Professional Documents

Culture Documents

As 3600-09 RC-PN-001

Uploaded by

Bunkun15Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

As 3600-09 RC-PN-001

Uploaded by

Bunkun15Copyright:

Available Formats

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

EXAMPLE AS 3600-09 RC-PN-001

Slab Punching Shear Design

PROBLEM DESCRIPTION

The purpose of this example is to verify slab punching shear design in SAFE

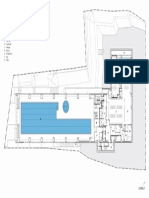

The numerical example is a flat slab that has three 8-m spans in each direction, as

shown in Figure 1.

0.3 m A B C D 0.3 m

8m 8m 8m

0.6 m

4

0.25 m thick flat slab

8m

3

Columns are 0.3 m x 0.9 m

with long side parallel

8m to the Y-axis, typical

2 Concrete Properties

Unit weight = 24 kN/m3

f'c = 30 N/mm2

8m

Y Loading

DL = Self weight + 1.0 kN/m 2

X LL = 4.0 kN/m2

1

0.6 m

Figure 1: Flat Slab for Numerical Example

The slab overhangs beyond the face of the column by 0.15 m along each side of

the structure. The columns are typically 0.3 m x 0.9 m, with the long side parallel

to the Y-axis. The slab is typically 0.25-m thick. Thick plate properties are used

for the slab.

EXAMPLE AS 3600-09 RC-PN-001 - 1

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

The concrete has a unit weight of 24 kN/m3 and a f 'c of 30 N/mm2. The dead load

consists of the self weight of the structure plus an additional 1 kN/m2. The live

load is 4 kN/m2.

TECHNICAL FEATURES OF SAFE TESTED

Calculation of punching shear capacity, shear stress, and D/C ratio.

RESULTS COMPARISON

Table 1 shows the comparison of the punching shear capacity, shear stress ratio,

and D/C ratio obtained from SAFE with the punching shear capacity, shear stress

ratio and D/C ratio obtained by the analytical method. They match exactly for

this problem.

Table 1 Comparison of Design Results for Punching

Shear at Grid Point B-2

Shear Stress Shear Capacity D/C ratio

Method (N/mm2) (N/mm2)

SAFE 1.811 1.086 1.67

Calculated 1.811 1.086 1.67

COMPUTER FILE: AS 3600-09 RC-PN-001.FDB

CONCLUSION

The SAFE results show an exact comparison with the independent results.

EXAMPLE AS 3600-09 RC-PN-001 - 2

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

HAND CALCULATION

Hand Calculation For Interior Column Using SAFE Method

d om = [(250 − 26) + (250 − 38)] / 2 = 218 mm

Refer to Figure 2.

U = 518+ 1118 + 1118 + 518 = 3272 mm

a x = 518 mm

a y = 1118 mm

518 Note: All dimensions in millimeters

Y

Critical section for

109 150 150 109 punching shear shown

dashed.

A B

Column Side 2

109

450

Side 1

Side 3

X

1118

Center of column is 450

point (x1, y1). Set

this equal to (0,0).

109

Side 4

D C

Figure 2: Interior Column, Grid B-2 in SAFE Model

From the SAFE output at grid line B-2:

V* = 1126.498 kN

M v2 = −51.991 kN-m

M v3 = 45.723 kN-m

EXAMPLE AS 3600-09 RC-PN-001 - 3

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

The maximum design shear stress is computed along the major and minor axis of column

separately:

V* uM v

=

vmax 1.0 + *

ud om 8V ad om

1126.498 • 103 3272 • 51.991 • 106

=

vmax, X • 1 +

3272 • 218 8 • 1126.498 • 10 • 1118 • 218

3

vmax, X = 1.579 • 1.0774 = 1.7013 N/mm2

1126.498 • 103 3272 • 45.723 • 106

=

vmax,Y • 1 +

3272 • 218 8 • 1126.498 • 10 • 518 • 218

3

vmax,Y = 1.579 • 1.1470 = 1.811 N/mm2 (Govern)

The largest absolute value of v max = 1.811 N/mm2

The shear capacity is calculated based on the smallest of AS 3600-09 equation 11-35,

with the d om and u terms removed to convert force to stress.

