Professional Documents

Culture Documents

TB02203002E - Tab 36 PDF

Uploaded by

Thomas MartinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TB02203002E - Tab 36 PDF

Uploaded by

Thomas MartinCopyright:

Available Formats

Resistance Grounding Systems 36.

0-1

October 2015

Sheet 36 001

Systems

Contents

Resistance Grounding Resistance Grounding Systems

High Resistance Grounding SystemMedium Voltage . . . . . . . . . . . . . . 36.1-1

22

23

High Resistance Grounding SystemLow Voltage . . . . . . . . . . . . . . . . . 36.2-1

Specifications 24

See Eatons Product Specification Guide, available on CD or on the Web.

CSI Format: . . . . . . . . . . . . . . . . . . . . . . . . . . . 1995 2010

High Resistance

25

Grounding SystemMV . . . . . . . . . . . . Section 16451A Section 26 05 26.11

High Resistance 26

Grounding SystemLV . . . . . . . . . . . . . Section 16451B Section 26 05 26.13

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

C-HRG Free-Standing

NEMA 1 Enclosure

CA08104001E For more information, visit: www.eaton.com/consultants

36.0-2 Resistance Grounding Systems

October 2015

Sheet 36 002

This page intentionally left blank.

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

For more information, visit: www.eaton.com/consultants CA08104001E

Resistance Grounding Systems 36.1-1

October 2015 High Resistance Grounding SystemMedium Voltage

Sheet 36 003

General Description

Medium Voltage High 22

HRG = High Resistance

Resistance Grounding System Grounding System

Wye HRG

51N

23

24

59

25

Utility

26

Delta HRG

59 27

Wye HRG Generator 28

59

29

Bus Bus

Duct Duct 51

51N 30

31

C-HRG Free-Standing NEMA 1 Unit

5 kV Switchgear

General Description 32

Where continuity of service is a high

priority, high resistance grounding can

add the safety of a grounded system 33

while minimizing the risk of service Conduit

interruptions due to grounds. The Cable

concept is a simple one: provide

Bus

Duct

34

a path for ground current via a

grounding transformer (with adjust-

able resistance across its secondary) To MCC To Power Circuit 35

that limits the current magnitude

and a monitor to determine when

an abnormal condition exists. Figure 36.1-1. HRGHigh Resistance Grounding System 36

The ground current path is provided Seismic Qualification

at the point where the service begins, 37

by placing a predominantly resistive

impedance in the connection from

system neutral to ground. Control 38

equipment continuously measures

ground current; a relay detects when the

current exceeds a predetermined level. Refer to Tab 1 for information on 39

An alarm alerts building personnel that seismic qualification for this and

a ground exists. The system has built-in other Eaton products.

fault tracing means to assist in finding 40

the source of the ground. A 120 Vac

supply (remote) is required for control

power for the system. 41

42

43

CA08104001E For more information, visit: www.eaton.com/consultants

36.1-2 Resistance Grounding Systems

High Resistance Grounding SystemMedium Voltage October 2015

Sheet 36 004

General Description

Application Issues Ground Current Detection When the fault is cleared, the current/

22 This member of Eatons medium voltage Any time a system is energized, voltage relay will reset. If the reset

a small ground current called the control is set on auto, the lights will

metal-clad switchgear family has return to normal on, ground fault

capacitive charging current will

23 actually been around for many years.

However, it is now offered as a stand- be observed. For medium voltage off, and the ground alarm contacts will

(4200 V and below) systems, this re-transfer. If the reset control is set on

alone unit that can be added to exist- manual, the lights and relay contacts

naturally occurring current is typically

24 ing installations. The C-HRG is used

3 A or less. will remain latched until the operator

to protect an electrical distribution turns the reset control to reset. The

system from damaging transient over- When one phase becomes grounded, lights and ground alarm contacts will

25 voltages caused by ground faults. additional current above the charging then return to normal. The system

It also provides a means to locate the level will flow. As all ground current can be reset only if the fault has

ground fault, therefore extending the must flow through the grounding been cleared.

26 life of the distribution system. resistor/grounding transformer

assembly, an ammeter in this circuit During a fault, the optional alarm

Ratings and Configurations horn can be silenced at any time by

will read the total amount of ground

27 The C-HRG MV is offered at the current. By placing a current-sensing using the alarm silence pushbutton.

5 kV class rating. It can be applied relay in series with the ammeter, the It will not re-sound until either the

to delta or wye ungrounded three- current relay can be adjusted to pick- system is reset, or the re-alarm timer

28 wire distribution systems. Standard up at a level in excess of the capacitive expires. The re-alarm timer is activated

dimensions are 36.00-inch (914.4 mm) charging current, thus indicating the by the alarm silence control. If the

W x 40.00-inch (1016.0 mm) D x abnormal condition. horn has been silenced but the fault

29 92.00-inch (2336.8 mm) H. has not been cleared, the timer will

Alternatively, an optional voltmeter- run. It has a range of 248 hours.

4200 V (Maximum) Delta Systems relay can be connected across the When the timer times out, the horn

30 To add high resistance grounding to an grounding resistors. The voltage will re-sound, alerting maintenance

ungrounded delta-connected system, across the resistors is proportional personnel that the fault has not

a neutral point must be created. Three to the amount of ground current. The been cleared.

