0 ratings0% found this document useful (0 votes)

830 views150 pagesBasic Avionics

BASIC AVIONICS

Uploaded by

Amal VinodCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

0 ratings0% found this document useful (0 votes)

830 views150 pagesBasic Avionics

BASIC AVIONICS

Uploaded by

Amal VinodCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

=

Flytech Aviation Academy

1-8-303/33, Nagam Towers, 3" and 4” Floor, ST.R Grete,

008. (

E-mail : info

Cy IvV- SEMESTER

SUBJECT: BASIC AVIONICS

MECHANICAL FIXED

AND

ROTARY WING 2°

a

AMO CDDADIIDDOOD DDD OODODGOOOO0D00000%

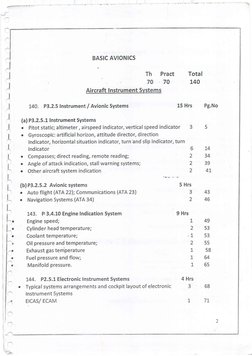

BASIC AVIONICS

Th Pract Total

70 - 70 140

Aircraft Instrument Systems

140. P3.2.5 Instrument / Avionic Systems 15 Hrs

{a) P3.2.5-1 Instrument Systems

Pitot static; altimeter , airspeed indicator, vertical speed indicator 3

© Gyroscopic: artificial horizon, attitude director, direction

Indicator, horizontal situation indicator, turn’and slip indicator, turn

Indicator

© Compasses; direct reading, remote reading;

© Angle of attack indication, stall warning systems;

© Other aircraft system indication

RNa

(b)P3.2.5.2 Avionic systems S Hrs

© Auto flight (ATA 22); Communications (ATA 23)

© Navigation Systems (ATA 34)

Nw

143. P-3.4.10 Engine Indication System 9 Hrs

Engine speed;

Cylinder head temperature;

Coolant temperature;

Oil pressure and temperature;

Exhaust gas temperature

Fuel pressure and flow;

Manifold pressure.

BRENENE

144. 2.5.1 Electronic Instrument Systems 4 Hrs

* Typical systems arrangements and cockpit layout of electronic 3

Instrument Systems

EICAS/ ECAM 1

Pg.No

14

34

39

41

43

46

49

53

53

55

58

64

65

68

71

t

{

|

|

145. P 2.5.15 Typical Electronic/Digital Aircraft Systems SHrs

EFIS-Electronic Flight Instrument System

FBW-Fly by Wire

FMS-Flight Management System

INS/IRS-Inertial Navigation/Reference System

BNE

ircraft Eletrical Systems

141. P3.2.6 Electrical Power (ATA 24) 13 Hrs

Batteries Installation and Operation;

DC power generation; AC power generation;

Voltage regulation;

Power distribution; Emergency Power, Generation;

Inverters, Transformers ,Rectifiers, Circuit protection

External/Ground power

BNNNwW

142. P 3.2.14 Lights (ATA 33) 5 Hrs

7

88a

95

97

103

106

108

¢ External; navigation; anti collision, landing, taxing, ice; 2 111

. Internal: Cabin, cockpit, cargo: a

114

P.2.5.15. Built in Test Equipment Sappalds,

ircraft Commu: in & Navigation Systems

P3.2.5.2 VHF communication system

P3.2.5.2 HE communication system

P3.2.5.2 — Seleal system

P3.2.5.2 ATA 34 navigation system

P2.5.15 GPs

P2515 ACARS

P2.5.15 TCAS

P2.2.4 AVIONICS GENERAL TEST EQUIPMENT

122

124

125

126-132

132

135

137

142

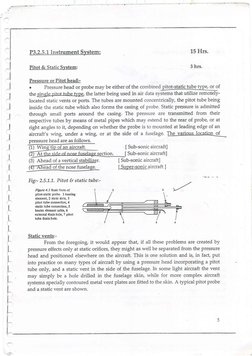

P3.2.5.1 Instrument System: 15 Hrs.

Pitot & Static System: 3 hrs.

Pressure or Pitot head:-

© Pressure head or probe may be either of the combined pitot-static tube type, or of

the single pitot tube type, the latter being used in air data systems that utilize remotely-

ocated static vents or ports. The tubes are mounted concentrically, the pitot tube being,

inside the static tube which also forms the casing of probe. Static pressure is admitted

through small ports around the casing. The pressure are transmitted from their

respective tubes by means of metal pipes which may extend to the rear of probe, or at

right angles to it, depending on whether the probe is to mounted at leading edge of an

aircraft's wing, under a wing, or at the side of a fuselage. The various location of _

pressure head are as follows.

@ Wingtpofanaircraft. [ Sub-sonic aircraft]

Gratis dent ne tadlagesection < _ Sub-sonic aircraft]

@) Ahead of a vertical stabilizer. [Sub-sonic aircraft]

¢ iead of the nose fuselage. [Super-sonic aircraft ]

Fig:- 2.5.L1. Pitot & static tube:-

Figure 4.5 Basic for of : 2 s eae

pitovsate probe. 1 eating

Clement, sate dois, 3

Pitot tube connection, 4

satis tube connection, 5

eater element cable, 6

external rain le, 7 pitot

‘ube din ole

Static vents:-

From the foregoing, it would appear that, if all these problems are created by

pressure effects only at static orifices, they might as well be separated from the pressure

head and positioned elsewhere on the aircraft. This is one solution and is, in fact, put

into practice on many types of aircraft by using a pressure head incorporating a pitot

tube only, and a static vent in the side of the fuselage. In some light aircraft the vent

may simply be a hole drilled in the fuselage skin, while for more complex aircraft

systems specially contoured metal vent plates are fitted to the skin. A typical pitot probe

and a static vent are shown.

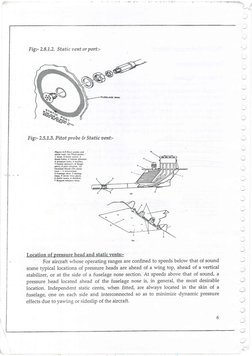

Fig:- 2.8.1.2. Static vent or port:-

Fig:- 2.5.1.3, Pitot probe & Static vent-

Location of pressure head and static vents

For aircraft whose operating ranges are confined to speeds below that of sound

some typical locations of pressure heads are ahead of a wing top, ahead of a vertical

stabilizer, or at the side of a fuselage nose section. At speeds above that of sound, a

pressure head located ahead of the fuselage nose is, in general, the most desirable

location. Independent static cents, when fitted, are always located in the skin of a

fuselage, one on each side and interconnected so as to minimize dynamic pressure

effects due to yawing or sideslip of the aircraft.

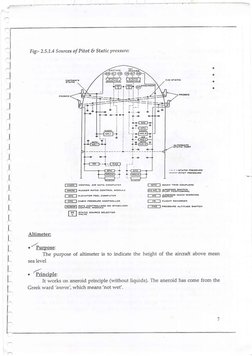

Fig:- 2.5.1.4 Sources of Pitot & Static pressure:

Altimeter:

PP

© “Purpose:

[CEEEE] conn aim ona comruren

HEE] roves matte conrnat toons

[LED cteveron cess commuren

[EEE] eatin mneseune cowrnouien

Ciaaee] Sora cermasssere om ersten

(CREED) eeren rr courses

GSS RA,

[EES] gear eer men

[ES eutorr ncconoen

CEE] rreseune aurmuoe aware

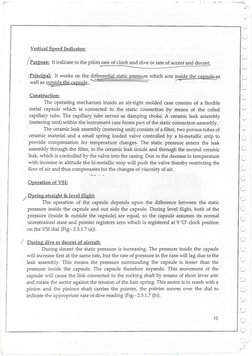

The purpose of altimeter is to indicate the height of the aircraft above mean

sea level

Ci

rinciple’

It works on aneroid principle (without liquids). The aneroid has come from the

Greek ward ‘aneros’, which means ‘not wet’.