2

0.17 1 + ϕ f ′c

ϕ fcv = min βh = 1.803N/mm2 in accordance with AS 9.2.3(a)

0.34ϕ f ′c

AS 9.2.3(a) yields the smallest value of ϕ fcv = 1.086 N/mm2, and thus this is the shear

capacity.

vU 1.811

=

Shear Ratio = = 1.67

ϕ f cv 1.086

EXAMPLE AS 3600-09 RC-PN-001 - 4

You might also like

- How To Construct A Concrete Swimming Pool - (PDF) - The ConstructorDocument13 pagesHow To Construct A Concrete Swimming Pool - (PDF) - The ConstructorBunkun15No ratings yet

- Basic Requirements in Swimming Pool Construction - The ConstructorDocument10 pagesBasic Requirements in Swimming Pool Construction - The ConstructorBunkun15No ratings yet

- Title - Section 6-1.29 - Swimming Pool Design Standards - New York Codes, Rules and RegulationsDocument24 pagesTitle - Section 6-1.29 - Swimming Pool Design Standards - New York Codes, Rules and RegulationsBunkun15No ratings yet

- Checklist ResPoolsDocument7 pagesChecklist ResPoolsBunkun15No ratings yet

- Intake Tower Existing DamDocument3 pagesIntake Tower Existing DamBunkun15No ratings yet

- Swimming Pool Site PlanDocument1 pageSwimming Pool Site PlanBunkun15No ratings yet

- Swimming Pool Details Structures SampleDocument1 pageSwimming Pool Details Structures SampleBunkun15100% (3)

- 4 Ways To Book PublishingDocument7 pages4 Ways To Book PublishingBunkun15No ratings yet

- How To Start A Bookstore BusinessDocument5 pagesHow To Start A Bookstore BusinessBunkun15No ratings yet

- Basements For HousingDocument2 pagesBasements For HousingBunkun15No ratings yet

- SAP2000 Command LineDocument2 pagesSAP2000 Command LineBunkun15No ratings yet

- Swimming Pool Roofing OptionsDocument2 pagesSwimming Pool Roofing OptionsBunkun15100% (1)

- Swimming Pool Sample LayoutsDocument1 pageSwimming Pool Sample LayoutsBunkun15No ratings yet

- Stable Sprayed ConcreteDocument2 pagesStable Sprayed ConcreteBunkun15No ratings yet

- Starting A Bookstore BusinessDocument11 pagesStarting A Bookstore BusinessBunkun15No ratings yet

- Live Load Distribution Factor CalculationsDocument5 pagesLive Load Distribution Factor CalculationsBunkun15No ratings yet

- Simple Beam Deflection - Uniform Load Partially Distributed at Left EndDocument1 pageSimple Beam Deflection - Uniform Load Partially Distributed at Left EndBunkun15No ratings yet

- Imperial College of Business Studies Employment Application FormDocument3 pagesImperial College of Business Studies Employment Application FormBunkun15No ratings yet

- University OrganogramDocument1 pageUniversity OrganogramBunkun15No ratings yet

- IRSE Green BookDocument2 pagesIRSE Green BookBunkun150% (1)

- Import - SAP2000 MS Excel Spreadsheet .Xls File: New ModelDocument1 pageImport - SAP2000 MS Excel Spreadsheet .Xls File: New ModelBunkun15No ratings yet

- Imperial College: of Business StudiesDocument1 pageImperial College: of Business StudiesBunkun15No ratings yet

- ETABS Additional MassDocument2 pagesETABS Additional MassBunkun15No ratings yet

- ETABS Insertion PointDocument3 pagesETABS Insertion PointBunkun15No ratings yet

- SAP2000 Sign CoventionDocument5 pagesSAP2000 Sign CoventionBunkun15No ratings yet

- ETABS End OffsetDocument2 pagesETABS End OffsetBunkun1567% (3)

- ETABS Joint RestraintsDocument2 pagesETABS Joint RestraintsBunkun15100% (3)

- ETABS Section PropDocument1 pageETABS Section PropBunkun15No ratings yet

- ETABS Property ModifierDocument1 pageETABS Property ModifierBunkun150% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Eaton Industrial Special Process List (SPL)Document5 pagesEaton Industrial Special Process List (SPL)amirkhakzad498No ratings yet

- P700 1 (4PP) GB (0213) PDFDocument4 pagesP700 1 (4PP) GB (0213) PDFShahzad AliNo ratings yet

