Professional Documents

Culture Documents

Short10 PDF

Short10 PDF

Uploaded by

ALBERTOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Short10 PDF

Short10 PDF

Uploaded by

ALBERTCopyright:

Available Formats

Technical Note No.

10

SITE TESTING FOR WATERTIGHTNESS

Site testing is frequently used to test the watertightness of windows and cladding as installed, and is

specified in Test Methods for Curtain Walling (CWCT, 1996). This technical note adds further

clarification on site testing procedures and equipment and the selection of test method. It should be

read in conjunction with Test Methods for Curtain Walling.

Introduction component or large-scale specimen has been

successfully tested in the laboratory. The site

Although many cladding components and testing procedure can then be applied at the

systems can be tested for watertightness in the laboratory to determine if the test is suitable.

laboratory or on a large-scale mock-up, these

tests neglect a critical issue with watertightness This approach will also generate a second piece

- the impact of site workmanship. of important information - which components or

parts of the system will not pass the test. It is

The fabricator and installer of a cladding system known, for example, that the hose test generates

are relied upon to ensure that the joined surfaces a strong jet of water with a penetrating power

of components are cut straight, gaskets properly far in excess of normal driven rain; this test will

fitted, and sealants properly installed. However, usually fail joints which are intended to be

the installer is often left to resolve intersections opened (for example around doors and opening

between joints, overcome inaccuracies in the as- lights of windows), unless a modification to the

built structure and ensure proper sealing to test procedure is made. It is often possible, on a

adjacent cladding systems. test mock-up, to modify the parameters for a site

hose test to determine the condition under which

For this reason it is often appropriate to test a an opening joint will pass the test with the

small part of the installed cladding system, to agreement of all parties.

ensure that fabrication and installation have not

in any way reduced the performance of the Specifying and witnessing site tests

system, and to check the performance of

Non-specialist specifiers should seek advice

interfaces with adjacent systems that did not

from a UKAS accredited test laboratory or

form part of the laboratory test. However, site

cladding consultant on how to specify and

testing itself can also be poorly applied, and this

witness site tests.

technical note aims to identify some of the key

issues of which the site test specialist and

Site tests

specifier should be aware.

Watertightness can be assessed on site using

The frame of reference

three distinct approaches - the hose, the spray

An important requirement before carrying out bar and the cabinet.

site testing is to have a frame of reference - the

assessor must know whether certain parts of a Hose testing

component or system are capable of passing the This test is defined in Test Methods for Curtain

specified test when properly fabricated and Walling (CWCT, 1996) and the AAMA

installed. This is simple to define when a standard 501-94. The CWCT hose test varies

© CWCT 1999This document has been printed from the CWCT ‘Cladding Forum’, access to which is restricted to subscribing

Members of the Centre for Window & Cladding Technology. Information about the availability of CWCT publications and

membership is available at our website – www.cwct.co.uk – or from the address at the end of this note.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 908 Bel Air Road - Most Recent Floor Plans McCleanDocument4 pages908 Bel Air Road - Most Recent Floor Plans McCleanwalterw100% (4)

- TL Design Manual - Rev0.5Document64 pagesTL Design Manual - Rev0.5Syed Ahsan Ali Sherazi100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Dumper Cycle Time Transport Digging Capacity CalculationDocument10 pagesDumper Cycle Time Transport Digging Capacity Calculationuttamksr100% (3)

- 201021-RP-WSP Engineer of The Year 2020-FinalDocument16 pages201021-RP-WSP Engineer of The Year 2020-FinalrmdarisaNo ratings yet

- 18.9 Confirmation of Verbal Instructions (CVI)Document2 pages18.9 Confirmation of Verbal Instructions (CVI)rmdarisaNo ratings yet

- How To Build A Plafit ChassisDocument4 pagesHow To Build A Plafit ChassisJohn Howard Green100% (2)

- Implementing Lean in Construction: A Lean Guide For Client OrganisationsDocument52 pagesImplementing Lean in Construction: A Lean Guide For Client OrganisationsrmdarisaNo ratings yet

- Exw P042 Ic03 QM WSP NC 00036 CaDocument9 pagesExw P042 Ic03 QM WSP NC 00036 CarmdarisaNo ratings yet

- The Effect of Waste Material Based On Lean Construction On The Performance of The Retail Building ProjectDocument12 pagesThe Effect of Waste Material Based On Lean Construction On The Performance of The Retail Building ProjectrmdarisaNo ratings yet

- The Principles and Applications of Lean Construction in SingaporeDocument15 pagesThe Principles and Applications of Lean Construction in SingaporermdarisaNo ratings yet

- Lean Construction: An Effective Approach For Project ManagementDocument6 pagesLean Construction: An Effective Approach For Project ManagementrmdarisaNo ratings yet

- A Case Study of Partnering in Lean ConstructionDocument16 pagesA Case Study of Partnering in Lean ConstructionrmdarisaNo ratings yet

- Connection Between Lean Design/Construction and Construction Worker SafetyDocument44 pagesConnection Between Lean Design/Construction and Construction Worker SafetyrmdarisaNo ratings yet

