Professional Documents

Culture Documents

Surface Intermediate: Utica Shale Basin-Bit Guide

Uploaded by

pendexxOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Surface Intermediate: Utica Shale Basin-Bit Guide

Uploaded by

pendexxCopyright:

Available Formats

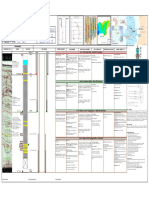

Utica Shale Basin—Bit Guide

SURFACE INTERMEDIATE

SDi519 SDSi716 Gi12 4JS H1809D MSi616 MSi816 GF15BVCPS F57YOD F37YA F47YA H1509D H1411D+

Fluid Fluid Fluid Air Air Fluid Fluid Fluid Fluid Air Air Air Air

VERTICAL CURVE /LATERAL

MSi616 MDi616 FHi28 F37YAPS F47YAPS H1209D SDi516 SDi513 SDi513 SDAi513 SDi616 SDi516 F27APS F47YAOD

Fluid Fluid Fluid Air Air Air Fluid Fluid Fluid Fluid Fluid Fluid Air Air

Available Bit Sizes† Nomenclature Features Recommended fixed cutter bit makeup torque Recommended roller cone bit makeup torque

Application Bit Bit Size, in Product Line Prefix Description Face Features Description API Reg Connection Bit Sub OD, Minimum, Normal, Maximum, Size Range, in [mm] API Pin Size, in [mm] Recommended Torque, ft.lbf [N.m]

Surface SDi519 17 ⁄2

1

Di IDEAS certified directional design L Low exposure Size, in in ft.lbf ft.lbf ft.lbf 3 1⁄ 2 – 41⁄ 2 [89 –114] 23⁄8 Reg [60] 3,000–3,500 [4,000–4,800]

SDSi716 171⁄2 S SHARC PDC drill bit M Replaceable Lo-Vibe 3 1,970 2,280 2,450 45⁄8 –5 [118 –127] 2 ⁄8 Reg

7 [73] 4,500–5,500 [6,000–7,500]

Gi12 171⁄2 C Carbonate V Lo-Vibe 2 ⁄8

3 31⁄8 2,660 3,100 3,300 51⁄ 8–73⁄8 [137–187] 3 ⁄ 2 Reg

1 [89] 7,000–9,000 [9,500–12,000]

31⁄4 3,400 3,950 4,200 71⁄ 2 –9 [194–229] 41⁄ 2 Reg [114] 12,000–16,000 [16,000–22,000]

4JS 171⁄2 HOX Heavy oil series K Impregnated cutter backing

31⁄ 2 3,380 3,950 4,200

Scan QR code with an iPhone® to

M Matrix body Hydraulic Features 9 1⁄ 2 –28 [241–711] † 65⁄8 Reg [168] 28,000–32,000 [38,000–43,000]

H1809D 171⁄2 27⁄8

33⁄4 and larger 5,080 5,900 6,300 14 3⁄4 –28 [375–711] † 6 ⁄8 Reg or 7 ⁄8 Reg [168 or 194]

5 5 34,000–40,000 [46,000–54,000]

download the Smith Bits Quick Calc

S Steel body H Higher number of nozzles than standard

Intermediate MSi616 121⁄4

K Kinetic impregnated bit N Lower number of nozzles than standard 41⁄8 5,700 6,600 7,000 181⁄ 2 –28 [470–711] † 75⁄8 Reg or 85⁄8 Reg [194 or 219] 40,000–60,000 [54,000–81,000] Hydraulics app from the iTunes® store.

MSi816 121⁄4

H Kinetic hybrid bit Y 30 series nozzles 31⁄2 41⁄4 6,940 8,050 8,550 Makeup torque must correspond to API pin connection for each bit size.

†

GF15BVCPS 121⁄4 Note: Some of the above bit sizes are available on special order with alternate pin connections.