- LV07 KDocument11 pagesLV07 KSalman Shah83% (6)

- Standard Support: Figure 1: Pressing F1 Redirects User To A Bing SearchDocument4 pagesStandard Support: Figure 1: Pressing F1 Redirects User To A Bing SearchDbluepengLumNo ratings yet

- Nexys 2Document12 pagesNexys 2sacramusNo ratings yet

- Elite Trader Package™ - Trader GuideDocument78 pagesElite Trader Package™ - Trader GuideOld PaladinNo ratings yet

- Gold Experience B1 WorkbookDocument14 pagesGold Experience B1 WorkbookOli Sisti100% (2)

- Piping and Plumbing Symbols ListDocument1 pagePiping and Plumbing Symbols Listsiddarth amaravathiNo ratings yet

- Audit Sampling (Chapter 9)Document25 pagesAudit Sampling (Chapter 9)cris100% (2)

- Aristotles Three Modes of PersuasionDocument3 pagesAristotles Three Modes of PersuasionJoy Grace DuremdesNo ratings yet

- The Roleof Social Media MarketingDocument13 pagesThe Roleof Social Media Marketingpreschool academyNo ratings yet

- 2014 04 14 Veterinary Instrumentation Presented The Simon Award 2014 For Outstanding Contribution in The Field of Veterinary Surgery To Michael Guilliard MA, VetMB, CertSAO, FRCVSDocument2 pages2014 04 14 Veterinary Instrumentation Presented The Simon Award 2014 For Outstanding Contribution in The Field of Veterinary Surgery To Michael Guilliard MA, VetMB, CertSAO, FRCVSHenry ScheinNo ratings yet

- Business Ethics PDFDocument16 pagesBusiness Ethics PDFRitika DiwakarNo ratings yet

- MHSIR00491976Document1 pageMHSIR00491976Patan Rafiq KhanNo ratings yet

- 4UIE - AB - Nov 23Document2 pages4UIE - AB - Nov 23aaaNo ratings yet

- Roundel 1961-06 Vol 13 No 5Document36 pagesRoundel 1961-06 Vol 13 No 5TateNo ratings yet

- Government Polytechnic, Pune: ET2107 - NODocument8 pagesGovernment Polytechnic, Pune: ET2107 - NOG012 Bhise AniketNo ratings yet

- MSA 516 Application Controls PowerPoint PresentationDocument21 pagesMSA 516 Application Controls PowerPoint PresentationPrince Ric100% (1)

- Effects of Reservoir Heterogeneity in Laminated ReservoirsDocument3 pagesEffects of Reservoir Heterogeneity in Laminated ReservoirsErik Andres Garcia VillarroelNo ratings yet

- ElectrogravimetryDocument5 pagesElectrogravimetryMELISSA VERONICA TUDELANO OSPINANo ratings yet

- Design MatrixDocument1 pageDesign MatrixThakur Kali DassNo ratings yet

- CPE-214 Computer-Aided Engineering Design - Lab - Manual - OBE - 2 PDFDocument64 pagesCPE-214 Computer-Aided Engineering Design - Lab - Manual - OBE - 2 PDFHamza RaufNo ratings yet

- Ways To Measure Public Opinion 3Document11 pagesWays To Measure Public Opinion 3Mohamed Abd ELfattahNo ratings yet

- RESEARCH FORM and STYLEDocument8 pagesRESEARCH FORM and STYLEKristian Karl Bautista Kiw-isNo ratings yet

- AHRICertificateDocument1 pageAHRICertificaterenatosustentechNo ratings yet

- Norton Introduction To Philosophy 2nd Edition Rosen Test BankDocument9 pagesNorton Introduction To Philosophy 2nd Edition Rosen Test Bankbenjaminhernandezfecmxjzrdt100% (14)

- DAA NotesDocument97 pagesDAA Notesanish.t.pNo ratings yet

- Manonmaniam Sundaranar University: B.Sc. Mathematics - Ii YearDocument98 pagesManonmaniam Sundaranar University: B.Sc. Mathematics - Ii YearSadia ahmadNo ratings yet

- ASLI 02 Supply Air Grilles Set - AIR ConditioningDocument21 pagesASLI 02 Supply Air Grilles Set - AIR ConditioningAminul Hassan50% (2)