Professional Documents

Culture Documents

Ctig PDF

Ctig PDF

Uploaded by

Pandrayar Maruthu0 ratings0% found this document useful (0 votes)

588 views19 pagesOriginal Title

CTIG.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

588 views19 pagesCtig PDF

Ctig PDF

Uploaded by

Pandrayar MaruthuCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 19

——————— tsi

LOCAL BREAKER

BACK-UP

RELAY TYPE CTIG

Commissioning

Instructions

Vv.

GEC ALSTHOM

——

INDIA

COMMISSIONING INSTRUCTIONS

FOR

LOCAL BREAKER BACK-UP RELAY TYPE

CTIG

COMMISSIONING INSTRUCTIONS

FOR

LOCAL BREAKER BACK-UP RELAY TYPE

CTIG

4. APPLICATION:

To safeguard ogainst the crastie Consequences of fallure to cleat faults rapidly,

mony powor supply cuthorties install two Indopencant systoms of protaction for

Major transmission lines, The'e remains however the possibly of the circult breckar

Iself falling to operate cnd this hazord Is traxillonally covered by remote breaker

backup.

Recent trends show a lean towards local breaker back-up and for this reason a

new relay, the Englbh Electric’ CTIG hos been developed with characierlslics

Particulatly suited to this application.

‘A simple arrangement of local breaker back-up, Is shown In Fig. To clear a fault

ot F, the pilmary protection tips breaker A. If this brecker falls the fault effectively

becomes « busbar faull and cll Infeed breakers B.C.0 & E cre tripped, simutancously

by the breaker backup fo [solale the busbar. This is effected by using on

Instontoneous overcurrent relay and a timer os shown in Fig.2 with local backup,

‘the fault Is cleared ropidty,

Foult clearance time (bock:up) = Protective relay operating time + Breakers B - E

tip fime.

Complete lsolation of a busbar is a somewhat draslle measure. Its therefore mest

Imporiont thet the backup does not opercte unnecessailly and the time delay

must be set occorinayy.

Time delay = Breaker A trip time +

OIC relay reset time +

Safely Margin.

To give optimum performance the desirable charactatisics of the overcurrent relay

oe: |

4. Consistent fast reset |

2. Conslstent high accuocy |

3. Low burden (uses main protection curent transformers). |

The CIIG Is a three phase or two phase and earthtault Instantaneous overcurent

relay which embodies these cheractoristics.

2. OPERATION: |

The type CGS? relay Is a three phase of two phase and ecrthfoult instantonsous

evercurent unit Intended for use with @ time delay unit 1o glve back-up protection

In the event of a clrcuil broaker failure, A particular fealure of the CNG relay Is a

{ast revel which enables the time deicy to be sat closer to the broaker tiip-time,

The principle of operation of the relay Is thal of peak-curtant measurement os

shown In Fig.3. Stolic clreulty is used fo give accurate and consistent performance,

extremely low burciens and compact dimensions. i

3. TECHNICAL DATA:

3.1 Curent settings - continuousy ocjustable on each phase between 20%

‘ond $20% of 1 oF 5 amps. 50 He. or 60 Hz. rated currant (CT secondary).

The relay will withstand twice raled curent continuously and 100 times

rated current for 4 second.

3.2 A.C. Burdens

A$ sotting curent |

Raled Tap setting Mutiplicr setting At rated

current * x current

maximum

et

19 20% 004 VA OLVA G6 VA

160% 0.07 VA 0.35 VA 0.04 VA

50 20% O05 VA O/6VA AVA,

160% O3VA 140A 0.08 VA

33

3.4

3.5

3.6

37

38

Operating Time:

At twice setting current

Typleal - 45 millseconds

Maximum = 20 milliseconds

Reset Time:

When the current Is reduced from twice setting value to zero Instan-

taneously

Typical : 45 milliseconds

Maximum = 20 milliseconds

Accuracy:

410% of current setting, for any fault condition, Tho relay Is callbrated at

20°C and 50 oF 60 He. The accuracy figure given applies for c temperalre

vatlation of -5°C lo +40°C ond frequency variation of -6% lo +2%.

Auxillary supply:

Stondlar nominal vottage $0, 440, 125 and 220 valts de,

D.C. Burden:

‘Maximum Burdon Watts

Nominal votts Continuous ‘Operated

30, 02 44

40 42 25

925 23 29

220 40 5.0

Contacts:

Two pois of elechically separate normally open self reset contacts.

