Professional Documents

Culture Documents

S 100 Structure Notes

Uploaded by

khawaldeh jamalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S 100 Structure Notes

Uploaded by

khawaldeh jamalCopyright:

Available Formats

STRUCTURAL NOTES

A. GENERAL 4. ALL THE CONCRETE SHOULD SATISFY THE DURABILITY CONDITION GIVEN BELOW FOR SUPER STRUCTURE CONCRETE ONLY.

A1. THE STRUCTURAL DRAWING SHALL BE READ IN CONJUNCTION WITH THE RELEVANT ARCHITECTURAL, REQUIREMENTS OF CONCRETE D. STRUCTURAL STEEL / SPACE FRAME

ELECTRICAL, MECHANICAL AND OTHER STRUCTURAL DRAWING IN PARTICULAR, CUT-OUTS IN SLAB NO TESTS TEST METHOD SPECIFICATION LIMIT GENERAL NOTE

D1. THE CONTRACTOR SHALL BE RESPONSIBLE FOR THE DESIGN OF THE PARAPETS & ARCHITECTURAL FEATURES.,

AND WALLS FOR BUILDING SERVICES SHALL BE READ IN CONJUNCTION WITH THE ELECTRICAL AND AND ANY STRUCTURAL STEEL WORK BY THE SPECIALIZED SUB CONTRACTOR. AND IN ACCORDANCE WITH THE DESIGN LOADS.

MECHANICAL DRAWINGS. 1. temperature ( at placement ) ASTM 1064 25° C max.

for all grades; ''' THE DESIGN CALCULATIONS SHALL BE SUBMITTED TO THE ENGINEER FOR APPROVAL.

A2. FOR MAIN SETTING LINES AND LEVELS, REFER TO THE ARCHITECTURAL DRAWINGS. 2. slump mm ( at placement ) BS 1881; pat 102 150 ± 25 mm

ALL DIMENSIONS MUST BE VERIFIED ON SITE AND ANY DISCREPANCIES SHALL BE BROUGHT D2. THE SHOP DRAWINGS SPECIFICATION AND METHOD OF STATEMENTS FOR THE STEEL WORKS SHALL BE SUBMITTED

3. water permeability DIN 1048 18mm max.

TO THE ENGINEER FOR APPROVAL PRIOR TO CONSTRUCTION.

TO THE ATTENTION OF THE ENGINEER BEFORE PROCEEDING WITH THE PORTION OF WORK INVOLVED.

4. rapid chloride penetration ( RCP ) ASTM C1202 1500 col.. max.

D3. ALL BOLTS SHALL BE GRADE 8.8 TO BS 3692.

A3. ABBREVIATIONS 1.8% col.. max.

5. water absorption BS 1881; part 122

D4. THE PROTECTIVE POINT SYSTEM FOR THE STEEL WORK SHALL BE IN ACCORDANCE WITH THE SPECIFICATION.

EF = EACH FACE

B (B1 & B2) = OUTER & INNER BOTTOM BARS 6. chlorides by weight of cementations material BS 1881; part 124 0.3% max.

D5 ALL STRUCTURAL STEEL WORK SHALL BE GRADE 5275 TO BS EN10025.

T (T1 & T2) = OUTER & INNER TOP BARS 7. sulphates (503) by weight of cementations material BS 1881; part 124 4.0% max.

BW (EW) = BOTH WAYS (EACH WAY) D6 UNLESS SHOWN OTHERWISE ON THE DRAWING, ALL CONNECTIONS SHALL BE IN ACCORDANCE WITH

''' :- TO BE CONFIRMED BY THE SUPPLIER. THE FOLLOWING MINIMUM REQUIREMENTS :

= COLUMN CONTINUED

= COLUMN UNDER NOTE:-2 NOS CONCRETE TEST PRISMS 3m X 3m X 3m TO BE TESTED ON SITE PRIOR TO ANY CONCRETING, ONE FOR SUB STRUCTURE AND

I) ALL WELDS SHALL BE AT LEAST 6mm CONTINUOUS FILLET WELDS ALL ROUND.

= COLUMN TRANSFERRED OR PLANTED AT THIS LEVEL. (NO COLUMN UNDER) ONE FOR SUPER STRUCTURE WITH FULL TEMPERATURE MONITORING ON SITE ALONG WITH DURABILITY TESTS.

II) ALL BOLTS SHALL BE AT LEAST M20. WITH A MINIMUM OF 2 BOLTS OER CONNECTION.

