Professional Documents

Culture Documents

MSDS 3877123

MSDS 3877123

Uploaded by

JiroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSDS 3877123

MSDS 3877123

Uploaded by

JiroCopyright:

Available Formats

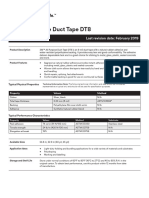

Double-Sided Tapes

9086 ∙ 9888T ∙ CT6348 ∙ 9088 ∙ 9088FL ∙ 55256

Product Information April 2010

Description 3MTM Double-Sided Tissue Tapes, 9086, 9888T and CT6348 consist of an acrylic adhesive

coated on both sides of a thin tissue carrier. 3M Double-Sided Film Tapes, 9088, 9088FL and

55256 consist of an acrylic adhesive coated on both sides of a thin polyester film. A release

liner is added to one side. The aggressive acrylic adhesive provides high initial adhesion to a

wide range of surfaces including wood, metal, paper and most plastics including

polyethylene and polypropylene.

Features • Excellent adhesion to most surfaces

• Flexible to conform to irregular surfaces

• Hand tearable

• High tack level offers high immediate adhesion

• Easily converted by die-cutting

• Dimensionally stable

Physical Properties/Typical Performance Characteristics*

Tape Double Sided Tissue Tapes Double Sided Film Tapes

9086 9888T CT6348 9088 9088FL 55256

Carrier Polyester Polyester Polyester

Tissue Tissue Tissue

0.012mm 0.012mm 0.012mm

Adhesive 375 Acrylic Acrylic 375 375 Acrylic

Acrylic Acrylic Acrylic

Liner White paper White paper White paper White paper Red Off-white

with black with red with red Polypropylene paper

3M Logo 3M Logo 3M Logo film

Liner

0.07mm 0.15mm 0.12mm 0.07mm 0.08mm 0.076mm

Thickness

Tape

Translucent Translucent White Clear Clear Clear

Colour

Tape

0.19mm 0.15mm 0.09mm 0.21mm 0.21mm 0.048mm

Thickness

Adhesion to steel 160 125 118 150 150 76

N/100mm N/100mm N/100mm N/100mm N/100mm N/100mm

Adhesion to 70** 86 67 70** 70** 45

Polypropylene N/100mm N/100mm N/100mm N/100mm N/100mm N/100mm

Temperature

Resistance

Min/Hours 1200C 1200C 1200C 1500C 1500C 2000C

Days Weeks 850C 800C 800C 930C 930C 800C

UV Resistance Excellent Good Good Excellent Excellent Good

Plasticiser

Good NR NR Good Good NR

resistance

Solvent

Very good Good Good Very Good Very Good Good

Resistance

*Not recommended for specification purposes; **Adhesion to polyethylene; NR Not Recommended

Adhesion Test Method: 1800 Peel Adhesion: 72 hours room temperature dwell, Peel speed 305mm/min

Format Available in 12mm, 18mm, 24mm, 36mm, 48mm and 300mm x 50m rolls

55256 is also available in 30m long rolls

Custom width rolls are available upon request

Application • Apply between 100 and 400C.

Technique • Ensure surfaces to be bonded are clean, dry and well unified.

• Firm application pressure helps develop better adhesive contact and improves bond

strength.

Application • Lamination of foams, fabrics and papers

ideas • Web splicing for paper and corrugated board

• Core starting

• Attaching lightweight signs, nameplates and plaques

• Production of promotional signage or sample boards

• Attaching plastic extrusions

Testing Always test the suitability of the product for your application before use.

Shelf life Store in a dry location out of direct sunlight and away from all sources of heat. Ideal

conditions are 200C and 50% relative humidity. Use within 2 years from date of

manufacture.

Health and This product is an “article” and does not require a Material Safety Data Sheet. However

Safety MSDSs have been produced for most articles and may be accessed by going to

Information www.3M.com/msds and entering the product number or 3M stock number. Alternatively,

contact 3M Customer Services.

Further Further information is available at www.3M.com or by contacting 3M Customer Services on

information free phone 0800 200 713 or free fax 0800 508 980.

Note The user is responsible for determining whether the 3M product, surface preparation, and method of

assembly are suitable for their particular purpose. Failure to determine the suitability of all factors involved

in the application may result in bond failure.