Insulation:

The relay will wilhsiand 25 kV 50 Hz. for 1 second betveen all clrculls

‘ond metal ports of the case ond between all electically separate circuits.

It wil also withstand 4.25 KV 50 Hz, for 4 second between open contacts.

4.

The relay will withstand 5 kV Impulse vollage test In accordance with IEC.

recommendation.

3.9 Case:

The relay I cuppllod In a ske (drawoul) core avaliable for flush oF

projection mounting and finished phenolic black as slancard,

INSTALLATION:

4.1 Location:

Tho location should be dry, clean, tree trem dust and. excessive vibrations

‘and reasonably well illuminated fo faclitats Inspection.

4.2 Mounting:

The telay case should be mounted In a vertical panel surtace (within +89)

30 that the unt Is prectically heslzontaa,

COMMISSIONING:

The following tesls are recommended for the Initial commissioning of CTIG39 relays.

54

1) General Inspection

li) Wiring checks

ii) Current trenstomner checks

My Insulation Teste

¥) Operational Tests

vi) Tip and clorm circulls check

General Inspection:

Wipe away any dust tha! hes collected on the outside of the relay bofo1e

‘opening the cover. Make a general inspection of the relay fo ensure thal

al moving pats are free to move and that there are ne signa of damage

‘anywhere, Check that there are no loose connections of termincls and

thot the equipment Is clean and free from dus Genera! Inspection Is

Rommelly camled out affer disconnecting the tipping suppy.

52

53

5.3.1.

5.3.2

Wiring Checks:

Moke 0 thorough check for thé Intemal ond extemal witing of the relay,

The Internal witing can be checked by teference fo the rely wking

lagram which Is supplied for each relay. The extemal witing should bo

checked with the help ef schematic dlagrams (showing reference number

of Inferconnecting wires, tolay teminal Nes. etc) supplied by the rolay

Pane! manufactures.

.T. Checks:

Polarity and ratio checks cn each current transformer are recommended,

Polarity Check:

Each current transformer should be individually tested to verity that the

pokally markings on the pmary and secondary windings are correct.

Fig.’ leales the test clrcult for this test. The emmeter ‘A’ Is a robust,

‘movi 1g coll, peimcnent megnel, Cente Ze10 type Instrument, A low

vollage bollay Is ued Via a single pole push bullen fo onorglio the

pilmary winding. On closing the push button, ine DC ammeter ‘A’ should

Indicate a positive fick and’ on opening, a negative lick.

I. Polarity check can also be camied cut by using primary Infection tes!

set mentioned in 5.3.2 below. Since CTIG39 relay is used as a backup

relay fo! the primary protective relays similar checks cariled out for the

primary relays should ba odaquate for this relay as well.

Ratio Check:

THs check |= camied cut during primary injection tests, The test apparatus

normally comprses a portable injection transiccmer arranged to operate

from the local mains supply and having several low vollage heavy curent

wingings which may be connected In series or parallel depending on

the current requited ond tessiance of the primary clicull. The Injection

transtormer is usually of chout 40 kve rating with a typical ratio of 250/10

+10 + 10 + 19 volts This permits cuents upto about 1609 ams. to be

obtained with the four secondary windings in parallel and upto about

250 amperes with the windings In serles. The Inieciion transformer current

can be controlled by a heey curent [about 40 omps) vorlable

‘qulo-transformer as shown In Fig.

If the main curent transformers cre fitted with test windings, thesa ean

be used In place of the primary windings for primary injecticn tests The

current required for pilmary Injection js then greatly reduced and can be

obicinad from less cumbersome equipment. However, these test windings

{aie net always provided on the current transfoimers due to space limitallan

foctor.

For conrying out the ratio check on current transformers, the test ctreult

shown In Fig6 Is used. Current Is pasted through the primary conductors

‘and measured on the test ammeter Al. The current transformer sacondary

current Is meosured on ammeter A2 and the rallo AA2 should

‘approximate to the ratio marked on the current transformer nameplate.

5.4 INSULATION TEST:

ksolate whing trom earth. Bind all relay terminals together and measure

the Insulation resislones to earth with 1000 V meggor, Recomect all wiring

according fo the schematic diagram. it Is especialy Impertant that the

dec. supplies are wired with conect polarity.