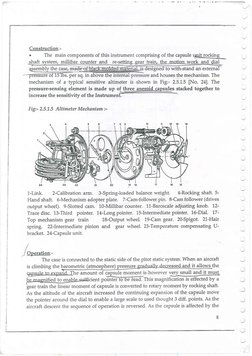

Construction:-

+ The main components of this instrument comprising of the capsule unit rockin

shaft system, millibar counter and__re-setting gear train, the motion work and dial

Rese 9 Pie, Speact, olence Ho i bag thele,

pes Clog mr aiklade , maagehs henley feta

a, nae aged ond Seoangs,

> mk speed ond

> Wied dhreclton -

Fig:- 5.15.7 415.3 Inertial Navigation System units.

The INS, which is the forerunner of systems and is still currently used in

some types of aircraft, utilizes analog and digital signal processing techniques,

mechanical arrangements such as gimbaled. platforms, and synchronous servo

transmission loops. A system consists of the four principal units shown in fig:- 5.15.7,

together with their interconnection, data outputs and the other aircraft systems with

which it is generally interfaced.

Fig:- 5.15.8 Inertial Navigation System units.

hey 84

7

1. Inertial Navigation Unit (INU):

This unit contains an inertial section consisting of accelerometers, gyroscopes

and gimbaled platforms, a digital computer and al associated circuit module cards,

and a battery unit.

2. Control and Display Unit (CDU):

This allows all associated data to be inserted into the computer, and to be read

out from it by means of segmented LED displays.

3. Mode Selector Unit (MSU):

This unit controls all the modes in which the system can be operated.

4. Battery Unit:

This unit provides DC power for turning the system on, and is also used as

back-up in the event that power from an aircraft's system is interrupted.

Although this type of system is highly accurate, the level of accuracy demanded

for the navigation of those aircraft that are designed for operation under what may be

termed the ‘computer chips with everything’ philosophy preclude its application to

such aircraft in favor of its more sophisticated descendant, namely, the inertial reference

system (RS).

Inertial Reference Unit (IRS):

It performs the same basic navigational functions as an INS, but, as it's fully

digital computer can also be pre-programmed with other relevant reference data,

there was some justification in changing its name.

The system consists of only two principal units. The outputs are supplied to a

greater number of interfacing systems, and since the majority of them are also

individually by digital computers, signal transmissions are via an ARINC 429 data

bus as opposed to conventional ‘had wiring’.

The inertial reference unit also contains accelerometers, gyroscopes and the

computer, but here, its similarity with the INU referred to earlier ends. The major

differences are

(@) The gyroscopes are of ring laser type instead of the spinning rotor

type. feat

(i) The complex mechanical arrangement of a gimbal system and

synchronous transmission loops is replaced by a mathematical

equation program so that acceleration and attitude signals required for

navigation are directly computed

(iii) The unit is directly mounted to an airframe, ie. itis of the ‘strap down’

type so that the aircraft itself become the inertial platform.

85

(iv) Magnetic and true heading are derived from a program of known data

related to the position data loaded into the computer, so that headings

can be computed without the aid of MHRS flux detector units (in facts,

these units are no longer required in aircraft equipped with an IRS).

(v) No battery unit and charger is used.

Power suppli

Both’DC and AC power is required for system operation which must be

maintained in the event of failures occurting. The sources from which power is derived

can vary depending on the type of system, but a common feature is that after starting

up, the system can be maintained in operation from either of the sources. This is effected

by the integration of power supply monitor and conversion circuits in the navigation

unit of a system.

In a typical gimbaled-platform INS, the AC power is supplied from an

essential busbar, and the DC power froma nickel-cadmium battery unit which is part

of the system installation. The unit provides auxiliary power for the initial start-up,

and also the power to maintain system operation in the event of AC power failure, or

a reduction in voltage level. Under these conditions, the battery unit will sustain

system operation in any operating mode for periods up to 15 minutes duration.

Indication that battery power is in use provided by illumination. of.an amber ‘BATT’

light on the control and display unit (CDU).

‘The battery unit has a direct connection to the system's mode selector switch so

that when this is set to the positions for initial starting of the system, battery power is

used momentarily for energizing a relay, the contacts of which are connected in the

Greuit from the aircraft's AC busbar. Thus, AC power is supplied to the navigation unit

via the relay which is then held in the energized state by the DC produced by the power

conversion unit. The battery supply remains on for a short ‘period (typically 10

seconds), enabling it to be checked during alignment of the system. On completion of

this check, the battery is isolated from the system and is on standby until there is an

interruption of the AC power supply. In the event that an external power source is

disconnected from an aircraft while the INS in on, battery power will automatically

be transferred to the system, and some warning of this is required in order to protect

the battery against an inadvertent discharge. In one example of warning system, 2

horn is located in the nose wheel bay of an aircraft, and is activated 30 + 10 seconds

after power transfer, thereby alerting the ground crew.

The INU is provided with a battery charger circuit which automatically comes

into operation when the battery is not in use, and whenever its voltage drops below

2655 V. The charger is disconnected when the on-charge voltage increases to 29.5 V.

In multi-system installations, and after interruption of an aircraft's power supply

switching arrangements are provided which enable battery units to be

86

to the systems,

paralleled in order to sustain the operation of one the navigation units. For example, in

4 triple installation the battery units of Nos 1 and 3 systems can be paralleled to supply

the navigation unit of the No. 1 system.

In aircraft equipped with IR systems, the use of battery units is eliminated

since DC power from the busbar of the aircraft's battery system is utilized for the

starting up of a system. This supply is also automatically switched on in the event of

alloss of AC power.

87

3.2.6 ELECTRICAL POWER ATA 24 13 Hrs

Batteries installation & operation 3 Hrs

DC power Generation AC power Generation 3 Hrs

Emergency Power generation & voltage regulation 2Hrs

Power distribution 2Hrs

Invertors transformers Rectifiers Circuit Protection 2 Hrs

External & Ground Power 1 Hr

Aircraft batteries:

Compared to general use batteries (Ground) aircraft batteries should have some specific

characteristics which ensure the safety of aircraft and batteries. Requirement of batteries

aircraft is to supply electrical consumers when emergency occurs (Failure of inbuilt Generators

or Rectifiers) as well as some aircrafts utilizes the batteries for starting of engines. Starting of

engines by means of batteries is to supply required DC consumers as well as AC consumers

(Inverters are driven by batteries to have AC power also).

During starting of engines required supply is given as per the starting current and voltage

by connecting series-parallel combination to improve the Ampere Hour and Voltage Rating of

Battery.

For aircraft batteries we require additional features are:-

Vent Plugs to release gases during flying without spillage of electrolyte,

High output to weight ratio,

High capacity,

Robust construct, (withstand to vibrations and shocks)

Free maintenance,

Battery Temperature sensor for indi

ing the status of battery,

Battery Operation:

Lead Acid Battery:

+4Ve Plate Lead Peroxide PbSO4

-Ve Plate Sponge Lad-Pb

Electrolyte: 30% of H2S04 and 70% of distilled water

Specific Gravity

Fully charged: 1270-1300 mm of Hg

Discharged: 1180 mm of Hg ot less

Cell voltage:

Fully Charged- 2.2 Volts

Discharged - 1.8 Volts

Separators Fiber Glass, Rubber, wood (Pine Cedar)

88

=e

-

Cell containers - Hard Rubber or Plastic composition (Like compartment)

Vent Plug: - Toescape the gasses and not leak out electrolyte

Chemical Reaction:

Terminals. - Made up of lead

TeRmninars

89

casvegs + pees

wm, Lee

Lead Acid Battery

Aireraft Lead Acid Battery

~ Charge

—

Disa

Capacity of the battery given b product of current in Amperes and the time in Hours

during which a cell ca supply current until its EMF falls 1.8 Volts/cell measured in

Ampere Hours (AH).

PbO2 + H2 SO4+Pb Pb SO4 +H20+PbSO4

Initial filling, Initial Charging, Capacity Test ( CT)

Maintenance:

Before initial filling check the manufacturers instruction, visual check, shelf life,

charging current Capacity Test or any special care.

Leakage Test? Leakage test of the battery must be carried to check the battery

condition for cracks or damages during transportation.

