Professional Documents

Culture Documents

Formulas Y Calculos WC

Formulas Y Calculos WC

Uploaded by

FGC0 ratings0% found this document useful (0 votes)

11 views5 pagesDetalle Formulas requeridas para los trabajos en los equipos de perforacion y workover

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDetalle Formulas requeridas para los trabajos en los equipos de perforacion y workover

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views5 pagesFormulas Y Calculos WC

Formulas Y Calculos WC

Uploaded by

FGCDetalle Formulas requeridas para los trabajos en los equipos de perforacion y workover

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

& FORMULAS & CALCULATIONS

ForMuLas & CALCULATIONS

FORMULAS AND CALCULATIONS

Pire/HoLe Caractry (BBLS/Pt)

Capacitypisift = *Diameterige + 1029.4

Diameter across the open hole of inner diameter of pipe

Pire/HOLe VoLUME (Has)

Volumeps = Hole Capacitypyisn x Lengt

ANNULAR CaPacrry (BB1S/FT)

Annular Capacity yi =

[ "(Hole Dia.jn:)~ **(Pipe Dia. jg) ] + 1029.4

‘Diameter aeross the open hole or inner diameter of easing.

**Any OD of tubular (Grllpipe, tubing, coiled tubing) in Well

ANNULAR VOLUME (BBLS)

Annular Volumes = Annular Capacity, py

* Lengthg

ANNULAR CAPACITY (BBLS/FT) WITH DUAL STRINGS

Annular Capacity =

[+Hote Diag: - (**Pipe} Dia. + **Pipey Diane)

= 1029.4

*Diameter across the open hole or inner diameter of casing.

‘** Any OD of tubular (drillpipe, tubing, coiled tubing) in well,

ANNULAR VOLUME (BBLS) OF DUAL STRINGS

Annular Volumeppy, = Annular Capacity pi * Length,

Tank Caracrry (Bats/rt)

Rectangular tanks

A. Volumeppyift= (Lengthy « Widtha) * 5.61

B. Tank Volume), = Tank Capacity, * Heights

‘Note: For bbl/inch, take bbV/ft capacity and divide by 12.

Vertical cylindrical tanks

‘A. Tank Capacitypjg/q = Tank Diameterjn) + 1029.4

B. Tank Volumepjyg = Tank Capacity jf * Height

Note: For bbVinch, take bbUt capacity and divide by 12.

To Conver VOLUME (BBLS) INTO LENGTH (F1)

Length = Volumeyy, * Section Capacityy pit

FLUID GRADIENT (rSW/FT)

Fluid Gradientysigj= Fluid Weighty * 0.052

Hyprostatic PRESSURE (PS!)

Hydrostatic Pressureng = True Vertical Depth

Fluid Weightppy* 0.052

> FORMATION PRESSURE (PS!)

Formation Pressures; = SIDPP pj

+ Hydrostatic Pressurepg to Formation

‘When oo SIDPP is vale:

Fam Presi = SICPpg (Kick Lengthy» Kick Desiipyg

0052) +t Lena x Mu Densiypy x82)

Kini, Moo Wercitr (ri

ill Mud Weightpyg = (SIDPPpg; =.052

Depth, rv)

+ Present Mud Weightppy

INITIAL CIRCULATING PRESSURE (ICP)

[CP = SIDPPp + Kill Rate Pump Pressures;

FINAL CIRCULATING PRESSURE (FCP)

FCP) «j= Kill Rate Pump Pressure; «

(Kill Mud Weightyyy + Present Mud Weighty)

Estimate SHUT-IN DRILLPIPE (OR TUBING) PRESSURE

SIDPPpgj = Form. Press.pj~ (TVD x Mud Wing x 0.052)

Estimarep Kick DENSITY (PPG)

SICPpgj ~ SIDPP psi

(Kick Length,» 0.052

Estimate INTEGRITY/FRACTURE MUD DENSITY (PPG)

Est. Int/Frac. Mud Densityyg = (Test Pressurepg; + 0.052

= Depth Testedg, ryp) + Test Mud Weighty

EstiMATED INTEGRITY/FRACTURE PRESSURE (PS!)

Est. Int/Frac, Pressure = (Est. Int/Frac. Mud Density

~ Pres. Mud Wtpp) x Depth Tested, yyy » 0.052

EsTiMarinG Maximum Prt Gain FROM 4 Gas KICK

Klick Den.ppg = Present Mud Wtpp ~

*Maximum Gainpjjs =

he Form. Press pj *Kick sizepyy.* Amn. Cappy

Kill Mud Weightpng

*Maximum casing pressure assumes proper use of wait & weight method.

