0% found this document useful (0 votes)

470 views45 pagesLinear & Geometrical Tolerance Guide

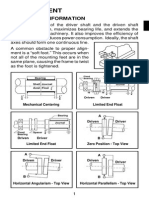

The document discusses tolerance and fits between parts. It defines tolerance as the total amount a dimension may vary between its maximum and minimum limits. There are four main ways to express tolerance: 1) direct limits, 2) geometric tolerances, 3) a general tolerance note, and 4) notes referring to specific conditions. It also discusses different types of fits between parts, including clearance, interference, and transition fits. Metric and imperial tolerance systems as well as hole basis and shaft basis fits are explained.

Uploaded by

venkeekuCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

470 views45 pagesLinear & Geometrical Tolerance Guide

The document discusses tolerance and fits between parts. It defines tolerance as the total amount a dimension may vary between its maximum and minimum limits. There are four main ways to express tolerance: 1) direct limits, 2) geometric tolerances, 3) a general tolerance note, and 4) notes referring to specific conditions. It also discusses different types of fits between parts, including clearance, interference, and transition fits. Metric and imperial tolerance systems as well as hole basis and shaft basis fits are explained.

Uploaded by

venkeekuCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPSX, PDF, TXT or read online on Scribd