Professional Documents

Culture Documents

S-Steel Analysis

S-Steel Analysis

Uploaded by

Amanpreet SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S-Steel Analysis

S-Steel Analysis

Uploaded by

Amanpreet SinghCopyright:

Available Formats

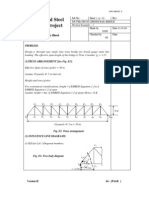

Example F.

1-2A

Section W18x50 braced at 3rd locations and ends.

S-Steel: Model member using physical member option

Beam Lb’ = Overall length = 35’

To find Top Lb/L and Bot Lb/L for S-Steel code input:

K x Lb = Factor x Lb’

Effective Unbraced S-Steel Overall

Length length factor member

Factor length

K = 1.0 (pin-pin)

Lb = 11.7’

Lb’ = 35’

Therefore Factor = (1 x 11.7) / 35 = 0.33

Use Top Lb/L and Bot Lb/L = 0.33 for S-Steel code check

Mr = 346 k/ft (S-Steel: Code AISC 360-05 LRFD) vs 302 k/ft (Example F.1-2A V14)

NOTE: Make sure Kx = Ky = 1.0 for S-Steel bending only beam design. If beam has axial load as well, then

calculate Kx and Ky as per E.1-B example.

Example E.1-B

Section W14x90 braced in Y-Direction at midpoint. No brace in X-direction.

Kx = 1.0 (effective length factor) ; Lx = 30’ (unbraced length)

Ky = 1.0 (effective length factor); Ly = 15’ (unbraced length)

Lx’ = Ly’ = 30’ (overall member length)

Kx’ = (Kx x Lx) / Lx’ = 1.0

and Ky’ = (Ky x Ly) / Ly’ = 0.5

Therefore use Kx’ = 1.0 and Ky’ = 0.5 for S-Steel code check

Cr = 927kips (S-Steel: Code AISC 360-05 LRFD) vs 929kips (Example E.1-B V14)

NOTE: Make sure Top Lb/L = Bot Lb/L = 1.0 for S-Steel compression only column design. If column has

bending moment as well, then calculate Top Lb/L and Bot Lb/L as per E.1-B example.

You might also like

- MONORAILDocument7 pagesMONORAILDiego Andres RamosNo ratings yet

- Steel Truss DesignDocument10 pagesSteel Truss DesignRichard Teves100% (3)

- Grating DesignDocument19 pagesGrating DesignAmanpreet SinghNo ratings yet

- Design of Steel Beam (LRFD, Load and Resistance Factor Design)Document5 pagesDesign of Steel Beam (LRFD, Load and Resistance Factor Design)surajoffshoreNo ratings yet

- "Monorail13" - Monorail Beam Analysis: Program DescriptionDocument9 pages"Monorail13" - Monorail Beam Analysis: Program DescriptionScott SamarooNo ratings yet

- Monorail 13Document26 pagesMonorail 13ramesh_madkatte1082No ratings yet

- Calculo de Viga para Puente GruaDocument14 pagesCalculo de Viga para Puente GruaFabio SalasNo ratings yet

- MonorailDocument14 pagesMonorailmetroroadNo ratings yet

- "Monorail" - Monorail Beam Analysis: Program DescriptionDocument14 pages"Monorail" - Monorail Beam Analysis: Program DescriptionYash SutharNo ratings yet

- "Monorail" - Monorail Beam Analysis: Program DescriptionDocument14 pages"Monorail" - Monorail Beam Analysis: Program DescriptionRoger T SomundohNo ratings yet

- "Monorail" - Monorail Beam Analysis: Program DescriptionDocument13 pages"Monorail" - Monorail Beam Analysis: Program DescriptionLexNo ratings yet

- MONORAIL13Document8 pagesMONORAIL13ankit kadamNo ratings yet

- Machine Design Bolt DesignDocument6 pagesMachine Design Bolt DesignKASHIF KHANNo ratings yet

- Underhung Monorail Beam Analysis Per AISC 9th Edition (ASD)Document13 pagesUnderhung Monorail Beam Analysis Per AISC 9th Edition (ASD)Baran GulsayNo ratings yet

