Professional Documents

Culture Documents

1.determining The Impact of Distributed Generation On Power Systems

1.determining The Impact of Distributed Generation On Power Systems

Uploaded by

Se SamnangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.determining The Impact of Distributed Generation On Power Systems

1.determining The Impact of Distributed Generation On Power Systems

Uploaded by

Se SamnangCopyright:

Available Formats

Determining the Impact of Distributed Generation on

Power Systems: Part 1 - Radial Distribution Systems

Philip P. Barker

Robert W. de Mello

Power Technologies, Inc.

Introd uction

Distributed Generation (DG) is predicted to play an increasing role in the electric power system of the near

fiture. Distributed generation is by definition that which is of limited size (roughly 10 MW or less) and

interconnected at the substation, distribution feeder or customer load levels. DG technologies include

photovoltaics, wind turbines, fuel cells, small 8z micro sized turbine packages, stirling-engine based

generators, and intemal combustion engine-generators. These technologies are entering a period of rapid

expansion and commercialization. For example, commercial-grade residential-scale fuel cells will arrive

within the next 2 or 3 years with expectations of millions of installed units within the next 10 years.

Photovoltaic programs are aggressively growing with plans to have nearly one million rooftops equipped

with PV within a decade. Wind farms are springing up worldwide with more than 3000 MW of new wind

capacity to be installed in the year 2000 alone. Even conventional internal combustion engine-generator

and small gas turbine installations are increasing as commercialhdustrial electricity users install them for

reliability and peak shaving applications. In fact, studies have predicted that distributed generation may

account for up to 20% of all new generation going online by the year 2010. With so much new distributed

generation being installed, it is critical that the power system impacts be assessed accurately so that these

DG units can be applied in a manner that avoids causing degradation of power quality, reliability, and

control of the utility system. This paper is the first in a two part series reviewing some of the concerns of

DG application and methodologies for assessing the system impacts. This first paper focuses primarily on

radial distribution systems while the second paper focuses on low voltage distribution networks and

dynamic stability issues.

Analyzing DG Impacts

DG on Distribution Systems

Distribution systems, whether they are radial type systems found in rural or suburban areas, or network

type systems found in urban areas are generally designed to operate without any generation on the

distribution system or at customer loads. The introduction of generation sources on the distribution system

can significantly impact the flow of power and voltage conditions at customers and utility equipment.

These impacts may manifest themselves either positively or negatively depending on the distribution

system operating characteristics and the DG characteristics. Positive impacts are generally called “system

support benefits,” and include:

0 Voltage support and improved power quality

0 Loss reduction

0 Transmission and distribution capacity release

Deferments of new or upgraded TBD infrastructure

Improved utility system reliability

Achieving the above benefits is in practice much more difficult than is often realized. The DG sources must

be reliable, dispatchable, of the proper size and at the proper locations. They must also meet various other

operating criteria. Since many DGs will not be utility owned or will be variable energy sources such as

(c) 2000 IEEE

0-7803-6420-1/00/$10.00 1645

solar and wind, there is no guarantee that these conditions will be satisfied and that the full system support

benefits will be realized. In fact, power system operations may be adversely impacted by the introduction

of DG if certain minimum standards for control, installation and place.mentare not maintained. This paper

will not address how to achieve equipment deferments or T&D capacity release with DG; that is a

comprehensive topic in itself that is best dealt with in a separate paper. Rather, this paper is focusing on the

voltage quality, loss reduction and reliability factors associated with DG. For DG to have a positive benefit

in these areas, it must at least be suitably “coordinated“ with the system operating philosophy and feeder

design. This means addressing issues related to voltage regulation, voltage flicker, harmonic distortion,

islanding, grounding compatibility, overcurrent protection, capacity limits, reliability and other factors. The

larger the aggregate DG capacity on a circuit relative to the feeder capacity and demand, the more critical is

this “coordination” with these factors.

Voltage Regulation and Losses

Radial distribution systems are normally regulated using load-tap-changing transformers at substations,

supplementary line regulators on feeders, and switched capacitors on feeders. Through the application of

these devices customer service voltages are usually maintained within the ranges specified in IEEE

Standard C84.1[’]. Voltage regulation practice is based on radial power flows from the substation to the

loads and DG introduces “meshed” power flows that interfere with the effectiveness of standard voltage

regulation practice.

As an example, if a DG unit is applied just downstream of a voltage regulator or LTC transformer that is

using considerable line drop compensation (as is shown in Figure I), then the regulation controls will be

unable to properly measure feeder demand. Figure 1 shows the voltage profiles that can occur under these

conditions with and without DG. Note that with distributed generation the voltage becomes lower on the

feeder. In this example the voltage is reduced because the DG reduces the observed load at the line drop

compensator control. This confuses the regulator into setting a voltage lower than is required to maintain

adequate service levels at the tail end of the feeder. This is the opposite effect of “voltage support”, a

commonly touted benefit of DG. Movement of the DG unit to the upstream side of the regulator (if

possible) or additional regulator controls to compensate for the DG output are solutions to this problem, but

they bring their own set of issues.

I

~~~~

Substation

r---------------

------ ------- ---I

i

I

Gen

- Area of Low

Voltago

p:

i

I

Feeder voltage profile at peak

demand with DG Unit Off

->”2 ----- Feeder voltage profile at peak

demand with DG Unit On

-

------z-,- - - .--._-_.*.................................................

...............................................................................................................................

L v v r A N X l Limit Row. A Linil(99.i ~ ~ 1 1 1 1 e I -----____

Substation End of

Bur Feeder

Location

Figure 1 - Example of DG unit interfering with voltage regulation1 on a distribution feeder. Line drop

compensation must be employed a t the LTC control to result in thie indicated voltage profiles.

(c) 2000 IEEE

0-7803-6420-1/00/$10.00 1646

DG may also result in high voltage at some electric customers. For example, a small residential DG system

that shares a common distribution transformer with several other residences may raise the voltage on the

secondary enough to cause high voltage at these customers. This can occur if the distribution transformer

serving these customers is located at a point on the feeder where the primary voltage is near or above the

ANSI upper limit (126+ volts on a 120 volt base). Normally, without DG, there would be voltage drop

across the distribution transformer and secondary conductors and voltage at the customer service entrances

would be less than the primary. The presence of the DG may introduce reverse power flow to counteract

this normal voltage drop, perhaps even raising voltage somewhat, and the service voltage may actually be

higher at the customer services than on the primary side of the distribution transformer; it may even exceed

the ANSI upper limit.

The preceding examples have shown ways that both high or low service voltage can occur due to the

incompatibility of DG with the radial power flow based voltage regulation approach used on most utility

systems. As a result, the DG influence on voltage for any potential application shodd always be assessed to

insure that no customers will be adversely impacted.

An accurate way to analyze the voltage regulation behavior of a system with DG is to run a power flow

simulation using software capable of analyzing multiple sources on the distribution system and the

operation of voltage regulators. The phase angle of the injected DG current relative to the utility system

voltage must be considered as well as the impedance characteristics of the line. In this analysis, it is

important to recognize that the DG injected power may result in a voltage that is within limits at the DG

site but could be out of limits farther downstream.

To determine if the DG will cause a significant impact on the feeder voltage, the size and location of the

DG, the voltage regulator settings, and impedance characteristics of the line must be considered. If line

drop compensation is used by the regulator, then DG units interconnected within the regulator’s zone and

downstream of the constant voltage point (CVP) will support (increase) the feeder voltage below the CVP.

Those above the CVP will lower the voltage below the CVP. If voltage support is the key reason for using

DG, then DG placement downstream of the CVP is crucial to meeting this objective (the farther

downstream of the CVP, then the greater the support). The values of line-drop-compensation utilized will

determine the CVP location on the feeder. Note that when no line-drop-compensation is used, the CVP is at

the regulator device itself.

In essentially all cases the impact on the feeder primary will be negligible for any individual residential

scale DG unit (<lOkW). However, when the aggregate capacity of many small units deployed reaches a

critical threshold or when the capacity of a single unit is large enough, then voltage regulation studies are

desirable to insure that the feeder voltage will be maintained within appropriate limits. The aggregate DG

capacity threshold for which studies become appropriate depends on many factors. However, a reasonable

rule-of-thumb is that if the injected current (measure at the primary level) is less than 5% of the feeder

loading at the interconnection point and if all customers had satisfactory voltage prior to the addition of the

DG, then a voltage problem on the primary is unlikely. Much above 5% injection and there is more reason

to worry about potential impacts. For shared secondaries with DG even a small generator that injects less

than 5% at the primary level could pose a voltage regulation risk to customers sharing the secondary. Thus,

analysis of voltage conditions will almost always need to consider impacts on the secondary where the DG

is located.

Distributed generation will also impact losses on the feeder. DG units can be placed at optimal locations

where they provide the best reduction in feeder losses. Siting of DG units to minimize losses is like siting

capacitor banks for loss reduction. The only difference is that the DG units will impact both the real and

reactive powerflow. Capacitors only impact the reactive power flow. Most generators will be operated

between 0.85 Lagging and 1.0 power factor, but some inverter technologies can provide reactive

compensation (leading current). A good loadflow analysis software should be able to model the effects on

system losses. On feeders where losses are high, a small amount of strategically placed DG with an output

of just IO-20% of the feeder demand can have a significant loss reduction benefit for the system.

Unfortunately, most utilities don’t have control over the siting locations, since DG is usually customer

0-7803-6420-1/00/$10.00(c) 2000 IEEE 1647

owned. Nonetheless, for utilities that are moving forward with their own DG programs, optimal siting of

units can increase the performance of the system.

Larger DG units must be sited with consideration of feeder capacity limits. In some cases overhead lines

and cables may be thermally limited meaning that the DG can inject power that exceeds the line’s thermal

limit without causing a voltage problem on the feeder. The power flow analysis should%“flag”the locations

where capacity constraints will be an issue from a thermal as well as a voltage perspective. In general, a

DG at a location that is thermally limited is not connected at the optimal point from a “power loss”

perspective.

Voltage Flicker

DG may cause noticeable voltage flicker. Flicker can be either a simpk: issue or a complex issue as far as

its analysis and mitigation are concerned. From the simple perspective. it can be the result of starting a

machine (e.g. induction generator) or step changes in DG output which result in a significant voltage

change on the feeder. If a generator starts, or its output fluctuates fiequently enough, flicker of lighting

loads may be noticeable to customers. One approach is to determine the magnitude and number of changes

of voltage occurring per unit time and see if these are above the visibility or irritation threshold levels of the

GE flicker curve[*](see Figure 2). If above the thre:shold, or if customer complaints occur, mitigation must

be considered. Mitigation approaches include reduced voltage starts on1 induction generators as well as

speed matching. Synchronous generators might require tighter synchronization and voltage matching.

Inverters might be controlled to limit inrush currents and changes in output levels. A less technical

approach to reduce flicker involves placing constraints on when and how often DG operators may start and

change the output of DG systems. In the case of wind and solar energy systems, the outputs will fluctuate

significantly as the sun and wind intensity change. Fortunately, these fluctuations tend to be smoother than

step changes associated with the GE flicker curve. For this reason, the GE flicker curve is a conservative

curve for assessing some types of solar and wind induced voltage fluctuations.

Figure 2 - GE Flicker Curve showing the “borderline of irritation” (see IEEE 519-1992 for

further details)

Determination of the risk of flicker problems due to basic generator starting conditions or output

fluctuations is fairly straightforward using the flicker curve approach, Imticularly if the rate of these

fluctuations is well defined, the fluctuations are “step” changes and there are no complex dynamic

interactions of equipment. The dynamic behavior of machines and their interactions with upstream voltage

regulators and generators can complicate matters considerably. For ex:unple, it is possible for output

fluctuations of a DG (even smoother ones @omsolar or wind systems) to cause hunting of an upstream

regulator and, while the DG fluctuations alone may not create visible flicker, the hunting regulator may

0-7803-6420-1/00/$10.00(c) 2000 IEEE 1648

create visible flicker. Thus, flicker can involve factors beyond simply starting and stopping of generation

machines or their basic fluctuations. Dealing with these interactions requires an analysis that is far beyond

the ordinary voltage drop calculation performed for generator starting. Identifying and solving these types

of flicker problems when they arise can be difficult and the engineer must have a keen understanding of the

interactions between the DG unit and the system. To model this on a computer requires good models of the

distributed generators (which are often not available) and their interactions with utility system equipment.

A software analysis package with the ability to analyze the dynamic behavior of systems is helpful for this

type of study. It may also be necessary to perform system measurements to assess voltage and power flow

oscillations and to identify how equipment controls can be "tuned" or modified to reduce flicker. In some

cases, these dynamic flicker problems can be solved without a detailed study by simply performing an

adjustment of a control element until the measured flicker disappears. In other cases, the fix is allusive and

requires considerable investigation to solve.

Harmonics

Distributed generators may introduce harmonics. The type and severity will depend on the power converter

technology and interconnection configuration. In the case of inverters, there has been particular concem

over the possible harmonic current contributions they may make to the utility system. Fortunately, these

concems are in part due to older SCR type power inverters that are line commutated and produce high

levels of harmonic current. Most new inverter designs are based on IGBTs that use pulse width modulation

to generate the injected "sine" wave. These newer inverters are capable of generating a very clean output

and they should normally satisfy the IEEE 519-1992 requirements (see Table 1 below).

A l l o w e d L e v e l R e l a t i v e to F u n d a m e n t a l

Harmonic Order ( 0 d d h a r m o n i c r )*

<11'b 4%

< 1 Ith to c 17Ib 2%

C 17th to < 23'' I .5%

c 23rd to < 35thth 0.6%

35th or greater 0.3%

Total Harmonic Distortion 5%

'Even harmonics are limited to 25% of odd valuer

Table 1. Harmonic Current Injection Requirements for Distributed Generators Per IEEE

519-1992.

Rotating generators such as synchronous generators can be another source of harmonics. Depending on the

design of the generator windings (pitch of the coils), core non-linearity's, grounding and other factors, there

can be significant harmonics. Triple harmonics are additive in the neutral; and the third harmonic is often

the most prevalent. Synchronous generators are often specified with a 2/3 pitch for the windings since this

produces much less third harmonic than those with other pitches. Unfortunately a 213 pitch machine has a

lower impedance to third harmonic and may cause more harmonic current to flow from other sources

connected in parallel with it. The grounding arrangement of the generator and step-up transformer will play

a major role in limiting the feeder penetration of harmonics. Arrangements can be selected to block or

reduce third harmonic injection to the utility system. This would tend to confine it to the DG site only.

In general, harmonic contributions from DG units are probably not as much of an issue as some of the other

problems discussed in this paper. Nonetheless, there are specific instances where problems have been

identified such as levels of distortion which exceed the IEEE-5 19 standard, resonance with capacitor banks,

or problems with equipment that are sensitive to harmonics. In extreme cases, equipment at the DG site

may need to be derated due to added heating caused by harmonics. Any DG installation design should be

reviewed to determine its compliance with IEEE 5 19 and whether harmonics will be confined to the DG

site or also injected into the utility system. For larger DG units or cases involving complex harmonic

0-7803-6420-1/00/$10.00 (c) 2000 IEEE 1649

problems, measurements and modeling of the system harmonics may be required to assess conditions. Any

analysis should consider the impact of DG currents on the background utility voltage distortion levels. The

limits for utility system voltage distortion are 5% far THD and 3% for any individual harmonic.

Impact on Short Circuit Levels

The fault contribution from a single small DG unit is not large, howevw, the aggregate contributions of

many small units, or a few large units, can alter the short circuit levels enough to cause fuse-breaker

miscoordination. This could affect the reliability and safety of the distribution system. As an example,

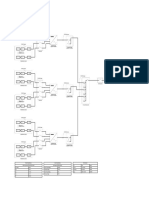

Figure 3 shows a typical fused lateral on a feeder where fuse saving [fault selective relaying] is utilized. If

DG units are added to the system, the fault current inay become large enough that the lateral fuse no longer

coordinates with the feeder circuit breaker during a fault. This would lead to unnecessary fuse operations

and decreased reliability on the lateral.

su

Breaker

,& Fault

Figure 3 - Fault contributions due to DG units 1,2 and 3 may increase the short circuit levels to the

point where fuse-breaker coordination is no longer achieved!

Typical short circuit levels of DG power converters are characterized in Table 2 and references [5][6][7]

and [SI.For inverters, the fault contributions will dlepend on the maxirnum current level and duration for

which the inverter manufacturer’s current limiter is set to respond. On some inverters fault contributions

may last for less than a cycle, in other cases it can be much longer. For synchronous generators, the current

contribution depends on the prefault voltage, subtransient and transient reactances of the machine, and

exciter characteristics. Induction generators can also contribute to faults as long as they remain excited by

any residual voltage on the feeder. For most induction generators, the significant current would only last a

few cycles and would be determined by dividing the prefault voltage by the transient reactance of the

machine, Even though a few cycles is a short time, it is long enough to impact fuse-breaker coordination

and breaker duties in some cases.

00-400% (duratior

~ Generator

Induction Generator or Selfbcited

S nchronous Generator

Starting at 500-100

- anddecayingto200-400%~cles

500-1 000% forJrst,kw cycles and decaying to

a negligible amount within 10

I

0-7803-6420-1/00/$10.00 (c) 2000 IEEE 1650

Using the table above, a 1000 kW synchronous generator would contribute a peak fault current on a 13.2

kV primary feeder of about 218 to 437 Amps to a fault for the first few cycles. This compares with typical

distribution circuits have primary fault currents ranging from about 100 amperes (at remote fringe areas) to

more than 10,000 amperes near the substation. Thus, the current contribution from DG units is enough to

impact fuse coordination in some cases, especially in weaker parts of the system. Table 2 represents the

worst case fault contributions and is only meant as an illustrative guide. For accurate analysis, the generator

data should always be obtained from the manufacturer. In addition, Table 2 is for faults at the generator

terminals. The contributions will decrease the farther the generator is from the fault. The configuration and

impedance of the DG site step-up transformer will also play a role. For example, a DG interface

configuration that does not provide a zero sequence path to the utility system will not contribute to ground

faults on the primary side.

When a single generator is added to the system, a manual calculation of the peak fault currents based on