31 single-phase transformers can be voltmeter-relays pickup adjustment

interconnected in a wye-broken delta is set above the capacitive charging Test Circuit

configuration to provide such a neutral current, to the desired detection level. A test circuit is provided to allow the

32 point. The transformers and grounding

resistors are chosen to limit the ground In both current and voltage detection

user to quickly determine that the

system is working properly. The test

current to a maximum value of 6 A. methods, the ground current ammeter circuit will operate only under normal

provides a direct reading of the total

33 Application Note: The neutral point may actual ground current present in the

conditionsit will not allow testing if

not be used to serve phase-to-neutral loads. the system is sensing a fault. The test

system at that time. It will be helpful operation does not simulate an actual

Also, this technique may be applied on wye-

to periodically note the ammeters

34 connected sources when the neutral point

reading: a trend toward higher values

system ground fault. It does, however,

is not conveniently accessible from the test the complete controls of the fault

service entrance location. One delta high may indicate the need for equipment indication and pulsing circuitry. The

35 resistance grounding would ground the maintenance, and hence reduce the system then reacts as it would under

5 kV system. occurrence of unplanned shutdowns. actual system ground conditions

Indication and Alarm Circuits lights transfer, alarm contacts transfer

36 4200 V (Maximum) Wye Systems and the (optional) horn sounds.

To add high resistance grounding to When a fault is detected, an adjustable

a wye-connected system, resistors time delay is provided to override Pulser Circuit

transients. When the time delay has

37 are placed across the secondary

been exceeded, the green normal

The pulser circuit offers a convenient

of a grounding transformer whose means to locate the faulted feeder and

primary is placed in series with the light will turn off, the red ground trace the fault to its origin. The pulser

fault light will turn on, and the

38 neutral-to-ground connection of the

ground alarm contacts will transfer.

is available any time a fault has been

power source. The resistors are detected. The pulse intervals are con-

chosen to limit the current to a If equipped with the optional alarm trolled by an adjustable recycle timer.

horn, it will sound.

39 maximum value of 6 A. The pulse light flashes on and off,

The grounding transformer secondary corresponding to the on-off cycles

Application Note: Per 1999 NEC 250.36(4),

line-to-neutral loads may not be connected breaker must be closed for the system of the pulser contactor. The pulser

40 to a system that the neutral is resistance- to be operational. Should this breaker contactor switches a bank of resistors

grounded. Also, if the system has two be opened at any time, the system will on and off, thus allowing a momentary

switchable sources not permanently signal a ground fault condition as a increase in the ground current

41 connected to the bus, two wye-type fail-safe feature. The breaker must be (approximately a 4 A current pulse

grounding systems are required as closed to clear the alarm signal. above the ground current).

shown in Figure 36.1-1.

42

43

For more information, visit: www.eaton.com/consultants CA08104001E

Resistance Grounding Systems 36.1-3

October 2015 High Resistance Grounding SystemMedium Voltage

Sheet 36 005

General Description

Locating a Ground Fault control switch to normal. The pulser

The current pulses can be noted with a will stop. If the reset control is in the 22

clamp-on ammeter when the ammeter manual position, turn it to reset to

is placed around the cables or conduit reset the fault sensing circuit. The red

feeding the fault. The operator tests ground fault light will turn off, and 23

each conduit or set of cables until the the green normal light will turn on.

pulsing current is noted. By moving Test mode is not available if the system

the ammeter along the conduit, or is detecting a ground. The sensing 24

checking the conduit periodically along circuit will disable the test circuit.

its length, the fault can be traced to its

origin. The fault may be located at the

Ground Fault 25

point where the pulsing current drops When the sensing circuit detects a fault,

off or stops. the green normal light will turn off

and the red ground fault light will 26

If little or no change in the pulsing turn on. The ground current ammeter

current is noted along the entire length will indicate the total ground current.

of a conduit, then the fault may be in To use the pulser, turn the system 27

the connected load. If the load is a control switch to pulse. The pulser C-HRG Unit Shown with the Door Open

medium voltage distribution equip- contactor will cycle on and off as con-

ment or motor control center, repeat trolled by the recycle timer relay. Use Product Features 28

the process of checking all outgoing the clamp-on ammeter to locate the Tapped resistors (limits primary

cable groups and conduits to find the faulted feeder. Open the feeder and current to 36 A)

faulted feeder. If the fault is not found clear the fault. If the reset control switch Current sensing ground fault 29

in an outgoing feeder, the fault may be is in the manual position, turn it detection (210 A pickup/0.520

internal to that equipment. to reset to reset the sensing circuit. second delay)

(If reset control is in auto, it will reset Ground current transformer

30

Application Note: It may not be possible

itself.) When ready to restore service (10/10 ratio)

to precisely locate faults within a conduit.

The ground current may divide into many to the load, close the feeder. Return

components, depending on the number of the system control to normal. Control circuit pull fuseblock 31

cables per phase, number of conduits per Ground current ammeter

feeder, and the number and resistance of Application (010 A, 1% accuracy)

each ground point along the conduits. The

When a ground fault occurs on an Indicating lights: 32

resulting currents may be too small to allow

ungrounded system, high transient volt- Red (ground fault)

detection or may take a path that the am-

meter cannot trace. An important note to ages can occur, which may cause more Green (normal) 33

keep in mind is that while the pulser can frequent equipment failures than if the

White (pulse)

greatly aid in locating a fault, there may be equipment were grounded. These tran-

certain conditions under which the pulses Adjustable pulsing timer

cannot be readily traced, and other test

sient overvoltages, as high as four times

(010 seconds)

34

the normal voltage, reduce the life of the

procedures (megohm, high-potential, etc.) systems insulation resulting in: 3-position selector switch

may be needed.

Motor failure

(normal, pulse, test) 35

Control switch for manual

Sequence of Operations Transformer failure or automatic reset

Normal Coil failure Ground fault contacts (1NO/1NC) 36

Electronic equipment failure Shorting terminal block for ground

Green normal light on

Cable insulation failure current CT

Red ground fault light off 37

White pulse light off By using a high resistance grounding UL label

System control switch in system, many facilities can gain the Wiremarkers

normal position benefit of a grounded system without

The system is completely assembled,

38

impairing the continuity of service to

Reset control switch in either wired and tested at the factory in

their equipment. The concept behind

auto or manual accordance with NEMA and UL

high resistance grounding is to pro-

requirements. A certified production

39

Test vide a path for the ground current to

flow while limiting its magnitude by test report is shipped with the unit.