Initial Filling: Initial filling of the battery to be carried out if the battery received with out

filling by manufacturer. Break down the electrolyte to the value prescribed by the manufacturer

by adding distilled water. Actual process of breaking down of electrolyte is add acid to water

slowly and stir with a glass rod until the specific gravity reaches to 1300 mm of Hg. Add 30%

‘of Concentrated Sulphuric acid solution and 70% of Distilled water, keep the acid to cool and

measure the SG by using Hydro Meter to read to the required value, if not add the necessary

Acid or Distilled water to get the required SG ( 1270-1300 mm of Hg). Fill the each cell with

the electrolyte till the plates are fully submerged in the acid.

Initial Charging: Charge the battery at the rate provided by the manufacturer maintenance

manual, normally all the batteries are charged at slower rate during initial charging. Supervise

the battery throughout the charging process to get all the cell voltages to 2.2 Volts. Charging

rate and time must be maintained to get proper charging of battery. Also observe the battery

temperature during the process of charging.

90

2

Capacity Test: Capacity test of the battery must be carried out to know the

capacity of the battery for use in aircraft. This process consists of Discharging the battery at

normal rate according to the AH rating, Fully charge the battery at normal rate i.e. the cell

voltage of the battery reaches to 2.2 Volts/cell then discharge the battery up to cell voltage

reaches to 1.8 Volts/cell. Calculate the capacity by noting the total time and rate of discharge

and original AH rating of the battery to ascertain the actual capacity of the battery [fthe capacity.

of the battery falls below 80% discard the battery for aircrafi use. Capacity Test is carried out on

the following oceasions:-

i) After Initial Filling

ii) After every 3 months

iii) Whenever the capacity of the battery suspected to be low.

Insulation Resistance Check: Insulation resistance check of the battery to be

carried out by using 250 volts. insulation tester or Meggar, insulation resistance should not be

less than 1 Meg Ohm.

m arte

Precautions during charging:

1. Emission of H2 and 02 ( Hydrogen and Oxygen) explosive mixture, no naked light

should be present. Lighter should not be lit or any Spark.

Forced air for removing dangerous fumes.

‘Tum off the battery charger first before disconnection of battery.

Nickel Cadmium Battery:

This battery works on the principle of Oxidation and reduction.

A steel battery box contains the cells connected in series to gain the desired voltage (1.2V per

cell nominal). Cells are made of light durable polyamide or nylon with multiple nickel-cadmium

plates welded together for each electrode inside. A separator or liner made of silicone rubber acts

as an insulator and a gas barrier between the electrodes. Cells are flooded with an electrolyte of

30% aqueous solution of potassium hydroxide (KOH). The specific gravity of the electrolyte

does not indicate if the battery is empty or full but changes mainly with venting of water. The top

of the cell contains # space for excess electrolyte and a pressure release vent. Large nickel plated

copper studs and thick interconnecting links assure minimum electrical resistance for the battery.

Charging:

Vented cell voltage rises rapidly at the end of charge allowing for very simple charger circuitry

to be used. Typically a battery is constant current charged at ICA rate until all the cells have

reached at least 1.55V. Another charge cycle follows at 0.1CA rate, again until all cells have

reached 1.55V. The charge is finished with an Over Charge or top-up charge, typically for not

Tess than 4 hours at 0.1CA rate. The purpose of the Over Charge is to expel as much if not all the

gases collected on the electrodes, Hydrogen on the Anode and Oxygen on the Cathode, and some

of these gases recombine to form water which in turn will raise the electrolyte level to its highest

level after which it is safe to adjust the electrolyte levels. During the Over Charge or top-up

os

Se 91

charge the cell voltages will go beyond 1.6V and then slowly start to drop. No cell should rise

above 1.71 (dry cell) or drop below 1.55V (gas barrier broken).

Charging is done with vent caps loosened or open. A stuck vent might increase the pressure in

the cell. It will also allow for refilling of water to correct levels before the end of the top-up

charge while the charge current is still on. However cells should be closed again as soon as the

vents have been cleaned and checked since carbon dioxide dissolved from outside air carbonates

the cells and ages the battery.

In an aircraft installation with a floating battery electrical system the regulator voltage is set to

charge the battery at constant potential charge (typically 14 or 28 volts). If this voltage is set too

high it will result in rapid water loss. A broken regulator diode will allow the charge voltage to

rise well above this, causing a massive overcharge with boiling over of the electrolyte.

The cells will age slowly due to carbon-dioxide carbonating the cells. To prevent this, the vents

should be kept closed and pressure tested periodically.

A typical aircraft battery used for engine starting has been rated to deliver over 15 kilowatts of

power for 15 seconds. The load operates at around the internal resistance of the battery and the

voltage loss at battery is equal to the load.

Construction:

It consists of the following:-

+Ve Plate - Nickel Oxy Hydroxide Ni(OH)4

-Ve plate - Cadmium

Electrolyte - KOH (70% H20 + 30% KOH)

Separator - Porous multi laminate of woven nylon with layers

of Cella Phone ( Cella Phone to prevent Thermal

Runway)

Container = Stainless Steel, Carbon Steel or Fiber Glass

Cell Cover - Plastic

Charge

Ni(OH)4 + KOH + Cd Niforyz? KOH + CD (OH)2

Diss

Like Lead Acid battery the basic difference is the Specific Gravity of the electrolyte does

not depends up on the state of charge. Electrolyte acting only as a media (Conductor) for

transfer of Ions from one electrode to other electrode, chemical composition does not change.

As the Nickel Cadmium batteries are working on the principle of Oxidation and Reduction

means:

Oxidation = . Any process that removes electrons from a substance

Reduction - Any process that adds electrons to a substance

‘As mentioned above for Lead Acid Battery Charging procedures to be followed according to the

manufécturers manuals i.e. current rating for charge or discharge and maintenance practices

which are requited to keep up the battery condition to get maximum life of the battery.

Never add water before charging, 2-3 hours after charging only should be added Low

level of electrolyte will give the state of battery.

Battery Reconditioning: — Due to Constant Voltage charging of battery in air craft the cells

may be imbalanced i.e. the voltage of each cell differs each other. Difference in Temperature,

varying self discharge rates and low level of electrolyte the

batteries must be inspected to the above faults to maintain

the battery condition throughout the life of battery.

Battery Maintenance:

Battery inspection, Battery Discharge, Battery

Discharge, Battery CT, Disassembly,Cleaning, Repair if

needed.

These all activities must be carried out according to the

manufacturers maintenance manual to keep the battery in

fully charged condition to give maximum efficiency to

increase the life of the battery to maximum level. Electric

leak check to be carried out prior to reconditioning in

charged state, Check the leakage current with mille

terminal and battery case that should not exceed 50 mA,

more than the limit replace the cell.

Cell damaged due to Thermal Runway

Cadmium

battery cell connections and vent plugs

ss --

Zeroing: Procedure of dropping cell voltage to Zero by’ Shorting (0.5V)_(During cell

imbalance).

Equalization: Dropping to Zero and recharging the battery with deep cycle at 5 Hrs rate.

93

rs

inci ‘unctions of battery o! aH

1. To share the load along with generator under transient conditions (inventers pumps and

short circuit).

2. To start the engine when ground power is not available (internal start)

3. To take over essential loads in case of generator failure.

Features of A/C Batteries :

1. A completely assembled metal encased battery cell containers are integral with metal

shielding box coated with acid resistant paint.

2, There has to be a provision for a tube to carry the battery gasses to over board for any

battery being charged on A/C.

3, Battery connections for light A/C (Cessna) are individual cables of (+ve) and (-ve). For

large A/C the method employed is the plug and socket type connectors. Socket is integral

part of battery container.

4, “Vented cell” (vent plugs for each cell) type battery is used for light A/C. The inter cell

‘connectors are internal and permittivity sealed with an epoxy resin. The battery contains

12 cells six on each side

5, The sealed (recombinant gas) battery is more powerful, less maintenance required when

compare with vented type.

6. Battery with sealed case except +ve and -ve connections visible for light A/C. A gas

collecting manifold is provided with an air inlet and an air flow through the manifold

carries gasses and fumes over board.

+7 ‘The Nickel cadmium battery is made of individual removable cells. For 12v A/C systems

9 or 10 cells, for 24v 19 or 20 cells connected in series. These individual cells are placed

in an insulated metal or plastic case connected to extemal post or quick disconnect unit.

