Professional Documents

Culture Documents

6004-0100-ALE-0100-PR-0043-PDF (MLD Response)

6004-0100-ALE-0100-PR-0043-PDF (MLD Response)

Uploaded by

romahi0 ratings0% found this document useful (0 votes)

20 views13 pagessdd

Original Title

6004-0100-ALE-0100-PR-0043-PDF(MLD Response)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsdd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views13 pages6004-0100-ALE-0100-PR-0043-PDF (MLD Response)

6004-0100-ALE-0100-PR-0043-PDF (MLD Response)

Uploaded by

romahisdd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 13

mirage w|i

ey Employer + Meraas / Mirage Development

SP de eae a

|| 8 [A [onc [soe [SEAT [nec

aise WRT) i oat

NETS

= Tae ea aa

rasaae oc oa Tae a

a

ET a

IMPLANCE The Contractor Perey coniems that the submited Wems have Been reviewed io detail and ae

FATEMENT correct andin trict conformance withthe Contract Documents, attach complance statement)

‘anya Project Manager

Audi iebenberg Date

|--8 WEP mute ad!

MOOR

Name, entre

Comments Sheet Attached?

a0 Be eR

al Coda Objet BR On Rca: C ODAC, av Fa aoe

tl. | mirage W9RS fs WSP

SUBMITTAL REVIEW COMMENTS

PRONECTAANE: [eater Ret [EPLOYER. | nag Laue ad Dele

commueror [alse ARNTEGT | Woods east

SETE_[eoncoreoatcor-rnoow _ [OsteatRevew | snoventr ante

Sine [PaaaeeaRaTEMOOA yous [aC] gt oD aC

No. | — tem ‘Comment Instruction’ Observation Contractor's Response

‘Approved subject to comments Blow:

73 Tis cin] ora Wa avowed A

azzoraancs toe Speceaon 014000 ally

Fequrements em 17 ~ Bung Smeape

‘esing Requcement DM Green Bung

Fegulston an Specteston 613 Gazed

‘lan Cora Was Rom 34 So Guy

Pie qualstn doses Specaiso bo

[baled separtey or approval Doctors

tebe subtanited by OM approval

= Teagan bs cried in SECOSRTESTS

‘hematod pproved by Oubal Muntaly

| tno spor ASTI E285 roqutemert

Comprehensive Peimnary Repo per

Balding bared on actual ste canton tobe

Submteg porto tstng acy

1 Sibi dati Tsing Work pogranme

Sequel to bulding constuction sor

Fanangove proganme

© Test Zones Tsing pe bling shal be

Sucealnte Component Secton sis, namely

Str ime

Al Tenant Units per Bulg to have

frau! Test Reports

2 Incas shared by Tenant Unts

1H Bulg / Transport Hub net

Rett Spaces

Fra Report for sung Envelope Taxing ©

‘nade annual anton fags

‘dort bullng envaope components

Ee blow

+ Rotng syst

Canam wa

1 Wat ceddig/ Panes

2 Bloc Prone

1 Sonic Penetatone

1 Vapour Barre

| Note: The submited Final Report shal be

‘General | " fevewedointy by Fapade Conutant, WSP-

2 | Geom) | Meera woods Bagot fr tat

reeommandation

Avene oo =

Victor Ebiasin| 5 November 2016

eer en aie rena

Popa: A: NOHecanB:neCeen abec crane: Obiin ail Ried Fer oman sy

PROIECT

Bluewaters Development JBR Island, Dubal, UAE.

CLIENT: ALEC (Al Jaber Engineering & Contacting) LC

TESTING SPECIALIST

eLealolall las

‘GREEN BUILDING SOLUTIONS

Prepareay_[SShone awe OF DOCUMENT | SUE] SCALE] SET

Gieced oy [oe TROT Ca ares

Towra y | Walen wr Bulsing Envelope Air eviion | 0

‘Tighiness Testing

Bluewaters Development:

BR Island, Dubai, UAE

(26 Reta and F& Outlets)

Document No: ALEC-096-002-MSO1_22-10-16

Moin Contractor /Consutont's Approval/Comments:

code ‘8* No oben Qo

Code ‘8*= No objection wth comments]

ode" bjcton a

Code 0"- Revs & Ressbmi o

‘Comments ifany

Project

Beet

‘CONTENTS

Noy pwn

$n 80108: AlrLeakage

‘Bluewaters Development JBR Islnd, Dubl, UAE Age: 096-002.