D Natural diamond bit W 40 series nozzles 41⁄ 2 and larger 8,400 9,850 10,500

F37YA 121⁄4

L LIVE U 50 series nozzles 51⁄ 2 13,700 16,600 17,000

F47YA

F57YOD

121⁄4

121⁄4

PR Pilot reamer Q Fixed ports 41⁄2 5 3⁄ 4 18,100 21,100 22,400 API gauge tolerances for fixed cutter

H1509D 121⁄4

T Turbine R Restrictor plate 4 1⁄ 2 and larger

71⁄ 2

18,550

40,670

21,600

47,300

22,900

50,200

and roller cone bits

ST Side track Gauge Features 6 5⁄ 8

H1411 121⁄4

SHO Staged hole opener E Extended gauge pad length 73⁄4 and larger 41,050 47,800 50,750 Bit size, in Fixed Cutter, in Roller Cone, in

Vertical MSi616 8 3⁄4

QD Quad-D dual diameter S Short gauge pad length 81⁄ 2 53,100 61,850 65,670 6 3⁄4 and smaller -0.015 – +0.00 -0.0 – +1/32

MDi616 8 3⁄4

G Reamers with API connections (box down, pin up) A Active gauge 75⁄8 8 3⁄ 4 63,500 73,750 78,300 6 25⁄32 to 9 -0.020 – +0.00 -0.0 – +1/32

FHi28 8 3⁄4

F37YAPS 8 3⁄4

R Reamers with IF connections (<6 5⁄8 in) (pin down, box up) B Back reaming cutters 9 and larger

10

68,600

96,170

79,800

102,600

84,750

108,950

9 1⁄32 to 13 3⁄4

1325⁄32 to 171⁄ 2

-0.030 – +0.00

-0.045 – +0.0

-0.0 – +1/32

-0.0 – +1/16

www.slb.com/SmithBits

Z Stinger conical diamond element PX TSP on gauge 8 5⁄ 8

F47YAPS 8 3⁄4

T Turbine sleeve 10 1⁄4 and larger 107,580 114,700 121,800 17 17⁄32 and larger -0.063 – +0.00 -0.0 – +3/32

H1209D 8 3⁄4 Nomenclature identifies blade count and cutter size. Example: M616 = 6 blades

PXX Full diamond on turbine sleeve Notes:

Curve/Lateral SDi513 7 ⁄8

7

8 ⁄2

1

8 3⁄4 and 16 mm cutters. 1. Recommended make-up torque dictated by all BHA components

D Dog sleeve 2. Higher makeup torque values within the above ranges are recommended when high WOB is used.

SDAi513 81⁄2 3. Box connection bits should use makeup torque values between Minimum and Normal.

Connection Features

SDi616 81⁄2 4. All connections must be lubricated with a joint compound meeting API requirements.

C Non-API standard connection

SDi516 81⁄2 8 3⁄4

F27APS 77⁄8

MDSiZ619 I IF connection

F47AOD 77⁄8

Cutter size

†

Bits in the above chart are only available in stated sizes. Smith Bits designs vary from Blade count

size to size. For additional bit sizes, please contact your local Smith Bits representative. Z—Stinger element

i—IDEAS certified

S—SHARC PDC drill bit

D—IDEAS directional certified

Stinger, IDEAS, Kinetic, Quad-D and SHARC are marks of Schlumberger. Other company, product, M/S—matrix or steel

and service names are the properties of their respective owners. Copyright © 2013 Schlumberger.

All rights reserved. 13-BT-0001

You might also like

- Var-3704 - Performanceupdates-Me - Brochure-V1.0sm - ROP DATA PDFDocument12 pagesVar-3704 - Performanceupdates-Me - Brochure-V1.0sm - ROP DATA PDFamir_hayfaNo ratings yet

- Stinger BrochureDocument22 pagesStinger BrochurediegoilNo ratings yet

- 12 BT 0123 Stinger North Dakota CsDocument2 pages12 BT 0123 Stinger North Dakota CsdiegoilNo ratings yet

- Dull Grading ManualDocument1 pageDull Grading ManualBaitaw WanwarangNo ratings yet

- HC606 Drill Bit ManualDocument1 pageHC606 Drill Bit ManualMahdy BasimNo ratings yet