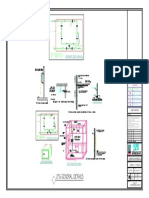

= OPENING IN SLAB OR WALL C5. USE OF CONCRETE ADDITIVES PURLIN BOLTS TO BE IN ACCORDANCE WITH THE SUPPLIERS RECOMMENDATIONS.

EJ = EXPANSION JOINT CONCRETE ADDITIVES APPROVED BY THE ENGINEER SHALL BE USED TO IMPROVE CONSISTENCY, WORKABILITY, QUALITY

III) ALL GUSSET PLATES SHALL BE AT LEAST 10mm THICK.

AND STRENGTH OF CONCRETE

C/C = CENTRE TO CENTRE.

CHEMICAL ADMIXTURES MANUFACTURER SHALL PROVIDE CERTIFIED TEST REPORTS FROM QUALIFIED, INDEPENDENT, ACCREDITED IV) ALL CAP PLATES SHALL BE AT LEAST 12 MM THICK

A4. DRAWINGS.

THE CONTRACTOR SHALL SUBMIT WORKSHOP DRAWINGS SHOWING ALL REQUIREMENTS FOR SERVICES, LABORATORIES SHOWING ACTUAL TEST RESULTS INDICATING MATERIALS COMPLY IN ALL RESPECTS WITH DURABILITY REQUIREMENTS

V) ALL BASE PLATES SHALL BE AT LEAST 12mm THICK.

PENETRATIONS ETC. FOR THE ENGINEER'S APPROVAL. MODIFICATION NECESSITATED BY DETAILED PLANT HIGH RANGE WATER REDUCING ADMIXTURE SHALL BE NAPHTHA LENE SULPHONATE POLYMER BASED MATERIAL LIKE

INFORMATION SHALL BE SUBJECT TO THE ENGINEER'S APPROVAL. CONPLAST SP 2000, OR CONPLAST SP 432 OR EQUAL APPROVED BY THE ENGINEER SHALL BE USED D7 THE STEEL FABRICATOR SHALL BE RESPONSIBLE FOR DESIGN OF CONNECTION IN ACCORDANCE

WATER REDUCING AND RETARDING ADMIXTURE SHALL CONFIRM TO BS EN-934-2 OR ASTM AT 494 TYPE FOR G WITH THE FACTORED DESIGN LOADS GIVE ON THE DRAWING. THE CONNECTION DESIGN CALCULATION

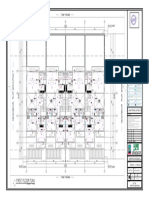

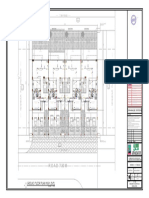

A5. STRUCTURE IS DESIGNED FOR RESIDENTIAL BUILDING (2B + G +3P.+ 23TYP.FLRS) SHALL BE SUBMITTED TO THE ENGINEER FOR APPROVAL PRIOR TO COMMENCEMENT OF FABRICATION.

B. EARTHWORKS AND FOUNDATIONS D8 THE PURLIN SUPPORTING THE CLAD AREAS OF THE ROOF STEEL STRUCTURE SHALL BE

COLD FORMED Z TYPE PURLINS SELECTED FROM APPROVED SUPPLIER, AND SHALL BE

B1. GRANULAR FILL UNDER FOUNDATIONS AND SLAB CAST-ON-GROUND SHALL BE SELECTED GRANULAR MATERIAL CAPABLE OF RESISTING THE FOLLOWING UNFACTORED WIND LOADS.

LAID IN 200 mm LAYERS AND MECHANICALLY COMPACTED TO AT LEAST 95% OF ITS MAXIMUM DRY DENSITY. C6. CONCRETE FORM WORK - DOWNWARD PRESSURE =2.0 KN/m²

B2. THE BACK FILLING MATERIAL SHALL BE SELECTED GRANULAR MATERIAL COMPACTED AT LEAST 95% OF ITS MINIMUM PERIODS IN DAYS FOR STRIKING OTHER FORM WORK SHOULD BE IN ACCORDANCE WITH THE FOLLOWING TABLE - UPWNWARD PRESSURE =2.0 KN/m²

MAXIMUM DRY DENSITY AND IN ACCORDANCE WITH THE SPECIFICATIONS.