Matnod Statement fr: Date 2210-2018

Buling Envsiope ir Tightness Testing Issue: ev: 0

Dua Green Buling Re Page 20110

Introduction

Testing Procedure

Test Apparatus and Instrumentation

Data analysis and Reports

Pre- Testing Requirements and Conditions

Safety Hazards and Control Measures

Fan Placement & Temporary Sealing Locations

fe

sil ul cas

ican sug

reject:

uewaters Development JBR Island, Dubs, UAE

Method Statement for:

Building Envelope Al Tightnes Testing

‘usa Green Bulding Regustons & Speciteations

Section 50108: air Lesage

Document Number

Alec. 096.002.

sos 2240-16

Date: 2210-2016

issue: fev: 0

Page 3f10

Lo inrropuction

‘Aan Pressurzston Test gves an overall value for airsightnes of space, and can help inti ar

leaks. The testing equipment consists of multiple calibrated fans that are sealed into elected building

apertures. The fans create a continuous flaw of pressure into the building (or Outof the uni when using

‘smoke vapor to locate leas). GBSI uses a proprietary (Retrtec} computing devic: with a bull in miro=

‘anemometer and specialized software to detect the rate of pressure retention ard loss due to possible

airleaks inthe construction. The test method described herein sas per Section 50.05 ofthe DUBA

‘GREEN BUILDING REGULATIONS & SPECIFICATIONS -2010 as we the elevant econ of The OMAISofat

{Green Building Rating System which specifies international standard testing protocols CIBSE TM23—

Testing Buildings for Ar Leakage and 8S EN 13829:2001 Thermal performance of buildings ~

Determination of ar permeability of bullaings~ Fan pressurization method). The tated allowable ait

permeability rae isnot to exceed 10 m3/ hr/m2 @S0Pa,

20. TESTING PROCEDURE

2.1 Bulging components:

Close all intentional exterior openings ofthe building or part ofthe bulling tobe tested (windows,

‘doors, and reguar).

“Al adjustable openings shall be closed an remaining intentional openings shall be sale.

The entire building or part ofthe buldng tobe tested shall be configured to respond to pressurization

asa single zone.

-Allinterconnecting door in part of the bullding tobe teste shall be opened so tata uniform pressure

|smaintaned within a range of ess than 10 % of the measured insideouside presureeiference.

Make general observations of the condition ofthe building, Take notes onthe windows, doors, opaque

walls, roof and lor, position af ajustable openings an any sealing applied to ientonal openings

The entire building or part ofthe buldng tobe tested shall be configured to resxond to pressurization

‘35. single zone. Al interconnecting doors shall be opened so that a uniform pressure ls maintained

within range of less than 10% ofthe measured inside/outside prescure difference

2.2 Testing conditions of building:

‘uring a test, internal doors of the conditioned space should be wedged open t's normal practice

for the boller room, switch rooms and lif rooms to be considered outside the buliding external

‘envelope. External doors and ther purpose made openings in the building envelope should be

closed, Mechanical ventilation systems (Both the Base Bullding and Future Tenent Systems) should

be turned of, with the inlet and outlet grilles sealed. Fire dampers and ventilatien lowers should be

closed. Drainage trans must contan water Or be temporally sealed

23 Allexternal envelope elements of the building shall be assessed for leakage, Elements included in

the bulging envelope such as: roofing sytem (eg roof sheeting), waling system fe. curtain wallng,

wall panels, block work and service penetrations and vapour bares) wil be tested agnnet he equired

= Soa Rar

ers Development land Dub UAE Aveo.

iso gran

: Meta sstoment fo: one 22102018

ds | fig tvtope a hres esting test fn

Ural dl cus | Sar Sicn Stang Kegon Spectcatone— ete

eG OUTOG BeBion Sos: A ante

performance standard, Any intentional opening inthe building envelope shall be lose or sealed

General observations of the condition af the ullding wil be recorded including nates onthe windows,

doors, opaque wal, roof and floor, postion of adjustable openings and any temporary sealing applied

telintentional openings.