Turn and hold the system control

switch in the test position. This using a resistor. The ground current 40

mode will test the control circuitry path is provided at the point where

only. It will bypass the sensing circuit service begins. Control equipment

and cause the green normal light continuously monitors the magnitude 41

to turn off and the red ground fault of the ground current. When the

light to turn on. The pulser will be ground current exceeds a predeter-

activated as well. The white pulse mined level, the built-in alarm relay 42

light will turn on and off as the pulser alerts building personnel that a ground

contactor closes and opens. However, fault exists. In addition, the C-HRG MV

the ground current ammeter will not Safe Ground system has a built-in 43

display the total ground current, fault pulsing as a means to assist in

including the incremental pulse finding the source of the ground fault

current. When ready, return the system without interrupting service.

CA08104001E For more information, visit: www.eaton.com/consultants

36.1-4 Resistance Grounding Systems

High Resistance Grounding SystemMedium Voltage October 2015

Sheet 36 006

Technical Data

Technical DataCircuit Diagrams

22

X3 X0 H3 X3

23 H3

X1 H1

H1 X2 H2 X1

H2 X2

24 Ungrounded To Ungrounded

To

Wye Distribution Delta Distribution

Circuits Circuits

25 X0

26 5 kV - CLE

Fuses 5 kV - CLE

Fuses

27 [1]

Mechanical

Control

Mechanical

Interlock

Interlock

Power

28 Transformer

3-Auxiliary

Control

Power

29 Transformers

Secondary Secondary

Circuit Circuit

B Breaker B Short Circuit B B Short Circuit

Breaker

30 T.B. T.B.

CT 10/10 A

Option Option

CT 10/10 A

Resistor Tap Resistor Tap

59

31 59

C C

4 4

32 1

3A 3A

Grounding Resistor

1

Grounding Resistor

2 4A AM 4A

2 AM

Pulsing Resistor

Pulsing Resistor

5A 5A

Pulsing Contactor

3 3

33

Pulsing Contactor

4 6A 6A

4

5IN

34 5IN

Ground Ground

35 Current Current

Adjustment Adjustment

Optional

Detector

Optional

Detector

Voltage

Voltage

T.B. T.B.

36 Current Current

Detector Detector

37 20 A 20 A

To To

Remote Control 120 V Remote Control 120 V

Fuses Fuses

38 Alarm Circuit 60 Hz Alarm Circuit 60 Hz

Supply Supply

20 A 20 A

39 Optional Optional

40 G R W G R W

Normal Alarm Pulsing Audible Normal Alarm Pulsing Audible

Alarm Alarm

41

Figure 36.1-2. Ungrounded Wye System Figure 36.1-3. Ungrounded Delta System

(With Standard Current and Optional Voltage Relay Fault Detectors) (With Standard Current and Optional Voltage Relay Fault Detectors)

42

43

For more information, visit: www.eaton.com/consultants CA08104001E

Resistance Grounding Systems 36.1-5

October 2015 High Resistance Grounding SystemMedium Voltage

Sheet 36 007

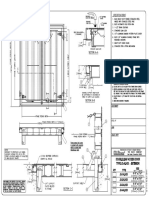

Dimensions

Dimensions in Inches (mm)

22

36.00

(914.4) 23

24

25

Vent

26

40.00

(1016)

27

28

Primary Conduit

3.50

Entrance

(88.9)

29

2.00 (50.8) Diameter

8.50 Knockout

(215.9) for Secondary

Conduit Entrance

3.62 30

(91.9)

1.50 3.25

(38.1) (82.6) 31

3.76

(95.6) Plan View

32

92.00

(2336.8)

33

0.81 0.81

(20.6) (20.6)

0.562 (14.3) Diameter (4) 2.75 34

(69.9)

2.50 3.00 35

2.75 (63.5) (76.2)

(69.9)

3.00

Ground

Provision

36

(76.2)

Entrance

2.50

(63.5) 37

3.75

(95.3)

38

7.12

Primary Conduit

(180.9) Entrance

39

3.75

(95.3)

36.00 40

(914.4)

3.50

(88.9) 9.38 2.75

Front View 3.75 (238.3) (69.9) 41

(95.3)

2.75

(69.9)

3.00

(76.2)

Secondary Conduit

Entrance

42

1.75

(44.5)

Approximate Weight = 2000 lb (1800 kg) Floor Plan 43

Figure 36.1-4. NEMA 1 Free-Standing

1 Minimum required clearances are: front 36.00 inches (914.4 mm), rear 30.00 inches (762.0 mm), left or right sides6.00 inches (152.4 mm).