B3. TESTS:- CPT TEST TO BE DONE ON BACK FILLING. AT LEAST 1/150m² SLAB ( PROPS LEFT UNDER ) 7 D9 THE FABRICATION AND ERECTION OF THE STRUCTURAL STEEL WORK SHALL BE

AREA. SUPERVISED BY QUALIFIED PERSONNEL TO ENSURE THAT ALL DESIGN REQUIREMENTS

BEAM SOFFITS ( PROPS LEFT UNDER ) 10

ARE MET. DETAILS OF ERECTION SEQUENCE SHALL BE SUBMITTED TO THE ENGINEER

C. REINFORCED CONCRETE PROPS TO SLABS 16 FOR APPROVAL PRIOR TO COMMENCEMENT OF ERECTION.

C1.CONCRETE SUB STRUCTURE PROPS TO BEAMS 21

(RAFT & BASEMENT WALLS) 1

VERTICAL SURFACES FOR WALLS & COLUMNS

CONCRETE FOR RAFT, R.C.C.BASEMENT WALL (ANY OTHER STRUCTURAL ELEMENT CONTACT WITH EARTH) SHALL HAVE A

CHARACTERISTIC STRENGTH, DETERMINED FROM CUBES AT 28 DAYS, OF 48 N/mm², E : BLOCKWORK.

MIX SHALL BE ( PORTLAND CEMENT WITH 36% TO 65% GGBS ( GROUND GRANULATED BLASTFURNACE SLAG )+ MICRO SILICA). C7. CURING

MAXIMUM WATER / CEMENT RATIO OF 0.35. a. HORIZONTAL SURFACES E1: BLOCKS SHALL HAVE A MINIMUM CHARACTERISTIC COMPRESSIVE STRENGTH OF 12.5 N/mm² AT

IT SHALL HAVE A CHARACTERISTIC STRENGTH, DETERMINED FROM TEST CUBES AT 28 DAYS, OF 48N/mm². 28 DAYS FOR LOAD BEARING WALLS AND 7.5 N/mm² FOR NON-LOAD BEARING PARTITIONS TO

1) POLYTHENE SHEET MUST BE PLACED IMMEDIATELY AFTER FINISHING

BS5628 : PARTS 1, 2 & 3 : 1992. ALL BLOCKS SHALL BE IN ACCORDANCE WITH LOCAL

C2. CONCRETE SUPER STRUCTURE (2ND BAS. TO 16TH TYPICAL FLOOR) (COLUMNS,WALLS,CORE WALLS & SPANDERL BEAMS.) 2) AFTER FINAL SET HAS TAKEN PLACE, POLYTHENE SHEET SHALL BE REPLACED BY WET HESSION MUNICIPALITY REGULATIONS.

3) AFTER 7 DAY HESSAIN & POLYETHENETO BE REMOVED AND ON APPROVED ALUMINIZED OR WHITE RESIGN -BASED

ALL CONCRETE WORK SHALL CONFIRM TO THE BRITISH STANDARD BS 8110 :1997. EXCEPT WHERE OTHERWISE NOTED, E2: ALL BLOCK WALLS SHALL BE CONSTRUCTED WITH LIGHT WEIGHT BLOCKS.

CONCRETE SHALL BE OF GRADE C60., IT SHALL HAVE A CHARACTERISTIC STRENGTH, DETERMINED FROM TEST CUBES AT 28 TROPICAL CURING COMPOUND APPLIED. THE HESSAIN & POLYTHENE SHALL REMAIN FOR FURTHER 7 DAYS ( ALTERNATIVELY )

DAYS, OF 48N/mm². AND HAVE NOMINAL MAXIMUM AGGREGATE SIZE OF 20mm TO BS 882. CONCRETE MIX DESIGN SHALL E3: BLOCK WALLS BELOW GROUND FLOOR LEVEL SHALL BE CONSTRUCTED WITH SULPHATE RESISTING BLOCK.(CONTACT WITH SOIL)

b. VERTICAL SURFACES

COMPLY WITH BS 5328. THE MINIMUM CEMENT CONTENT SHALL BE 420 kg/m³

1) POLYTHENE OR WET HESSAIN SHALL BE SECURED TO THE SURFACES IMMEDIATELY AFTER REMOVAL OF THE FORM WORK

MIX SHALL BE (PORTLAND CEMENT WITH 36% TO 65% GGBS ( GROUND GRANULATED BLASTFURNACE SLAG )+ MICRO SILICA ). E4: THE STRUCTURAL FLOOR PLANS SHOW THE LAYOUT OF LOAD BEARING WALLS ONLY. ALL OTHER

MAXIMUM WATER / CEMENT RATIO OF 0.35. THE CEMENT SHALL BE ORDINARY PORTLAND CEMENT (OPC) TO BS 12. 2) AFTER 7 DAYS THE HESSAIN & POLYTHENE SHALL BE REMOVED AND ON APPROVED ALUMINIZED OR WHITE RESIN BASED BLOCKWORK WALLS ARE TO BE CONSIDERED AS NON-LOAD BEARING PARTITIONS AND SHALL BE