3M New Zealand Ltd

Industrial Adhesives &Tapes

PO Box 33-246 Takapuna 0740

Phone: 0800 474 787

Fax: 0800 508 980

Email: 3mnzib1@mmm.com

www.3M.com/industrial

You might also like

- Akamai Performance Matters Key Consumer Insights EbookDocument32 pagesAkamai Performance Matters Key Consumer Insights EbookAnand SeshadriNo ratings yet

- Dennis Chen Interview PresentationDocument16 pagesDennis Chen Interview PresentationDennis ChenNo ratings yet

- General Purpose Polyester/ Silicone Tape: 8952 8952L (Linered)Document2 pagesGeneral Purpose Polyester/ Silicone Tape: 8952 8952L (Linered)Hardware 02No ratings yet

- 3M 9731RWDocument4 pages3M 9731RWcbol91311No ratings yet

- 3M Preservation Sealing Tape 481Document6 pages3M Preservation Sealing Tape 481Mait YNo ratings yet

- Flame Retardant Label Materials 7203 and 7204Document2 pagesFlame Retardant Label Materials 7203 and 7204FAH MANNo ratings yet

- 3m Ecdst 9750 TdsDocument4 pages3m Ecdst 9750 TdsGhost_suolNo ratings yet

- 3M Optically Clear AdhesivesDocument5 pages3M Optically Clear AdhesivesPanagiotis ArgyropoulosNo ratings yet

- Cinta Teflon Cafe PTFE 5151Document2 pagesCinta Teflon Cafe PTFE 5151rodrigoNo ratings yet

- 3M 5386Document2 pages3M 5386monkey1929No ratings yet

- 3M 8979 TDSDocument2 pages3M 8979 TDSmaimonides76No ratings yet

- Shenzhen Xinst Technology Co.,LtdDocument11 pagesShenzhen Xinst Technology Co.,LtdNicacio LucenaNo ratings yet

- Adh Transfer Tapes Prod InfoDocument3 pagesAdh Transfer Tapes Prod InfohshchandraNo ratings yet

- ID-7385C TDS May 11Document2 pagesID-7385C TDS May 11febrin rohmanNo ratings yet

- 3M Acrylic Foam Tape GT7108: Technical Data SheetDocument3 pages3M Acrylic Foam Tape GT7108: Technical Data SheetRajiv SharmaNo ratings yet

- 3M Duct Tape 8979Document2 pages3M Duct Tape 8979Jun Xian WaiNo ratings yet

- 3M™ Scotch® Transparent Film Tape 600: September, 2009Document5 pages3M™ Scotch® Transparent Film Tape 600: September, 2009San ApolonioNo ratings yet

- General Purpose Vinyl Tape: Technical Data April, 2014Document2 pagesGeneral Purpose Vinyl Tape: Technical Data April, 2014ismail mijasNo ratings yet

- 3M Glass Cloth Tape 361Document5 pages3M Glass Cloth Tape 361edwardNo ratings yet

- Cinta 365 ElectricaDocument2 pagesCinta 365 ElectricamiguelNo ratings yet

- Adhesive Trim Tape: High-Strength Double-Sided Adhesive Tape With Polyethylene Carrier and Acrylate AdhesiveDocument1 pageAdhesive Trim Tape: High-Strength Double-Sided Adhesive Tape With Polyethylene Carrier and Acrylate AdhesiveAnas EidNo ratings yet

- HBR XL - Crosslink Closed Cell PDSDocument2 pagesHBR XL - Crosslink Closed Cell PDSHuy ThaiNo ratings yet

- Double Coated Splicing Tapes: Technical Data March, 2008Document3 pagesDouble Coated Splicing Tapes: Technical Data March, 2008douglas lopezNo ratings yet

- Scotch: Filament TapeDocument2 pagesScotch: Filament TapeGuillermo CorreaNo ratings yet

- 3M Scotch Transparent Film Tape 600 2Document6 pages3M Scotch Transparent Film Tape 600 2Deepak LoganathanNo ratings yet

- 3M Medical Materials & Technologies: Included On Coa For OrdersDocument2 pages3M Medical Materials & Technologies: Included On Coa For OrdersVivian MirandaNo ratings yet

- 3M FT-DT8DuctTapeDocument2 pages3M FT-DT8DuctTapeElviera MphieNo ratings yet

- 3m TapeDocument3 pages3m Tapeali ergünNo ratings yet

- Plating Masking TapDocument2 pagesPlating Masking TapkkphadnisNo ratings yet

- 481 Preservation Sealing TapeDocument2 pages481 Preservation Sealing TapeSixmonNo ratings yet

- 3M Filament Tape 897Document2 pages3M Filament Tape 897German CalvoNo ratings yet

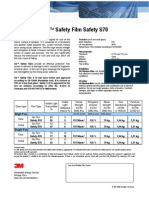

- Safety S70 Sample Card 082011Document2 pagesSafety S70 Sample Card 082011Sharon SunasseeNo ratings yet

- Ficha 218Document2 pagesFicha 218Victor Javier Reyes NavarroNo ratings yet

- Adhesive Film & TapeDocument6 pagesAdhesive Film & TapeJothi Vel MuruganNo ratings yet

- Electroplating/Anodizing Tape: Technical Data December, 2006Document2 pagesElectroplating/Anodizing Tape: Technical Data December, 2006sanjay ukalkarNo ratings yet