CA08104001E For more information, visit: www.eaton.com/consultants

36.1-6 Resistance Grounding Systems

High Resistance Grounding SystemMedium Voltage October 2015

Sheet 36 008

Technical DataHigh Resistance Pulsing Grounding Systems

Table 36.1-1. CH MV HRG Systems Application Table

22 Resistor System System Primary CPT CPT Secondary Resistance Pulsing Pulsing Pulsing Resistor Watts Dissipated (kW)

Tap Voltage Ground Ratio kVA/Ph Ground for Ground Resistor Secondary Primary

Watts Watts Total Average

Current Current Current Value Current Total

Ground Pulsing Watts Watts

23 Total (Ohms) (Ohms) Current

2400 V 1

1 Delta 2400 3.0 2400/120 10 20.00 10.40 7.80 26.70 4.0 4.16 5.55 9.77 6.94

24 2 Delta 2400 4.0 2400/120 10 26.70 7.80 7.80 26.70 4.0 5.55 5.55 11.10 8.33

3 Delta 2400 5.0 2400/120 10 33.30 6.24 7.80 26.70 4.0 6.93 5.55 12.48 9.71

4 Delta 2400 6.0 2400/120 10 40.00 5.20 7.80 26.70 4.0 8.32 5.55 13.87 11.10

25 1

2

Wye

Wye

2400

2400

3.0

4.0

1400/140

1400/140

15

15

30.00

40.00

4.62

3.46

3.46

3.46

40.00

40.00

4.0

4.0

4.16

5.54

5.54

5.54

9.70

11.08

6.94

8.32

3 Wye 2400 5.0 1400/140 15 50.00 2.77 3.46 40.00 4.0 6.93 5.54 12.47 9.71

4 Wye 2400 6.0 1400/140 15 60.00 2.31 3.46 40.00 4.0 8.31 5.54 13.85 11.09

26 3300 V 1

1 Delta 3300 3.0 3600/120 10 30.00 6.35 4.76 40.00 4.0 5.72 7.62 13.34 9.53

27 2

3

Delta

Delta

3300

3300

4.0

5.0

3600/120

3600/120

10

10

40.00

50.00

4.76

3.81

4.76

4.76

40.00

40.00

4.0

4.0

7.62

9.53

7.62

7.62

15.24

17.15

11.43

13.44

4 Delta 3300 6.0 3600/120 10 60.00 3.18 4.76 40.00 4.0 11.43 7.62 19.05 15.24

1 Wye 3300 3.0 1950/195 25 30.00 6.35 4.76 40.00 4.0 5.72 7.62 13.34 9.53

28 2 Wye 3300 4.0 1950/195 25 40.00 4.76 4.76 40.00 4.0 7.62 7.62 15.24 11.43

3 Wye 3300 5.0 1950/195 25 50.00 3.81 4.76 40.00 4.0 9.53 7.62 17.15 13.44

4 Wye 3300 6.0 1950/195 25 60.00 3.18 4.76 40.00 4.0 11.43 7.62 19.05 15.24

29 4160 V 1

1 Delta 4160 3.0 4160/120 15 34.67 6.00 4.50 46.22 4.0 7.21 9.61 16.82 12.02

2 Delta 4160 4.0 4160/120 15 46.22 4.50 4.50 46.22 4.0 9.61 9.61 19.22 14.42

30 3 Delta 4160 5.0 4160/120 15 57.77 3.60 4.50 46.22 4.0 12.01 9.61 21.62 16.82

4 Delta 4160 6.0 4160/120 15 69.33 3.00 4.50 46.22 4.0 14.42 9.61 24.03 19.23

1 Wye 4160 3.0 2400/240 25 30.00 8.00 6.00 40.00 4.0 7.20 9.60 16.80 12.00

31 2 Wye 4160 4.0 2400/240 25 40.00 6.00 6.00 40.00 4.0 9.60 9.60 19.22 14.40

3 Wye 4160 5.0 2400/240 25 50.00 4.80 6.00 40.00 4.0 12.00 9.60 21.60 16.80

4 Wye 4160 6.0 2400/240 25 60.00 4.00 6.00 40.00 4.0 14.40 9.60 24.00 19.20

32 1 Resistances and currents listed are an engineering guide only. Final results may differ somewhat from those listed because of resistor limitations.

Product Selection

33 Eatons C-HRG High Resistance Grounding Assembly can be completely described by an 8-digit

catalog number: MVRG-_ _ _ _ _ _ _ _

34 Table 36.1-2. High Resistance Pulsing Grounding Systems Catalog Numbering System

35 MVRG F W W C L L T S

36 Enclosure Type 2 Wiremarkers

Free-standing enclosure for mounting grounding Marks all internal wiring

transformer and resistors internally. for ease of maintenance.

Fault Sensing

37 F = Free-standing NEMA 1 S = Standard wrap-on

R = Free-standing NEMA 3R outdoor C = Overcurrent relay (51N) T = Tube/heat shrink type

V = Overcurrent relay (51N)

and voltage relay (59)

38 Service Voltage D = Overcurrent relay (51N) Indicating Lamps

and indicating voltmeter Standard lights are industrial,

W = 4160 V, 60 Hz

X = 2400 V, 60 Hz oil-tight, transformer type.

39 Y = 3300 V, 60 Hz Audible Alarm Optional are the same

type lights except with

Alarm contacts are standard on a push-to-test feature.

System Neutral Point all assemblies.

40 T = Transformer type

Choose wye when the neutral point of the power source N = No audible alarm incandescent lamps

is accessible for direct connection to grounding trans- L = Alarm horn with re-alarm timer X = Push-to-test

former. Choose delta when there is no neutral

41 or when neutral is not accessible.

transformer type

Loss of Control Power Alarm

W = Wye

D = D (wye broken delta grounding transformer) A relay is connected across the

42 customers 120 Vac supply.

N = No relay

L = Alarm relay with 1NO and 1NC

43

2 MV HRG is available for outdoor applicationcontact Eaton.

Example: MVRG-FWWCLLTS defines a free-standing NEMA 1 enclosure, 4200 V / 60 Hz, wye-connected system, current-sensing con-

trol scheme, alarm horn with re-alarm timer, alarm relay with 1NO and 1NC, transformer type incandescent lights, wrap-on wiremark-

For more information, visit: www.eaton.com/consultants CA08104001E

Resistance Grounding Systems 36.2-1

October 2015 High Resistance Grounding SystemLow Voltage

Sheet 36 009

General Description

Low Voltage High Resistance 22

Grounding

General Description 23

Where continuity of service is a high

priority, high-resistance grounding

can add the safety of a grounded 24

system while minimizing the risk of

service interruptions due to grounds.

The concept is a simple one: provide 25

a path for ground current via a

resistance that limits the current

magnitude, and monitor to determine 26

when an abnormal condition exists.

