Professional Documents

Culture Documents

Scan Pak Kirman

Scan Pak Kirman

Uploaded by

Iswahyudi Aprilyastono0 ratings0% found this document useful (0 votes)

3 views2 pagesScan Pak Kirman

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentScan Pak Kirman

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views2 pagesScan Pak Kirman

Scan Pak Kirman

Uploaded by

Iswahyudi AprilyastonoScan Pak Kirman

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

Chapter 11

4.2 Approvel tests for multi-run technique

4.2.1 Where approval for use with the multi-run

technique is requested, deposited metal and butt weld

tests are to be carried out.

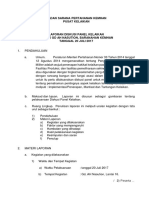

4.3 Deposited metal test assemblies {multi-un

technique)

4.3.1 One deposited metal test assembly is to be

prepared as shown in Fig. 11.4.1, using any grade of

ship structural steel

Longitudinal

LV teoale toa

Bom

ates ca

aT

Chany rets

omm

Fig. 11.4.1 Deposited metal test assembly

4.3.2 The bevelling of the plate edges is to be carried

‘gut by machining or mechanized gas cutting. In the

latter case any remaining scale is to be removed from the

bevelled edges.

4.3.3 Welding is to be in the downhand position, and

the direction of deposition of each run is to alternate

from each end of the plate. After completion of each run,

the flux and welding slag is to be removed. Between

‘each run the assembly is to be left in still air until ic has,

cooled to less than 260°C, the temperature being taken

in the centre of the weld, on the surface of the seam. The

thickness of the layer is to be not less than the diameter

of the wire nor less than 4 mm,

4.3.4 The welding conditions (amperage, voltage

and rate of travel) are to be in accordance with the

Section 4

LLOYO'S REGISTER OF SHIPPING

recommendations of the manufacturer and are to

conform with normal geod welding practice for multi-

un welding,

4.3.5 The chemical analysis of the deposited weld

is to be supplied by the

‘manufacturer and is to inchide the content of all

ant aflaying elements.

4.3.6 Two longitudinal tensile and three impact

‘specimens are to be taken from each test assembly

‘shown in Fig. 11.4.1. Care is to be taken that the axes

of the tensile test specimens coincide with the centre of

the weld and the mid-thickness of the plates. The impact

test specimens are to be cut pecpandicular to the weld

with their axes 10 mm from the upper surface. The

notch is to be positioned in the centre of the weld and

Cut in the face of the test specimen perpendicular to the

surface of the plate.

4.3.7 The results of all tests are to comply with the

requirements of Table 11.4.1, as appropriate. Where

the upper level for tensile strength is exceeded, special

consideration will be given to the approval of the wire-

flux. combination, the other mechanical properties

shown by the test results and the chemical composition

of the weld metal being taken into consideration,

4.4 Butt wold test assemblies (multiun technique)

4.4.1 One butt weld test assembly is to be prepared

{a shown in Fig. 11.4.2.

4.4.2 The grade of steel used for the preparation of

the test assembly is to be as follows:

Grade 1 wire-flux combination A

Grade 2 wire-fiux combinations A, Bor D

Grade 3 wire-flux combinations A, B, Dor

Grades 1Y, 2Y and 3Y wire-flux

‘combinations AH, DH or EH

4.4.3 Whete higher tensile steel is used, the tensile

‘strength is to be not less than 490 Nimm*. The chemical

campasition, including the content of grain refining

elements, is to be reported.

4.4.4 The plate edges are to be prepared to form a

‘single V-joint, the included angle between the fusion

faces being 60° and the root face being 4 mm. The

bevelling of the plate edges is to be carried out by

machining or mechanized gas cutting. In the latter cose,

any remaining scale is to be removed from bevelled

edges.

4.4.5 Welding is to be cartied out in the downhand

position by the multi-run technique, and the welding

Conditions are to be the same as those adopted for the

deposited metal test assembly. The bask sealing run is

to be applied in the dawnhand position after cutting out

the root run to clean metal. After being welded, the test

assembly is not subjected ta any heat treatment.

4.4.6 _Itisrecommendad that the welded assembly be

subjected to a radiographic examination to ascertain if

there are any defects in the weld priar to the preparation

of test specimens.

4.4.7 The test specimens as shown in Figs. 11.3.3

and 11.4.2 are to be prepared from each test assembly.

Approval of Welding Consumables

5.8 Annual tests

5.5.1 Annual tests are to consist of at least the

following:

(a) Wires approved for semi-automatic or for both

Semi-automatic and automatic multi-run welding:

fone deposited metal test assembly prepared in

accordance with 5.2 using a wire of diameter within

the range intended for the welding of ship struc

tures.

(b) Wire approved for automatic multi-run welding:

fone deposited metal test assembly prepared in

accordance with 5.3 using a wire of diameter as

stated in (a).

{c) Wites approved for two-run automatic welding:

fone butt weld test assembly prepared in accor:

dance with 5.4 using pistes 20 to 25 mm in

thickness. The diameter of wire used is to be

reported.

5.5.2 The test specimens are to be prepared and

tested in accordance with the requirements of this

Section. except that only the following tests are

required:

(3) For deposited metal assemblies (semi-automatic

‘and automatic multi-unl: one tensile and three

impact tests.

(b) For butt weld assemblies (two-run sutomaticl: one

transverse tensile, two bend and three impact

tests. One longitudinal tensile test is also required

where the wire is approved solely for two-run

automatic welding.