manufacturers data can be performed to screen for a serious impact on the existing short circuit levels. For

multiple generation devices scattered throughout the system or large generators, the only accurate approach

is to perform a software based short circuit analysis which correctly models the short circuit behavior of the

generators. In many cases, the DG units won’t pose a threat to existing coordination; only a relatively few

cases may require changes in protection settings.

Grounding and Transformer Interface

Distributed generation must be applied with a transformer configuration and grounding arrangement

compatible with the utility system to which it is to be connected. Otherwise, voltage swells and

overvoltages may be imposed on the utility system that damage utility or customer equipment.

Most U.S. distribution systems are four-wire-multigrounded-neutralsystems that are defined as being

effectively grounded with respect to the substation source. For a single line to ground fault, this

arrangement limits the voltage rise on unfaulted phases to about 125 to 135% of the prefault conditionr31141.

By IEEE definition, effective grounding means that the positive sequence reactance is greater than the zero

sequence resistance (XI>%) and the zero sequence reactance is less than three times the positive sequence

reactance (3X1>X,). Use of a DG source that does not appear as an effectively grounded source connected

to such systems may lead to overvoltages during line to ground faults on the utility system. This condition

is especially dangerous if a generation island develops and continues to serve a group of customers on a

faulted distribution system. Customers on the unfaulted phases could in the worst case see their voltage

increase to 173% of the prefault voltage level for an indefinite period. At this high level, utility and

customer equipment would almost certainly be damaged. Saturation of distribution transformers will help

slightly to limit this voltage rise. Nonetheless, the voltage can still become quite high (1 50% or higher). For

example, marginally rated lightning arresters would probably fail in less than 5 seconds if the voltage

reached just 150% of the prefault condition 14].

To avoid problems, all DG sources on multigrounded neutral systems that are large enough to sustain an

island should present themselves to the utility system as an effectively grounded source. If they do not, they

should use appropriate protective relaying to detect primary side ground fault overvoltages and quickly trip

off-line (instantaneous trip). The former approach is preferred since it limits by design the voltage swells

that the system will see during a fault. The latter approach, while used successfully in many installations,

could subject the customer to many cycles of severe overvoltage prior to the DG unit being cleared f?om

the system. And if the DG is not cleared quickly enough, equipment could be damaged.

Some common transformer configurations found at DG sites are shown Table 3. Not all of these provide

effective grounding. Use of an adjacent grounding transformer bank is one approach for creating a DG

source that behaves as an effectively grounded source when the step-up transformer does not provide

effective grounding. It should be noted that any additional grounding sources on the system, whether it is

by a grounding bank or by using an appropriate step-up transformer winding arrangement, will have the

effect of reducing (diverting) the zero sequence return current seen at the substation that arises from line to

ground faults on the feeder. The amount of current diverted is determined by the ratio of the DG grounding

source impedance to the substation grounding impedance. This effect has the impact of desensitizing the

(c) 2000 IEEE

0-7803-6420-1/00/$10.00 1651

ground fault relaying at the substation since the substation will see letss current for a given magnitude line

to ground fault out on the feeder. To asses the implact of this problem, the grounding source impedance of

the DG site must be analyzed to insure that it won’t divert more than a small fraction of the fault current

(perhaps 10% as a rule of thumb). For smaller DG units it usually is not an issue. For a larger unit acting as

a ground source or for cases involving many small units acting together as ground sources, the short circuit

studies need to identify the impact of this and see if any changes are required in relay pickup settings. A

grounding resistance can be used on the DG ground source neutral connection to limit the impact. This also

helps to reduce circulating current in any delta winding of the transfarmer,that are caused by zero sequence

voltages on the feeder.

Proper review of the generator characteristics and utility system design prior to installation of the DG unit

can insure that grounding compatibility problems are dealt with appropriately. Grounding compatibility is

crucial to insure that power quality and reliability are not degraded b-y the addition of DG units.

Table 3 - Some transformer arrangements used for DG sites

-

or I suitably sized primaryside grounding bank is provided I

Delta/Delta

Wye-groundeWye grounded

grounding bank is provided or if the generator is wye-

grounded and meets neutral impedance requirements

Wye-grounded/Delta Typically provides effective grounding regardless of

I generator grounding arrangement

Islanding

Islanding occurs when the distributed generator (or group of distributed generators) continues to energize a