This provides for maximum continuity

of service, because no tripping occurs 27

for the resistance limited ground fault.

The ground current path is provided 28

at the point where the service begins,

by placing resistance in the connection

from system neutral to ground. Control 29

equipment continuously measures

ground current; a relay detects when

the current exceeds a predetermined 30

level. An alarm alerts building person-

nel that a ground exists. The system C-HRG Free-Standing NEMA 1 Unit C-HRG Wall-Mounted Unit

(Separately Mounted Resistors Not Shown)

has built-in fault tracing means to assist

in finding the source of the ground.

31

An integral transformer provides

control power from the primary source. Source

32

Standard Features

Current sensing ground fault detection 33

(15 A pickup/0.520 second delay)

HV

Ground current transformer

(10/10 ratio) 34

Control circuit disconnect switch

(fused)

Lockable door handle

C-HRG

High Resistance

600 V (Ma x.)

35

Grounding

Ground current ammeter System Main Breaker

(010 A, 1% accuracy) 36

Indicating lights:

Red (ground fault)

Green (normal)

37

White (pulse) DS-VSR

Feeder

Motor Feeder Feeder

Adjustable pulsing timer Starter Breaker Breaker Breaker 38

(010 seconds)

Tapped resistors (15 A)

Three-position selector switch Conduit Bus Duct Cable Tray Conduit

39

(normal, pulse, test)

Control switch for manual or

automatic reset 200 Hp MCC

Distribution

Switchboard Transformer

40

Ground fault contacts (1NO/1NC)

Shorting terminal block for ground

M M M

41

current transformer 3 Wor 4 W

Panel-

UL label Motor Loads Misc. 3 W Board

Rated for use up to 200 kA fault

Loads

42

current system

Figure 36.2-1. Typical Distribution System

Front accessible

Nylon flag type wiremarkers

1 Phase-to-neutral loads require a delta-wye distribution transformer. The neutral on the secondary 43

side of this transformer must be solidly grounded.

Three zig-zag or wye-broken

delta grounding transformers for

systems without a neutral point

CA08104001E For more information, visit: www.eaton.com/consultants

36.2-2 Resistance Grounding Systems

High Resistance Grounding SystemLow Voltage October 2015

Sheet 36 010

General Description

Application Issues Indication and Alarm Circuits Pulser Circuit

22 When a fault is detected, an adjustable The pulser circuit offers a convenient

600/347 V (Maximum) Wye Systems time delay is provided to override tran- means to locate the faulted feeder and

To add high resistance grounding to sients. When the time delay has been trace the fault to its origin. The pulser

23 a wye-connected system, resistors exceeded, the green normal light will is available any time a fault has been

are placed in series with the neutral- turn off, the red ground fault light will detected. The pulse intervals are con-

to-ground connection of the power turn on, and the ground alarm contacts trolled by an adjustable recycle timer.

24 source. The resistors are chosen to will transfer. If equipped with the The pulse light flashes on and off,

limit the current to a maximum optional alarm horn, it will sound. corresponding to the on-off cycles

value of 5 A. of the pulser contactor. The pulser

25 When the fault is cleared, the current/ contactor switches a bank of resistors

600 V (Maximum) Delta Systems voltage relay will reset. If the reset on and off, thus allowing a momentary

To add high-resistance grounding control is set on auto, the lights will increase in the ground current

26 to an ungrounded delta-connected return to normal on, ground fault (approximately a 5 A current pulse

system, a neutral point must be created. off, and the ground alarm contacts will above the ground current).

Three single-phase transformers can re-transfer. If the reset control is set on

27 be interconnected in a zig-zag manual, the lights and relay will Locating a Ground Fault

or wye-broken delta configuration remain latched until the operator turns The current pulses can be noted with a

to provide such a neutral point. The the reset control to reset. The lights clamp-on ammeter when the ammeter

28 transformers and grounding resistors and ground alarm contacts will then is placed around the cables or conduit

are chosen to limit the ground current return to normal. The system can be feeding the fault. The operator tests

to a maximum value of 5 A. reset only if the fault has been cleared. each conduit or set of cables until the

29 pulsing current is noted. By moving

Ground Current Detection During a fault, the optional alarm horn

can be silenced at any time by using the ammeter along the conduit, or

Any time a system is energized, checking the conduit periodically along

30 a small ground current called the

the alarm silence pushbutton. It will

its length, the fault can be traced to its

not re-sound until either the system

capacitive charging current will origin. The fault may be located at the

is reset, or the re-alarm timer expires.

be observed. For low voltage (600 V point where the pulsing current drops

31 and below) systems, this naturally-

The re-alarm timer is activated by the

off or stops.

alarm silence control. If the horn

occurring current is typically 1 A

has been silenced but the fault has If little or no change in the pulsing

or less.

32 not been cleared, the timer will run. current is noted along the entire length

When one phase becomes grounded, It has a range of 248 hours. When the of a conduit, then the fault may be

additional current above the charging timer times out, the horn will in the connected load. If the load is a

33 level will flow. As all ground current re-sound, alerting maintenance person- panelboard, distribution switchboard

must flow through the grounding nel that the fault has not been cleared. or motor control center, repeat the

resistor/grounding transformer assem- process of checking all outgoing cable

34 Test Circuit

bly, an ammeter in this circuit will read groups and conduits to find the faulted

the total amount of ground current. A test circuit Is provided to allow feeder. If the fault is not found in an

By placing a current-sensing relay in the user to quickly determine that the outgoing feeder, the fault may be

35 series with the ammeter, the current system is working properly. The test internal to that equipment.

relay can be adjusted to pick up at circuit will operate only under normal

a level in excess of the capacitive conditionsit will not allow testing if Application Notes