FOR TESTING, CERTIFICATION, PLACING, COMPACTING, CURING AND PROTECTION OF CONCRETE REFERENCE SHALL BE MADE TROPICAL CURING COMPOUND APPLIED CONSTRUCTED AFTER COMPLETION OF THE STRUCTURE. FOR SETTING OUT OF BLOCK WALL REFER

TO THE GENERAL PROJECT SPECIFICATION. CONTRACTOR SHALL SUBMIT ALL ADDITIVES & PLASTICIZERS REQUIRED FOR c. CURING COMPOUND APPROVED BY THE CONSULTANT COMPLYING ASTM TO BE USED FOR A MINIMUM OF 7 DAYS FOR PILE CAP. TO ARCHITECTURAL DRAWINGS.

IMPROVING THE WORKABILITY OF CONCRETE FOR THE APPROVAL OF THE ENGINEER.

C6. CONCRETE FORM WORK E5: LOAD BEARING BLOCK WALLS SHALL BE REINFORCED HORIZONTALLY WITH GALVANIZED EXPANDING

MINIMUM PERIODS IN DAYS FOR STRIKING OTHER FORM WORK SHOULD BE IN ACCORDANCE WITH THE FOLLOWING TABLE METAL LATHS PLACED AT EVERY 5th . COURSE VERTICALLY.

C3. CONCRETE SUPER STRUCTURE (16TH TYPICAL FLOOR LEVEL TO TERRACE FLOOR LEVEL)

E6: BRACING OF BLOCK WALLS TO BE PROVIDED FOR WALLS EXCEEDING 14m2 AREA

(COLUMNS,WALLS,CORE WALLS & SPANDERL BEAMS.) SLAB ( PROPS LEFT UNDER ) 7

BEAM SOFFITS ( PROPS LEFT UNDER ) 10 F: ALUMINIUM/SHEETING PH5

ALL CONCRETE WORK SHALL CONFIRM TO THE BRITISH STANDARD BS 8110 :1997. EXCEPT WHERE OTHERWISE REVISION :

NOTED, CONCRETE SHALL BE OF GRADE C60: IT SHALL HAVE A CHARACTERISTIC STRENGTH, DETERMINED FROM F1 SHEETING TO BE ALUMINUM STANDING SEAM ROOF PANELS 1.0 mm THK.OR AS/SPECIFICATION

PROPS TO SLABS 16 07

TEST CUBES AT 28 DAYS, OF 48N/mm². AND HAVE NOMINAL MAXIMUM AGGREGATE SIZE OF 20mm TO BS 882. F2 LINER SHEET, THICKNESS 0.7 mm ALUMINUM IN 25 MICRONS POLYESTER COLOR COATING. OR

CONCRETE MIX DESIGN SHALL COMPLY WITH BS 5328. THE MINIMUM CEMENT CONTENT SHALL BE 480 kg/m³. PROPS TO BEAMS 21 06

AS/SPECIFICATION.

MIX SHALL BE (PORTLAND CEMENT WITH 36% TO 65% GGBS ( GROUND GRANULATED BLASTFURNACE SLAG ). 1 05

VERTICAL SURFACES FOR WALLS & COLUMNS

MAXIMUM WATER / CEMENT RATIO OF 0.35. THE CEMENT SHALL BE ORDINARY PORTLAND CEMENT (OPC) TO BS 12.) G: SOIL REPORT 04

FOR TESTING, CERTIFICATION, PLACING, COMPACTING, CURING AND PROTECTION OF CONCRETE REFERENCE C7. CURING

03

SHALL BE MADE TO THE GENERAL PROJECT SPECIFICATION. CONTRACTOR SHALL SUBMIT ALL ADDITIVES & a. HORIZONTAL SURFACES NATIONAL LAB FOR SOIL INVESTIGATION REF NO. DXB/0053/15 DATE 6TH JUNE 2015

02

PLASTICIZERS REQUIRED FOR IMPROVING THE WORKABILITY OF CONCRETE FOR THE APPROVAL OF THE ENGINEER. 1) POLYTHENE SHEET MUST BE PLACED IMMEDIATELY AFTER FINISHING 01

CONCRETE (GRADES)

2) AFTER FINAL SET HAS TAKEN PLACE, POLYTHENE SHEET SHALL BE REPLACED BY WET HESSION NO. DATE REVISED APPROVED

(SUB STRUCTURE AND SUPER STRUCTURE).