2.4 Unfinished Future Tenant Spaces. Retall and FB spaces that are tobe completed by the tenant after

‘the main building handover wil typically not be aright a the time ofthe building ar ghtness tes. This

Is primarily due to the standard contractual condition for leased sub spaces within a larger building

which requie:

~ Main ar conditioned ar distribution is supplied to the bulding commor spaces ofthe

‘etal and F&B tenant complexes ony; A/C equipment and distribution witin the spaces sto be

completed by the tenant aftr building handover. Thus unfinished tenant spaces wil leak li at

the time ofthe whole building testing and will ned to be temporary sealed

‘Many final finishing materials tobe supplied and Installed bythe tenant ster building hand

‘over, Uninsalled finishes suchas flooring and entrance framing or vestibule typically wl affect

the artightnes of the tenant space atthe time of whole bulding testing. for example, service

and entrance doors wll be undercut higher to allo forthe ial finished for level

‘The proper procedures fr the preparation of unfinished spaces is outined in ATTMA Technical Standard

2 "Measuring air Permeability of Buléing Envelopes (Non —Dwellings!” and CIBSE Technical Manual 23

“Testing Buildings for Air Leokage" Unfinished oF uninstalled ems such as final doors and open afe

vents are to be iemperarly sealed for the whole building test. In bref, once areae that requis

‘temporary sealing ae identified, G3S| would require AFC to carey out the temperary sealing under the

{GBSIs supervision. Testing and certification ofthe adequacy ofthe temporary sealing shall be the fll

responsibilty 0 GBS as the independent testing authority

2.5 Connect the air moving equipment tothe building envelope using a window, coor, or vent opening.

Ensure thatthe oits between the equipment and the building are sealed to eliminate any leakage.

2. Pressure measuring devices The indoor/outdoor pressure difference shal be measured atthe

lowest floor level ofthe buléing envelope under consideration, Ensure that Interlr and exterior

Dressure drops are not influenced by the ar moving equipment. The exterior pressure tap should be

protected from the effects of dynamic pressure. n windy conditions iis good practice to place the

tentrior pressure tap some aetance aay fram the bulidng but not close to other obstacles. It shall be

avoided thatthe tubing is exposed to large temperature diferences (eg. due to the sun,

—

—

fe Ein DevlpmentJOR snd Dubs UAE Ae an

Method Statement for Date 2210-2006

{pil alldas | Baling Ervtone ir Tghnes Testing — Issue: _Jtew0

‘Dubai Green Building Regulations & Specifications ~ Page SoF0

GHEVBIING SOUT) Secon Sor o8: Air Leakage

30 TEST APPARATUS AND INSTRUMENTATION

3.1 The folowing isa general description of the required apparatus. Any arangenent of equipment

sing the same principles and capable of performing the test procedure within the allowable tolerances

shall be permitted.

3.2 Ale Moving Equipment—Fan, blower, HVAC alr movement component or blower door assembly that

Is capable of moving ar into and out ofthe conditioned space a requlred flow rates (at bath positive

and negative pressurization) under a range of test pressure ifferences. The syst shall provide

constant airflow at each incremental pressure diference at fited pressure forthe period required to

obtain readings of airflow rate

3.3 Pressure-Measurng Device—Manometer or pressure Indicator to measure pressure difference wth

fan Instrument capable of measuring pressure citferences with an accuracy of: 2Painthe range of OP

1060?

53.4 Alrlow Measuring System—Device to measure arflow with an accuracy of 47 % of the measured

flow. The arlow measuring system shall be recently calibrate.