36 charging current, thus indicating the system is sensing a fault. A sepa-

It may not be possible to precisely

the abnormal condition. rate grounding resistor is provided,

connected to a relay operated by the locate faults within a conduit. The

37 Alternatively, an optional voltmeter- test position of the mode selector ground current may divide into many

relay can be connected across the switch. The relays contact grounds components, depending on the num-

grounding resistors. The voltage phase B through the test resistor, ber of cables per phase, number of

38 across the resistors is proportional causing ground current to flow. The conduits per feeder, and the number

and resistance of each ground point

to the amount of ground current. The system then reacts as it would under

voltmeter-relays pickup adjustment actual system ground conditions along the conduits. The resulting

39 is set above the capacitive charging lights transfer, alarm contacts transfer currents may be too small to allow

current, to the desired detection level. and the (optional) horn sounds. detection or may take a path that the

ammeter cannot trace. An important

In both current and voltage detection

40 methods, the ground current ammeter

note to keep in mind is that while the

pulser can greatly aid in locating a

provides a direct reading of the total, fault, there may be certain conditions

actual ground current present in the

41 system at that time. It will be helpful

under which the pulses cannot be

readily traced, and other test proce-

to periodically note the ammeters dures (meg-ohm, high-potential, etc.)

reading; a trend toward higher values

42 may indicate the need for equipment

may be needed.

maintenance and hence reduce the Application Note: Per 1993 NEC 250.5b,

occurrence of unplanned shutdowns. exception No. 5, line-to-neutral loads may

43 not be connected to a system where the

system is resistance-grounded.

For more information, visit: www.eaton.com/consultants CA08104001E

Resistance Grounding Systems 36.2-3

October 2015 High Resistance Grounding SystemLow Voltage

Sheet 36 011

General Description

Sequence of Operations manual position, turn it to reset to Construction Features

reset the fault sensing circuit. The red

1. Tapped resistors supply ground

22

Normal ground fault light will turn off, and

the green normal light will turn on. current between 1 and 5 A in 1 A

Green normal light on increments.

Red ground fault light off Test mode is not available if the system 23

is detecting a ground. The sensing 2. Pulse current is an additional

White pulse light off

circuit will disable the test circuit. 5 A. (Pulse currents of a lower

System control switch in 24

normal position magnitude may be difficult to

Ground Fault

detect.)

Reset control switch in either When the sensing circuit detects a

auto or manual fault, the green normal light will turn 3. Pulse timer is adjustable from 3 25

off and the red ground fault light will to 60 pulses per minute.

Test

turn on. The ground current ammeter

4. Time delay for current sensing

Turn and hold the system control will indicate the total ground current.

relay is 0.5 to 20 seconds with a

26

switch in the test position. Phase B To use the pulser, turn the system

will be grounded via the test resistor. 1 to 5 A pickup. (Time delay for

control switch to pulse. The pulser

The ground-current will activate the voltage sensing relay is 1 to 27

contactor will cycle on and off as con-

sensing circuit, causing the green 60 seconds.)

trolled by the recycle timer relay. Use

normal light to turn off and the red the clamp-on ammeter to locate the 5. Fused disconnects are supplied for

ground fault light to turn on. The faulted feeder. Open the feeder and control and ground transformers. 28

pulser will be activated as well. The clear the fault. If the reset control

white pulse light will turn on and switch is in the manual position, 6. All door-mounted equipment is

off as the pulser contactor closes and turn it to reset to reset the sensing guarded against accidental contact. 29

opens. The ground current ammeter circuit. (If reset control is in auto, it 7. All exterior nameplates are fas-

will display the total ground current, will reset itself.) When ready to restore tened with stainless steel screws.

including the incremental pulse service to the load, close the feeder. 30

current. When ready, return the system Return the system control to normal. 8. Nameplates are 2-ply with

control switch to normal. The pulser 3/16-inch lettering. The nameplate

will stop. If the reset control is in the size is 1-inch x 2-1/2 inches white 31

background with black lettering

is standard.

Continuously Rated Ground Fault System 9. Top and bottom cable entry areas 32

Operating Instructions

4 6 To Trace Ground Fault

are standard.

33

A. Turn pulser selector switch to pulse position.

2 8

Ammeter will indicate current pulses at a

rate matched by white pulse lamp. 10. Phase and neutral terminals

B. Test each feeder conduit with clamp-on

ammeter to locate conduit that causes the accept #12 AWG to #8 AWG.

clamp-on ammeter to pulse. Fault is in that

conduit or in connected load. See instruction

manual for information on fault locating.

11. Ground terminal accepts wire sizes

0 Ac

Amperes

10 C. Once fault has been located:

1. Open feeder

2. If reset control is in manual, reset system

3. Clear fault

from #8 AWG to 500 kcmil. Ground 34

4. Close feeder

5. Return system control switch to normal bus is 1/4-inch x 2 inches copper.

To Test Ground Fault System

Pulse

Group Current

Note: Test circuit will not operate if system is presently

detecting a ground fault. 12. The paint is applied using an 35

Ammeter A. Turn and hold system control selector switch in test

position. After time delay expires, lights will transfer

to indicate a fault, and pulser will begin operating.

electro-deposition coating system.

W B. Return system control switch to normal. Reset Metal surfaces are prepared by

36

system. Turn reset control to auto or manual.

spray and dip cleaning, and

System Control

Normal

Reset Control

Manual

Ground Normal

phosphatizing. The standard

Pulse Test Auto Reset Fault color is ANSI 61, light gray.

R G 13. Line side fuses are rated for use up 37

to 200 kA fault current systems. All

other fuses are rated to protect

Ground Voltage

Meter Relay

each circuit as required. 38

Device 59N

Voltage

14. The resistors are wire wound on

Meter Relay a steel tube, insulated by Micarta. 39

S V Resistors are mounted on a steel

Alarm

Horn

rack with ceramic insulators.

40

Meter Relay Setpoint Adjustment

1.

Instruction

Press S & up-arrow keys

Display

PAS 15. No. 8 AWG wire is used for internal

2. Press S key SP1, then setpoint

3. Adjust setpoint 1 using setpoint connections from the neutral point

up/down arrow keys

to ground. Control connections

4.

5.

6.

Press S key

Adjust setpoint 2 using

up/down arrow keys

Press S key

SP2, then setpoint

setpoint

END,RUN,

are a minimum of #14 gauge. All 41

meter reading

See meter relay manual for complete Ground Alarm control wires insulation is type SIS.

programming instructions.

High-Resistance Grounding System Ratings

16. UL listed. 42

Current Ratings: 5A Ground Current, Max.

Rated Time:

5A Pulsing Current, Max.

Continuous Duty at Rated Current

Alarm 17. A list of recommended spare parts

Silence

can be provided after the final

The system neutral conductor shall not be

connected to ground at the switchboard or at the

source (utility or generator) except through the

grounding impedance.

PB engineering is complete. 43

18. Steel pocket on the inside of the

door is provided to hold drawings

Figure 36.2-2. Front Door Layout and manuals.

CA08104001E For more information, visit: www.eaton.com/consultants

36.2-4 Resistance Grounding Systems

High Resistance Grounding SystemLow Voltage October 2015

Sheet 36 012

Product Selection

Catalog Numbering System

22 Table 36.2-1. Type C-HRG (Low Voltage) Catalog Numbering System

23 F 4 W N C R N S F 4 6

24 Enclosure Type System Frequency

F = Free-standing, Type 1 Distribution Wire Harness 5 = 50 Hz

System Voltage Length for N

25 S = Free-standing, Type 1

with screened vents 6 = 600 V

(No Enclosure)

6 = 60 Hz

R = Free-standing, Type 3R 4 = 480 V 4 = 4-foot harness

W = Wall-mounted, Type 1 3 = 380 V 6 = 6-foot harness

26 N = No enclosure 2 = 208240 V 8 = 8-foot harness

(panel-mounted) 0 = 10-foot harness

V = Wall-mounted, Type 1 2 = 12-foot harness

27 with 3R resistor enclosure N = Free-standing,

no harness required

System Neutral Point

28 W = Wye (and accessible at system) Wire Marker

Z = Delta (zig-zag grounding transformers) P = Machine printed

D = Delta (wye-broken delta grounding transformers) F = Sleeve type

29 H = Heat shrink, sleeve type

Distribution System Fault Current

6 = 25 kA at 600 V, 65 kA at 480 and 380 V, 200 kA at 240 V Indicating Lights

30 1 = 150 kA at 480 and 380 V, 200 kA at 240 V S = Standard incandescent

2 = 200 kA at 600 V, 480 V or 380/280 V L = Standard LED

N = Not applicable (when using W above) P = Push-to-test incandescent

31 D = Push-to-test LED

T = Transformer-type incandescent

Ground Fault Sensing

X = Push-to-test transformer-type

C = Current-sensing relay, with low pass filter 1

32 D = Voltage sensing relay, double set point

Loss of Control Power Relay (Alarm)

H = Voltage sensing relay (D) with low pass filter 1

N = No relay

33 L = Alarm relay with 1NO/1NC contact

Audible Alarm

34 N = No audible alarm

R = Alarm horn with re-alarm timer

35 1 Low pass filter attenuates high frequency ground current signals, as typically produced by variable speed drives, allowing the ground relay to see only

power frequency ground current.

36

37

38

39

40

41

42

43

For more information, visit: www.eaton.com/consultants CA08104001E

Resistance Grounding Systems 36.2-5

October 2015 High Resistance Grounding SystemLow Voltage

Sheet 36 013

Technical Data

Technical Data

22

HV 600/347 V (Max) Wye, Ungrounded HV 600 V (Max) Delta, Ungrounded

23

To To

Distribution Distribution

Equipment Equipment

24

N A B C G R W A B C G R W

CLF

CLF

Control

Zig-Zag

Grounding

CLF

CLF

Control

25

Circuit Transformers Circuit

CLF CLF

AM 51N AM

26

Pulser Grounding Test

59N Pulser

Grounding Test

27

Resistor Resistor Resistor Resistor Resistor Resistor

28

G G

29

Figure 36.2-3. Four-Wire SourceFault Detection via Current Relay Figure 36.2-6. Three-Wire SourceFault Detection via Voltmeter Relay

HV 600/347 V (Max) Wye, Ungrounded HV 600 V (Max) Delta, Ungrounded

30

To

Distribution

Equipment

To

Distribution

Equipment

31

N A B C G R W A B C G R W 32

CLF CLF

Control Control

CLF CLF

CLF

Circuit

CLF

Circuit

33

AM

Wye -

Broken Delta

Grounding

Transformers

Pulser

Resistor

Grounding

Resistor 34

59N Pulser Grounding Test Test

Resistor Resistor Resistor Resistor

AM 51N

35

G G

36

Figure 36.2-4. Four-Wire SourceFault Detection via Voltmeter Relay Figure 36.2-7. Three-Wire SourceFault Detection via Current Relay

37

HV 600 V (Max) Delta, Ungrounded HV 600 V (Max) Delta, Ungrounded

38

To To

Distribution Distribution

Equipment Equipment

39

A B C W A B C G R W

G R

Zig-Zag

Grounding

CLF

CLF

Control

CLF

CLF

Control 40

Circuit Circuit

Transformers CLF

CLF

AM 51N Wye -

Broken Delta

41

Pulser Grounding 59N

Grounding Resistor Resistor

Transformers

Pulser

Resistor

Grounding

Resistor

Test Test

Resistor

42

Resistor AM

G G

43

Figure 36.2-5. Three-Wire SourceFault Detection via Current Relay Figure 36.2-8. Three-Wire SourceFault Detection via Voltmeter Relay