- NCR Trend Analysis - BarzanDocument15 pagesNCR Trend Analysis - BarzanrmdarisaNo ratings yet

- 18.6 Action Taken ReportDocument1 page18.6 Action Taken ReportrmdarisaNo ratings yet

- 18.8 Design Request For InformationDocument1 page18.8 Design Request For InformationrmdarisaNo ratings yet

- MagnubroucherDocument12 pagesMagnubroucherrmdarisaNo ratings yet

- Quality Management Principles As Per ISO 9001:2015: Prepared By: Kranthi Tulluru On 25FEB16Document21 pagesQuality Management Principles As Per ISO 9001:2015: Prepared By: Kranthi Tulluru On 25FEB16rmdarisaNo ratings yet

- IopDocument10 pagesIoprmdarisaNo ratings yet

- MH Ban 18150270000010018Document1 pageMH Ban 18150270000010018rmdarisaNo ratings yet

- CEPEsampleDocument5 pagesCEPEsamplermdarisaNo ratings yet

- 4 5918214429920462111Document3 pages4 5918214429920462111rmdarisaNo ratings yet

- A. Process MapDocument2 pagesA. Process MaprmdarisaNo ratings yet

- RBS 22 02/2102 Installation CourseDocument88 pagesRBS 22 02/2102 Installation CourseGeoffrey AlleyneNo ratings yet

- Lecture18-RTL Combinational Components - A-EDocument82 pagesLecture18-RTL Combinational Components - A-EattarshahriarNo ratings yet

- 20151124-Rail Update Middle EastDocument19 pages20151124-Rail Update Middle EastHemant ChauhanNo ratings yet

- Ginni International Limited-1Document17 pagesGinni International Limited-1Charanpreet SinghNo ratings yet

- Introduction To Probability TheoryDocument207 pagesIntroduction To Probability TheoryRahulNo ratings yet

- Biomedicines 11 00128Document13 pagesBiomedicines 11 00128dmandatari7327No ratings yet

- Cable TrunkingDocument5 pagesCable TrunkingLeo GeeNo ratings yet

- Train Resistance CalculationsDocument6 pagesTrain Resistance Calculationssalkan_rahmanovic810No ratings yet

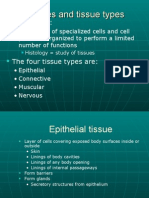

- Tissues and Tissue TypesDocument42 pagesTissues and Tissue TypesMustafa Akbar100% (1)

- CasesDocument29 pagesCasesGretchen Delos ReyesNo ratings yet

- Mohamed Yr 10 Physics Exam (Midterm)Document15 pagesMohamed Yr 10 Physics Exam (Midterm)victor bettNo ratings yet

- 55 Samss 002Document15 pages55 Samss 002Eagle SpiritNo ratings yet

- Bonn Convention On The Conservation of Migratory SpeciesDocument13 pagesBonn Convention On The Conservation of Migratory SpeciesDeveshreeNo ratings yet

- Case Study On Kohinoor SquareDocument31 pagesCase Study On Kohinoor SquareJimmy Wangmo DorjiNo ratings yet

- Introducing The Adafruit Bluefruit LE Sniffer: Created by Kevin TownsendDocument44 pagesIntroducing The Adafruit Bluefruit LE Sniffer: Created by Kevin TownsendRickScheck4567No ratings yet

- NavigationDocument203 pagesNavigationHein Htet AungNo ratings yet

- Sample Graph DataDocument13 pagesSample Graph DataLuan SampaioNo ratings yet

- ACI Committee 309 - Behavior of Fresh Concrete During Vibration, ACI 309.1R-81 (ACI Journal)Document1 pageACI Committee 309 - Behavior of Fresh Concrete During Vibration, ACI 309.1R-81 (ACI Journal)bournelinNo ratings yet

- CV - Nirmal Shanker-CompressedDocument6 pagesCV - Nirmal Shanker-Compressednirmal_elex7863No ratings yet

- Adambakkam 2 StreetDocument16 pagesAdambakkam 2 StreetManiNo ratings yet

- viewNitPdf 3094372 PDFDocument7 pagesviewNitPdf 3094372 PDFPratik GuptaNo ratings yet

- Hyper 181 N180Document2 pagesHyper 181 N180David ThomsonNo ratings yet

- Cern Zechariah 11 and The Mysterious Stranger No 44 I1 PDFDocument38 pagesCern Zechariah 11 and The Mysterious Stranger No 44 I1 PDFVincit Omnia Veritas100% (1)

- Modeling of Automotive Airbag Inflators Using Chemistry Solver in Ls Dyna RDocument3 pagesModeling of Automotive Airbag Inflators Using Chemistry Solver in Ls Dyna RFred OveNo ratings yet

- Oscillators With Answers PDFDocument16 pagesOscillators With Answers PDFlakshmidevanNo ratings yet

- Drought Preparedness and MitigationDocument45 pagesDrought Preparedness and MitigationTinashe KambaramiNo ratings yet