2.5 Temperature-Measuring Device—Instrument to measure temperature with an accuracy of #1 K3.6

Corrections for air density , in kg/ma, ata temperature, barometric pressure nPa, andthe relative

!humity expressed in % wl be obtained as pr the formula contained in Annex 3 of the EN 13823

protocol

AODATA ANALYSIS AND REPORTS.

44.1 The survey report wil provide the attested test results for the CIBSE TM23 - “Testing of

Duilaings for air leakage” Standard. Test Method for Oetermining Air Letkage Rate by Fan

Pressurzation data results for each bulding tested and willbe supplementec with photographie

Images 35 required. The epor: willbe submitted in POF digtal form,

4.2. ACIBSE 123 - "Testing of bulldings for ar leokage” and Standard Test Metro for Determining

Air Leakage Rate by Fan Pressurization Report wil include the folowing information:

2) All details necessary to identity the object tested: purpose of test; building adess and

Estimated date of construction ofthe bul

b) reference to this standard and any deviation from i

Test objet

Description of which parts ofthe bulding were subject to the test

= Surface area and internal volume of space subject tothe test and other required dimensions ofthe

‘ulin;

‘Documentation of calculations sa thatthe stated results can be verfed;

+The status of ll opeings on the bulding envelope, latched, sealed, open, et.

Docoment Namba

ALEC“ 086-002

SOL 220-1

* Issue: 1 _/Rev: 0

pal al

hi tad ina Sam shane so Sosy Page bat

Detaled description of temporarily sealed openings, if any;

The ype of heating, ventilating and ae conditioning system;

1) Apparatus and procedure:

Equipment and technique employed

Test data

+ zeroslow pressure differences 0p0,1*, 0p0,1-, DpO.2+ , Dp0,2-, DpO. and £02 for pressureation

and / oF depressurization test

inside and ouside temperatures

wind speed, barometric pressure iit is part ofthe eaculation;

+ Table of induced presurediferences and corresponding airflow rates

Air leakage raph;

= The airflow coefclent, the airflow exponent, and the ar leakage coeficent, fer both

pressurization and / or depressuriztion tests determined by the method indisted in along with ther

eonfidenc mits

ar change rate, nS0 at 50a, for pressurization and/or depressurization and men vale;

derived quantity according to national egulation;

Date of test

48) Building description, including location and elevation {above mean sea level in meters)

4) Construction, Including date bul, floor areas for canltioned space, and velumes for conditioned

spaces.

|) Condition of openings in building envelope Including: Doors, closed, lacked or unlocked; windows,

‘closed, latched or unatched; ventilation openings dampers closed or open ane a statement whether

the test zone i iterconnected with at least door sized openings to other units. A synopsis ofthe HVAC

system;

1) A description ofthe testing procedure, including the test equipment used manufacturer, model, serial,

umber), and calibration record ofall measuring equipment

) Measurement dat, including: Fan pressurization measurements (inside-outide2er0 flow bullding

pressure differences); nse and outside temperature (t start and end of test) and the product ofthe

absolute value of the indoor/outdoor air temperature diference multiple by the building height;

tabular list of all air leakage measurements and calculations: time, bullding eressure diflerence ar

density, nominal airflow rate, fan allow rate, and ait leakage rate; and any deviations from standard

procedure.

|) Wind speed/direction measured on ste, recording the height above the ground at which wind speed

was measured

1m) Caleulations, including the leakage coefficient and pressure exponent for bothpressuriation and de

pressurization aswell asthe effective leakage aeas for pressurization, depressriation, and combined

Project. Docent Ramee

‘Bluewaters Development JBR AEC: 096002.

son 224018

Date 2250-2016

sil lcs it fae

exasinesana es earaceneen etme me

5.0. PRETESTING CONDITIONS AND REQUIREMENTS.

5.1. Bulding Sign-off by the ALEC Quality Engineering Department. ALEC sal supply signed QA/OS

statement tothe effec thatthe building has been constructed in accordance withthe DUBAI GREEN

BUILDING REGULATIONS & SPECIFICATIONS. ands ready for ar ightnes testing.