8. Ventilation is provided with in the battery compartment through ‘rubber tubes both inlet

‘and outlet. Some cases acid traps in the form of polythene bottles are inserted in the Tines

to prevent acid spray being objected on the outer skin of A/C.

9, Temperature sensing devices are located with in the battery container to provide a

warning of high battery temperature and to prevent over charging y disconnecting

batteries from the charging source at a predetermined temperature.

Battery Connections

04

‘A switch in an aircraft electrical systems that can disconnect the battery from the bus and open

‘the generator or alternator field circuit.

‘When the master s/w is closed current flows through the coil and produces the magnetic pull that

closes the contacts. Current flows tox the battery bus. The point in the A/C from which all other

circuits get their power. The purpose of reverse biased diode installed across the coil of the

battery contactor allows the induced current that is produced when the master s/w contacts open

to be dissipated in the coil rather than arcing across the switch contacts.

Direct current power system consists of a.DC generator. Internal battery and its associated

protection and controlling equipment. If AC generator is prime supply source. Transformer

rectifier unit (TRU) for supplying DC. Auxiliary power Unit (APU’s) can either be Dc generator

or AC generator and TRU.

Beturerual power Supply Systenis

A single battery or several batteries connected mostly in parallel are used to supply essential

services under emergency conditions. Number of batteries employed in A/C depends on size of

A/C and the power requirements for operation of essential services.

DC ALTERNATOR

> The rotor is formed by two extruded steel pole pieces which are press fitted on to the

rotor shaft, with 2 ventilating fan on drive end, to sandwich a field coil, thus form core of

electromagnet. Each pole piece has six fingers, which in position mesh do not touch each

other.

> The excitation current 4 amps maximum is fed to field coil on the rotor via brushes and

slip rings. Slip rings are press fitted on to the rotor shaft

> The stator is made of number of steel stampings riveted together to form the core around

which three star connected phase coil are wound. One end of each winding connected to

bridge rectifier assembly other end to neutral point, stator assembly clamped between the

end frames.

95

> DC alternator is driven by either belt and pully or gear driven and flange mounted on

engine, cooling is by fan as load is low.

ectier coves

Figure : The internal circuit of a typical light-aircraft

DC alternator

The output of alternator either 14V (13.8 to 14.2V) for 12V battery 28V (27.6 to 28.4) for

24V batter. Maximum load is 60 Amps.

The drive end head contains a pre-lubricated bearing, an oil seal, collar and shaft seal and

blast tube connection, fan for ventilation. Slip rings, slip ring end bearing, inner race and

spacer are other end.

The rotor windings and leads are treated with high temperature epoxy cement to provide

vibration and temperature resistance.

‘The stator of alternator has special electrical lead that is connected to the center of three

phase winding. This lead may be used to activate low voltage warning system or relays, if

not used insulated and secured to stator core. The entire stator assembly coated with heat

resistant epoxy varnish

Six diodes rectify the AC voltage mounted on assembly plate +ve diode electrically

separated by ve diode. Each diode is connected to alternator stator either by high

temperature solder or crimp type terminals.

The brush end housing provides the mounting for rectifiers and its assembly plates. The

output and auxiliary terminal studs brush and roller assembly. The outer race assembly

and grease seal

96

=

x

>

>

The brush holder assembly has two brushes, each brush is connected to separate terminal

stud and insulated from ground.

Figure: A typical alternator for a light airplane.

eau

Output voltage of DC generator varies with load and speed. It is important to keep

voltage constant under varying load and speed. This can be achieved by controlling the

strength of field in tum controlling the field current, This is possible by using variable

resistor in the field circuit out side the generator.

The three types of voltage regulators used on AJC are

i Vibrating contact method

Carbon Pile voltage regulator

Solid state voltage Regulator.

Solid State Voltage Regulator ;

> Most widely used it consists of transistors as switching devices Zener diodes as voltage

regulator and resistances.

di

vi ri

a cs Te

ek nr —

Nompor floap

ve

97

> V input DC voltage whose variations to be regulated. Zenerdiode is always reverse

connected (Reverse biased) across Vin when PD across diode is greater than V2. It

conducts draws very high current through series resistance R. Load resistance Ri,

Constant Vou.

> Ryis fixed Vis increased, will increase I this increase of lis absorbed by I, Zener diode

without effecting the IL.

> The three transistors are NPN arrangement. When the alternator s/w is on field relay

energies. Current from bus bar (Battery) initially flows to the base of TR2 through 2

voltage dividing network made of Ri and Rz and Ry. The purpose of this network is to

establish system operating voltage by working in conjunction with Zener diode ‘Z’.

> With power applied current flows to emitter collector junction of TR2 this amplified

output from emitter circuit flows to the base of TR3 there by switching it on so that

battery current supplied to the field winding can be conducted to ground via collector

emitter junction of TR3.

> When the DC alternator is running rectified output supplied to bus bar. When the DC

alternator output reaches the preset operating value the current flowing in the reverse

direction through Zener diode cause it to break down and to allow the current flow to the

base of TRI thus TRI si switched on the collector emitter junction of TR1 now conducts

there by diverting the current always form base of TR2 switch off thus switching off

“TR3. By this excitation current is switched off to field. So dropping alternator output.

Figure: Solid-state voltage regulator

> When the alternator output falls to a value which permits Zener diode to cease conduction

making TRI switch off. Thus current to the field winding restored through TR2 and TR3,

98

> This sequence of operating repeated so the DC alternators output voltage can be

7 maintained preset operating value.

| » The rectifier D1 across field winding provides a path so that field current can fall at a

a slower rate and thus prevent generation of high voltage at TR3 each time it is switches

7 off.

| tart erator

| ‘Turbine-Engine Starter-Generator System;

Most of the smaller turbine engines jet airplanes have a combination starter-generator rather than

@ separate starter and generator. These units resemble heavy-duty, compound-wound DC

generators, but they have and extra set of series windings. The series motor windings are

\ switched into the circuit when the engine is started, but as soon as it is running, they are switched

out

I sorernate

I Pest

|

Be

|

cae 4 ae

) —

4 ‘shane

Lt >

L Figure (a): Internal circuit of a turbine

| engine starter generator.

Starter-generator :

ie A single-component starter and generator used on many of the smaller gas-turbine engines.

It is used as a starter and when the engine is running, its circuitry is shifted so that it acts as a

generator.

99

Figure 7-42 Turbine-engine starter-generator system.

Brush Less Alternators

Advantages:

i. Lower maintenance cost, since there is no brush or slip ring wear.

ii, High stability and consistency of output because variations of resistance and conductivity

at brushes and slip rings are eliminated. ee

Better performance at high altitude. Because arcing of brushes are eliminated.

2) Se

{a :

oureur ane

PERUANENT EXCITER excrreR

FIELD ourrur

HAGKET OUTPUT RECTIFIER

(foro

Figure 7-42 Ina brushless alternator there are actually three generators,

the permanent magnet generator, the exciter generator, and the main generator. The

permanent magnet generator induces voltage into the exciter generator, which in turn supplies

the field current for the main generator.

> There are three separate generators in one case

100

i. Permanent magnet generator

ii, The exeiter generator

iii, Main alternator.

> Permanent magnet is connected to the rotor, which rotates induces alternating current

‘output in stationary three phase armature winding. This 1200 Hz out put is connected to

GCU (generator control unit). It rectifies and sends De voltage to exciter field winding

(Stationary).

‘c= VARIABLE-DISPLACEMENT Pi

xc

DisPLaceMenT PUMP WOBBLE PLATE

J. coveron comaot

EvUNDER

as

\

(GENERATOR

one

canmier

SHAFT

om

oan rae redress

RXED.UNIT RING GEAR”

Figure: A constant speed drive axial-gear differential

such as the one shown here, is used in the Sunstrand

integrated Drive Generator

> Exciter generator armature mounted on same rotor shafi, when it rotates with in static

field. Alternating current is induced in 3-phase rotor. This output is connected to rotating

rectifiers unit, which changes this AC to DC sends this De to main alternator field

(rotating)

> Permanent magnet, exciter generators three phase armature, Rectifiers and main

alternator field (rotor) form the rotating part (rotor) of brush less alternator.

> When main alternator field rotates 3-phase AC EMF is induced in the (¥) star wound

stator which is connected to AC bus bar. The output 208v 3-phase or 120v 1-0 AC bus

bar supplies to various AC loads.