portion of the utility system that has been separated from the main utility system (see Figure 4). This

separation could be due to operation of an upstream breaker, fuse, or automatic sectionalizing switch.

Manual switching or “open” upstream conductors could also lead to islanding. Islanding can occur only if

the generator(s) can self excite and sustain the loaid in the islanded section. In most cases it is not desirable

for a DG to island with any part of the utility systfembecause this can lead to safety and power quality

problems that will affect the utility system and lOi5dS. For example, if an island develops on a feeder during

standard reclosing operations, the islanded DG units will quickly drift out of phase with the utility system

during the “dead period.” Then, when a reclose occurs, the utility will connect out of phase with the island

if reclose blocking into an energized circuit is not provided at the breaker control. This can cause damage to

utility equipment, the DG units supporting the island, and customer 1,oads.Islanding also increases the

likelihood that DG sources may be allowed to subject the island to out of range voltage and frequency

conditions during its existence. And it can pose a serious safety threat during downed conductors and utility

repair operations since the public and utility workers may be exposed to circuits that otherwise would be

de-energized. Finally, islanding can hinder service restoration by requiring line crews to spend extra time

disabling the island conditions. This will impact reliability indices such as SAIDI.

0-7803-6420-1/00/$10.00 (c) 2000 IEEE 1652

SUBSTATION FEEDER

--3 E+m A

Utility crew

opens switch

This area of

primary stili

en erg ized

House with

Fuel Cell and

grid connected

inverter

-

Figure 4 Islanding can happen in a variety of circumstances. Proper protection must be provided to

avoid islanding in all typical applications of DG. Most utilities and the IEEE have standards

specifying the protection required to help prevent island development. Active anti-islanding is a

robust new protection approach being applied to inverters.

To prevent islanding, a DG unit operating in parallel with the utility system should in a timely manner

sense a significant voltage sag or discontinuity of service on the utility side and disconnect from the

system. Many utilities have standards that require that this time be about 10 cycles or less for serious feeder

disturbances (deep voltage sags or interruptions). IEEE has also developed standards; for example, IEEE

929 recommends that small photovoltaic inverters should initiate a disconnect within 6 cycles for such

events [’I. This is fast enough to allow the DG’s to disconnect prior to the fastest reclosing times used in the

industry.

Voltage and frequency relays are used as a means of anti-island protection. In most cases, if a generator

becomes islanded, it will not be able satisfy the sudden change in its load without a significant change in

voltage and/or frequency and the relays will trip the unit off line. This type of anti-islanding protection is

called “passive.” Passive protection can be fooled if the generator is able to carry the load of the island

without a substantial change in voltage or frequency so, as a further safeguard, many smaller inverters

today also use what is called “active” anti-islanding protection. One common “active” approach is for the

inverter to be “tuned” to operate while islanded at a frequency other than 60 Hz.While the utility signal is

present the inverter is “forced” to operate at 60 Hz.During an intemption, it will drift to its natural “tuned”

frequency once the “forcing utility voltage function” disappears (that is when it becomes islanded). In the

process of drifting to the natural inverter frequency, the unit will trip its internal frequency relays, which

are set to trip for a deviation from power frequency outside the range of 59.3 to 60.5 Hz. Active anti-

islanding is more robust than passive, but even it cannot guarantee that an island won’t develop in some

rare cases. Some active anti-islanding techniques developed by Sandia Laboratories are discussed in

reference [9].

Since islanding can cause severe voltage quality and reliability problems, the proper use and setting of anti-

islanding controls is one of the more important issues for DG installations. For small photovoltaic inverters

IEEE standards are already available which describe the settings and types of controls required [’I. For other

types of inverters and larger installations, the settings and controls required are still being defined. IEEE

has a new standard under development (IEEE P1547) which will address all DG sizes and technologies.

Most utilities and many state energy commissions also have standards that address the islanding issues.

Intentional Islanding for Re/iabi/ify

The implementation of DG can increase reliability of electric service if units are configured to provide

“backup- islands” during upstream utility source outages. To be effective this requires reliable DG units

0-7803-6420- 1/00/$10.00 ( c ) 2000 IEEE 1653

and carehl coordination of utility sectionalizing and protection equipment. Any time such a scheme is

implemented it needs to be well planned to avoid causing problems. Figure 5 shows one scheme where an

upstream automatic switch is used to island a section of a distribution feeder. For this approach to work the

switch must open during upstream faults and the generators must be able to cany the load on the islanded