ESTIMATING MAX, CASING PRESSURE FROM A Gas KICK

*Maximum Casing Press.ppjs = 200 x

ee

(Form. Press pg * 1000) Kick Size), *Kill Mud Wi ppg

‘Ann. Cap. per 1000"

a

‘Maximum casing pressure assumes proper use of wait & weight method,

32 504-464-4144

WELL ContRoL SCHOOL, 33

|

}

i

|

i

j

RMULAS & CALCULATIONS &

THEORETICAL DisTANCE AND RATE OF GAS MIGRATION

‘A, Migrationg = Press, Increasep,; > Mud Weightpp *.052

B. Migration Ratejymin = Migrationg + Migration Time, in

GevERaL Gas Law

PV; PpxVp

Tye ae

Simplified, ignoring effects of emp., T and compressibility :

Pressure, x Volume, = Pressure, x Volume,

or

‘Volume, = Pressurey x Volume,

Pressure

‘TRIPLEX PUMP OurPUT (SINGLE ACTING)

Pump Outputppie/stk = ID Liner? x Length Pump

Strokejn * 0.000243 « Pump Efficiency ¢¢

Durex Pum Ovrrur (DouBLe ACTING)

Pump Outputppjgistk = ID Liner? + ID Liner?

= OD Rod? x Length Pump Strokejn * 0.000162

x Pump Efficiencyoger

STROKES To Spor, PuMP on Disptace a VoLuME.

Strokes = Volumepjts * Pump Outputs

‘TIME TO Spot, PumP OR DispLace 4 VOLUME

Timepin ~ Volumeppis * Pump Outputypys/stk

+ Pump Ratestks/min

PUMP PRESSURE CORRECTION For DiFreReNT DENSITY

New Pump Press.ngj = Original Pump Press.pgj *

(Mud Weight #2yp * Mud Weight #lppp)

[Pum Pressure CORRECTION FOR DIFFERENT Pum Rate

New Pump Pressureng = (Rate #2ss/min

~ Rate #1 yks/min)” Pump Pressure # yg,

Pump Rate 1N GALLONS PER STROKE (GAL/STK)

Pump Rategatistk = Pump Outputpbisistk 42

Pump Rare tN GALLONS PER MINUTE (GPM)

Pump Rategpm = (Pump Speedtks/min

Pump Outputppjs/sti) * 42

rc

© SrrapPiNe We1cutr ESTIMATION (LBs)

‘Stripping Weighty, =

| (©7854 Pipe Dia.jg: x Shutin Pressure.) + *Frictionypg

| *2000 fb is general, minimum friction force to overcome to stip pipe

| sSough annular preventer; this varies with preventes and pipe sizes.

‘Trip MARGIN (PPG)

Trip Marginyye = Annular Presure Losspsi

+ Well Depth * 0.052

VoLuME oF SLUG (B81)

Slug Volpj, = Mud Wtppg x Dry Pipe Length x Pipe cap pp

Slug Weighty, ~ Present Mud Weightyp

SLUG WeiGutr (PPG)

Slug Wippg = Present Fluid Weightypy +

resent Mud Wtpyg * Dry pipe lath x Pipe Cappy

U Slug Volumepiis

BARRELS TO FILL WHEN PULLING PIPE.

Bbls to fill = Pipe Displacement) * Length Pulled

Or

Bbls = Adjusted Pipe Weightypy* 2748 x Lengthy,

| STROKES TO FILL WHEN PULLING PIPE

Stks = Bbls to Fill + Pump Outputypis/tk

*Max Lencra (F1) Putten Prior 10 Fint-vP

Dry Pipe: Max. Length =

(Pressure Drops; * Mud Weighty, + 0.052)

*(Csg. Cap ppisit— Pipe Displ ppisift) * Pipe Disp pbisift

‘Wet Pipe: Max. Length =

(Pressure Dropps; + Mud Weighty» * 0.052)

*(Csg. Cap.ppist— Pipe Displ ppisit — Pipe Cap.ppis/A)

+ Pipe Displypisit + Pipe Cap-poisin)

*75 psi, or 5 stands of drillppe/tubing, is max. allowed by MMS.

PLastic Viscostry (PV cPs)

PVcps = Fann 600 Reading ~ Fann 300 Reading

‘Yiewp Por (YP LBs/100 Fr?)