- Spec 3m 375Document2 pagesSpec 3m 375Thích Rong ChơiNo ratings yet

- 3M™ Scotch-Seal™ Mastic Tape and Pads 2229: Data Sheet May 2013Document2 pages3M™ Scotch-Seal™ Mastic Tape and Pads 2229: Data Sheet May 2013peloquin1349391No ratings yet

- VHB Acrylic Foam Tape: Technical Data March, 2001Document2 pagesVHB Acrylic Foam Tape: Technical Data March, 2001daskhagoNo ratings yet

- 2K005E Tech Data (June.2011)Document2 pages2K005E Tech Data (June.2011)Giang TúNo ratings yet

- ACFInterconnect 6000575Document4 pagesACFInterconnect 6000575mazacotesNo ratings yet

- Glass Cloth Tape: Technical DataDocument2 pagesGlass Cloth Tape: Technical DataАндрей МошкинNo ratings yet

- 2K010 Tech Data (June.2011)Document2 pages2K010 Tech Data (June.2011)Giang TúNo ratings yet

- 3M™ Acrylic Foam Tape 4222: Technical Data SheetDocument2 pages3M™ Acrylic Foam Tape 4222: Technical Data SheetDejChonlateeNo ratings yet

- Specificatie Tehnica BOPPDocument2 pagesSpecificatie Tehnica BOPPkrys780% (1)

- 10-D1-VHightech (Very High Density Foam)Document1 page10-D1-VHightech (Very High Density Foam)GPNo ratings yet

- 766 Safety TapeDocument2 pages766 Safety TapeAch Dja'far SNo ratings yet

- MSDS For 3M Auto Glass UrethaneDocument6 pagesMSDS For 3M Auto Glass UrethanejsdoodnathNo ratings yet

- Technical Data: AT159 Polycoated Matt Cloth TapeDocument1 pageTechnical Data: AT159 Polycoated Matt Cloth TapeAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- 3M Aft 5665Document2 pages3M Aft 5665febrin rohmanNo ratings yet

- 3M Thinsulate TAI2047Document2 pages3M Thinsulate TAI2047Nic CheongNo ratings yet

- 3M General Purpose Vinyl Tape 764Document5 pages3M General Purpose Vinyl Tape 764SergioNo ratings yet

- 850 - Clear & Colored - TDS 2013Document2 pages850 - Clear & Colored - TDS 2013KarinaNo ratings yet

- Signet's 3M Masking Tape Selection GuideDocument1 pageSignet's 3M Masking Tape Selection GuideSignet AustraliaNo ratings yet

- 3M Adhesive 08115Document4 pages3M Adhesive 08115Syavash EnshaNo ratings yet

- Mono Filament TapeDocument1 pageMono Filament Tapetesting eiplNo ratings yet

- Tape 27 para Alta TemperaturaDocument3 pagesTape 27 para Alta TemperaturaralvaradoarayaNo ratings yet

- 3M Double Coated Extended Liner Tape 476XLDocument3 pages3M Double Coated Extended Liner Tape 476XLcafiwek448No ratings yet

- Bopp TapeDocument1 pageBopp TapebouzirpafNo ratings yet

- Gasket Jointing FullDocument48 pagesGasket Jointing FullManishBoyNo ratings yet

- 3m Safety Tape 5072Document2 pages3m Safety Tape 5072Erikas KulpinasNo ratings yet

- Massa AcrilicaDocument1 pageMassa AcrilicaAndre MoutelaNo ratings yet

- DMA C I: Esigned Xperiment LANDocument4 pagesDMA C I: Esigned Xperiment LANDennis ChenNo ratings yet

- Residuals CheckDocument1 pageResiduals CheckDennis ChenNo ratings yet

- Title: Engineer - Product Improvement Location: Santa Barbara, CADocument2 pagesTitle: Engineer - Product Improvement Location: Santa Barbara, CADennis ChenNo ratings yet

- Analysis of Variance (Anova) Aliasing Confounding Alpha RiskDocument8 pagesAnalysis of Variance (Anova) Aliasing Confounding Alpha RiskDennis ChenNo ratings yet

- From: Ziyan (Dennis) Chen To: Work-Out Anytime Eastlake Marietta CC: Ziyan (Dennis) Chen Date: 30-August-2018Document1 pageFrom: Ziyan (Dennis) Chen To: Work-Out Anytime Eastlake Marietta CC: Ziyan (Dennis) Chen Date: 30-August-2018Dennis ChenNo ratings yet

- Audience: Engineering Portrait of Portfolio - Statement of Purpose, Intent and StrategyDocument1 pageAudience: Engineering Portrait of Portfolio - Statement of Purpose, Intent and StrategyDennis ChenNo ratings yet