SLAB AND BEAMS FOR ALL FLOORS C60. 3) AFTER 7 DAY HESSAIN & POLYETHENETO BE REMOVED AND ON APPROVED ALUMINIZED OR WHITE RESIGN -BASED PROJECT:

H: WATER TABLE

TROPICAL CURING COMPOUND APPLIED. THE HESSAIN & POLYTHENE SHALL REMAIN FOR FURTHER 7 DAYS ( ALTERNATIVELY )

C4. CONCRETE (GRADES) WATER TABLE IS AT 5.0 TO 5.3m BELOW EXISTING GROUND SURFACE LEVEL. PROPOSED: RESIDENTIAL BUILDING

THE CHARACTERISTIC CUBE STRENGTH ARE FOR CONCRETE WHICH HAVE BEEN CURED AT TEMPERATURE OF 20± 1°C. b. VERTICAL SURFACES

AND ARE THE VALUMES BELOW WHICH NO MORE THAN 5% OF THE TEST RESULTS MAY FALL. THE 7 DAY STRENGTHS 1) POLYTHENE OR WET HESSAIN SHALL BE SECURED TO THE SURFACES IMMEDIATELY AFTER REMOVAL OF THE FORM WORK

DEWATERING WILL BE CONTRACTOR'S RESPONSIBLITY. ( 2B + G + 3P + 23 TYPICAL FLRS. )

SHALL BE USE ONLY AS A GUIDE TABLE OF MIXES. 2) AFTER 7 DAYS THE HESSAIN & POLYTHENE SHALL BE REMOVED AND ON APPROVED ALUMINIZED OR WHITE RESIN BASED CLIENT:

CONCRETE GRADE FOR (COLUMNS/SPANDREL BEAMS/CORES %%UCOLUMNS,WALLS,CORE WALLS,BEAMS,SPANDERL TROPICAL CURING COMPOUND APPLIED DESIGN LOADS

BEAMS,SLABS,RAFT & BASIC WALLS) c. CURING COMPOUND APPROVED BY THE CONSULTANT COMPLYING ASTM TO BE USED FOR A MINIMUM OF 7 DAYS FOR PILE CAP.

LOADS :- AL KHALEEJ ARABI PROPERTIES

1) PARKING FLOOR SLAB (BASEMENT FLOOR)

FLOORS conc. class 28 days strength N/mm² C8. REINFORCEMENT

-DEAD LOAD-

SELF WEIGHT + 1.0 KN/m² FINISHING

TITLE:

REINFORCEMENT SHALL BE DEFORMED TYPE 2AND MARKED TO INDICATE HIGH YIELD STRENGTH OF 460 N/mm² TO BS 4449 .

16TH TYPICAL TO SERVICES 0.5 KN/m²

C60 48

TERRACE FLOOR THE CONTRACTOR SHALL PROVIDE DETAILED AND BAR BENDING SCHEDULES FOR THE ENGINEER'S APPROVAL.

-LIVE LOAD-

5.0 KN/m²

GENERAL DETAILS

2ND BASEMENT TO

16TH TYPICAL C60 48 CHAIRS, SPACERS ETC. SHALL PROVIDE AS NECESSARY, TO THE APPROVAL OF THE ENGINEER ON SITE.

FLOOR LEVEL

RAFT & COMPRESSION LAP LENGTH OF THE REINFORCEMENT TO BE 50 TIMES THE BAR DIAMETER 2) GROUND FLOOR

C60 48

BASEMENT WALL

+111.20 cm

-DEAD LOAD-

THE TENSION LAP LENGTH SHOULD BE AT LEAST EQUAL TO THE DESIGN ANCHORAGE SELF WEIGHT + 2.0 KN/m² FLOOR FINISHING + 2.5 KN/m² PARTITION WALLS.

NOTE:- 1. MIX DESIGN TO BE PROPOSED FOR ALL MIXES BY THE SUPPLIER TO THE CONSULTANT FOR APPROVAL . SERVICES 0.5 KN/m²

LENGTH OR EQUAL TO 50 TIMES THE BAR DIAMETER.

2. (*) SUPPLIER SHOULD CONFIRM THE MIX DESIGN FOR CONCRETE WITH NO SHRINKAGE CRACKS. AND THE QUANTITIES -LIVE LOAD-

GIVEN ABOVE ARE TENTATIVE. 5.0 KN/m² & 10.0KN/m.2 ENG. ADNAN SAFFARINI

ALL CONDUITS SHALL RUN ABOVE BOTTOM REINFORCEMENT AND BELOW TOP REINFORCEMENT OF SLAB,

NOTE:- 1. MIX DESIGN TO BE PROPOSED FOR ALL MIXES BY THE SUPPLIER TO THE CONSULTANT FOR APPROVAL INSIDE BEAM AND COLUMN LINK AND BETWEEN WALL EXTERNAL REINFORCEMENT LAYERS. 3) PODIUM FLOOR DESIGN, SUPERVISON & CONSULT