YPips/00ft’ = Fann 300 Reading — PV

34

504-464-4144

Wet ControL ScHOoL, 35

ee

& FORMULAS & CALCULATIONS

APPARENT VISCOSITY

= Fann 600 Reading 2

Barre REQUIREMENTS

*Baritegy =

{Kill Mud Wippg~ Present Mud Wtpyyg) * 1470 * Pit Volpi

(35 Kill Mud Wo) « 100

* Note: 100 Ib, sacks of barite

VotuMe INCREASE DUE To Bante ADDITION

Volume Increaseppjs = *Total Barite Required, + 14.7

“*Note: 100 Tb, sacks of bate

AVERAGE WeIGutr (PPG) W:

A. Total Volumeppjs =

IN MIXING TWo DENSITIES

Volume Iiypis + Volume 2p

B, Average Weightpog =

[0001 Ippis * Mud WE lpg) + (Vol 2pp}s * Mud Wt 2pp,)]

Total Volumeppis

‘Teme, Erect: CALCIUM/SODIUM CHLORIDE SOLUTIONS

As solution temperature increases, the volume increases with a

resultant decrease in density

Density Changepp, = 0.003 * (Ty ~T2)

(1) = existing temperature °F, Ty = desired temperature °F)

ANNULAR VELOCITY (Ft/MMIN)

Annular Velocity y/mmin = 24.51 * GPM + (Dh? — dp?)

"Dh is hole diameter; dp is pipe diameter.

Est, EQUIVALENT CincuLATING Density (ECD)

For mud weights 13 ppg and les:

= Yield Poi

ECDpps = Mod Wipe + | Sem Poins |

For Mud Weights greater than 13 ppg:

ECDppg = Mud Wlopg +

(Oe A AVY.

| ow ( 300* (Dh w)

ECD USING ANNULAR PRESSURE Loss

ECDppg = (Ann. Press. Loss * 052 + TVDq) + Mud Whippy

GPM For Optimization: ROLLER Cone BITS

Bitsizeiy < *Rangegomm/in

*Generally 30-50 gpuvin of bit siz,

36

504-464-4144

~ GALLONS PER MINUTE FOR PDC BITS.

Méximum Flowrategym = 12.72 * Bit Diameterin * 147

Crrmicat. Vetocrry (Fr/sny)

Critical Velocity in = 60 *

(08 * PV + 1.08 V PV2 +926 (Dh — dp)? x YP x Mud Wt

it ‘Mud Wt x (Dh = dp)

GPM To Osraty Crrricat VeLocrry

GPM = Critical Velocity « (Dh? — dp?)

24.51

Pressure Drop Across Bir

| Formula for sizes of nozzles in 32nds:

| Pressure Drop; = 156.482 * GPM? x Mud Wt

(ety? + Jety? + Jets?)

Nozze Sizes (arts wrt 2+ NozzLes)

Nowe Sie = 3.536. [GPM (eo

No.of eis V Press: Drop across Bit

Ssxerpretation of answers:

Banswer is 11.2-11.5, use (2)-11/32 and (1)-12/32; 11.5-11.8,

sss (1)-11/32 and (2)-12.32; 11.8-12.2, use (3)-12.32,

Hypravtic Horserower at Brt (HHP)

SEP at Bit = (GPM x Pressure Drop Across ity) + 1714

‘TorAt, HypRavtic HorsrroweR (HHP)

HHP = (GPM x Total Pump Pressurepi) + 1714

HHP/Square INcH oF Brr DIAMETER

= HEP at Bit

(0.7854 * Bit Diameterig?

% HHP ar Bir

(HHP at Bit « 100) * Total HHP

Pressure Drop Across Bit x 100

Total Pump Pressure

Nozze (Jet) Vetocrry (Fr/sec)

Nozzle Velocity y/geg = __418.3 « GPM

Formula using HHP:

Formula using pressure

Jety? + Jety? + Jets?

Inract Force (Ls)

Impect Force = GPM » Mud Wiyyg % Nozze Velocitypjee

1932

~ Wett ConTrot ScHooL 37

& COILED TuBING FRE® POINT OILED FuBinG STRETCH TABLE &

Size (Inch [cross Sectional] Free Point

FREE Point CALCULATION eee peer reas

e OD x Wall Thickness | Area (Sq ta) | Constant

From Hook’s law, if tubing is under a tension

force F, then the elastic elongation is given by 4.250x0.087 0304 7000

AL=FL 0,095 0328 8200

Eoa @ x0102 0351 8775

where AL = tubing stretch (in); F = axial force

on tubing (Ibs); L = free length of tubing (f); xo om, an

‘Ag,= nominal cross sectional area of tube x0.125 0.420 10500

Ge tl Weeat ae of elasticity x0.134 04st 11275

To determine the free point, pull he pipe into O06: oz ae:

x0.095 0399 975 j

xo.102 0.428 10700 j

x0.109 0.456 11400

x0.125 0512 12800 |

x0194 0552 19800 {

x0156 0.629 15725 |

table for the |

the fol 1.750x0.100 0538 19450

*x0125 0.605 15125 |

x0134 0.652 16300

x0.156 074s 10625

xOA75 ast 20775

2.000.109 0619 15475

Example: Determine the minimum length of 0.125 0698 17450 fi

free coiled tubing being stretched when a

10,000 foot string of 1.25” OD, 0.087” wall x0134 0753 18825 \

tubing stretches 39 inches with an applied pull x0A156 61 21525

of 5,000 pounds over tubing weight. {

: x0175 0.962 24050

L=ALC faa A

ae 2375x0125 0837 20905

D

x0194 0.904 22600

= 39 x 760

ae x0.156 1.035 28875

5,928 feet x0.175 1188 28065

é x0.190 1241 31005

24 504-464-4144 Wett ConTrot SCHOOL 25

eel

aL

vely-p9r-vOS

OOH TOYLNOD TSM

6L

Connection Data Tube Data f=

Thee = = ) cy a a a

so oe | on on | tw oe | wi wim | ox | on [onram a

cursos | igor | 1208 105 | 1800 | 1278 | 1104] arst | ost | tagoon | resco | agan | sie00} siono | arsoo | ose | sez | conto | oooio

te N0L-80 2162 .

“fornia | 2162

esis | 22

Noweacat | 230

“onemen | 306

Mommie | 288

aos | 25

140 Pato | 1900 | 1810 } 1406 | 0200 | 1058 |-ttom0 | 000 } szae0 | rx7500] zao00 | 2700 | s18 | 587 | ome | ooo

140 436 | 1900 | 1510 | 1405 | 0200 | tome | s05o10 | 000 | sapw0 | 144100] zeazt | ase20 | o18 | 987 | ooare | anor

=

a

140 | om | can} so | 1510 | 1406 | oat | 1268 | soon | oom | 2s | asow | sean | ssa0 | ove | sar | oom | oon

am

om

an

130

ONIGN, NOILOINNOD WNIWayd

© [> Cofmecto Data S* iw oe cleo 8 a a a ee SP,

Toe ee We a

so oe | ox | ins | ow oo: | on | rs | sean | re | ome | im | om | om | ion [oar ma] =

Tee, [sme] 20 [ames] ome] au fase] ar] a] eo» fone Jase aoe] ase | vim a0] | ones Joan] 2

“rowan | 390 | 220 | sam | miso] ar | 2a 20s | ox | 20 | oom | wom | caw | var] srs | isso | aes | ss | cous | ons] S

tawescm | ser | ais | asm | ween] aan | 20 | 22a | oz | 221 | coo | um | zamo |oao| 1530 | sam | ano | 1s | ome | ons] 2

“rm | sar | 2s | sam | ras | oar | 23s | ze | oz | zat | eum | rm | ara | 40] ean | won | zoo | rs | ose | come | &

“ran | sen | aa | as | eso | 2m | 2s | 2am | oa | 2a) so | can | aa | aa] zo | eam | ano | tos) oosx | oom] =

SSS || a | fc ea ae | ane] on [in | ae aa] a | ne |] oes | ase]

snow | asa | ase | 4am | to | aso | asm} ae | os | aso | mam | rss | seo | aan] sso | vam | sz | ras | oso | oom] =

Se ea oe ooo cose] ©

eet se ee Pt Et Wns ng tS saa es

Sor | axe | ae | am |r sn | am || ae || rte | mu | ane | so] ze | am | ana | ar | cn]

“oor 1s | as | aso | po | asm | ss | ae | oar | aa | se | sn | 0 Lasen| oo | xm | sno | za | corr | cos} >

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Cuñas PerforaciónDocument22 pagesCuñas PerforaciónFGC86% (7)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

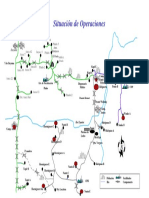

- Mapa Bloque SurDocument1 pageMapa Bloque SurFGCNo ratings yet

- Ambientes SedimentariosDocument53 pagesAmbientes SedimentariosFGC100% (1)

- Estratigrafia SecuencialDocument30 pagesEstratigrafia SecuencialFGCNo ratings yet

- Reparación & Mantenimiento PozosDocument99 pagesReparación & Mantenimiento PozosFGC100% (2)