- Tab Bump Inspection Fixture Note PageDocument3 pagesTab Bump Inspection Fixture Note PageDennis ChenNo ratings yet

- Ziyan Chen (Dennis) Resume 11-15-2017Document3 pagesZiyan Chen (Dennis) Resume 11-15-2017Dennis ChenNo ratings yet

- Laff NlaDocument470 pagesLaff NlaDennis ChenNo ratings yet

- Matrix Notation PDFDocument31 pagesMatrix Notation PDFDennis ChenNo ratings yet

- Effective Use of @riskDocument95 pagesEffective Use of @riskDennis ChenNo ratings yet

- Bottom PlateDocument1 pageBottom PlateDennis ChenNo ratings yet

- Utility 3000R Reefer BrochureDocument12 pagesUtility 3000R Reefer BrochureAmaro RazielNo ratings yet

- Engg. Management MCQs Part 2Document4 pagesEngg. Management MCQs Part 2Axl MontecalvoNo ratings yet

- Operating Airline Disclosure - DEI2!9!127Document9 pagesOperating Airline Disclosure - DEI2!9!127Jose PulidoNo ratings yet

- BEC2012 - Modeling Instructions For Designing Prefabricated Elements - V103Document45 pagesBEC2012 - Modeling Instructions For Designing Prefabricated Elements - V103Erika PamelaNo ratings yet

- JamkashDocument69 pagesJamkashSahil Amla100% (2)

- Pk55xx Rfk55xx 29007799r001 Install Man FR Du It enDocument32 pagesPk55xx Rfk55xx 29007799r001 Install Man FR Du It enGary DonaldsonNo ratings yet

- Teldene®: Technical Data SheetDocument2 pagesTeldene®: Technical Data SheetRoberto LujánNo ratings yet

- June 2011 IssueDocument60 pagesJune 2011 IssueTreatment Plant Operator MagazineNo ratings yet

- Profile: Contact InformationDocument3 pagesProfile: Contact InformationMahesh KhabraniNo ratings yet

- Bsai™ & Bsaig™Document4 pagesBsai™ & Bsaig™kztro066No ratings yet

- Id Film-Capacitor eDocument86 pagesId Film-Capacitor ealltheloveintheworldNo ratings yet

- H. S. Bawa - Manufacturing Processes-1Document296 pagesH. S. Bawa - Manufacturing Processes-1Mechpec MechNo ratings yet

- 1.25, Dual SPST, CMOS Analog Switches: General Description FeaturesDocument12 pages1.25, Dual SPST, CMOS Analog Switches: General Description FeaturesStefan GlaserNo ratings yet

- Blockchain Startups: Watch Out ForDocument44 pagesBlockchain Startups: Watch Out ForPriya AnandNo ratings yet

- 45 Samss 009Document6 pages45 Samss 009naruto256No ratings yet

- Screwdriver Bit SectionDocument30 pagesScrewdriver Bit SectionnamkvalNo ratings yet

- Advanced Men Material Transportation System in Underground Coal MinesDocument18 pagesAdvanced Men Material Transportation System in Underground Coal MinespuzNo ratings yet

- O&M Guidelines Pipeline & Compressor Revision 3Document59 pagesO&M Guidelines Pipeline & Compressor Revision 3Vinod M100% (1)

- Aircraft Transparency Testing - Airtificial BirdsDocument18 pagesAircraft Transparency Testing - Airtificial BirdsAnonymous gM6RZL5lYdNo ratings yet

- Part 3-Chap 2 - Classification of Buildings Based On OccupanciesDocument60 pagesPart 3-Chap 2 - Classification of Buildings Based On Occupanciesfaruque65No ratings yet

- TE Dorman Smith Product Portofolio 2011Document182 pagesTE Dorman Smith Product Portofolio 2011Ashby KbNo ratings yet

- Fluid Mechanics LaboratoryDocument3 pagesFluid Mechanics LaboratoryWira LiantoNo ratings yet

- CPA Master Programme Revised (Updated) PDFDocument5 pagesCPA Master Programme Revised (Updated) PDFAvan FanNo ratings yet

- BB Discovery Report-UpdatedDocument186 pagesBB Discovery Report-UpdatedParvez AlamNo ratings yet

- Cornado 2258eDocument22 pagesCornado 2258eJostin Castillo HurtadoNo ratings yet

- Toyo CatalogDocument196 pagesToyo CatalogAnand SinghNo ratings yet

- Additional Information HEREDocument4 pagesAdditional Information HEREShabir TrambooNo ratings yet

- Ti3776 - DDC Series BroDocument2 pagesTi3776 - DDC Series Broapi-36492444No ratings yet

- 2013-Q4 Ascend V1ewpoint (Issue 41)Document16 pages2013-Q4 Ascend V1ewpoint (Issue 41)awang90No ratings yet