Professional Documents

Culture Documents

Differentials

Differentials

Uploaded by

Ahmed0 ratings0% found this document useful (0 votes)

16 views9 pagesDifferentials cat

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDifferentials cat

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views9 pagesDifferentials

Differentials

Uploaded by

AhmedDifferentials cat

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 9

Differentials

Fig. 4. Differential or. Cuno.

Introduction

This lesson explains why differentials are used in the power train,

identifies the components of a differential and describes the

operation of a differential.

Objectives

1. Understand the importance of differentials.

2. Know the components of a standard differential.

3. Understand the operation of a standard differential.

Differ

os

ag

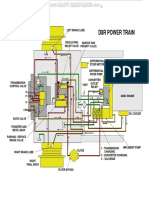

Fig. 4.2 Power To The Differentials

Power to the Wheels

‘The power from the transmission is transmitted to the differential and

bevel gear before it goes to the wheels, Figure 4.2 illustrates a

machine with two differentials. Wheel loaders and smaller models of

articulated trucks have differentials at the front and rear wheels.

Larger models of articulated trucks have a third differential at the

center axle. Some machines, such as off-highway trucks, only have a

rear differential.

Fig. 43 Machines

All of the machines shown in Figure 4.3 contain differentials.

wheel loaders and backhoe loaders have a differential inthe front and

rear axle,

x

Fig. 44 Bevel Gear and Pinion

Power to the Wheels

Figure 4.4 shows a bevel gear and pinion set. This changes the

power output by 90 degrees.

With the bevel gear and pinion set, power from the transmission

drives the pinion gear. The pinion gear drives the bevel gear. The

axle shafts for the wheels turn with the bevel gear.

‘An arrangement such as this is used on some of the older motor

graders. In some motor grader applications, a short turning radius is

not important, turns are not made frequently. The effects on the

machine may not be excessive. In other machines, such as off-

highway trucks, a solution was needed to deal with the effects of

tums. In all machines, a differential will decrease the amount of

drive train stress.

Fig. 4.8 Turning Radius

‘Turns ®

In Figure 4.5, the rear differential is shown making a U-turn. The

front wheels are steering the machine, The front wheels are not

shown . In this particular situation, the inside wheel travels a half

circle with a 10 foot (3.05 m) radius and the outside wheel travels a

half circle with a 20 foot (6.1 m) radius.

Fig. 4.6 Distance Traveled In A Turn

Figure 4.6 shows the additional distance that the outside wheel has

to travel in order to make this turn. The distance traveled by the

inside wheel is 31.5 feet (9.6 m) and the distance traveled by the

outside wheel is 63 feet (19.2 m).

With a solid axle, one tire cannot travel a greater distance than the

other without some tire slippage.

Fig. 4.7 Solid Axle

If the rear axle was a bevel gear and pinion set, the axle between the

two wheels would be one piece. The rear wheels would always be

driven at the same speed, try to go in the same direction and try to

travel the same distance.

‘When the front wheels force the machine around the turn, the rear

wheels would resist. The front wheels would have to force the rear

wheels to follow the turn.

As a result, the front tires and the rear tires will begin to wear

excessively. Many of the other stresses and strains will not be

evident until a part, such as an axle, fails.

Fig. 48 Separate Axle

Separate Axles

To improve operations in a turn, the rear axle is cut in half. If that is

all that is done, the machine is driven with one wheel and other wheel

nuns free.

While this will make it easier to round a turn, all the stress has been

placed on one axle. The driving tire will wear rapidly and the

machine will pull to one side in straight ahead operation.

Fig. 4.9 Differential Housing and Side Gears

Differential Housing and Side Gears ©

Anhousing is placed around the two separate axles. The housing

provides some support for the axle shafts. The housing also acts as a

container for all of the differential components. ‘The differential

housing rotates with the bevel gear.

Then a gear is added to the end of each axle. These gears are

generally called side gears or output gears. The side gears rotate with

the axles. The side gears are not connected to the differential

housing.

Cree SF alaeG 0" Gove

2 Fig. 4.10 Side Gears

Side Gears

In Figure 4.10, the side gears are splined to the end of each axle.

The bevel gear and the pinion can be seen. Notice that the side gears

are not splined to the differential housing. The side gears turn

independent of the differential housing.

appiass OU Ure de og

Fig. 4.1 Spider and Differential Pinion Gears

Spider and Differential Pinion Gears

The side gears are not connected directly to the bevel gear or to the

differential housing.

‘The spider has four ends that are at right angles to one another.

These ends fit through holes in the differential housing. It does not

touch the side gears, but turns with the differential housing.

Four gears are mounted on the four ends of the spider. The ends of

the spider go through the center axis of the gears. These gears are

called differential pinion gears, bevel gears or spider gears.

‘The differential pinion gears are at a right angle to the side gears.

The differential pinion gear teeth mesh with the side gears. When the

differential pinion gears rotate with the spider, the side gears move

with them,

? 9°

e4

Fig. 4.12 Spider and Differential Pinion Gears

Jeon

Spider and Differential

Figure 4.12, shows the spider and the differential pinion gears. The

smaller part of the spider fits in holes in the differential housing,

Fig. 4.13 Spider

Spider ry

In Figure 4.13, the spider has been placed in the differential

housing. If the differential pinion gears are not installed, the bevel

gear will rotate the differential housing and spider without turning the

side gears.

Fig. 4.14 Differential Pinion Gears

Figure 4.14, shows the differential pinion gears placed on the ends

of the spider. The differential pinion gear teeth mesh with the side

gear teeth,

If there is no resistance from the axles, the differential pinion gears

will not rotate on their axes. The torque on both of the side gears will

be equal. The differential pinion gears will be held between them. In

this situation, the differential housing, the spider and the differential

pinion gears rotate as a solid mass and drive the side gears.

When the machine is being driven straight ahead with equal traction

under each wheel, it is as if the axle shafts are solid. There is no

relative motion inside the differential housing.

Fig. 4.15 Differential Pinon Gears

Turn

During a turn, the inside wheel is more resistant to the turn than the

outside wheel, This resistance causes different torques on the two

side gears, When one of the axles slows down, the differential pinion

gears will walk around the slower side gear. The movement of the

differential pinion gears causes the other side gear to speed up. The

two axles tum at different speeds.

When one wheel has more traction than the other wheel, the

differential operates in the same manner as if the machine is turning.

The same amount of torque is sent to both wheels. This torque is

only equal to the amount that is necessary to turn the wheel with the

least resistance.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Bm2000 OperatingDocument174 pagesBm2000 OperatingAhmed75% (4)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Lubrication FundamentalsDocument63 pagesLubrication FundamentalsAhmed100% (2)

- Material Caterpillar d8r Bulldozer Transmission Power Train Hydraulic System Components DiagramsDocument50 pagesMaterial Caterpillar d8r Bulldozer Transmission Power Train Hydraulic System Components DiagramsAhmed92% (25)

- Part (3) Transmission Hydraulic SystemDocument20 pagesPart (3) Transmission Hydraulic SystemAhmedNo ratings yet

- Dana 70Document42 pagesDana 70wbjamesNo ratings yet

- Eixo Dif Simples Vel ENGDocument62 pagesEixo Dif Simples Vel ENGAhmedNo ratings yet

- Troubleshooting Perkins PJ EngineDocument220 pagesTroubleshooting Perkins PJ EngineAhmed100% (1)