Professional Documents

Culture Documents

UK Blastopak

Uploaded by

hansegvCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UK Blastopak

Uploaded by

hansegvCopyright:

Available Formats

P ro d u c t s

D i v i

si o

Parker Blastopak

se

n

r H

DIN EN

Eu

Parke

ro p e

New Hose Range for

1829-2

Water-Blasting Applications

APPROVED

y

Be

fet

st

Sa

er

P

fo

rma i gh

nce & H

Choose the improved

performance of

Parker Blastopak Hose

Parker’s Blastopak range BPK-XX is

the new offer of hoses with four

or six spirals that better meets the

requirements of water-jetting and

blasting applications.

High-pressure water-blasting hoses

are widely used for many industrial

applications like water cutting, cleaning

and removal of corrosion or paint

or other kinds of materials.

In water-blasting applications, ultra-high

pressure systems are commonly used,

where the safety and robustness of a

product are essential.

Parker’s range of Blastopak hoses is

the ideal solution for these kinds of

applications.

With its high working pressure from

800 bar (80 MPa) in size -16 up to

Contact Information: Product Features:

1100 bar (110 MPa) in size -4 to -12, • Size -4 to -16

good flexibility combined with dedicated

Contact your local

Parker Sales Company • Reinforcement of

interlock fittings is the right choice to four (size -4, -6, -8) or

ensure better performance and safety six (size -12, -16) spirals of

at the same time. www.parker.com

highly tensile steel wire

Safety factor burst/working pressure

• Working pressure

of 2.5:1; the product meets the

1100 bar (110 MPa), except

requirements of global specification

size -16, 800 bar (80 MPa)

DIN EN 1829/2 (impulse) in all

• Safety factor 2.5 : 1

common hydraulic applications.

• Meets the DIN EN 1829-2

specifications

• Also available in fixed

lengths of 20 and 40 m

• Interlock technology

fittings series WB

BPK

Blastopak ParLock Multispiral

DIN EN 1829-2

• Interlock technology

• Reinforcement of four or six

spirals of highly tensile steel wire

Primary Applications • DIN EN 1829-2

Water blasting applications, water cutting applications,

cleaning and paint or corrosion removal.

Not recommended for dynamic hydraulic applications

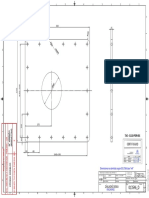

Construction

Tube: Synthetic rubber

Reinforcement: Four or six spirals of highly tensile steel wire Applicable Specifications

Cover: Synthetic rubber DIN EN 1829-2

Continuous Service Temperature Range Recommended Fluids

-10 °C up to +70 °C Water, water-soap emulsion

Max. Service Temperature Range Fitting Series

-40 °C up to +93 °C Internal and external skiving WB

Pressure Rating

max. min.

Part Number Hose Hose working burst min. bend

weight

I.D. O.D. pressure pressure radius

R50TC_R56TC

DNDN Zoll

Inch size

Size mm

mm OD

mm MPa1

MPa psi1

psi MPa2

MPa psi2

psi Bend

mm weight

kg

<tab>Hose

BPK-4 6 1/4 4 6.4 17.6 110.0 15900 275.0 39800 100 0.64

BPK-6 10 3/8 6 9.5 21.8 110.0 15900 275.0 39800 130 1.10

BPK-8 12 1/2 8 12.7 25.5 110.0 15900 275.0 39800 200 1.40

BPK-12 20 3/4 12 19.1 35.2 110.0 15900 275.0 39800 250 2.50

BPK-16 25 1 16 25.4 41.8 80.0 11600 200.0 29000 300 3.00

Hose layline example

BPK-12 WP 1100 bar (16000 psi)

The correct crimp specification

online and always up to date

at the push of a button!

www.parker.com/crimpsource-euro Bulletin BUL/4480-B168/UK 2015-02

punctum

You might also like

- Tesla Katalóg 5 - Elektronické Součástky 1989 - Tesla Eltos (1989, CZ, Scanned by Elped)Document880 pagesTesla Katalóg 5 - Elektronické Součástky 1989 - Tesla Eltos (1989, CZ, Scanned by Elped)Ladislav KolorosNo ratings yet