OPERATIONAL TESTS:

To check the eccuracy of the relay curent settings, It's necessary to camry

Out secondary injection tests on the relay using curent of sinuoldal

waveform within practical limits. “English Electric” portoble test equipment,

type CFB. which Is described in detail In the publication M/381I Is specially

designed for carrying out these tests,

5.5.1 With ihe equipment connected as shown In Fig? with appropiate de.

ousllary supply, check, by gradually increasing the curten, that the pick

Up CUMent of the Ielcy Is within 40% of the setting values - for plug

settings of 20%, 40%, 80% and 160% ond current multiplier pelentiomoter

soltings ranging from 4 fo 2,

5.5.2 Sinilaily check that the diop off curient of the relay at these setfings to

be approximately 95% of the pick-up values of curren!,

5.5.3 The operating fime of the relay can be ascerlcined at twice the selling

Current value ond this shall be less than 20 milliseconds,

554

5.6

Check for sctisfactory operation of the relay over the range of 60% to

430% of nominel vollage of the auxillary supply. Care should be taken In

‘extending the corect polarity of the dc. supply to the relay terminals,

TRIP AND ALARM CIRCUIT CHECKS:

During electical tests, the trlp ond alarm circults are usually renderod,

Inoperatve by removal of fsolating links, relay trip latches ete. It Is nus

erseniic! that on completion of theye fest, the tripping, Inter-rieping and

olorm clrcults are checked.

Close the teley conlacts by hand offer restoring all the links and latches

{o their original position and check that the correc! saquence of events

Is Inlilated ond the right alarm comes on,

6. MAINTENANCE:

G4

Inspection:

Drawout Case

To Inspect the telay, loosen the cover nuls and remove the cover. Rotate

the latches which then provide finger holes for withdrawing the relay

chassis, The action of rotating the latches operates a swilch which alates

the trip elrcuits

Dust Filter:

Dust fliers should be examined ot lecst once in a year. If necessary the

fitor element should be clecned cs follows:

Remove the filler unit fora the rolcy case, Remove tha while/block nylon

filer element, Wash tne element In detergent, rinse ond diy. Dip Ihe

element in light machine oll and shake olf excess oll. Replace the ter

urit in the reley case.

ATTRACTED ARMATURE UNIT:

the allracled aimolure relays are very simple and robust and rerely go

wrong, Unless the relay Is not operating corectly or damage hes occured,

It should be left undisturbed.

Hecttical tests can be cented out ence a yecr, if desired, to veilfy that

the relay operctes satisfactorily and that the pick-up Is within the specified

tolerance.

Contact should be examined fo ensure that they are clean, I it &

necessary fo clean them a bumishing tool should be Used. It Is most |

Important that fles or abrasive materials are NOT used for cleaning }

contocts.

It the contacts are badly damaged, elther relum the relay to the factory

‘of replace the contacts and process as set oul in “Mechanical Settings’.

Mechanical Settings:

‘Atacted armature units will pot function comectly unless contac! pressures,

ermature gops ae, ave within tha manufacturing tolerances. These settings

will not change during normal use and It Is not necessary to make any

routine checks on them, However, if parts have bean replaced or repaired

the settings must be readjusted.

Contacts:

When replacing contacts thoy should be bent slightly adjacent to the

Insulating blocks, so thet they exert a pressure on the push-tods or support

arms.

Bofore commencing with the seltings ensure that

The amature platform Is level

The bottom contacts are siting on the push-rod shoulders

The push-rods are vertical

The contact figs are level when viewed from the front.

With O010" feeler guage between the armature and coreface close

the amature by exerting pressure above the centra line of the coreface.

‘Adjust the top contact cnd support z9 that the conlocls, Just touch, This

ives @ follow through of 0.020",

Set the contact gap to 0.45410.050" by adjusting the armature stop.

Using a gramme guage, check that the fixed contact ifts eff Its support

when a pressure of 20/25 grammes ls exertad and that the bottom contact

touches the lop contoct when a pressure of 20/30 grammes ts applied,

Tho prestures should be token with the arm of the guage placed under

the tigs of the contact Any adjustment Is obtained by Increasing or

decreasing the bend out Into the contact at the start of the sotting

procedure. Check ail sellings.

Operation Indicator:

The shlold must be perfectly fice to drop when the contacls are about

to touch or Jus! before they fouch, but naver after. This enables that the

contacts do not close without the operation indicator boing displayed.