MECHANICAL COUPLERS TO BE USED FOR 40 mm,32 mm AND 25 mm DIA BARS. -DEAD LOAD-

2. MAXIMUM PEAK TEMPERATURE OF CONCRETE TO BE NOT MORE THAN 70° C & THE MAXIMUM DIFFERENTIAL TEMPERATURE SELF WEIGHT + 1.0 KN/m² FLOOR FINISHING. HEAD OFFICE , POST BOX - 4000 DUBAI : 04-2222002

SHOULD NOT BE MORE THAN 18° C. ( SPECIFICATION OF COUPLERS WRITTEN ON FOUNDATION PLAN ALSO. ) SERVICES 0.5 KN/m² ABUDHABI:02-626050,SHJ:06-5733100,ALAIN:03-668970

3. ALL THE CONCRETE SHOULD SATISFY THE DURABILITY CONDITION GIVEN BELOW FOR SUBSTRUCTURE CONCRETE PARALLEL THREADED COUPLERS WITH BAR BREAK GUARANTEE TO BE USED -LIVE LOAD-

ONLY. 5.0 KN/m².

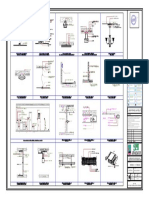

C9. COVER TO REINFORCEMENT. 4) TYPICAL FLOOR SLAB

REQUIREMENTS OF CONCRETE ARCHITECT Ar. AHMED SAFFARINI SIGN

COVER TO REINFORCEMENT SHALL BE FOLLOWS UNLESS SHOWN OTHERWISE ON THE DRAWING :- -DEAD LOAD-

NO TESTS TEST METHOD SPECIFICATION LIMIT PILES =75mm SELF WEIGHT + FINISHES(2.0 KN/m²) & PARTITION WALLS = 2.5 KN/m² STRUCTURE ENG. SHAKEEB SIGN

PERIPHERAL WALL LINE LOAD = 7.5 KN/m

PILE CAP BOTTOM =AS/SKETCH SERVICES 0.5 KN/m²

1. 30° C max. " ELECTRICAL ENG. ----- SIGN

temperature ( at placement ) ASTM 1064 PILE CAP SIDES & TOP =75mm EXTERNAL -LIVE LOAD-

for all grades; ''' GROUND BEAMS =40mm INTERNAL / 75mm EARTH FACES 2 KN/m² MECH. ENG. ----- SIGN

2. slump mm ( at placement ) BS 1881; pat 102 150 ± 25 mm SUSPENDED SLAB =25mm INTERNAL 40mm EXTERNAL 5) TERRACE FLOOR SLAB

3. 10mm max. BEAMS, LINTELS & CAPPING BEAMS =30mm INTERNAL 40mm EXTERNAL -DEAD LOAD- CAD BY: SYED SHAMEEM SIGN

water permeability DIN 1048

COLUMNS =30mm INTERNAL 40mm EXTERNAL /60mm EARTH FACES SELF WEIGHT + 3.5 KN/m² FINISHING + PARAPETS + ARCHITECTURAL FEATURES

4. 1500 col.. max. R.C. WALLS =30mm INTERNAL 50mm EXTERNAL /60mm EARTH FACES SERVICES 0.5 KN/m²

rapid chloride penetration ( RCP ) ASTM C1202 CHECKED BY : DATE: MAY 2016

WATER TANK =50mm INTERNAL 50mm EXTERNAL -LIVE LOAD-

5. BS 1881; part 122 1.8% col.. max. 5 KN/m² +30KN/m² (WATER TANK )

water absorption EXTERNAL RELATES TO CONCRETE FACES EXPOSED TO THE EXTERNAL ENVIRONMENT. REVIEWED BY : DATE:

SEISMIC ZONE - 2B AS/ UBC 97

6. chlorides by weight of cementations material BS 1881; part 124 .15% max. C10. JOINT FILLER/SEALANT SOIL PROFILE TYPE - SC.

EMIRATES: CITY: LOCATION: PLOT NO.:

7. sulphates (503) by weight of cementations material BS 1881; part 124 4.0% max. JOINTS FILLER SHALL BE FLEXL BY FOSROC OR EQUIVALENT APPROVED. JOINT SEALANT SHALL BE

DUBAI DUBAI BUSINESS BAY 346-572

THIOFLEX 600 BY FOSROC OR EQUIVALENT APPROVED. ALL APPLICATIONS ARE TO BE CARRIED OUT BB.A05.032

" :- 10° C FOR RAFT

''' :- TO BE CONFIRMED BY THE SUPPLIER. STRICTLY IN ACCORDANCE WITH THE MANUFACTURER'S INSTRUCTION.