- MonorailDocument14 pagesMonorailAnand.5No ratings yet

- "Monorail13" - Monorail Beam Analysis: Program DescriptionDocument8 pages"Monorail13" - Monorail Beam Analysis: Program DescriptionPhan Van SonNo ratings yet

- Steel 2022 BeamDocument26 pagesSteel 2022 BeamRaven Von DizonNo ratings yet

- "Monorail" - Monorail Beam Analysis: Program DescriptionDocument14 pages"Monorail" - Monorail Beam Analysis: Program DescriptionMohamed NkNo ratings yet

- "Monorail" - Monorail Beam Analysis: Program DescriptionDocument14 pages"Monorail" - Monorail Beam Analysis: Program DescriptionJaafar DahlanNo ratings yet

- MonorailDocument14 pagesMonorailZain AndabloNo ratings yet

- Flexural TheoryDocument62 pagesFlexural TheoryReceb AgaNo ratings yet

- EXAMENDocument39 pagesEXAMENAlex Asdasd MCNo ratings yet

- S Beam ASDDocument5 pagesS Beam ASDAnonymous DJrec2No ratings yet

- MonorailDocument13 pagesMonorailJay PadamaNo ratings yet

- Design of Steel Beam 89edDocument5 pagesDesign of Steel Beam 89edAdi SatriaNo ratings yet

- Prepared by Jishnu V Engineer Bhel-IsgDocument38 pagesPrepared by Jishnu V Engineer Bhel-IsgmSNDjvnsnNo ratings yet

- Angle Flex SeatDocument3 pagesAngle Flex Seatitissa INGENIERIANo ratings yet

- MonorailDocument13 pagesMonorailleodegarioporralNo ratings yet

- "Monorail13" - Monorail Beam Analysis: Program DescriptionDocument26 pages"Monorail13" - Monorail Beam Analysis: Program Descriptionsagar_sonawane_21No ratings yet

- Daniel Tian Li: Depressed Floor Deck Capacity Using Steel Properties Only (Non Composite)Document1 pageDaniel Tian Li: Depressed Floor Deck Capacity Using Steel Properties Only (Non Composite)Nikki RobertsNo ratings yet

- "Angleflexseat" - Allowable Steel Beam End Reaction: Program DescriptionDocument3 pages"Angleflexseat" - Allowable Steel Beam End Reaction: Program DescriptionAamirShabbirNo ratings yet

- Copy Monorail Design ExcelDocument28 pagesCopy Monorail Design ExcelDatos Adjuntos0% (1)

- Oemp 3 - Part 2Document4 pagesOemp 3 - Part 2api-497657561No ratings yet

- Table 3-2 W Shape Selection by ZXDocument8 pagesTable 3-2 W Shape Selection by ZXMohammed OmerNo ratings yet

- Structural Steel Design Project: Calculation SheetDocument10 pagesStructural Steel Design Project: Calculation Sheetkingkingking1988No ratings yet

- 2 - Compact and Non-Compact Sections For Steel BeamsDocument4 pages2 - Compact and Non-Compact Sections For Steel BeamsSarveshwaran Senthil KumarNo ratings yet

- Slab Roof Result SummaryDocument11 pagesSlab Roof Result SummaryFrancis Jan DiscayaNo ratings yet

- Steel W-Beam LTB v1.1Document2 pagesSteel W-Beam LTB v1.1Pak Keung YipNo ratings yet

- Slab Support Design ExamplesDocument5 pagesSlab Support Design ExamplespkNo ratings yet

- Design of Composite Beams Using Allowable Stress Design: Presented By: Dr. Sherine SwelemDocument70 pagesDesign of Composite Beams Using Allowable Stress Design: Presented By: Dr. Sherine Swelemabdelrahman emadNo ratings yet

- BM Das 8th Edition Permeabilty Exercise SolutionDocument60 pagesBM Das 8th Edition Permeabilty Exercise SolutionRiyad ArafatNo ratings yet

- ACI-350 P-M Interaction 2.1Document33 pagesACI-350 P-M Interaction 2.1corneliortizNo ratings yet