section maintaining suitable voltage and frequency levels at all island’edloads. Unless a static switch is

employed, this scheme would usually result in a momentary interruption to the island since the DG would

necessarily trip during the voltage disturbance caused by the upstream fault. A DG assigned to carry the

island must be able to restart and pickup the island load after the switch has opened. Power flow analysis of

island scenarios must be performed to insure that proper voltage regulation is maintained and to establish

that the DG can handle inrush during “starting” ofthe island. The DCi unit must be able to load follow

during islanded operation and the switch will need to sense if a fault current has occurred downstream of

the switch location and send a signal to block islanding if a fault has occurred within the island zone. When

utility power is restored on the utility side, the switch must not close unless the utility and “island” are

tightly in synchronism. This requires measuring the voltage on both sides of the switch and transmitting

that information to the DG unit supporting the island so that it can “synchronize” with the utility and allow

reconnection. Overall, this is complicated but new automated switch technologies and communications

approaches make this scheme much more practical than in past years.

Area

slupported

during utility

1 outage

Substation

Figure 5 - Intentional islanding of a portion of a distribution feeder with a DG will require

considerable planning and control efforts to work safely and properly. Such an implementation

could improve reliability on a rural feeder without autoloop capability.

Conclusions

DG has much potential to improve distribution system performance and it should be encouraged. However,

distribution system designs and operating practices are normally based on radial power flows and this

creates a special challenge to the successful introduction of distributed generation. This paper has described

a few of the issues that must be considered to insure that DG will not degrade distribution system power

quality, safety or reliability. This paper focused on radial systems, ahhough some of the issues discussed

are common to low voltage distribution networks. For a review of low voltage network considerations and

other issues related to DG dynamics, the second paper (Part 2) of this series is referenced [lo].

It is clear that detailed analysis and special equipment to prevent protilems will be required in many cases

where larger DG units are applied. However, it is important to recognize that due to the economics of small

DG installations, a detailed study can not be performed for every small DG installation. That would be too

much of a burden from a cost perspective on both the utility and DG operators (or whoever ends up paying

for the studies). To resolve this issue, DG applications need to be screened with a “very low cost

0-7803-6420-11001$10.00(c) 2000 IEEE 1654

methodology’’ to determine which ones warrant careful study versus which ones can be successfully

operated just by meeting basic requirements. From this perspective, there are probably three categories of

DG installation:

1. Those that can clearly be installed per codes and standards without any special requirements

2. Those that are borderline (may need some limited special studies or have limited additional

equipment requirements)

3. Those that are clearly in need of detailed system impact studies and addition equipment

requirements

The capacity rating alone of a DG unit is not sufficient information to determine whether the installation is

in Category 1,2 or 3. The factors that determine system impacts include not only the size, but the dynamic

characteristics of the generator, the characteristics of the distribution system at the point of interconnection

and the presence of other customers on the same secondary. As an example, it is possible for a 1000 kW

DG connected at a stiff 12 MVA substation bus to cause less impact on system voltage than a 25 kW DG

operating on the secondary of a 50 kVA distribution transformer serving many customers!

To avoid requiring costly impact studies for all but those applications that actually need them, proposed DG

projects can be screened based on factors such as:

Utility system fault levels at the point of DG interconnection

The size of the DG unit, its intended mode of operation and expected output fluctuations

Aggregate capacity of DG on the system

The DG short circuit level and duration

Secondary configuration of the DG site (including presence of adjacent customers)

Feeder voltage regulation practice

The transformer and grounding compatibility of the system

Size of generation relative load at the interconnection point

Type of power converter.

These and other factors will determine the likelihood of causing a significant impact on the system and

adjacent customers. The screening can be done manually or it can be done automatically by software based

screening tools. A typical software screening tool would lead the user through a series of questions about

the utility system characteristics and the DG unit characteristics and would perform various calculations to

identify if the proposed DG installation needs a detailed study or can be installed without significant

concern of adverse impacts. Generally, the larger installations will most commonly need special studies

and attention but there will be smaller units that occasionally may require specialized study. Effective