Agjusiment Is made by bending the spring calch, which locates In a

notch In the amature.

Contacts:

Two palis of normally open self reset contacls are filled and rated as

follows:

Moke ond cony Moke and camy

‘continuously for 3 seconds Break

ac. 1250 VA with maxima 7600 VA with maxima 4250 VA with maxima

of Somps.and of S0.ampr.and of 5. amps. and

660 volts 660 volts 600 vals.

de. 1250 watts with 7900 watts with 100 watts (esistive)

mexima mexima 50 waits fincuctive}

‘of 5 amps. ond of 30. amps. and with mesima of 5 amps

660 vols 660 vals cand 660 volts

Note: the static circulty s so designed that these rarely go wrong. and unles:

Ine relay Is not opercting correctly or damage has occurred these should

be left undisturbed.

Fig,

e

TRIP CIRCUS 0.

oh ke

nbs

a

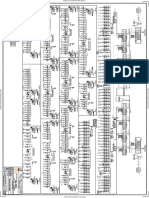

staTHC ciRcuiTs:

Pes 3a

MULT. -Por TAP SETTING

Fig.-2 Simplified Internat and External Connection

Disgeam

te iNeut

on ‘i 2

2 |» lpruase anioce| | [curnenr re

Fig.-3 Block Diagram |

a |

as0¥

= | ‘=

=e

CURRENT TRANSFORMER

is

o

Ta ciahon \|_4

jecimes WL,

IMIECTION TRANSFORMER

20/0418 ym yi0v, 1ORVA

Fig.-5 Primary injection Test Set

TEMPORARY.

‘Som emcur Ls —Y¥

RELAY on rest Block

CONTACT FINGERS

RimaRy insecrion|

rest set

das

Fig. -6 Current Transtormer Radio Check

auaen optnarine

cowatrs Contacts

- a 4. : { : 4 ; ee Wu

eee Gis)

Cae kee eeu

ts

i

RELAY CASE_ORAW CUT

conracr rineces,

22) Pot

1S SORT EE Oveu seme

Fig.-7 Connections for Testing CTIG Relays In

Drawout Cases Using English Electic

Overcurrent Test Equiamert Type CFB

Measurement & Control Division

GEG ALSTIIOM INDIA UMITED, olovaram Works: 1911, GST Road, Macros - 600 O43 Tel: 402624, Tx 26056/26096, Fax: 044-2007276

TeRLove-ca'95,

Regional offices: © Bombay © Caicuia = Macros © New Deh

Braneh Ofticos # Aimmedabad —@ Bangalore Shubaneswer# Chondigerh —# frnckulor |

Guwahati soour # fenour © Lusanow

© Nout @ocira 1 Secunderabad

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Shift SH Engr MAYDocument1 pageShift SH Engr MAYAnonymous vcadX45TD7No ratings yet

- 33 KV Multifunc Meter - 33KV SBDocument2 pages33 KV Multifunc Meter - 33KV SBAnonymous vcadX45TD7No ratings yet

- Transformer Efficiency and Regulation CalculationDocument1 pageTransformer Efficiency and Regulation CalculationAnonymous vcadX45TD7No ratings yet

- To Whom So Ever It May ConcernDocument2 pagesTo Whom So Ever It May ConcernAnonymous vcadX45TD7No ratings yet

- TBEAEI Vendor List For CustomersDocument4 pagesTBEAEI Vendor List For CustomersAnonymous vcadX45TD7No ratings yet

- Balance Items of TowerDocument2 pagesBalance Items of TowerAnonymous vcadX45TD7No ratings yet

- Checklist IslandingDocument2 pagesChecklist IslandingAnonymous vcadX45TD7No ratings yet

- SMS SLDDocument1 pageSMS SLDAnonymous vcadX45TD7No ratings yet

- Commissioning Certificate 4561001627Document1 pageCommissioning Certificate 4561001627Anonymous vcadX45TD7No ratings yet

- Ge Shunt ReleaseDocument4 pagesGe Shunt ReleaseAnonymous vcadX45TD7No ratings yet

- Circuit Breaker BomDocument4 pagesCircuit Breaker BomAnonymous vcadX45TD7No ratings yet

- 230 Setting TestDocument2 pages230 Setting TestAnonymous vcadX45TD7No ratings yet

- Fault CalculationDocument35 pagesFault CalculationAnonymous vcadX45TD7No ratings yet