> The generator control unit monitors. The alternator output in turn regulates the field

current if needed.

101

I

Figure: A typical constant-speed drive and generator assembly.

d Dri

enerator,

IDG produces AC power, it contains both the generator and constant speed drive in one unit.

>

>

v

This system reduces the weight and size of traditional two unit system.

‘The CSD contains hydraulic trim assembly and differential assembly, converts variable

engine RPM to an alternator speed of 1200 RPM.

This increase in speed and better cooling allow the reduction of alternator size without

decreasing output power.

Boeing 757 has 90 KVA brush alternator for continuous operation. fy

102

Emergency Power Generation

Aircraft Electrical Systems _ EHJ Pallet 52

Emergency power is required in the case of failure of all generators and APU generator.

These generators have low output since it has to supply only essential consumer equipment under

emergency conditions. :

‘These generators are driven by ram air.

The drive consists of two bladed fan or

the fan to a single AC generator.

The complete unit is stowed on a special mounting in the A/C fuselage and when required handle

in flight compartment

When deployed at air speed of 120 to 430 kms, the fan and generator driven up to their

appropriate speeds by the air stream and electrical power is delivered via regulator at rated

valued.

Fan speed is 4800 RPM gear develops generator shaft speed 1200 RPM.

After deployment it can only be restored when the aircraft is on the ground.

The nominal power is 5 KVA.

Nominal Voltage is 115/200V Ac Three phase 400Hz.

turbine and a step up ratio gear train which connects

Power Distribution

Electrical system requirements:

Title 14 of the code of federal regulation part 23 FAR part 25

Each electrical system must be able to furnish the required power at the proper voltage to

each load circuit essential for safe operation.

Each electrical system must be free from hazards in itself in its method of operation and

in its effects on other parts of the Air craft must be protected from the damage minimal

possibility of electric shock.

Electrical power sources must function properly when connected in combination or

independently and no failure or malfunction of any electrical source may impair the ability of the

remaining source to supply essential loads.

Each system must be designed so that essential load circuits can be supplied in the event

of reasonably probable faults or open circuits.

There must be at least one generator/alternator if the electrical system supplies power to

load circuits essential for safe operation and immediate waming to flight crew in the event

failure.

There must e a master switch installed in the electrical system that allows the electrical

power source to be disconnected from the main bus.

Aircraft can be operated safely in Visual Flight Rules ( VFR) condition for a period not

less than 5 minutes with the normal electric power sources excluding the battery in operative

Classi 1 of electrical consumers:

Vital services: ‘Those which would be required after an emergency wheels up landing,

Eg — Emergency lighting. Crash switch operation of fire extinguishers. Connected to hot

battery bus bar.

Essential Services: Those required to ensure safe flight in an in flight emergency situation

will be always supplied from generator or batteries Eg: Engine Instruments.

Non Essential Services: Isolated in an in flight emergency for load shedding purpose.

‘Connected to generator: Eg. Entertainment system ( Gally Equipment)

Hot Batterv Bus: A bus bar connected directly to the battery without any relay or switch

in beoween. Vital services connected

De bus bar system:

The system comprises of intemal batteries, external power receptacle and DC generators.

Vital loads are connected to battery bus bar (Hot battery bus).

Essential DC consumers are connected to center bus bar. Both the DC generators

connected to centre bus bar through their individual bus bars and circuit breakers. In addition to

DC generators batteries and external DC supplies are connected to centre bus bar for essential

consumers in emergency and ground operations.

‘Non essential DC consumers are connected to individual generator bus bars which are

energized by ground power supply during ground operations.

Under normal operation of flight DC generators supplies non-essential loads

independently and essential loads in parallel to centre bus bar in turn batteries are getting

charged at constant voltage system.

In case of NO.I DC generator fails, No.2 Generator supplies the essential loads through

centre bus bar. Non essential loads are disconnected . If No.2 generator fails No.1 follows the

same sequence.

When both generators are failed internal batteries take over’s the loads of centre bus bar

(Essential consumers) only.

‘Addition to DC consumers AC consumers are also getting supply from DC Power

through its intemal conversion equipment ( Invertors)._ AC non essential consumers are supplied

by individual inverters which are connected to No.1 and No.2 DC generator bus bars, and

essential AC consumers are connected to Inverter which is connected to centre bus bar.

Tn case of any generator failure the inverters which are connected to the individual DC

Generator bus bars are disconnected. Emergency AC loads are getting supply from inverter,

which is connected to centre bus bar and fed by other generator which is serviceable.

If both generators are failed the centre bus bar is fed by batteries in tum powers the

inverter which is supplying the AC essential consumers.

eas eeeai es

=>

10s

Split bus bar system (AC power source)

Difficulty in parallel running of alternators on AC bus bars are splitted. Each alternator

hhas got individual bus ber.

Aircraft is utilizing non parallel constant frequency alternators as a primary source.

Direct current is supplied by TRU’s ( Transformer Rectifier Units)

The essential AC consumer loads are supplied from essential bus bar, which under

normal operating conditions is connected to No 1 AC bus bar.

The main bus bars (No.1 AC bus bar and No2 bus bar) are normally isolated each other

by “bus tie breaker” (BTB) indicating these are not paralleled.

Internal aircraft battery supplies battery bus br. Dc essential bus bar which provides DC

supply to vital and essential DC Consumers. Alternating current essential consumers are

provided with static inverter out put through which essential AC consumer bus bar by change

over switch operation.

If any one of the AC generator fails the BTB energizes closes its contact thus by serving

NO. and No.2 AC bus bars. So all AC consumers, both TRU’s are functioning

If both AC generators No.1 and No.2 fails Non essential AC loads ( No.1 and No.2 AC

bus bars) are isolated by the relay between No.1 AC bus bar and Essential AC bus bar thus relay

de energized shifts the contact so AC essential loads are supplied by static inverter from DC

essential bus bar.

DC supply is derived from independent TRU’s also from batteries No. TRU supplies

essential DC loads. Where as NO.2 to no essential. Both the DC bus bars are inter connected by

an Isolation relay.

‘The batteries are connected to hot bus bar or battery bus bar. ‘

This is inter connected 10 No.1 DC bus bar or essential DC bus bar by battery rélay

In case both alternators fails the main DC bus bar ( DC non essential bus bar) isolated

from

ig 22

Spt bstr stem (rary +. pone sue)

essential DC bus bar with the operation of isolation relay.

105

[VERTERS

Tnverter is a device for converting direct current in to alternating current as per

requirements (26 V 400 HZ or 115 V 400 HZ).

Inverters are used to supply essential AC consumers in case of failure of main AC

generators on large aircraft.

In small aircraft inverters are used to supply AC to Consumers like engine instruments

which works on alternating current. Inverters are classified as rotary an Static.

Silicon Diodes because of their ability to handle large blocks of power in a small space, are used

as power diodes. (Germanium diodes are used for ratings up to a few watts only).

‘A typical cross-section of the silicon diode is shown in Fig. 10.6. The active material is a thin

wafer (a few thousandths of a millimeter only) of treated silicon connected to copper or

‘aluminum terminals by special process. One terminal is in the form of a pig tail (a connector

used in the case of small units) and the other a stud to facilitate mounting. The barrier layer is

within the wafer. The whole unit is hermetically sealed to exclude the contaminants.

Silicon diodes are mechanically rugged, resistant to vibration and shock, and can be operated in

any position. They can also be rotated at high speeds, as in generators and synchronous motors,

without any adverse effect on their performance.

The fife of ;- hermetically sealed silicon diode has not been established, but if operated within

the designed conditions, it can be indefinite. The feilure is usually due to manufacturing defects

or improper operating conditions. The efficiency of silicon diodes varies from 96 to 99.5%.

Fig. 10.6. Section of a Sion Diet

TRANSFORMER RECTIFIER UNITS

Transformer Rectifier Units (TRU) are combinations of static transformers and rectifiers,

and are utilized in some aircraft systems es secondary supply units, and also as the main

conversion units in aircraft having rectified aircraft power systems,

106

=

‘Schema crit of tansfoeneeciferit

Fig. 3.16 illustrates 2 TRU designed to operate on a regulated three-phase input of 200 volts to 2

frequency of 400 HZ and to provide a continuous DC out put of 110A at approximately 26 Volts.