- Magnetofony III (1976 - 1981) - Bozděch, Josef (1987, CZ) - ElpedDocument287 pagesMagnetofony III (1976 - 1981) - Bozděch, Josef (1987, CZ) - ElpedLadislav KolorosNo ratings yet

- Vodice Kabely Krimpovani Naradi Katalog 2015-WebDocument204 pagesVodice Kabely Krimpovani Naradi Katalog 2015-Webv.kotekNo ratings yet

- Wingroot Gun Bays - 648356Document4 pagesWingroot Gun Bays - 648356fooNo ratings yet

- Kingspan Konstrukcni Detaily 06 CZDocument52 pagesKingspan Konstrukcni Detaily 06 CZbarta2tomasNo ratings yet

- Sonocontrol 14 Flyer SonotecDocument2 pagesSonocontrol 14 Flyer SonotecHygor ViegasNo ratings yet

- Part 2Document4 pagesPart 2Pablo GiraudoNo ratings yet

- Knauf Protupozarne-Obujmice WebDocument20 pagesKnauf Protupozarne-Obujmice WebMiroslav LuladžićNo ratings yet

- Prirucka FinalDocument32 pagesPrirucka FinalMartinNo ratings yet

- Bosal Canbus Vonohorog Visszajelzo Szerelesi UtmutatoDocument5 pagesBosal Canbus Vonohorog Visszajelzo Szerelesi Utmutatokoaa85No ratings yet

- VL FoundationDocument1 pageVL FoundationNicoleta DobreNo ratings yet

- TLG 1000 B3 Nabíječka PDFDocument2 pagesTLG 1000 B3 Nabíječka PDFJurik_JanNo ratings yet

- St.1007a, Ti.1401d, Ti.4201c, Ph.1003a, Střecha, Okraj, Povlak PVC-P, Okap, Stěna, Etics, Římsa, 2022-12Document1 pageSt.1007a, Ti.1401d, Ti.4201c, Ph.1003a, Střecha, Okraj, Povlak PVC-P, Okap, Stěna, Etics, Římsa, 2022-12pitr134No ratings yet

- VT510 Text CZDocument1 pageVT510 Text CZNicoleta DobreNo ratings yet

- Pegas 160 e Servisni Manual - Service Manual mg001 - 03.wt2cqDocument10 pagesPegas 160 e Servisni Manual - Service Manual mg001 - 03.wt2cqcd10dcNo ratings yet

- Schneider Socket CatalogueDocument2 pagesSchneider Socket CatalogueVinzoKeiNo ratings yet

- ADMAG SE Magnetický Indukčný PrietokomerDocument2 pagesADMAG SE Magnetický Indukčný Prietokomerslecka2658No ratings yet

- Katalog Komponentu ESTADocument29 pagesKatalog Komponentu ESTALelkesBNo ratings yet

- Manual RFSG 1mDocument2 pagesManual RFSG 1makvod87No ratings yet

- Novy Katalog Krbova Kamna RomotopDocument31 pagesNovy Katalog Krbova Kamna RomotopJirkaLáníkNo ratings yet

- A13M429-THYSSEN-PME004-004 - Rev. 2Document1 pageA13M429-THYSSEN-PME004-004 - Rev. 2Jose Carlos Moraga LópezNo ratings yet

- ART361 Text CZDocument1 pageART361 Text CZNicoleta DobreNo ratings yet

- 321 600 300 153 ZGB 3T2 054 204 VW Universal RHD Audi A1 RHD, Audi A1 Sportback RHDDocument64 pages321 600 300 153 ZGB 3T2 054 204 VW Universal RHD Audi A1 RHD, Audi A1 Sportback RHDmattprcsoportNo ratings yet

- Zvaracky TIGDocument7 pagesZvaracky TIGlincolnelectricNo ratings yet

- Ebro Gasabsperrklappe Technisches Datenblatt - CZDocument6 pagesEbro Gasabsperrklappe Technisches Datenblatt - CZOto ŠabíkNo ratings yet

- Vovedni Informacii Za InstalaciiDocument77 pagesVovedni Informacii Za InstalaciiStefanija ManevaNo ratings yet

- Střešní Samovrtné Šrouby Dabo® - Povrchová Úprava ClimadurDocument5 pagesStřešní Samovrtné Šrouby Dabo® - Povrchová Úprava ClimadurJan DvořákNo ratings yet