5.2. Pre-Test Bulling Walk Through with ALEC personnel. Upon receiving the aoove mentioned

buleing eadiness sign-off, GBI will ondct ask walkthrough with ALEC personnel to review existing

conditions and advise on required areas tobe temporally Sealed, ALEC and G8SIto coordinate on

‘timeline of required temporary sealing scope.

5.3.Final walkthrough One Day rior tothe proposed test date, During the final preparation prior to

the day ofthe test, G8! will conduct final survey to very the onsite testing cordtions, All surveys will

‘be conducted nfl co-ordination with ALEC; areas of potential pressure loss that may seriously affect

‘or negate the testing results (if any] wll be noted in the report.

TIME UNE Fo!

Project Decor Nambar

‘Bluowaters Development JBR sland, Dubs, UAE ALEC 096-02.

|i esos

Ps etod Stent for: uae s0 08

us _| ing tone ites Texting ‘uct jo

pil als | pa cn Seng Renton © Srectcatons— rane

ENGIN SOUTONS| Section Stas: A Leakage

{6.0 SAFETY HAZARDS AND CONTOL MEASURES.

6.1 ye Protection—Giass breakage tthe building pressure diferences normally applied to the test

structure is uncommen however, or added safety, adequate precaution, such zs the ure of eye

protection shal be taken to protect the personnel

6.2 Safety Clothing—Use safety equipment required for genera eld work, inclusing safety shoes, and

hard hats

6.3 Equipment Guards—the alrmoving equipment shall have 2 proper guard or cage to house the fen or

blower and to prevent acidental accesso any mouing pats ofthe equipment.

64 Noise Protection—Exposure to the nose level generated by fans canbe hazardous othe hearing of

involved personnel and hearing protection Is required.

{6.5 Debris and Fumes—The blower or fan forces large volume of ar into or outof a building while in

‘operation. Cre shal be exercised to not to damage pants, pets, occupants, internal furnishings due to

Influxof cold or warm ar. Caution shall be exercised against sucking debris or exhaust gazes fom

fireplaces and flues into the interior ofthe bulding. Active combustion devices shall be shutoff or the

safety determined of conducting the test bya propery trained technician before conducting the test

6 During execution ofthe job all measure shall be adopted to ensure safe working. All personnel

Involved wil use necessary PE as required. The workers willbe made aware of safety requirements

related to this activity trough safety induction taining.

6:7 All equipment wil be inspected by GBS! personnel prior to use. Good housekeeping should be

maintained in all wrk areas, Waste Management should be tity flowed to keep the jobsite neat

‘and clean,

Project Docanent Nambe=

Blubwatore Development JBR Island, Dubal, UAE Alec 096902-

ed

Ms (teste —

A Poe See

Ce er um: — Habe

‘Section S01. 05: Ar Leakage

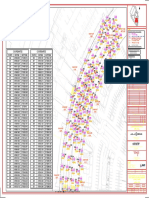

Testing Envelope Description & Fan Placement Diagram

Testing envelope calculations ae based on ATTMIA TECHNICAL STANDARD L2—Saction 3.2.3 8.3.2.4

Envelope Area Caleulation Dimensions are taken from architectural drawings a supplied by LEC,

1

= FA LOCATIONS GROUND FLOOR: TESTING FANLGATENDAGRAE

TTYPICAL TESTING ENVELOPI

Building Cluster 8,Tenent Space HA (1 of 2 Total Retail and F&B Spaces)

FLOOR AREA: 3,555.18m2 TOTAL VOLUME: 20,774.21 m3

‘TOTAL HEIGHT: VARIES ENVELOPE SURFACE AREA: 6,855.86 m3

a

=

GPG Bonetti ot Kicoemr

atnod Statement for Date 22102076

sil lle | Buin rvetope air Tignes esting ‘sse:1_/rer.0

Dubal Green Bulding Regulations & Specesions

| sev sounO) etn Sots: nr enge Page if 10

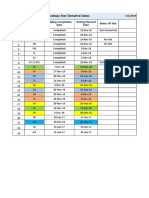

‘Total Test Volumes: Bluewaters Development BR and Buldrg Envelope Testing Regrane

