Professional Documents

Culture Documents

Edoc 006458

Uploaded by

AbdielhSantanaLopezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Edoc 006458

Uploaded by

AbdielhSantanaLopezCopyright:

Available Formats

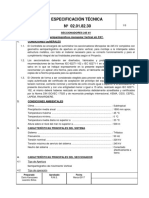

CURRENT IN AMPERES

100000

10000

20000

30000

40000

50000

60000

70000

80000

90000

1000

2000

3000

4000

5000

6000

7000

8000

9000

100

200

300

400

500

600

700

800

900

5 6 7 8 9 10 20 30 40 50 60 70 80 90

1000 1000

900 900

100E

125E

150E

175E

200E

250E

800 800

50E

65E

80E

700 700

600 600

500 500

400 400

300 300

200 200

100 100

90 90

80 80

70 70

60 60

50 50

40 40

30 30

20 20

10 10

9 9

8 8

7 7

6 6

5 5

TIME IN SECONDS

TIME IN SECONDS

4 4

3 3

2 2

1 1

.9 .9

.8 .8

.7 .7

.6 .6

.5 .5

.4 .4

.3 .3

.2 .2

.1 .1

.09 .09

.08 .08

.07 .07

.06 .06

.05 .05

.04 .04

.03 .03

.02 .02

.01 .01

5 6 7 8 9 10 20 30 40 50 60 70 80 90

100

200

300

400

500

600

700

800

900

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

20000

30000

40000

50000

60000

70000

80000

90000

100000

CURRENT IN AMPERES

TOTAL CLEARING TIME-CURRENT CHARACTERISTIC CURVES

SMD® FUSE UNITS—S&C VERY SLOW SPEED

BASIS—These fuse units are tested in accordance with the proce- COORDINATION—These curves represent the total time required for Sometimes a selected ampere rating will fail to meet the coordi-

dures described in ANSI Standard C37.41-1981, and they are rated a fuse unit to melt and interrupt a fault current, and should be fol- nation requirements in any available speed. In this case the selec-

to comply with ANSI Standard C37.46-1981. As required by these lowed in coordination problems where fuses are applied as “pro- tion of another ampere rating for either the protecting or protected

standards, the minimum melting current is not less than 200% of tecting” devices. fuse usually will satisfy all requirements.

fuse-unit ampere rating, and the minimum melting and total clearing

Any preloading reduces melting time. With respect to the “pro- Do not assume that other fuses that do not employ S&C’s silver,

curves are based on tests starting with the fuse unit at an ambient

tected” fuse, the effect of preloading must be determined and adjust- helically coiled fusible element construction can better resolve a

temperature of 25°C and no initial load.

ments made to its minimum melting curve: coordination impasse than the use of another ampere rating in one

CONSTRUCTION—Fusible elements are silver, helically coiled, and 1. When close coordination is required; of the S&C speed options. Such other fuses, including “time-lag”

of solderless construction. 2. When, regardless of the preciseness of coordination, the pro- speeds, “super-slow” speeds, and “high-surge” speeds, require the

tected fuse is subjected to temporary overloads. use of “safety-zone” or setback allowances and, in addition, they

TOLERANCES—Curves are plotted to maximum test points. All varia-

have larger construction tolerances (plus 20% in current; plus 40%

tions are minus. There are cases where the coordination requirements may be

in terms of time). The application of these two factors will give a time

very exacting, for example, in coordinating a transformer primary

APPLICATION—S&C Very Slow Speed fuse units are for application interval between the adjusted minimum melting curve and the total

fuse with a secondary breaker and a source-side breaker. The time

in circuits where additional time margin in the “protected” fuse is clearing curve greater than in the case of S&C speed options.

interval between the operating characteristics of the two breakers

necessary for coordination, but where load conditions do not

may be very narrow. Under these circumstances there must be an

require fuses of a larger ampere rating.

extremely short time interval between the minimum melting and the

FUSE UNITS AVAILABLE—

Like all high-voltage fuses, these fuse units are intended to total clearing characteristics of the fuse.

accommodate overloads, not to interrupt them. Accordingly, they Type Kv Nom. Ratings Ampere Ratings

The fuse units represented by these curves possess this short

feature fusible elements which are designed with a minimum melting SMD-1A . . . . . . . . . . . . . . . . 115/138 . . . . . . . . .50E through 100E

time interval feature, since—having a nondamageable fusible ele-

current of 200% of the fuse-unit ampere rating (for fuse units rated SMD-2B . . . . . . . . . . . . . . 115 and 138 . . . . . . .50E through 250E

ment of precise construction—they require:

100 amperes or less) or 220% of the fuse-unit ampere rating (for

1. As little as 10% total tolerance in melting current—compared to

fuse units rated over 100 amperes). As a result, these fuse units

the 20% tolerance of many fuses (20% and 40% respectively

have considerable peak-load capabilities; however, they should

in terms of time).

never be exposed to loading in excess of the peak-load capabilities

2. No “safety-zone” or setback allowances.

listed in S&C Data Bulletin 210-190.