- The Ideal Bit Drag Bits: Fishtail Type Natural Diamond Polycrystalline Diamond Compact (PDC)Document45 pagesThe Ideal Bit Drag Bits: Fishtail Type Natural Diamond Polycrystalline Diamond Compact (PDC)ShourovjossNo ratings yet

- Catalogue: Products For Oil&gas IndustryDocument39 pagesCatalogue: Products For Oil&gas Industryfarid said errahmaniNo ratings yet

- Log ResponsesDocument1 pageLog ResponsesHamza Lahbiben0% (1)

- Profile & Cutter Placement: Reference Photo: 17 1/2" FC619Document1 pageProfile & Cutter Placement: Reference Photo: 17 1/2" FC619Hendra SiswantoNo ratings yet

- Bi-Center Drill Out Procedure: Rotary and PDM ConfigurationsDocument2 pagesBi-Center Drill Out Procedure: Rotary and PDM ConfigurationsashadNo ratings yet

- Defining BitsDocument2 pagesDefining BitsahmedNo ratings yet

- Drill Bit TechnologyDocument39 pagesDrill Bit TechnologyMohamed MamdouhNo ratings yet

- The Oil Industry in 40 CharactersDocument34 pagesThe Oil Industry in 40 CharactersSeptianNo ratings yet

- Bi Center Presentation Brocas PerforacionDocument14 pagesBi Center Presentation Brocas PerforacionOscar RuedaNo ratings yet

- Analisis Penggunaan Bit For ChevronDocument15 pagesAnalisis Penggunaan Bit For Chevronfaishal hafizhNo ratings yet

- Drill BitsDocument38 pagesDrill Bitsrizky8474No ratings yet

- Drilling Solutions CatalogDocument15 pagesDrilling Solutions Catalogعلی محمودیNo ratings yet

- Deliver The Well: Rodney Howard Halliburton, AberdeenDocument100 pagesDeliver The Well: Rodney Howard Halliburton, AberdeenЮрий УсковNo ratings yet

- Supplemental Technical InformationDocument5 pagesSupplemental Technical InformationpendexxNo ratings yet

- Bits NomenclatureDocument78 pagesBits Nomenclaturerimel warnes100% (1)

- 2011 - Reelwell Company FolderDocument12 pages2011 - Reelwell Company FolderMohamed SadekNo ratings yet

- Quad-D: 6 - 7 in QDM4213 Dual DiameterDocument1 pageQuad-D: 6 - 7 in QDM4213 Dual DiameterpendexxNo ratings yet

- Reduce Torsional Vibration and Improve Drilling Operations: Jerome Rajnauth, PHDDocument15 pagesReduce Torsional Vibration and Improve Drilling Operations: Jerome Rajnauth, PHDAnonymous DDqgH1Y2MKNo ratings yet

- Rolling PDC Cutter Advances Drilling Efficiency in Granite Wash FormationDocument4 pagesRolling PDC Cutter Advances Drilling Efficiency in Granite Wash FormationRio RizkiNo ratings yet

- Adomite Regain Fluid-Loss Control Additive For Fracturing: Product BenefitsDocument1 pageAdomite Regain Fluid-Loss Control Additive For Fracturing: Product BenefitsizzybjNo ratings yet

- Fixed Cutter Bits Nomenclature & Features: Shine Narayanan Bits Product Engineer Schlumberger 14 March 2014Document7 pagesFixed Cutter Bits Nomenclature & Features: Shine Narayanan Bits Product Engineer Schlumberger 14 March 2014Hrishikesh ShindeNo ratings yet

- Fixed Cutter Bit, DAD ClassDocument18 pagesFixed Cutter Bit, DAD ClassAboZaidNo ratings yet

- Rev 01-Dec-06Document70 pagesRev 01-Dec-06zhujianglongNo ratings yet

- LTK 70 01 003Document2 pagesLTK 70 01 003romeoleonNo ratings yet

- W5D2 - DE - Introduction To Well Trajectory PlanningDocument54 pagesW5D2 - DE - Introduction To Well Trajectory PlanningFernandoNo ratings yet

- Diamond Bit Design HandoutDocument19 pagesDiamond Bit Design Handoutamin peyvand100% (1)