screening tools of this nature that consider factors on both the utility side and DG side of the system are

under development and are strongly needed in the industry to streamline processing of an almost explosive

growth in DG interconnection applications and projects. This will help to promote DG and maintain

adequate safeguards to protect utility system reliability, safety and performance.

References

1. Voltage Ratings of 60 Hz Electric Power Systems, ANSVIEEE (284.1-1995,Published by Institute of

Electrical and Electronic Engineers, 1995

2. IEEE Recommended Practices and Requirements for Harmonic Control in Electric Power Systems,

IEEE Standard 5 19-1992, Published by Institute of Electrical and Electronic Engineers, 1992

3. IEEE Guide for the Application of Neutral Grounding in Power Systems, Parts 1-4, IEEE Std. C63.92

Parts 1-4, , Published by Institute of Electrical and Electronic Engineers, 1992

0-7803-6420-1/00/$10.00(c) 2000 IEEE 1655

~~ ~ ~~

4. IEEE Guide for the Application of metal Oxide Surge Arresters for Alternating Current Systems, IEEE

Std. C62.22-1997, Published by Institute of Electrical and Electronic Engineers, 1998

5. Recommended Practice for Utility Interface of E'hotovoltaic (PV) S'ystems, IEEE Std. 929-2000,

Published by IEEE, 2000

6. IEEE Guide for Interfacing and Dispersed Storage and Generation Facilities with Electric Utility

Systems, ANSIAEEE Std. 1001- 1988, April 1989. Published by IEIEE.

7. Onan Liquid-Cooled Generator Set Application Manual (T-030), Onan Corporation, November 1993

8. Static Power Converters of 500 kW or Less Serving as the Relay Interface Package for Non-

Conventional Generators, IEEE 93THO 597-5 PWR, Published by IEEE, 1993.

9. G.A. Kern, R.H. Bonn, J. Ginn, S . Gonzalez, Results of Sandia Najional Laboratories Grid-Tied Inverter

Testing, Presented at the 2ndWorld Conference and Exhibition on I?hotovoltaic Solar Energy

Conversion, 6-10 July 1998, Vienna, Austria. (Available at Sandia S website www. sandia.gov/pv)

10. Philip Barker, Jim Feltes, David Smith, "Determining the Impact of Distributed Generation on Power

Systems: Part 2 - Low Voltage Network System.s and DG Dynamics

0-7803-6420-1/00/$10.00 (c) 2000 IEEE 1656

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Leviton Applications Manual and Reference Guide For Surge Protection and Line Conditioning ProductsDocument66 pagesLeviton Applications Manual and Reference Guide For Surge Protection and Line Conditioning ProductsBen E100% (1)

- Switch Gear SlideDocument54 pagesSwitch Gear SlidebutunsonaNo ratings yet

- PS 3KVA Service ManualDocument14 pagesPS 3KVA Service ManualNailson Martins100% (1)

- Sts DiagramcmitDocument480 pagesSts DiagramcmitManh Quyen100% (1)

- EventAnalysis TutorilaDocument10 pagesEventAnalysis TutorilaLovemore MutikaniNo ratings yet

- EPRI Substation Grounding Project PDFDocument28 pagesEPRI Substation Grounding Project PDFmsd_hmsd1633100% (1)

- IEC 60146-1-2 (Ed4.0) enDocument88 pagesIEC 60146-1-2 (Ed4.0) enDipankar Chakraborty50% (4)

- 7PG21 Solkor RF Complete Technical ManualDocument78 pages7PG21 Solkor RF Complete Technical ManualjanarthananNo ratings yet

- Rish Master 3430 ManualDocument79 pagesRish Master 3430 Manualsumit100% (1)

- Notifier FZM 1 Interface ModuleDocument2 pagesNotifier FZM 1 Interface Modulenastyn-1No ratings yet

- Medi ManualDocument39 pagesMedi ManualBabuPD75% (8)

- High Resistance GroundingDocument6 pagesHigh Resistance GroundingpecampbeNo ratings yet

- SMC-Flex™ Smart Motor Controller: Solid-State Motor ControlDocument100 pagesSMC-Flex™ Smart Motor Controller: Solid-State Motor ControlHernan PatarroyoNo ratings yet

- Electrical Power Transmission: Cep ProjectDocument22 pagesElectrical Power Transmission: Cep ProjectVinay MakhijaniNo ratings yet

- 3P60100110K1GDocument1 page3P60100110K1GNedim HadžiaganovićNo ratings yet

- Datasheet of ACE Air Cooked Oil Cooler AH1428Document1 pageDatasheet of ACE Air Cooked Oil Cooler AH1428Vineet TanejaNo ratings yet

- Sop of LT AcbDocument9 pagesSop of LT AcbAkhilesh Kumar SinghNo ratings yet

- Manual HRN-43 43NDocument2 pagesManual HRN-43 43NArtem MarchenkoNo ratings yet

- ABB Generator Protection TerminalDocument8 pagesABB Generator Protection Terminalbrock100% (1)

- Must Power 5KVA - ManualDocument16 pagesMust Power 5KVA - ManualRoberto MenendezNo ratings yet

- 12V - 230V 50Hz Square Wave Inverter With IR2153Document3 pages12V - 230V 50Hz Square Wave Inverter With IR2153Abubakar SidikNo ratings yet

- Navitas EPC BrochureDocument4 pagesNavitas EPC Brochuresandeep bagulNo ratings yet

- Comparison of HVDC Light and HVDC Classic Site Aspects PDFDocument6 pagesComparison of HVDC Light and HVDC Classic Site Aspects PDFRamesh EpiliNo ratings yet

- Pertemuan 7. Unit Protection (T. DAVIES) Protection of Industrial Power SystemsDocument24 pagesPertemuan 7. Unit Protection (T. DAVIES) Protection of Industrial Power Systemswijayaroni363No ratings yet

- Helioscope 5647489 SLDDocument2 pagesHelioscope 5647489 SLDAnindio PrabuNo ratings yet

- Eaton Protective Devices Catalog en UsDocument65 pagesEaton Protective Devices Catalog en UsjoseNo ratings yet

- VSOP For Unit Synchronization.Document15 pagesVSOP For Unit Synchronization.pradeep1987coolNo ratings yet

- SED-050 Battery String Calculator - v12.0Document2 pagesSED-050 Battery String Calculator - v12.0Joe HoangNo ratings yet

- TWG 5B DraftDocument87 pagesTWG 5B DraftMoe ThidarNo ratings yet

- Avtron Hoja Técnica LPH-100 KWDocument2 pagesAvtron Hoja Técnica LPH-100 KWHernán Peñafiel ReaNo ratings yet