This narrow time band normally will provide the desired coordi-

Since these fuse units have silver element construction which is

nation. If the selected S&C Very Slow Speed fuse unit does not meet

not subject to damage by aging or transient overcurrents, it is unnec-

the coordination requirements, check to see if the same ampere

essary to replace unblown fuse units in single-phase or three-phase

rating in the S&C Slow Speed or S&C Standard Speed will satisfy.

installations when one or more fuse units have blown.

Supersedes TCC No. 176-1-9 dated 1-25-88 c1988

TCC NUMBER 176-1-9

s S&C ELECTRIC COMPANY • Chicago

S&C ELECTRIC CANADA LTD. • Toronto

Page 1 of 1

August 29, 1988

You might also like

- Generador de Van de GraaffDocument10 pagesGenerador de Van de GraaffIvan Tocte67% (3)

- Practica Unidad 4 - Sistemas MecatrónicosDocument12 pagesPractica Unidad 4 - Sistemas MecatrónicosJesus ArguellesNo ratings yet

- Trabajo PC4Document21 pagesTrabajo PC4Brian BravoNo ratings yet

- Combinado GEDocument2 pagesCombinado GEdanielliram993No ratings yet

- Regulacion Del TransformadorDocument7 pagesRegulacion Del Transformadorfreddy canoNo ratings yet

- Modulos 3 y 4 SegundoDocument62 pagesModulos 3 y 4 SegundoVanny HR100% (1)

- Amplificador de Sonido Con Transistores de 10w y 8ωDocument7 pagesAmplificador de Sonido Con Transistores de 10w y 8ωYefer Tony Sánchez CáceresNo ratings yet

- Is-Syso-01 - Soldadura ElDocument2 pagesIs-Syso-01 - Soldadura ElIvan PérezNo ratings yet

- Censo de Carga ElectricaDocument18 pagesCenso de Carga Electricajose50% (4)

- Practica 6 - TeresaDocument17 pagesPractica 6 - Teresaangel urielNo ratings yet

- Consumo Eléctrico PDFDocument5 pagesConsumo Eléctrico PDFLuis Alberto Queché LópezNo ratings yet

- Tif Diseño de Elementos de MaquinasDocument95 pagesTif Diseño de Elementos de MaquinasLUIS IBERICO ESCRIBA CASTRONo ratings yet

- Format Oapa General 3Document9 pagesFormat Oapa General 3Angel Miguel Delgado TapahuascoNo ratings yet

- Seccionador Horizontal SemipantograficoDocument8 pagesSeccionador Horizontal SemipantograficoAdrián RomeroNo ratings yet

- Lab 2 Elt2731a Baptista Torrez Jhonathan MarceloDocument9 pagesLab 2 Elt2731a Baptista Torrez Jhonathan MarceloJhonathan BaptistaNo ratings yet

- Chevrotronica IIDocument80 pagesChevrotronica IILeandro LópezNo ratings yet

- Conversion ElectromagneticaDocument5 pagesConversion ElectromagneticaJULIO ERNESTO CASTRO RICONo ratings yet

- Investigacion Lb2Document1 pageInvestigacion Lb2Liliana MoPaNo ratings yet

- Diseño de Un Transformador de Puesta A Tierra en ZigZagDocument4 pagesDiseño de Un Transformador de Puesta A Tierra en ZigZaghectorhsc100% (2)

- FÍSICA I y IIDocument85 pagesFÍSICA I y IIKARLA ANALLETZI DURAN MENDOZANo ratings yet

- Unidad II. Motores, Transformadores y Dispositivos de ControlDocument63 pagesUnidad II. Motores, Transformadores y Dispositivos de ControlScarlet Ang80% (10)

- Motores MonofasicosDocument14 pagesMotores MonofasicosalexisNo ratings yet

- Modelo Matematico - Calculo de Altura de AntenasDocument22 pagesModelo Matematico - Calculo de Altura de AntenasJUAN ANTONIO MARQUEZ CORNEJONo ratings yet

- Boletin Preguntas TestDocument21 pagesBoletin Preguntas TestDiego Alonso Fuentes CastroNo ratings yet

- 19 Corriente EléctricaDocument7 pages19 Corriente EléctricaRosita BalarezoNo ratings yet

- Circuitos RL, RC, Y RLC.Document16 pagesCircuitos RL, RC, Y RLC.Guillermo DiazNo ratings yet

- Wuolah Free Problemas ElectricaDocument128 pagesWuolah Free Problemas ElectricajaNo ratings yet

- Aplicaciones Del Movimiento de Partículas Con Carga en Un Campo MagnéticoDocument3 pagesAplicaciones Del Movimiento de Partículas Con Carga en Un Campo MagnéticoKEYLON MARIO DCOSTA BOLANO (:-)No ratings yet

- Guia Laboratorio 04 COMPARADORES 2020Document12 pagesGuia Laboratorio 04 COMPARADORES 2020gianpierNo ratings yet

- Informe #1 - Filtros Pasivos y ActivosDocument7 pagesInforme #1 - Filtros Pasivos y ActivosCarol Marianne Rodriguez ChaconNo ratings yet