SECTION 6

Bonsumables for use in clectro-slag and eleciro-aas

welding

6.1 General

6.1.1 The requirements for the approval of consum-

ables used for electro-slag ot clectro-gas_ welding

(including consumable nozzles, where applicable) are

generally as detailed in Section 4 for two-run

‘submerged-arc welding consumable:

6.1.2 For Grades 1¥, 2¥ and 3Y, approval of the

consumables may be restricted for use only with

‘specific types of higher tensile steel. Thisis in respect of

the content of grain refining elements, and if general

approval is required, a niobium treated steel is to be used

for the approval tests.

62

Butt weld tast assemblies

.2.1 Two butt weld test assemblies are to be

prepared, one with plates 20 to 25 mm in thickness and

the other with plates 36 to 40 mm in thickness, The

grade of normal strength steel used is to correspond

with the grading sought for the consumable. The grade

of higher tensile steel used should correspond similarly

and be in accordance with 6.1.2. ‘The chemical

composition of the plate, including the content of grain

refining elements, is to be reported.

The welding conditions and the edge prepar

tion adopted ara to be in accordance with the

recommendations of the manufacturer and are to be

reported.

13

Chapter 11

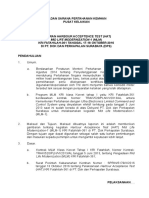

6.2.9. Test specimens as follows, and as shown in

Fig. 11.6.1, are to be prepared from each test assembly:

(a) Two longitudinal tensile test specimens,

{b) Two transverse tensile test specimens.

{c)_ Two bend test specimens.

{d) One macro-section.

{e) Four sets of three impact test specimens notched in

accordance with Fig. 11.6.2.

6.2.4 The results of all transverse ind impact

tests from positions (1), (2) and (3) are to comply with

the requirements given in Table 11.4.2 as appropriate.

‘The position of fracture of the transverse tensile test is

to be reported. The energy values for impact tests from

position (4) are to be reported for information,

that for Grades 1Y, 2¥ and 3Y the tensile strength

bbe not less than 490 N/mm

6.2.6 The bend test specimens are to be in accor-

dance with 4.6.7. Each surface of the weld is to be

tested in tension.

Longitudinal onste

Charoy tes

(ue Fig 1182)

\Loneituina tensile

Fig. 11.6.1 Butt wold tast assombly for slectro-slag or

electro-ges welding

5 Bi

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Proposal MaratuaDocument7 pagesProposal MaratuaIswahyudi AprilyastonoNo ratings yet

- BAB I Power PointDocument25 pagesBAB I Power PointIswahyudi AprilyastonoNo ratings yet

- METODOLOGI PENELITIAN Utk Mahasiswa PKS 1Document27 pagesMETODOLOGI PENELITIAN Utk Mahasiswa PKS 1Iswahyudi AprilyastonoNo ratings yet

- RPM 00342Document3 pagesRPM 00342Iswahyudi AprilyastonoNo ratings yet

- Paparan Alkom Medium Tank Tahap 8 Agustus 2017Document9 pagesPaparan Alkom Medium Tank Tahap 8 Agustus 2017Iswahyudi AprilyastonoNo ratings yet

- Laporan Diskusi PanelDocument3 pagesLaporan Diskusi PanelIswahyudi AprilyastonoNo ratings yet

- Lap Imaa Nau 7 16-20 CTH DNDocument8 pagesLap Imaa Nau 7 16-20 CTH DNIswahyudi AprilyastonoNo ratings yet

- Kontrol DanDocument29 pagesKontrol DanIswahyudi AprilyastonoNo ratings yet

- Fisiologi PenyelamanDocument36 pagesFisiologi PenyelamanIswahyudi AprilyastonoNo ratings yet

- Kronologi Pengujian KAL 28M PAPARANDocument8 pagesKronologi Pengujian KAL 28M PAPARANIswahyudi AprilyastonoNo ratings yet

- Notulen Sun Panduan Sertifikasi Konstruksi 26 Okt17Document2 pagesNotulen Sun Panduan Sertifikasi Konstruksi 26 Okt17Iswahyudi AprilyastonoNo ratings yet

- Protokol Test Tambahan NewDocument113 pagesProtokol Test Tambahan NewIswahyudi AprilyastonoNo ratings yet

- Hasil Pengecekan DokumenDocument7 pagesHasil Pengecekan DokumenIswahyudi AprilyastonoNo ratings yet

- Buku Panduan Uji Fungsi Hyperbaric ChamberDocument16 pagesBuku Panduan Uji Fungsi Hyperbaric ChamberIswahyudi AprilyastonoNo ratings yet

- Sindroma Tertelan Air Asin Dan Hipotermia - RS DR Suyoto - 23 Nov 2016Document35 pagesSindroma Tertelan Air Asin Dan Hipotermia - RS DR Suyoto - 23 Nov 2016Iswahyudi AprilyastonoNo ratings yet

- Uji Chamber HyperbaricDocument6 pagesUji Chamber HyperbaricIswahyudi AprilyastonoNo ratings yet

- 18 Binatang Laut BerbahayaDocument78 pages18 Binatang Laut BerbahayaIswahyudi AprilyastonoNo ratings yet

- Kedaruratan Penyelaman Dan P3K - RS DR SUYOTO - 23 NOV 2016Document23 pagesKedaruratan Penyelaman Dan P3K - RS DR SUYOTO - 23 NOV 2016Iswahyudi AprilyastonoNo ratings yet

- Nitrogen Narkose & Washout - DR - Adiriyono, SPKLDocument9 pagesNitrogen Narkose & Washout - DR - Adiriyono, SPKLIswahyudi AprilyastonoNo ratings yet

- Welding Defect Mei 2013Document49 pagesWelding Defect Mei 2013Iswahyudi Aprilyastono100% (1)

- Hat MLM 1 FTH 17 Oktober 2016 1Document13 pagesHat MLM 1 FTH 17 Oktober 2016 1Iswahyudi AprilyastonoNo ratings yet