- Transformador ZT931 - CZDocument2 pagesTransformador ZT931 - CZfrank torresNo ratings yet

- Linky Dalkove DopravyDocument1 pageLinky Dalkove DopravyVojta HojgrNo ratings yet

- F-16CJ - AGM-88 HARM Resine EduardDocument2 pagesF-16CJ - AGM-88 HARM Resine EduardfooNo ratings yet

- Tds Izolmat Plan Pye g200 s40 CZDocument3 pagesTds Izolmat Plan Pye g200 s40 CZMark SmithNo ratings yet

- Křížový Dipól 137 MHZDocument2 pagesKřížový Dipól 137 MHZVladimir MullerNo ratings yet

- Audio Spectrum Analyzer PT041 (2016)Document4 pagesAudio Spectrum Analyzer PT041 (2016)Iliescu CristianNo ratings yet

- Zpracovani OtazekDocument59 pagesZpracovani OtazeknamNo ratings yet

- Kabelova Oka - GPHDocument199 pagesKabelova Oka - GPHPVFS PVFSNo ratings yet

- Otázky 41 50 MKADocument9 pagesOtázky 41 50 MKAKhoaNo ratings yet

- SOLARDocument1 pageSOLARJan JíchaNo ratings yet

- 23 KalnikDocument1 page23 KalnikPeter ŠtefánekNo ratings yet

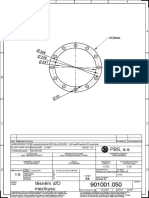

- Těsnění Malé PřírubyDocument1 pageTěsnění Malé PřírubyPetr JanataNo ratings yet

- Radioamatér 1/05Document1 pageRadioamatér 1/05Jorge MarinNo ratings yet

- ART360-361 FoundationDocument1 pageART360-361 FoundationNicoleta DobreNo ratings yet

- 23169G-S19A - Gate A - 4,8x2,5-partial-REV01Document1 page23169G-S19A - Gate A - 4,8x2,5-partial-REV01Steven ChenNo ratings yet

- Navod K Obsluze Nado v11Document10 pagesNavod K Obsluze Nado v11Petr DvořákNo ratings yet

- 1-48 BF 110 C-D Main Undercarriage WheelsDocument2 pages1-48 BF 110 C-D Main Undercarriage WheelsDoru SicoeNo ratings yet

- Asplan FTTH Vinewood BabelanDocument1 pageAsplan FTTH Vinewood BabelanGiga Primerindra SiraitNo ratings yet

- Verlegeanleitung PREFALZ. ObsahDocument22 pagesVerlegeanleitung PREFALZ. ObsahMatjaž FerencNo ratings yet

- QE MP2RS G8 Module Connection InstructionDocument2 pagesQE MP2RS G8 Module Connection InstructionNémeth TamásNo ratings yet

- Catálogo MKZ SamotkaDocument26 pagesCatálogo MKZ SamotkaLuís CamposNo ratings yet

- Prakticka Elektronika 2001-09Document47 pagesPrakticka Elektronika 2001-09sq9nipNo ratings yet

- Pi200 NG600 CsDocument8 pagesPi200 NG600 CsgabrieldarochaaNo ratings yet

- Katalog PREHLEDOVY 2023 Online VerzeDocument66 pagesKatalog PREHLEDOVY 2023 Online VerzeVáclav KrálNo ratings yet

- Expanzni-Nadoby Prospekt CZDocument2 pagesExpanzni-Nadoby Prospekt CZDavid KolarNo ratings yet

- JSK4260-050 A4 SCHDocument3 pagesJSK4260-050 A4 SCHcheteubaNo ratings yet

- Ba Manual OktoberDocument7 pagesBa Manual OktoberAzka FebiolaNo ratings yet

- Přehled Provedení: Opvp10 Opvp14 Opvp22 OPT22/OPT20 OPVF10Document10 pagesPřehled Provedení: Opvp10 Opvp14 Opvp22 OPT22/OPT20 OPVF10Marek DužíNo ratings yet

- Danfoss 1992Document5 pagesDanfoss 1992Pavel RybkaNo ratings yet

- 1-48 Tempest Mk. V Gun Bays EduardDocument4 pages1-48 Tempest Mk. V Gun Bays EduardDoru SicoeNo ratings yet