PROJECT No.: DATE: SCALE: SHEET NO:

P-46460 02-01-2016 1 : 200 S 100

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- m106 U Factory Sheet-1Document1 pagem106 U Factory Sheet-1khawaldeh jamalNo ratings yet

- El 103 First Floor PlanDocument1 pageEl 103 First Floor Plankhawaldeh jamalNo ratings yet

- El 102 Ground Floor PlanDocument1 pageEl 102 Ground Floor Plankhawaldeh jamalNo ratings yet

- El 104 Roof Floor PlanDocument1 pageEl 104 Roof Floor Plankhawaldeh jamalNo ratings yet

- El 101 Setting Out PlanDocument1 pageEl 101 Setting Out Plankhawaldeh jamalNo ratings yet

- m107 U Factory Sheet-2Document1 pagem107 U Factory Sheet-2khawaldeh jamalNo ratings yet

- M105 Generla Details Ac Layout PDFDocument1 pageM105 Generla Details Ac Layout PDFkhawaldeh jamalNo ratings yet

- El 105 Typical Installation DetailsDocument1 pageEl 105 Typical Installation Detailskhawaldeh jamalNo ratings yet

- M104 Thermal Load Schedule PDFDocument1 pageM104 Thermal Load Schedule PDFkhawaldeh jamalNo ratings yet

- LPG 106 Schematic Diagram Gas LayoutDocument1 pageLPG 106 Schematic Diagram Gas Layoutkhawaldeh jamal0% (1)

- m105 Generla Details Ac LayoutDocument1 pagem105 Generla Details Ac Layoutkhawaldeh jamalNo ratings yet

- m104 Thermal Load ScheduleDocument1 pagem104 Thermal Load Schedulekhawaldeh jamalNo ratings yet

- Green Building General Notes SummaryDocument1 pageGreen Building General Notes Summarykhawaldeh jamalNo ratings yet

- g002 Green Building DeclarationDocument1 pageg002 Green Building Declarationkhawaldeh jamalNo ratings yet

- LPG 106 Schematic Diagram Gas Layout PDFDocument1 pageLPG 106 Schematic Diagram Gas Layout PDFkhawaldeh jamal100% (1)

- g002 Green Building DeclarationDocument1 pageg002 Green Building Declarationkhawaldeh jamalNo ratings yet

- LPG 107 LPG General DetailsDocument1 pageLPG 107 LPG General Detailskhawaldeh jamalNo ratings yet

- P 104 First Floor PlanDocument1 pageP 104 First Floor Plankhawaldeh jamalNo ratings yet

- LPG 104 Terrace Floor PlanDocument1 pageLPG 104 Terrace Floor Plankhawaldeh jamalNo ratings yet

- LPG 103 First Floor PlanDocument1 pageLPG 103 First Floor Plankhawaldeh jamalNo ratings yet

- LPG 102 Ground Floor PlanDocument1 pageLPG 102 Ground Floor Plankhawaldeh jamalNo ratings yet

- LPG 103 First Floor PlanDocument1 pageLPG 103 First Floor Plankhawaldeh jamalNo ratings yet

- P 109 Fic LocationDocument1 pageP 109 Fic Locationkhawaldeh jamalNo ratings yet

- P 102 Ground Floor PlanDocument1 pageP 102 Ground Floor Plankhawaldeh jamalNo ratings yet

- P 106 Roof Floor Plan Water SupplyDocument1 pageP 106 Roof Floor Plan Water Supplykhawaldeh jamalNo ratings yet

- P 103 Ground Floor Plan High LevelDocument1 pageP 103 Ground Floor Plan High Levelkhawaldeh jamalNo ratings yet

- P 107 Stair Case Head Room Roof Floor PlanDocument1 pageP 107 Stair Case Head Room Roof Floor Plankhawaldeh jamalNo ratings yet

- P 002 Drainage General NotesDocument1 pageP 002 Drainage General Noteskhawaldeh jamalNo ratings yet

- S 207 Column Details 8Document1 pageS 207 Column Details 8khawaldeh jamalNo ratings yet

- Structural (For Tender)Document12 pagesStructural (For Tender)khawaldeh jamalNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Castel - From Dangerousness To RiskDocument10 pagesCastel - From Dangerousness To Riskregmatar100% (2)