- 2 Borehole EnlargementDocument10 pages2 Borehole EnlargementpsaumNo ratings yet

- Drill Bit Classifier 2007Document17 pagesDrill Bit Classifier 2007amin peyvandNo ratings yet

- Bit BallingDocument18 pagesBit BallingGPC100% (1)

- An Introduction To Drilling Dynamics: All Rights ReservedDocument34 pagesAn Introduction To Drilling Dynamics: All Rights ReservedFarouq EngNo ratings yet

- Expandable Drill BitDocument6 pagesExpandable Drill BitJohnSmithNo ratings yet

- Sharoshechnye DolotaDocument79 pagesSharoshechnye DolotaperstasNo ratings yet

- Cutting Efficiency With PDC BitDocument6 pagesCutting Efficiency With PDC BitDanny RevillaNo ratings yet

- 8 5-Mme65rDocument1 page8 5-Mme65rWHWENNo ratings yet

- 094 XS616Document1 page094 XS616AhmedNo ratings yet

- Wellbore Skematic DrawingsDocument74 pagesWellbore Skematic DrawingsMino MinoNo ratings yet

- Fixed Cutter - IADC Dull GradingDocument2 pagesFixed Cutter - IADC Dull GradingCésar González CruzNo ratings yet

- PDC CatalogDocument32 pagesPDC Catalogruzzo2003No ratings yet

- Hydro-Mechanical Anderreamer Tech SummaryDocument2 pagesHydro-Mechanical Anderreamer Tech SummaryYaqoob Ibrahim100% (1)

- 16 SB115CDocument1 page16 SB115CAdnane BensmaineNo ratings yet

- PDC Dull GradingDocument52 pagesPDC Dull GradingimampranadipaNo ratings yet

- Formation Pressure For Well DesignDocument20 pagesFormation Pressure For Well DesignadeniyiNo ratings yet

- 10 - UiTM Presentation Bit BHA Drilling Technology RevCDocument10 pages10 - UiTM Presentation Bit BHA Drilling Technology RevCNaufal Syafiq Mohd IsaNo ratings yet

- Banda East Well Montage 28sept08 A4 SizeDocument1 pageBanda East Well Montage 28sept08 A4 SizeSyed IrtazaNo ratings yet

- Engineering Data SectionDocument29 pagesEngineering Data SectionLazharNo ratings yet

- Drillbits-Slb 04Document89 pagesDrillbits-Slb 04DockodeLibra0% (2)

- Performance Drill BitDocument24 pagesPerformance Drill BitemilianoNo ratings yet

- Reference Photo:: 6 In. (152.4mm) ATJ-4Document1 pageReference Photo:: 6 In. (152.4mm) ATJ-411tkt11No ratings yet

- Oil Shale Petrophysical Formation EvaluationDocument21 pagesOil Shale Petrophysical Formation EvaluationAmine BoucedraNo ratings yet

- 084 HCR506ZX Tech SheetDocument1 page084 HCR506ZX Tech SheetpendexxNo ratings yet

- RRC Guideline for Permitting Saltwater Disposal Wells in Seismically Active Areas of the Permian BasinDocument16 pagesRRC Guideline for Permitting Saltwater Disposal Wells in Seismically Active Areas of the Permian Basinluis blandonNo ratings yet

- SPE-148904-MS Open Hole SidetrackDocument8 pagesSPE-148904-MS Open Hole SidetrackKd FaNo ratings yet

- RST DD Classroom TrainingDocument35 pagesRST DD Classroom TrainingUmair AslamNo ratings yet

- 3 Way Ball Valve Technical DatasheetDocument2 pages3 Way Ball Valve Technical Datasheetshahkunal11No ratings yet

- QTN 2336Document2 pagesQTN 2336shahkunal11No ratings yet

- AutoTrak Operations Manual - Section 5 - Troubleshooting AutoTrak 3.0Document33 pagesAutoTrak Operations Manual - Section 5 - Troubleshooting AutoTrak 3.0pendexx0% (1)

- AutoTrak Service LevelsDocument2 pagesAutoTrak Service LevelspendexxNo ratings yet

