88% found this document useful (8 votes)

7K views7 pagesPerkins 4000 Series Injector Timing Guide

The document provides instructions for servicing an engine's fuel injection system. It describes how to:

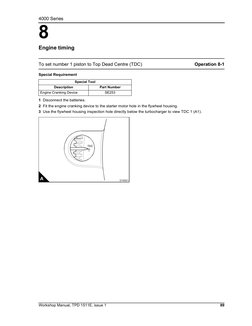

1) Set the number 1 piston to top dead center using an engine cranking device to view the timing mark.

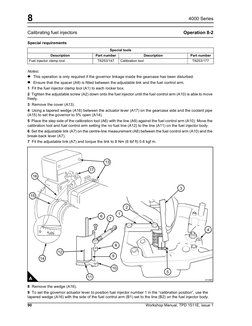

2) Calibrate the fuel injectors using special tools by adjusting links and checking calibration lines.

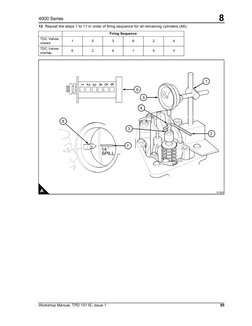

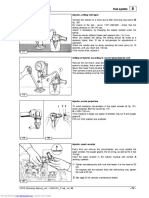

3) Set the governor to the zero fuel position using a spacer tool between the break-back lever and cylinder head.

4) Apply light pressure to the timing pin using a screwdriver as a reference point for fuel injection timing.

5) Time the fuel injectors by turning the engine backwards and forwards to align spill marks with timing pointers, adjusting rockers, and checking clearance with

Uploaded by

Anonymous V9fdC6Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

88% found this document useful (8 votes)

7K views7 pagesPerkins 4000 Series Injector Timing Guide

The document provides instructions for servicing an engine's fuel injection system. It describes how to:

1) Set the number 1 piston to top dead center using an engine cranking device to view the timing mark.

2) Calibrate the fuel injectors using special tools by adjusting links and checking calibration lines.

3) Set the governor to the zero fuel position using a spacer tool between the break-back lever and cylinder head.

4) Apply light pressure to the timing pin using a screwdriver as a reference point for fuel injection timing.

5) Time the fuel injectors by turning the engine backwards and forwards to align spill marks with timing pointers, adjusting rockers, and checking clearance with

Uploaded by

Anonymous V9fdC6Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd