 votes)

11 views1 pageASSS

Original Title

ASME-31.8-2

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentASSS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views1 pageAsme 31.8 2

Asme 31.8 2

Uploaded by

sri9987ASSS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

Copyrighted material hoansed to Saipem incla Projecis Limited. Mo furtnerreproducton or eistioutlon permed.

ries ewes by: ig harkemn@esipem. som] @ 201305-02

ASME B31.82082

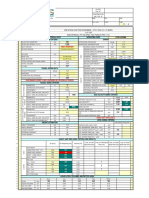

Table 841.1.7-1 Longitudinal joint Factor, E

‘Spec Na. Pipa Cs Efactor

ASTAAS Seamless 100

Bectrc Resistance Welded 190

Fumace Sut Welied, Continuous Wel 0.60

AST ALOE Seamless 100

ASTI AL34 —Blectric Fusion ArcWelded 030

AST ALIS Bectrc-esstance Welded 190

ASTM AZ? Bectrifusion ArcWelded 020

ASTMAIS3 Seamless 100

Blctrc Resistance Welded 4100

ASTIASE1 — SubmergedsAre Welded 1.00

ASTUAGTS — Bectrie-usion- Welded

‘asses 13, 23, 33,43, 53 030

asses 12, 22, 32,42, 52 41.00

ASTMAS72 circ Fusion Welded

asses 13, 23, 93,43, 53, 020

‘asses 42, 22, 32,42, 52 100

ASTUAGS1 — Gectrie-usion Welded

‘dassas 13, 23, 33.43, 53 020

(asses 12, 22, 32,42, 52 1100

ASTIAASSA — Gleetrc Resistance Welded 100

ASTI ALOOS Double Submerged:Are Welded 41.00

‘ASTM ALOOE Laser Beam Weitad 1.00

APIS. Bectrie Weited 100

Seamless 100

Submergedsar Welied (Longitudnal 1.00

‘Seam or Helical Sear)

Fumace-Sut Weldad, Continuous Weld 0.60

[GENERAL NOTE: Defintions for the varlous Classes of welied pipe

ave given in para. 804.73.

Table 841.1.8-1 Temperature Derating Factor,

T. for Steal Pipe

Tenperatre Dering

Rempemture, 7 C0 actor, F

250 (421) silower 1.000)

300 (149) oer

35017) oss

‘400 (204) 0.500

450 (032) oer

‘GOVERAL NOTE: For\mtemnadlate emperatres interpolate for dara

ing facto,

turbulence and pressure drop and contribute to exces-

sive sound pressure levels (aerodynamic noise} and can

‘cause internal piping erosion.

(h) Other (Nonmaridalory) Considerations for Pressure/

Flow Control Facilities

(1) Filtration of gas, particularly for instrumenta-

tion, instrument regulators, etc, should be considered

‘where particulate contaminants are a present or poten-

tial problem.

(2) Installation of conical reducers immediately

downstream of a regulator or control valve will allow

a more gradual expansion of gas to larger piping and

4

reduce turbulence and pressure drop during gas

expansion.

(i) Electrical Facilities and Electronic Equipment for

Pressure/Flow Contr! anc Metering Facilities

(1) All electrical equipment and wiring installed in

pressure/flow control facilities and metering facilities

shall conform to the requirements of NEPA 70 and other

applicable electrical codes. Additional API and AGA.

references are listed in Nonmandalory Appendix C.

(2) Electronic control, monitoring, and gas mea-

surement equipment shall be properly grounded and

isolated from piping to help prevent overpressure/

accidental shutoff situations caused by equipment fail-

ture due to lightning strikes and electrical transients and

to prevent safety hazards caused by fault currents. Elec-

trical isolation equipment for corrosion control purposes,

should not be installed in buildings unless specifically

designed to be used in combustible atmospheres.

(3) Uninterruptible power sources or redundant

back-up systems should be considered to help prevent

‘overpressure/unintentional shutoff situations caused by

power outages

(2) A useful reference for electronic gas measure-

ments is API Manual of Petroleum Measurement

Standards, Chapter 21 — Flow Measurement Using

Electronic Metering Systems, Section 1— Electronic Gas,

Measurement.

(p) Pipeline Installation by Directional Drilling

(1) Qualifications. Drilling, contractors shall main-

tain written design and installation procedures

add crossings to be completed by the directional

drilling method. Drilling equipment operators and per-

sonnel responsible for establishing the location of the

pilot head and reamer during drilling operations shall

be qualified by training and experience in the implemen-

{ation of the contractor's procedures.

(2) Geotechnical Eoaluations. Geotechnical evalua-

tions should be considered at the crossing location to

‘establish subsurface conditions.

(3) Installation Forces and Stresses. Loads on, and

stresses in, the pipe string during installation shall be

‘evaluated to ensure protection of the pipe against yield~

jing, buckling, collapse, and undesired movement of the

pipe string due to the combined effects of external pres-

sure, friction, axial forces, and bending. (See directional

drilling references in Nonmandatory Appendix C.)

(B) Protective Coating. The frictional and abrasive

forces that may be exerted on the pipe coating during

installation shallbe considered when specifying the type

of coating system to be applied to the pipe and weld

joints. During installation, care shall be taken to protect

the quality and integrity of the external corrosion,

coating.

(5) Additional Evaluation Mensures. In addition to

the minimum inspection and post-inspection testing

requirements of this Code, consideration shall be given,

‘Copyright © 2013 by the American Society af Mechanical Engineers

‘No reproduction may be made of this material without written consent of ASME.

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 1Document7 pages1sri9987No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- RT PDFDocument2 pagesRT PDFsri9987No ratings yet

- Banchmark Olga Vs LedaDocument79 pagesBanchmark Olga Vs Ledasri9987100% (1)

- Fluid Flow and Simulation SoftwaresDocument57 pagesFluid Flow and Simulation Softwaressri9987100% (1)

- Standard DocumentDocument43 pagesStandard Documentsri9987100% (1)

- Hazid/Envid/Dsr 1& Dsr2 /hazop /sil / Select Phase Action Tracking SheetDocument6 pagesHazid/Envid/Dsr 1& Dsr2 /hazop /sil / Select Phase Action Tracking Sheetsri9987No ratings yet

- Flow AssuranceDocument10 pagesFlow Assurancesri9987No ratings yet

- E ReceiptDocument1 pageE Receiptsri9987No ratings yet

- DcrerweDocument1 pageDcrerwesri9987No ratings yet

- Objective: Vessel Sizing Report Using ICARUSDocument2 pagesObjective: Vessel Sizing Report Using ICARUSsri9987No ratings yet

- Liquid Vs DistanceDocument1 pageLiquid Vs Distancesri9987No ratings yet

- FIG. 20-3 Water Content of Hydrocarbon GasDocument1 pageFIG. 20-3 Water Content of Hydrocarbon Gassri9987No ratings yet

- Acoustic Induced Vibration - Flare Systems PDFDocument2 pagesAcoustic Induced Vibration - Flare Systems PDFsri9987No ratings yet

- Aww June 2014Document76 pagesAww June 2014sri9987No ratings yet