Professional Documents

Culture Documents

3 - WPS PDF

3 - WPS PDF

Uploaded by

giomar.gallarday0 ratings0% found this document useful (0 votes)

15 views1 pageOriginal Title

3.-WPS.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views1 page3 - WPS PDF

3 - WPS PDF

Uploaded by

giomar.gallardayCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

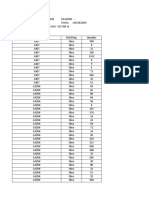

PLAN DE GESTION DE CALIDAD SM/QCRWPS.01

ESPEGIFICAGION DEL PROCEDIMIENTO DE SOLDADURA [HOA det

ee _DICION 1

De acuerdo al oédigo AWS D1.1/01.1M:2018 MISION ene-16

WELDING PROCEDURE SPECIFICATION (WPS)

PREQUALIFIED ‘QUALIFIED BY TESTING

or PROCEDURE QUALIFICATION RECORDS (PQR)

dentication # — __su-wes.o2

ompany Name SMA METAL INDUSTRIAL Revision _1 Dato 00/276 By __Jamos Ru

elding Process(es) GMAW. ‘Authorized by lames Ruiz Date 0912/16

jpporting PAR N’ (3) Precaliicado Type Manual ‘Semi-Automatic 1X

Machine ‘Automatic

JOINT DESING USED

yee TCFI-GF [ J POsTION.

ingle Double Weld Position of Groove Fille

sacking: No Ex Vertical Progression Up Dow

Backing Mater =

001 Opening _0- 5mm _Root Face Dimension [HEECTRIGAT CHARACTERISTICS |

roove Angle Radius (-U) 7

leack Gouging Yes NoLx ‘Transfer Mode (GMAW) Shot-Ciruting

Method: = Globular Pulsed spray [Xx

BASE METALS J Curent: Ac ocer[X] _ ocen|

alorial Spec. ‘other

[Type or Grade “Tungsten Electrode (GTAW)

[Thickness: “Groove = Filet 30 nasta Size =

menor a 75 Type

WS Specification ‘AWS A518 TECHNIQUE

WS Classification “AWS ER 705 6 ‘Stinger or Weave Bead: Weave

Mut-pass or Single Pass (per si) Sige

Number of Electrodes ‘Only

Fux ‘Gas Electrode Spacing Longitudinal =

‘Composiion _60% Ar-20% CO, Lateral =

tectrode-Fix(class) _—~__FlowRete 15-25 i Angle

‘Gas Cup Siz 10-15 mm Contact Tube to Work Distance,

Peening ~

PREHEAT Interpass Cieaning ‘Grinding and Wire Brish

Pretest Temp. Min T.amb (20.0 25°C)

nterpass Temp. Min = Max Temp. —

Time =

Ss Wer bnig PRocepuRe:

Pass or Filler Metals Current 2

weld | Process Vous} Travel Speed

eae ciass | pam | yPe® | Ampsor Wire (cmvimin)

Polarity | Feed Speed |

1 | emaw [er 7056|iomm| ocep | 220+ 10% | 267% | 1602 26% 1]

J bm

TO-F12.6F

[Aerobade por Ing. James Ruiz A

oye

4

6} exe. 2017

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Ficha Tecnica Compresora KaeserDocument1 pageFicha Tecnica Compresora Kaesergiomar.gallardayNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Protocolo de Montaje TR-4 CERRAMIENTO Eje EDocument2 pagesProtocolo de Montaje TR-4 CERRAMIENTO Eje Egiomar.gallarday100% (4)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- Protocolo de Montaje TR-4 CERRAMIENTO 1ra NaveDocument2 pagesProtocolo de Montaje TR-4 CERRAMIENTO 1ra Navegiomar.gallardayNo ratings yet

- Indice para Dossier de CalidadDocument2 pagesIndice para Dossier de Calidadgiomar.gallardayNo ratings yet

- Ficha Tecnica de Tablero ElectricoDocument4 pagesFicha Tecnica de Tablero Electricogiomar.gallardayNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Evasocial Jenkins Gas de CamiseaDocument11 pagesEvasocial Jenkins Gas de Camiseagiomar.gallardayNo ratings yet

- Reportes para FabricacionDocument4 pagesReportes para Fabricaciongiomar.gallardayNo ratings yet

- Modelo de Reportes.Document81 pagesModelo de Reportes.giomar.gallardayNo ratings yet

- SHA LP TT81 Rev.0Document207 pagesSHA LP TT81 Rev.0giomar.gallardayNo ratings yet

- Montacarga Duplex Rev 0 - 02Document1 pageMontacarga Duplex Rev 0 - 02giomar.gallardayNo ratings yet

- Tabla de Torques - Fejucy PDFDocument1 pageTabla de Torques - Fejucy PDFgiomar.gallardayNo ratings yet

- Ficha de Mantto Tablero ElectricoDocument4 pagesFicha de Mantto Tablero Electricogiomar.gallardayNo ratings yet

- Protocolo de Montaje Malla A' 1ra NaveDocument2 pagesProtocolo de Montaje Malla A' 1ra Navegiomar.gallardayNo ratings yet

- Procedimiento para Montaje de Cobertura Cencosud Rev - XXXXDocument3 pagesProcedimiento para Montaje de Cobertura Cencosud Rev - XXXXgiomar.gallardayNo ratings yet