The circuit is shown schematically in Fig. 3.17. The unit consists of a transformer and two three-

phase bridge rectifier assemblies mounted in separate sections of the casing. The transformer

has a conventional Star-wound primary winding and secondary windings wound in Star and

Delta. Each secondary windings connected to individual bridge rectifier assemblies made up of

107

six silicon diodes, ad connected in parallel. An ammeter shunt (dropping 50 mV at 100A) is

‘connected in the output side of the rectifiers to enable current taken from the main DC terminals.

These terminals, together with all others associated with input and output circuits, are grouped on

a panel at one end of the unit. Cooling of the unit is by .natural convection though gauze-

covered ventilation panels.and in order to give waming of over-heating conditions, thermal

switches are provided at the transformer and rectifier assemblies, and are connected to

independent warning lights. The switches are supplied with DC from an éxternal source (

normally one of the busbars) and their contacts close when temperature conditions at their

respective locations rise to approximately 150°C and 200°C.

EXTERNAL & GROUND POWER

Requirement:

External/Ground Power required to furnish electrical power for scheduled maintenance,

rectification and ground handling operations like cargo loading and ground starting of aircraft

Engines/APU

DC External Power Supply Connections:

Two pin extemal ground power connector. Ground / Flight switch

When selected to Ground external supply connected to main bus bar when selected to

“Flight” battery is connected to main bus bar thus DC generator charges the battery

Larger diameters smaller diameters of ground power connectors or receptacles prevent a

reverse polarity condition. Cover of the unit had to be rotated to expose the sockets.

3 opin plug

External supely

Three Pin

Receptacle

system:

Fig 4.2

asic cxternal power supply system ide

Three pin receptacle consists of two +Ve pins ( one larger other smaller)

One ~ Ve pin ( Larger)

Pins are enclosed by protective shroud. Complete unit is fitted in a recessed housing located

appropriate part of air frame structure, Access to the plug from out side the aircraft via a hinged

flap provided with quick release fasteners.

Short. + Ve pin is connected to the coil of External Power relay. It is connected at last

while in. While removing the socket it breaks first. In the event of external power supply socket

“Live” the extemal power relay coil de energized thus contact open before the main pins are

disengaged. This prevents arcing of heavy duty main contacts at main pins.

Fuse R De

A ppicel aircraft ground-power circuit

External ac supply connector and control panel:

This system is used for large public transport aircraft.

The receptacle is of six prong type. . Three large prongs for the corresponding three

Phases (A,B C) and one more large prong for ground or neutral connection between aircraft

structure and extemal power. The two shorter prongs connect DC power for the interlocking

relays which connect the extemal AC power to the aircraft.

Control panels contains of three single phase AC circuit breakers and three more breakers

which protect relay control and indicating light circuits with in Aircraft external power supply

circuits. Indicator light, Inter phone jack plug sockets and pilots call button.

White indicator light indicates external AC power is connected but is not supplying

power to any AC loads bus bar on the aircraft. “Blue light” indicates when ever AC power

‘supplied to load bus bars.

Pilots call button switch and inter phone jack plug sockets provide for communication

between ground crew and flight crew.

109

2a de baer yee non babe

SPLIT BUS BAR SYSSTEM ( AC POWER SOSURC!

Difficulty 1 parallel running of alternators on aircraft bus bars are splitted. Each

alternator has got individual bus bar.

‘Aircraft is utilizing non parallel constant frequency alternators as a primary source.

Direct current is supplied by TRU’s ( Transformer Rectifier Units)

The essential AC consumer loads are supplied from essential bus bar, which under

normal operating conditions is connected to No 1 AC bus bar.

The main bus bars (No.1 AC bus bar and No2 bus bar) are normally isolated each other

by “bus tie breaker” (BTB) indicating these are not paralleled.

If any one of the AC generator fails the BTB. energizes closes its contact thus by serving

NO.1 and No.2 AC bus bars. So all AC consumers, both TRU’s are functioning.

If both AC generators No.1 and No.2 fails Non essential AC loads ( No.i and No.2 AC

bus bars) are isolated by the relay between No.1 AC bus bar and Essential AC bus bar thus relay

de energized shifts the contact so AC essential loads are supplied by static inverter from DC

essential bus bar.

DC supply is derived from independent TRU’s also from batteries No.1 TRU supplies

essential DC loads. Where as NO.2 to no essential. Both the DC bus bars are inter connected by

an Isolation relay.

The batteries are connected to hot bus bar or battery bus bar.

This is inter connected to No.1 DC bus bar or essential DC bus bar by battery relay

In case both alternators fails the main DC bus bar ( DC non essential bus bar) isolated

from essential DC bus bar with the operation of isolation relay.

110

P.3.2.14 Aireraft Lighting System: ATA 33

lect ighting: Internal and External lighting, Anti collision Lights, Strobe

lights, Landing lights and their circuits.

ATA __ 100 Chapter 033 deals with lighting

- All airerafts approved for flying at night must be equipped with various lights.

Abert Lighting:

1. Marking of an aircraft position by means of navigation lights.

2. Position marking by means of flashing lights.

Forward illumination for landing and taxing.

Illumination of wings and engine air intakes to check for icing.

Illumination to permit evacuation of passengers after an emergency landing.

pee

urs

Navigation Positional Lights:

Internationally accepted by statutory rules of air and orders for air traffic and air navigation

control regulations.

Nav Lights ce

GREEN

STAR BAR,

tums MI

RIGa

= white

=

A green light at or near star board or right wing Tip — visible in the horizontal plane

from a point directly ahead ( forward motion) through an area of 110° to star board

A ‘red ‘ light at or near port or left wing tip with a similar are of visibility (110°) to

port

‘A “white” light usually mounted on the top of vertical stabilizer (Fin) or aircraft tail.

‘Their rear or aft position must show 70°each side of the center line of the’aircraft and

to the rear (140°)

White light mounted on each trailing wing tip for DC-10 lock head 1011: Tri star

aircraft

Lamp is of filament type with a transparent colored screen or cap.

These lights are operated with single circuit. One fuse of one CB and one switch.

Leading edge landing lamps can be turned on several miles away from landing.

Aanding Light

These lights are required to provide adequate light to illuminate the runway when

aircraft is making landing. A parabolic reflector is used to concentrate the light into

the beam of desired width.

These lights may be installed to the stationary part of nose gear, in the leading

edges of the wings or engine cowl. Retractable landing lights in the lower surface of

wings.

Landing lamps have 600 Watis capacity with a supply of 28 V DC or 28 V AC.

Leading edge landing lamps can be turned on several miles from landing.

When the contro! switch is paced in “ Extend” position , 115 V supply passes

through extend field winding of motor until itis interrupted by extend limit switch,

Retract limit switch closes soon after motor extending the, light. The switch in the

supply circuit to light also closes but light is not illuminated until it is fully extended

and the control switch placed on position. Power supply to light reduced to 115 V

step down transformer .

Figure

7 nas

oo Aa

Retract RevRasr

Extending / Reteactng Landing Light civeuit

in Refract Posi u2

These are sealed beam type located at fuselage nose section ( nose landing gear

assembly). The power rating 250 Watts and 28V DC or AC

= Some of the aircraft landing/taxing light filaments combined in one light having 600

‘watts and 400 watts respectively.

~ Some larger transport aircraft are equipped with lights as run way tum off lights. The

purpose is to illuminate the points along the runway at which aircraft must tum to

leave the run way after landing. Operated by switch and solenoid.

/Aanti collision lights:

- It is designed to make the presence of an a/c visible to pilot and crew members of

other aircraft in the vicinity. Particularly in area of high density aviation activity at

night and in conditions or reduced visibility.

~ These lights are mounted on the top of the fuselage. The top of the vertical stabilizer

(for small aircraft) and on the bottom of the fuselage.

+ Two basic type of anti collision lights

(@ Rotating beam

(b) Strobe lighting

Rotating beacons or rotating beam lights:

It consists of filament lamp unit with reflector and motor. Motor may

drive reflector or lamp unit: through gear and pinion type with specific

reduction ratio. Light unit can be operated 28 V DC or 28 V AC::motor

. 115 V AC. Typical speed of motor 40-45 rev/min giving a frequency of

80-90 cycles per minute.