- Monorail Design Excel PDFDocument7 pagesMonorail Design Excel PDFsagar1503No ratings yet

- ANGLEFLEXSEATDocument3 pagesANGLEFLEXSEATwidNo ratings yet

- Monorail 0.5 TonDocument9 pagesMonorail 0.5 TonAndreas HendiNo ratings yet

- MonorailDocument14 pagesMonorailMarly ReyesNo ratings yet

- Foundation Chapter 4Document5 pagesFoundation Chapter 4Shakil AkhterNo ratings yet

- Design of Field Winding of Shunt Motor: PresentationDocument19 pagesDesign of Field Winding of Shunt Motor: PresentationRafael Sena SantanaNo ratings yet

- Hss WF Moment Conn 2.0 Final 1Document251 pagesHss WF Moment Conn 2.0 Final 1Lester BaculiNo ratings yet

- Strength of Materials EngineerdogDocument150 pagesStrength of Materials EngineerdogEng-Mohammed Abu NuktaNo ratings yet

- One Way Joist Slab (By Prof. A. Charif)Document12 pagesOne Way Joist Slab (By Prof. A. Charif)سجى وليدNo ratings yet

- Slab Design Summary Report-Drg Ok-Staad - PrintDocument16 pagesSlab Design Summary Report-Drg Ok-Staad - PrintmichaelNo ratings yet

- ACI-350 P-M Interaction 2.1Document27 pagesACI-350 P-M Interaction 2.1Franklyn P. GenoveNo ratings yet

- Steel Beam Design Excel SheetDocument9 pagesSteel Beam Design Excel SheetFahad Iqbal100% (2)

- Two Way SlabDocument60 pagesTwo Way SlabpvsvprasadcivilNo ratings yet

- Design of Steel BeamsDocument108 pagesDesign of Steel BeamsNajif IsmailNo ratings yet

- Slab Design As Per Is 456Document8 pagesSlab Design As Per Is 456RATNA SINGHNo ratings yet

- Torsion 9Document13 pagesTorsion 9Vasanth KumarNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Mod 453 Conx Rev-0 ESK-11Document1 pageMod 453 Conx Rev-0 ESK-11Amanpreet SinghNo ratings yet

- Mod 453 Conx Rev-0 ESK-5Document1 pageMod 453 Conx Rev-0 ESK-5Amanpreet SinghNo ratings yet

- Mod 453 Conx Rev-0 ESK-3Document1 pageMod 453 Conx Rev-0 ESK-3Amanpreet SinghNo ratings yet

- Mod 453 Conx Rev-0 ESK-1Document1 pageMod 453 Conx Rev-0 ESK-1Amanpreet SinghNo ratings yet

- Mod 453 Conx Rev-0 ESK-2Document1 pageMod 453 Conx Rev-0 ESK-2Amanpreet SinghNo ratings yet

- Webinar ConfirmationDocument2 pagesWebinar ConfirmationAmanpreet SinghNo ratings yet

- Project StatementDocument2 pagesProject StatementAmanpreet SinghNo ratings yet

- Column Cap Plate001Document2 pagesColumn Cap Plate001Amanpreet SinghNo ratings yet

- Client Project Subject 1 OF: Engineering Calculations Cover SheetDocument4 pagesClient Project Subject 1 OF: Engineering Calculations Cover SheetAmanpreet SinghNo ratings yet

- Project TimesheetDocument2 pagesProject TimesheetAmanpreet SinghNo ratings yet

- Biology Calgary, AB: Calgary N.E. LabDocument2 pagesBiology Calgary, AB: Calgary N.E. LabAmanpreet SinghNo ratings yet

- Ids Project Database: Dead Closed Closed Dead Closed Dead Open Open Closed Dead Open Open Dead Dead ClosedDocument2 pagesIds Project Database: Dead Closed Closed Dead Closed Dead Open Open Closed Dead Open Open Dead Dead ClosedAmanpreet SinghNo ratings yet

- Moment To Column WebDocument905 pagesMoment To Column WebAmanpreet SinghNo ratings yet