- NOV ShockForce - Technical AssessmentDocument1 pageNOV ShockForce - Technical AssessmentpendexxNo ratings yet

- 6 Griffith Double Acting Hydraulic Mechanical Drilling Jar Series 431 428 440 441 480 411 437 Operating ManualDocument19 pages6 Griffith Double Acting Hydraulic Mechanical Drilling Jar Series 431 428 440 441 480 411 437 Operating ManualAnonymous F2tu2TrzVtNo ratings yet

- Supplemental Technical InformationDocument5 pagesSupplemental Technical InformationpendexxNo ratings yet

- 17.500 Tffi716s-A4 PDFDocument1 page17.500 Tffi716s-A4 PDFpendexxNo ratings yet

- Rubicon - Nighthawk - Logan Sup-R-Jar Operation Service ManualDocument72 pagesRubicon - Nighthawk - Logan Sup-R-Jar Operation Service ManualpendexxNo ratings yet

- Auto TrakDocument16 pagesAuto TrakpendexxNo ratings yet

- AutoTrak G3 PDFDocument4 pagesAutoTrak G3 PDFpendexxNo ratings yet

- NOV ShockForce - Technical Assessment PDFDocument1 pageNOV ShockForce - Technical Assessment PDFpendexxNo ratings yet

- NOV - Powerstroke Drilling JarDocument2 pagesNOV - Powerstroke Drilling JarpendexxNo ratings yet

- NOV PowerStroke - Technical AssessmentDocument1 pageNOV PowerStroke - Technical AssessmentpendexxNo ratings yet

- NOV - Drilling Jars - General SpecsDocument8 pagesNOV - Drilling Jars - General Specspendexx100% (3)

- 8.500 Dd5560-A2Document1 page8.500 Dd5560-A2pendexxNo ratings yet

- 8.500 Dd5560m-A3Document1 page8.500 Dd5560m-A3pendexxNo ratings yet

- Product Report: Design SpecificationsDocument1 pageProduct Report: Design SpecificationspendexxNo ratings yet

- 8.500 DSF713M-B32Document1 page8.500 DSF713M-B32pendexxNo ratings yet

- D391000177-MKT-001 Rev 06 WISE Catalog PDFDocument28 pagesD391000177-MKT-001 Rev 06 WISE Catalog PDFpendexxNo ratings yet

- VAR-3199 IMax Brochure v5.0-SmDocument8 pagesVAR-3199 IMax Brochure v5.0-SmdiegoilNo ratings yet

- 11 BT 0109 Kaldera BR PDFDocument4 pages11 BT 0109 Kaldera BR PDFpendexxNo ratings yet

- VAR 3486 - PDC UpdatedMay2014 v1.0 SM PDFDocument32 pagesVAR 3486 - PDC UpdatedMay2014 v1.0 SM PDFpendexxNo ratings yet

- Axeblade Unit Petroleum CsDocument2 pagesAxeblade Unit Petroleum CsdiegoilNo ratings yet

- IPM Tapa de InformeDocument1 pageIPM Tapa de InformependexxNo ratings yet

- 17.5 Ebxt12dslc 728812Document1 page17.5 Ebxt12dslc 728812pendexxNo ratings yet

- 086 Datasheet16531Document1 page086 Datasheet16531pendexxNo ratings yet

- Schlumberger HistoryDocument4 pagesSchlumberger HistorypendexxNo ratings yet

- 12.25 MM75D 767489Document1 page12.25 MM75D 767489pendexxNo ratings yet

- 6.5 FXG64D PDFDocument1 page6.5 FXG64D PDFpendexxNo ratings yet

- Budgetary ControlsDocument2 pagesBudgetary Controlssiva_lordNo ratings yet

- Bank NIFTY Components and WeightageDocument2 pagesBank NIFTY Components and WeightageUptrend0% (2)

- MBO, Management by Objectives, Pooja Godiyal, Assistant ProfessorDocument20 pagesMBO, Management by Objectives, Pooja Godiyal, Assistant ProfessorPooja GodiyalNo ratings yet