Strobe Light

It consists of quartz or glass tube filled with xenon gas. This is connected to the power

supply unit consists of capacitor. Capacitor converts 28 V DC of 115 V AC in to high input DC

of 450 Volts. Capacitor charges at this voltage and periodically discharged by trigger circuit

between two electrodes in the xenon filed tube. Thus producing high intensity flash of light in

the blue white colour. It has got the frequency of 70 flashes per minute.

The principle is capacitor discharge in flash tube or strobe scope.

Strobe light can be used as anti collision system or at wing tips. The duration of flash is

0.001 sec. intensity is more can be seen from miles

Fitted in such a way light will not affect the vision of crew members.

Anti collision lights if not installed by manufacturer, must be installed as per FAA

publication AC 43-12-2A, regulation conceming such lights are provided FAR part 23 and part

25.

ICE Inspection Lights: These lights are used to detect the formation of ice on the leding

‘edges of wings and also at the air intakes of turbine engines. They are recessed into the side of

fuselage and pretest to direct the beams to at a required angle for rear mounted engines lights

recessed to the trailing edges of wings. The power of lamps are 60 to 250 watts depending on

light intensity

/ Internal Lighting System:

1. Illumination of Cockpit Instruments and control panels.

2. Illumination of Passengers cabins and passenger information signs

3. Indication and waming system of operating conditions.

Cockpit or Operational Lighting:

Integral lighting is one in which light source is with.in instruments. These lights installed

behind face of instrument panel. These lights illuminate the instruments but do not shine

directly to wards the pilot or copilot. All instrument lights are shielded like this. These lights

provide wit dimming arrangement so intensity can be adjusted.

Pillar and bridge lighting number of lights are positioned on panels to illuminate small

adjacent areas.

Flood lights lamps are positioned around the cockpit to illuminate specific panels or

general area.

Warning lights are provided to alert the pilot and crew to operating conditions with in

aircraft systems.

Red - Danger

Amber- Caution

Green - Safe Condition

White - Information purpose

Passenger Cabin Lighting System:

Depends up on size of cabin and largely on the interior-décor adopted for the type of

aircraft can be cartied from roof mounted incandescent lamp fittings to large number of

fluorescent lamps located in ceilings and had racks to give pleasing. Concealed and functional

lighting effects. Works on DC or AC.

Passenger service lighting fitted in galleys, toilet compartments freight compartments and

equipment bays. Lights can be incandescent type or electro luminescent type.

Passenger information signs like “Fasten Seat Belts”. “Return to Cabin” are conttolled by

switches on cockpit over heed panel.

Emergency Lighting System:

These lights are fitted at cabin exits escape hatches of lower levels. It provides lighting

for emergency evacuation of passengers in situation like crash landing during night. These lights

are controlled by emergency battery pack or air craft battery.

ua

=

P.2.5.15 Built In Test Equipment (BITE) 01 Hr

ECAM (Electronic Centralized Aireraft Monitoring) o1Hr

EICAS (Engine Indication and Crew Ale 02 Hr

BITE (BUILT IN TEST EQUIPMENT)

BITE system found on modern aircraft is designed to rectify the faults in the various

aircraft systems encountered during maintenance. It provides fault detection, fault isolation and

operational verification after the fault rectification.

Gaga,

wl

B

[a}

oi

1G

Haas

Fe

BEBE

0080

6000

@ageo8

0000

It provides

fault detection

continuously during aircraft operation if a fault is detected the BITE system stores necessary

defect information in a non volatile memory, sense the appropriate display signal to the flight

desk. Ifa fault requires immediate attention the flight crew will notify ground engineer via radio

transmission.

The technician must assess the appropriate BITE system on ground for the fault isolation,

the BITE system will display the failure data with code information. A simple BITE system

incorporates GO or NO GO Red or Green lights on the equipment black or LRU (Line

Replaceable Units). In advanced BITE system has a Automatic transmission of data from the

aircraft to the maintenance facility on ground during the flight (ACARS) ( Amic Communication

Addressing and Reporting System). When BITE button is pressed on ground a 24 character fault

display system is activated, this display is in a coded message which is de coded by reference

maintenance manual. The fault information is displayed for two seconds the display

automatically advances to the next fault.

After system fault rectified the button should be pressed to reset and operational check to

be performed. It performs two types of test programs.

The operational program is designed to check input signals, protection circuitry, control

circuitry, out put signals and the operation of BITE circuitry.

The maintenance program of BITE is recorded into the system only when the aircraft is

‘on the ground and maintenance test routine is required. When requested the maintenance BITE

fexercise all input circuitry and software routines of the system being checked. The output data

are than monitored and faults are displayed on the BITE.

Engine Indicati System (EICAS):

‘The display of the parameters associated with engine performance and airframe systems

control by means of CRT-type display units has, like those of flight instrument systems, become

{standard feature of many types of aircraft. The display units form part of two principal systems

designated as Engine Indicating and Crew Alerting System(EICAS) and Electronic Centralized

‘Aircraft Monitoring(ECAM) system, which were first introduce in Boeing-757and 767 aircraft

and the Air Bus A310.

i

In respect of EICAS, engine operating data is displayed on its CRT units, thereby

eliminating the need for traditional instruments.

The basic system comprises two display units, a control panel, and two computers

Supplied with analog and digital signals from engine and system sensors. The computers

deeignated “Left” and “Right”, and only one isin control ata time: the other is on “standby” and

in the event of failure it may be switched in either manually or automatically.

116

These units provide a wide variety of information relevant to engine operation, and

operation of other automated systems, and they utilize colour shadow mask CRTs and associated

card modules. The upper unit displays the primary parameters N1 speed, EGT, and warming and

caution messages. In some cases this unit can also display EPR (Engine Power Ratings)on the

type of engines installed and on the methods of processing data by the thrust management

control system.

The lower unit displays secondary engine parameters, ie N2 speed, fuel

flow, oil quantity, pressure and temperature, and engine vibration

oom

Dispey st poet

Seven colours are produced by the CRTs and they are used as follows:~

White

Red

Green -

Blue -

Yellow

Magenta

(Brown pink)

Cyan -

(Light yellow)

Al Scales, normal operating range of pointers, digital readouts

Warning messages, maximum operating limit marks on scales, and

digital readouts

Thrust mode readout and selected EPR/NI, speed marks or target

cursors

Testing of system only

Caution and advisory messages, caution limit marks on scales,

digital readouts.

During in-flight engine starting, and for cross-bleed messages

Names of all parameters being measured ( eg. NI, Oil

pressure, TAT, etc.) and status marks or cues.

Ww

EICAS is designed to categorize displays and alerts according to function and usage, and

for this purpose there are three modes of displaying information:

@ Operational

Gi) Status

ii) Maintenance mode

Modes( i) and (ii) are selected by the flight crew on the display select panel, while mode (iii) is

selected on the maintenance panel which is for the use of engineers only.

Electronic Centralized Aircraft Monitoring (ECAM|

Display Units: These units are mounted side-by-side: the left-hand is dedicated to

information on the status of systems, warnings and corrective action in a sequenced check-list

format, while the right-hand unit is dedicated to associated information in pictorial or synoptic

format.

Display Modes: These are four display modes, three of which are automatically

selected and referred to as flight phase-related, advisory (mode and status), and failure related

modes. ‘The fourth mode is manual and permits the selection of diagrams related to any one of

12 of the aircraft's systems for routine checking, and also the selection status messages provided

no warnings have been

“triggered” for display.

The failure related mode is appropriate and an example of @ display presentation is, there is a

problem associated with the number one generator. The left hand display unit shows the affected

system in message form, and in red or amber depending on the degree of urgency, and same

time, a diagram is displayed on the right-hand display unit. When the number one generator has

switched off, the light in the relevant push button switch on the flight deck overhead panel is

illuminated, and simultaneously, the blue instruction on the left hand display unit changes to

White. The diagram on the right hand display unit is also “re drawn” to depict by means of an

amber line that the number one generator is no longer available, and the number two generator is.

supplying the bus bar system. This is displayed in green which is normal operating colour of the

118

displays. After corrective action has been taken, the message on the left-hand display unit can be

removed by operating a “clear” button switch on the ECAM Control panel.

