Professional Documents

Culture Documents

RAPID P0022 PUNJ PIP ISO 5900 2187, Rev 0, PL 5900 00564 02

Uploaded by

kishorsinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RAPID P0022 PUNJ PIP ISO 5900 2187, Rev 0, PL 5900 00564 02

Uploaded by

kishorsinghCopyright:

Available Formats

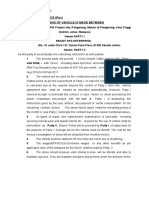

FABRICATION MATERIALS

PT PMRC PART & DESCRIPTION N.S. (INS) QTY WEIGHT

NO.

1 PAATFPZBEEX4A3G Pipe, ASME B36.10M, BE, ASTM 4 29776MM 478.81

A106-B, Seamless, S-40

2 NNAGDCMBCG4A3G0H3Q Nippolet, MSS SP-97, BE x MTE, ¾x¾ 1 0.00

ASTM A105, CL 3000, S-40XS-160

z

3 NCAFKRBEAN4A3G 90 Deg. LR Elbow, ASME B16.9, 4x4 1 3.90

y x BE, ASTM A234-WPB, Seamless,

S-40XS-40

END-CONNECTION-PIPELINE TOTAL FABRICATION WEIGHT 482.71

PL-5900-00564-01

E 6724060

N 5066579 PIPE SUPPORTS

EL 107757

PT PMRC PART & DESCRIPTION N.S. (INS) QTY

NO.

4 LS12-4"-250-CSS40 Pipe Support 1

36

44 SS1-A-300-CS

6 SS1-A-300-CS Pipe Support 4 5

FW01

1 96

50 7 G1-B Pipe Support 4 3

SS1-A-300-CS

ERECTION MATERIALS

6

7

PT COMPONENT DESCRIPTION N.S. (INS) QTY WEIGHT PMRC

G1-B

SPOOL1 NO.

SPOOL2

6 18

62 5 Cap, ASME B16.11, CL 3000, FTE, ASTM A105, ¾x¾ 1 0.00 NAACDCMTFZZ0H

TOTAL ERECTION WEIGHT 0.00

G1-B

86

17

FW02 TOTAL WEIGHT 482.71

1

CUT PIPE LENGTH

26 CUT N.S.

6 17 ITEM-CODE PIECE NO LENGTH (INS) REMARKS END PREP.

7

SS1-A-300-CS PAATFPZBEE 2 -3 6755MM 4 BE / BE

SS1-A-300-CS

33

83 PAATFPZBEE 3 -4 11509MM 4 BE / BE

FW03

SS1-A-300-CS

PAATFPZBEE 1 -2 11512MM 4 BE / BE

6

11

66 JOINT INFORMATION

1

SPOOL3 6 END-CONNECTION-PIPELINE

PL-5900-00564-03 S/NO SIZE WELD F/S SPOOL DIA-INCH

E 6724060

G1-B N 5031721

EL 108805 1 4.00 BW FW SP1 4

2 4.00 BW FW SP2 4

7 22

2

79 3 4.00 BW FW SP3 4

SPOOL4

4 4.00 BW SW SP3 4

16

89

40

2 5 0.75 OLET FW SP4 0.75

FW05 1 3 6 0.75 TH FW SP4 0

4 DIA-INCH SHOP 4 DIA-INCH FIELD 12.75 TOTAL 16.75

5

SW04

FW06 Thd

LS12-4"-250-CSS40

END-POSITION-CLOSED

E 6724060

N 5032124

EL 107594

100-PL-5900-00564-1C114CQ-N 1C114CQ

LINE NUMBER SIZE LINE SPEC. INSUL INSUL THK

SERVICE: PL CODE: B31.3

OPERATING 2.00 44

Barg °C

DESIGN 7.00 75

OWNER: PROJECT TITLE:

PETRONAS RAPID PROJECT,PENGERANG

NOTES: 8) FOR ALL SMALL BORE TAPPINGS xxxx & ABOVE, SMALL BORE TAPPING

1) ALL DIMENSIONS, ELEVATIONS & CO-ORDINATES ARE IN MM. NEAR PSVS. CONTROL VALVE, ALL ORIFICE TAPPING VIBRATION PRONE (P0022)

2) FIELD WELDS TO BE DECIDED BY THE FABRICATOR/CONTRACTOR. LINES. STIFFNERS SHALL BE PROVIDED AS PER SIZE, REFER PIPE

3) ALL BOLT HOLES TO STRADDLE NORTH AND/OR VERTICAL CENTERLINE. SUPPORT NO. RAPID-P0022-PUNJ-PIP-SID-5100-1003. P&ID REF:

ISOMETRIC LINE ID:

4) DIMENSIONS FOR LINES 1-1/2" AND BELOW TO BE CHECKED AT SITE BEFORE 9) FOR LINES REQUIRING STRESS RELEIVING, WELDED SUPPORT

0 ISSUED FOR CONSTRUCTION 26.10.2016 Rajib A.Sharma

PL-5900-00564-02

FABRICATION, DIMENSIONS ARE FOR GUIDANCE ONLY. ATTACHMENTS SHALL BE WELDED PRIOR TO STRESS RELEIVING.