- Chapter 08Document18 pagesChapter 08soobraNo ratings yet

- Presentation On Ich Topics & Guidelines With A Special Reference ToDocument79 pagesPresentation On Ich Topics & Guidelines With A Special Reference ToVidyaNo ratings yet

- COT EnglishDocument4 pagesCOT EnglishTypie ZapNo ratings yet

- UT Dallas Syllabus For Ee3311.002.07f Taught by Gil Lee (Gslee)Document3 pagesUT Dallas Syllabus For Ee3311.002.07f Taught by Gil Lee (Gslee)UT Dallas Provost's Technology GroupNo ratings yet

- Indian Institute OF Management, BangaloreDocument20 pagesIndian Institute OF Management, BangaloreGagandeep SinghNo ratings yet

- Chetan Bhagat's "Half GirlfriendDocument4 pagesChetan Bhagat's "Half GirlfriendDR Sultan Ali AhmedNo ratings yet

- The Bloodless GospelDocument7 pagesThe Bloodless GospelKJVNo ratings yet

- Ch. 7 - Audit Reports CA Study NotesDocument3 pagesCh. 7 - Audit Reports CA Study NotesUnpredictable TalentNo ratings yet

- Dr. Malik's Farms BrochureDocument18 pagesDr. Malik's Farms BrochureNeil AgshikarNo ratings yet

- Motivations for Leaving Public Accounting FirmsDocument33 pagesMotivations for Leaving Public Accounting Firmsran0786No ratings yet

- E PortfolioDocument76 pagesE PortfolioMAGALLON ANDREWNo ratings yet

- 9AKK101130D1664 OISxx Evolution PresentationDocument16 pages9AKK101130D1664 OISxx Evolution PresentationfxvNo ratings yet

- Homo Sapiens ActivityDocument8 pagesHomo Sapiens ActivityJhon Leamarch BaliguatNo ratings yet

- Panasonic TC-P42X5 Service ManualDocument74 pagesPanasonic TC-P42X5 Service ManualManager iDClaimNo ratings yet

- ASD Manual and AISC LRFD Manual For Bolt Diameters Up To 6 Inches (150Document1 pageASD Manual and AISC LRFD Manual For Bolt Diameters Up To 6 Inches (150rabzihNo ratings yet

- Migration (LIN 19/051: Specification of Occupations and Assessing Authorities) Instrument 2019Document28 pagesMigration (LIN 19/051: Specification of Occupations and Assessing Authorities) Instrument 2019Ajay palNo ratings yet

- CIGB B164 Erosion InterneDocument163 pagesCIGB B164 Erosion InterneJonathan ColeNo ratings yet

- Linguistics: Chapter 1 - 10Document41 pagesLinguistics: Chapter 1 - 10Ahmad A. JawadNo ratings yet

- Revised Man As A Biological BeingDocument8 pagesRevised Man As A Biological Beingapi-3832208No ratings yet

- Joyful Living: (Based On Chapter 13: Advaitananda Prakaranam of Panchadashi of Sri Vidyaranya Swami)Document11 pagesJoyful Living: (Based On Chapter 13: Advaitananda Prakaranam of Panchadashi of Sri Vidyaranya Swami)Raja Subramaniyan100% (1)

- Wsi PSDDocument18 pagesWsi PSDДрагиша Небитни ТрифуновићNo ratings yet

- Application Programming InterfaceDocument12 pagesApplication Programming InterfacesorinproiecteNo ratings yet

- DNT Audit Cash CountDocument2 pagesDNT Audit Cash CountAnonymous Pu7TnbCFC0No ratings yet

- Moderntheater 170210003221 PDFDocument80 pagesModerntheater 170210003221 PDFDycan MikeNo ratings yet

- A Systematic Scoping Review of Sustainable Tourism Indicators in Relation To The Sustainable Development GoalsDocument22 pagesA Systematic Scoping Review of Sustainable Tourism Indicators in Relation To The Sustainable Development GoalsNathy Slq AstudilloNo ratings yet

- FINAL - Plastic Small Grants NOFO DocumentDocument23 pagesFINAL - Plastic Small Grants NOFO DocumentCarlos Del CastilloNo ratings yet

- Delhi Public School: Class: XI Subject: Assignment No. 3Document1 pageDelhi Public School: Class: XI Subject: Assignment No. 3Aman Kumar BhagatNo ratings yet

- Hardware Purchase and Sales System Project ProfileDocument43 pagesHardware Purchase and Sales System Project Profilesanjaykumarguptaa100% (2)

- Policies and Regulations On EV Charging in India PPT KrishnaDocument9 pagesPolicies and Regulations On EV Charging in India PPT KrishnaSonal ChoudharyNo ratings yet