Electrical Power Systems for Large Aircraft:

The electrical systems for large turbojet transport aircraft are different than those used with

smaller aircraft, primarily because these aircraft use alternating current for their primary power.

The DC needed for charging the battery and for certain motor and instrument systems is

produced by transformer rectifier, or TR, units. They reduce the voltage of the AC produced by

the engine-driven generators to 28 volts and then rectify it, or change it, from AC into DC See

figure 7-59 on the next page.

Figure 7-59 shows a simplified block diagram of the electrical power system of a Boeing

721 jet transport airplane. Electrical power is produced by three 115 volt, three-phase, 400

Hertz alternating-current generators driven by the engines through constant-speed drive (CSD

units. The CSD’s hold the speed of the generators constant to keep the frequency of the AC they

produce constant as the engine speed varies over their normal operating range.

Each generator is connected to its own bus through a generator breaker (GB), and the

three buses can be connected at the tie bus by the use of bus tie breakers ( BTB) that are

controlled from the flight engineer’s control panel,

A turbine-powered auxiliary power unit (APU) drives a three-phase AC generator thet

can be connected to the tie bus through the APU generator breaker to supply electrical power to

the aircraft when the engines are not running. The APU operates a fixed RPM so it does not

drive CSD. An extemal power unit can also be connected to the aircraft, and its AC output can

be connected to the tie bus through the EXT breaker.

All the circuits that are essential to the operation of the aircraft are connected to a

essential bus, which can be supplied with AC from any of the three engine-driven generators, the

APU the external power unit: or a standby inverter that produces 115 Volt AC 400 Hz from 28

Volt DC battery power. A selector switch on the panel allows the flight engineer to select the

source of power for the essential bus,

Direct current is produced by two transformer-rectifier (TR) units that take AC from

buses | and 2 and supply DC to DC buses | and 2. A third TR unit takes AC from the essential

bus and produces DC for the essential DC bus.

The battery supplies power for starting the APU and for emergency operation of certain

essential radio and instrument systems. The battery is kept charged by a battery-charger unit that

receives its AC power from the AC transfer bus. Monitoring circuits inside the battery are

connected into the battery-charger circuit so that if the battery temperature becomes too high, the

charging current will automatically decrease.

119

‘The battery is connected to the hot battery bus al all times, but is automatically

disconnected from the DC loads in normal operation.. These loads are supplied from the two DC

busses and the essential DC bus.

Transformer Rectifier (TR): A component in a large aircraft electrical system used to

reduce the AC voltage and change it into DC for charging the battery and for operating DC

equipment in the aircraft.

TR Uni ‘A transformer-rectifer unit. A TR unit reduces the voltage of alternating current

land changes it into direct current.

Constant-Speed Drive( CSD): A Special drive system used to connect an alternating

current generator to an aircraft engine. The drive holds the generator speed ( and thus is

frequency) constant as the engine speed varies.

‘Auxiliary Power Unit (APU): A small turbine or reciprocating engine that drives a

generator, hydraulic pump and air pump. The APU is installed in the aircraft and is used to

supply electrical power, air and hydraulic pressure when the main engines are not running.

Essential Bus: A bus that may be supplied with AC from any of the generators through a

selector switch. It supplies current to the circuits that are essential to the operation of the

aircraft.

120

996

Por Re ee

AIRCRAFT COMMUNICATION AND NAVIGATION

LIST OF CONTENTS

TOPIC [NAME OF THE REFERENCE BOOKS

NUMBER | TOPIC

P3.2.5.2 ATA 23 communication | A/C Radio Systems: James

system, Powell

P3252 ATA 34 navigation ‘Ale Radio Systems: James

system Powell

P2.5.15 GPS A/C Communication And

Navigation System: Mike

Tooley

2.5.15 ACARS:

Tooley

P2.5.15 TCAS A/C Communication And

Navigation System: Mike

Tooley

P2.2.4 AVIONICS GENERAL | Basic Electronics:

TEST EQUIPMENT Vk mehta

This book consists of total 29 figures.

121

A

VHF COMMUNICATION

.TA23 (COMMUNICATION)

ireraft Communication ~ The conveyance of information to or from aircraft by radio or other

signals.

> NF radio has long been the primary mean of communication between aircraft and the

‘ground.

> VHF communication system supplies voice and data communication over line-of -Sight Cos)

distances. It gives communication between airplanes or between ground station and

airplanes.

> VHF communication is used for various purposes including air traffic control approach

and departure information transmission of metrological information ground handling of

aircraft company communication and also for the aircraft communications addressing

SEE POTIE SIEM OCOD sete — asaecnte

>» FREQUENCY: 118 to 136.97%SMHz

r 720channels with 25 KHz spacing

(Or)

360 channels with 50 KHz spacing

> MODE OF OPERATION: Double sideband(DSM) amplitude modulation&

eur Puree aa:

If

> COMPRESSOR STAGE:

> INSTALLATION:

Single channel simplex (s.c.s) we

pate

> RANGE: 200 to 300 NM. a x

* . ¢ oh

> PROPOGATION: Space wave propagation. |X 6, ©

ax

> OUTPUT POWER: 25 to 40'w.

ou’ ay

> The maximum line of light (los) distance between an aircraft and a ground station in qe

nautical miles(am), is given by pee /

D: Ss

vn os ye”

Where h is the aircrafts altitude in feet above ground.

118.00 to 121.400 ai

= 121.600 to 123.050 S

= 123.150 to 136.475

>» SQUELCH CIRCUI

Aircraft VHF receivers invariably incorporate a system of muting the receivers

audio stages in the absence of an incoming signal. This system is designed to

climinate the annoying and distracting background noise that is present when no

signals are being received

In order to improve the intelligibility of VHF voice communications the speech amplifier

stage of an aircraft VHF radio is invariably fitted with a compressor stage. This stage

provides high gain for low amplitude signals and reduced gain for high amplitude signals.

The result is an increase in the average modulation depth.

A single VHF installation consists of three parts namely control unit transceiver and

antenna. In addition crew phones are connected to the vhf via AIS.

>

HF radio provides aircraft with an effective means of communication over long distance

HF COMMUNICATION

oceanic and trans-polar routes.

HF communication systems are fitted to aircraft flying routes which are for some part of the

flight out of range of VHF service. Such aireraft obviously include public transport aireraft

flying intercontinental routes. oo sen

FREQUENCY: 2.8 TO 24 MHZ,

21200 channels with IKHZ spacing

(Or)

2.1 lac of channels with 100HZ of spacing

MODE OF OPERATION: Single side band(SSB) amplitude modulation

And Single channel simplex (S.C.S)

RANGE: Above 1000nm,

PROPAGATION: Sky wave propagation.

pe

124

BOO -SOO Lar.

OUTPUT POWER: 400 w pep

> The long range is achieved by use of sky waves which are refracted by the ionosphere to.

‘such an extent that they are bent sufficiently to return to the earth. The h.f ground wave

suffers quite rapid attenuation with distance from the transmitter. Ionosphere attenuation also

takes place, being greatest at the lower h.f frequencies.

> A feature of aircraft h.f systems is that coverage of a wide band of rf and use of a resonant

antenna requires efficient antenna tuning arrangements which must operate automatically on

changing channel in order to reduce the VSWR to an acceptable level.

ANTENNA COUPLER: Couples the antenna to a transmitter or receiver,

Match the antenna to the radio. KL.

» ANTENNA TUNING UNIT: Tunes the antenna to a single particular frequency

v

This unit makes one antenna to transmit and

Receive many frequencies

SELCALL SYSTEM (SELECTIVE CALLING SYSTEM)

> The SELCAL system supplies the flight crew with indications of calls that

come in from the airline’s ground stations.

> Itis not necessary for the pilots to continuously monitor the company

communication channels.

> Airlines radio network supply communication between ground stations and

airplanes.

"> For SELCAL operation, each airplane has a different four-letter code (ex:

AKDM). Each letter in the code equals a different audio tone.

> The ground stations send the applicable tones to call a particular airplane.