5) ALL ELEVATIONS QUOTED ARE PIPE CENTER LINE/FACE OF FLANGE. 10)PAINTING SPECIFICATIONS SHALL BE AS PER DOC NO. 5900-0001

6) SPRING LOOKS TO BE RELEASED POST HYDROTEST. RAPID-P0022-PUNJ-MCI-SPN-5100-0001. CONTRACTOR:

7) FOR REINFORCEMENT PAD AT BRANCHES, PAD THICKNESS. SAME AS HEADER 11)NDT REQUIREMENT SHALL BE AS PER ASME B31.3

REV DESCRIPTION DATE DRAWN STRESS MATL CHKD APPD

PIPE, PAD OD - TWO TIMES DIAMETER OF PIPE UNLESS OTHERWISE MENTIONED. 12)INSULATION SPECIFICATION SHALL BE AS PER DOC NO. JOB NO: PD5026 DWG NO: RAPID-P0022-PUNJ-PIP-ISO-5900-2187

RAPID-P0022-PUNJ-MCI-SPN-5100-0002 STRESS CATEGORY PAINTING SYSTEM PWHT RADIOGRAPH: TEST TYPE: H

13)IF MIS-MATCH FOUND BETWEEN DESIGN PARAMETERS OF ISOMETRIC &

LINE LIST, THEN LINE LIST TO BE CONSIDERED AS FINAL DOCUMENT.

1 1A : No RANDOM TEST PRESSURE: 75.75 Barg AREA: 5900 UNIT: 5900 SHT. NO. 1 OF 1 REV. NO. 0

You might also like

- Supersucker and Jetting Machines Materials RequirementDocument2 pagesSupersucker and Jetting Machines Materials RequirementkishorsinghNo ratings yet

- Confined Space HazardsDocument29 pagesConfined Space HazardskishorsinghNo ratings yet

- Confined Space HazardsDocument29 pagesConfined Space HazardskishorsinghNo ratings yet

- ADHARCARDDocument1 pageADHARCARDkishorsinghNo ratings yet

- AERemitterAccount PDFDocument2 pagesAERemitterAccount PDFkishorsinghNo ratings yet

- Confined Space HazardsDocument29 pagesConfined Space HazardskishorsinghNo ratings yet

- Sumit Biodata-2020 PDFDocument1 pageSumit Biodata-2020 PDFkishorsinghNo ratings yet

- Cooler Drawin API-23 Seal PlanDocument5 pagesCooler Drawin API-23 Seal PlankishorsinghNo ratings yet

- GHHKHDocument8 pagesGHHKHkishorsinghNo ratings yet

- 1 Guide For WPS PQR WPQR PDFDocument6 pages1 Guide For WPS PQR WPQR PDFmuhammadazhar100% (1)

- 46RFEDSRFDocument1 page46RFEDSRFkishorsinghNo ratings yet

- Cooler Drawin API-23 Seal PlanDocument5 pagesCooler Drawin API-23 Seal PlankishorsinghNo ratings yet

- SEEKDocument1 pageSEEKkishorsinghNo ratings yet

- Plm-102 Sideentrymixers Pty A4Document12 pagesPlm-102 Sideentrymixers Pty A4kishorsinghNo ratings yet

- Nord G1012Document114 pagesNord G1012Fabinho GarciaNo ratings yet

- Blinding GuidelineDocument13 pagesBlinding GuidelinekishorsinghNo ratings yet

- JijDocument3 pagesJijkishorsinghNo ratings yet

- YIUUDocument10 pagesYIUUkishorsinghNo ratings yet

- Nord G1012Document114 pagesNord G1012Fabinho GarciaNo ratings yet

- CBDocument20 pagesCBkishorsinghNo ratings yet

- SEALDocument6 pagesSEALkishorsinghNo ratings yet

- DDRHEECDocument89 pagesDDRHEECkishorsinghNo ratings yet

- Sec - 1701 - Non-Jacketed 4127 Q Viking PumpDocument13 pagesSec - 1701 - Non-Jacketed 4127 Q Viking PumpkishorsinghNo ratings yet

- PDFDocument18 pagesPDFkishorsinghNo ratings yet

- Canada FeeeDocument39 pagesCanada FeeekishorsinghNo ratings yet

- Case Study: Effective Lock Out Tag OutDocument2 pagesCase Study: Effective Lock Out Tag OutkishorsinghNo ratings yet

- Viking PumpDocument36 pagesViking PumpSakir Zak100% (2)

- greasePETRONAS BROUCHERE PDFDocument12 pagesgreasePETRONAS BROUCHERE PDFkishorsinghNo ratings yet

- 4127qviking UmpDocument12 pages4127qviking UmpkishorsinghNo ratings yet

- JSA 04 Confined Sapce EntryDocument1 pageJSA 04 Confined Sapce EntrykishorsinghNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)