Number of AIR TIGHTNESS TESTS. 6

‘Total Etinated TEST VOLUME 202,608.26 m3

ane ee

enim) | 35045 | 3457 | 39078 | 2652 | 2295 | 200.55

‘we-teoe| so | s00 | soo | soo | soo | soo

Teatvotwe | 7.7528 | 217283 | 69570 | 132560 | 108975) 41275

a 4 as a

ses [re sree [ie = Ea 5A

“hestwa)| 24545 | 7azs? | @2p03 | a1ng0_| 363i | uisa20_| 260.8

Tim. ete | 5.00 00 | so0 | soo | so 5.00

Testvalane | 4,227.30, 3108.18 | isso) 96708 | $6500 | —a.30050

oom] s [aa z

ang | SE mA 3

Tewinah| $8053, 33570_| 227656 | tas93 | ous?

‘eneie| 500 | 500 | 500 | soo | son | 00

Twsivoime | 2.95465 | 58680] 1e7as0 | 1114450 | Geeaes | 240728

aur) 3

‘ane | EBL s

hes) 7875.48 3385.16 | 612574 | saa?

Fo Hehe $00 500 | wares | 500 | 5.00

Tetvoune 3737720 woyraai | Sosre70 | 013.38

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Drainage Lay Out: Coordinates CoordinatesDocument1 pageDrainage Lay Out: Coordinates CoordinatesromahiNo ratings yet

- TerrazzoDocument5 pagesTerrazzoromahiNo ratings yet

- 6004 0100 ALE 0000 SH 0004 Up Dated Preferred Subcontractor List (04!02!15)Document23 pages6004 0100 ALE 0000 SH 0004 Up Dated Preferred Subcontractor List (04!02!15)romahi0% (1)

- Air Envelop Test Tracker As Per 01-05-2018Document2 pagesAir Envelop Test Tracker As Per 01-05-2018romahiNo ratings yet

- Form WorkDocument38 pagesForm WorkromahiNo ratings yet

- (IRS-GC-503-2017-106) Response Closing - Out of Pending Items at Roof LevelDocument2 pages(IRS-GC-503-2017-106) Response Closing - Out of Pending Items at Roof LevelromahiNo ratings yet

- Louvers Against The Elements - A Winnable Fight!Document77 pagesLouvers Against The Elements - A Winnable Fight!romahiNo ratings yet

- Cover LetterDocument1 pageCover LetterromahiNo ratings yet

- Item Document Reference Date Issued Details of Design Outstanding Trades AffectedDocument1 pageItem Document Reference Date Issued Details of Design Outstanding Trades AffectedromahiNo ratings yet

- Mohamed Aslam: Professional SummaryDocument2 pagesMohamed Aslam: Professional SummaryromahiNo ratings yet

- Planning, Pre Preplanning, Designing, ExecutionDocument3 pagesPlanning, Pre Preplanning, Designing, ExecutionromahiNo ratings yet

- Alec Response:: Cost's Can Be Discussed and Agreed As Part of The Final Account and Disruption Claim NegotiationsDocument3 pagesAlec Response:: Cost's Can Be Discussed and Agreed As Part of The Final Account and Disruption Claim NegotiationsromahiNo ratings yet

- Roof Issues Contraints List: 3/20/2018 S.No Building Zone Area Issues RemarksDocument2 pagesRoof Issues Contraints List: 3/20/2018 S.No Building Zone Area Issues RemarksromahiNo ratings yet

- Zone 11 - Programme To CompletionDocument1 pageZone 11 - Programme To CompletionromahiNo ratings yet

- Architectural Inspection Status Summary of 05-11-2016Document2 pagesArchitectural Inspection Status Summary of 05-11-2016romahiNo ratings yet

- Test Results & Reports SubmittalDocument1 pageTest Results & Reports SubmittalromahiNo ratings yet