- Column Array Loudspeaker: Product HighlightsDocument2 pagesColumn Array Loudspeaker: Product HighlightsTricolor GameplayNo ratings yet

- Exp 8 - GPG - D12B - 74 PDFDocument4 pagesExp 8 - GPG - D12B - 74 PDFPRATIKSHA WADIBHASMENo ratings yet

- KPMG Inpection ReportDocument11 pagesKPMG Inpection ReportMacharia NgunjiriNo ratings yet

- Journal Entries & Ledgers ExplainedDocument14 pagesJournal Entries & Ledgers ExplainedColleen GuimbalNo ratings yet

- Artist Biography: Igor Stravinsky Was One of Music's Truly Epochal Innovators No Other Composer of TheDocument2 pagesArtist Biography: Igor Stravinsky Was One of Music's Truly Epochal Innovators No Other Composer of TheUy YuiNo ratings yet

- Ujian Madrasah Kelas VIDocument6 pagesUjian Madrasah Kelas VIrahniez faurizkaNo ratings yet

- Google Dorks For PentestingDocument11 pagesGoogle Dorks For PentestingClara Elizabeth Ochoa VicenteNo ratings yet

- Algorithms For Image Processing and Computer Vision: J.R. ParkerDocument8 pagesAlgorithms For Image Processing and Computer Vision: J.R. ParkerJiaqian NingNo ratings yet

- BIBLIO Eric SwyngedowDocument34 pagesBIBLIO Eric Swyngedowadriank1975291No ratings yet

- Top Malls in Chennai CityDocument8 pagesTop Malls in Chennai CityNavin ChandarNo ratings yet

- Rounded Scoodie Bobwilson123 PDFDocument3 pagesRounded Scoodie Bobwilson123 PDFStefania MoldoveanuNo ratings yet

- Bharhut Stupa Toraa Architectural SplenDocument65 pagesBharhut Stupa Toraa Architectural Splenအသွ်င္ ေကသရNo ratings yet

- Level 3 Repair PBA Parts LayoutDocument32 pagesLevel 3 Repair PBA Parts LayoutabivecueNo ratings yet

- Change Management in British AirwaysDocument18 pagesChange Management in British AirwaysFauzan Azhary WachidNo ratings yet

- Motor Master 20000 SeriesDocument56 pagesMotor Master 20000 SeriesArnulfo Lavares100% (1)

- Ancient Greek Divination by Birthmarks and MolesDocument8 pagesAncient Greek Divination by Birthmarks and MolessheaniNo ratings yet

- Acne Treatment Strategies and TherapiesDocument32 pagesAcne Treatment Strategies and TherapiesdokterasadNo ratings yet

- Prof Ram Charan Awards Brochure2020 PDFDocument5 pagesProf Ram Charan Awards Brochure2020 PDFSubindu HalderNo ratings yet

- 621F Ap4405ccgbDocument8 pages621F Ap4405ccgbAlwinNo ratings yet

- Onan Service Manual MDJA MDJB MDJC MDJE MDJF Marine Diesel Genset Engines 974-0750Document92 pagesOnan Service Manual MDJA MDJB MDJC MDJE MDJF Marine Diesel Genset Engines 974-0750GreenMountainGenerators80% (10)

- If V2 would/wouldn't V1Document2 pagesIf V2 would/wouldn't V1Honey ThinNo ratings yet

- MODULE+4+ +Continuous+Probability+Distributions+2022+Document41 pagesMODULE+4+ +Continuous+Probability+Distributions+2022+Hemis ResdNo ratings yet

- Survey Course OverviewDocument3 pagesSurvey Course OverviewAnil MarsaniNo ratings yet

- Cold Rolled Steel Sections - Specification: Kenya StandardDocument21 pagesCold Rolled Steel Sections - Specification: Kenya StandardPEng. Tech. Alvince KoreroNo ratings yet

- GlastonburyDocument4 pagesGlastonburyfatimazahrarahmani02No ratings yet

- PESO Online Explosives-Returns SystemDocument1 pagePESO Online Explosives-Returns Systemgirinandini0% (1)