CA08104001E For more information, visit: www.eaton.com/consultants

36.2-6 Resistance Grounding Systems

High Resistance Grounding SystemLow Voltage October 2015

Sheet 36 014

LayoutDimensions

22 2.00 0.56 (14.2) Dia. (4) 2.36 0.63 (16.0) Dia. (6)

(50.8) (59.9)

5.00 x 5.00 (127.0 x 127.0)

Conduit Entry Area 5.00 x 5.00 (127.0 x 127.0)

23 0.75

(19.1)

(Top and Bottom)

3.41

(86.6)

Conduit Entry Area

(Top and Bottom)

24.00 3.00 37.00

(609.6) 3.47 (76.2) (939.8) 5.00

(88.1) 2.36

24 (59.9)

(127.0)

16.00 5.00

3.13 Front 5.00

25 (79.5) (127.0)

(406.4) (127.0)

Plan View

Front 1.44

0.94

Plan View (36.6)

26 4.00 (101.6) Vent Neutral and (23.9)

Phase Terminals

#12 to #8 AWG Neutral and Phase Terminals

#12 to #8 AWG

27 Ground

Current

Ammeter Instruction

Nameplate Ground

Current

Ammeter

28 Instruction

Nameplate

29

92.00 93.00

30 (2336.8) (2362.2)

Voltmeter Alarm

Relay

31 Horn

Voltmeter

Relay Alarm

Horn

32

Resistors Resistors

Ground Terminals Ground Terminals

33 #8 to 500 kcmil #8 to 500 kcmil

Grnd Bus

Grnd Bus

34 21.00

(533.4)

26.00

(660.4)

Front View Approx. 650 Lb (295 kg) Front View Approx. 950 Lb (431 kg)

35

Figure 36.2-9. NEMA 1 Free Standing Figure 36.2-10. NEMA 3R Outdoor

36

37 12.00

(304.8)

2.00 4.00 (101.6)

5.00 x 5.00 (127.0 x 127.0)

(50.8)

Conduit Entry Area

Top View

38 1.75

0.375 (9.5) Dia. (4)

(44.5)

Ground

Current

Ammeter Instruction

1.13

0.438 (11.1) Dia. (4)

39 Nameplate (28.7)

0.50 (12.7)

13.00

(330.2) 1.13 (28.7) KOs

(3)

40 50.00 52.00

Neutral and 12.50

(317.5)

13.50

(342.9)

Phase Terminals

(1270.0) (1320.8) #12 to #8 AWG

Ground Terminals

41 #8 to 500 kcmil

17.13

(435.1)

16.38

(416.1)

Voltmeter Alarm

Front View Side View

42 Relay Horn

16.00 Typical Resistor Assembly

43 (406.4) 17.00 (431.8) (Dimensions May Vary Shown

for General Reference Only)

Front View

Control Assembly Approx. 300 Lb (136 kg) Approx. 75 Lb (34 kg)

Figure 36.2-11. NEMA 1 Wall Mounted Dimensions for estimating purposes only.

For more information, visit: www.eaton.com/consultants CA08104001E

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- CS InfiniumHDFib ORDocument2 pagesCS InfiniumHDFib ORThomas MartinNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- DPC UG Legrand LX Configuration GuideDocument20 pagesDPC UG Legrand LX Configuration GuideThomas MartinNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Underground Electric Distribution Standards ManualDocument280 pagesUnderground Electric Distribution Standards ManualThomas MartinNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- JD Alh20Document1 pageJD Alh20Thomas MartinNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- DPC DS OptiCoolReadyBarracuda R2Document2 pagesDPC DS OptiCoolReadyBarracuda R2Thomas MartinNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 2022 Printable CalendarDocument12 pages2022 Printable CalendarAnonymous ecgjAADNo ratings yet

- In-Wall Storage Where & When You Want ItDocument8 pagesIn-Wall Storage Where & When You Want ItThomas MartinNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- AGi32 Quick Reference v14Document2 pagesAGi32 Quick Reference v14Thomas MartinNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Data Center Efficiency White PaperDocument8 pagesData Center Efficiency White PaperMiguel Ángel EscobedoNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- HC Wave Ss Involve Wave Instant Hot Cold Water System Specifications en Us 1567778Document1 pageHC Wave Ss Involve Wave Instant Hot Cold Water System Specifications en Us 1567778Thomas MartinNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Augiworld: Tools & Techniques To Help Us CollaborateDocument36 pagesAugiworld: Tools & Techniques To Help Us CollaborateThomas MartinNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- AGi32 Quick Reference v14 PDFDocument8 pagesAGi32 Quick Reference v14 PDFThomas MartinNo ratings yet

- Augiworld: Tools & Techniques To Help Us CollaborateDocument36 pagesAugiworld: Tools & Techniques To Help Us CollaborateThomas MartinNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- TB02203002E - Tab 36asdfDocument13 pagesTB02203002E - Tab 36asdfThomas MartinNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- TB02203002E - Tab 36 - Eatonasdf PDFDocument14 pagesTB02203002E - Tab 36 - Eatonasdf PDFThomas MartinNo ratings yet

- Square D Coordinating BreakersDocument26 pagesSquare D Coordinating BreakersThomas MartinNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Meter - Class - 2000specDocument2 pagesMeter - Class - 2000specThomas MartinNo ratings yet

- GMP Dairy ProductDocument19 pagesGMP Dairy ProductGregory BaileyNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- BZ 50 PPDocument1 pageBZ 50 PPThomas MartinNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- GMP Dairy ProductDocument19 pagesGMP Dairy ProductGregory BaileyNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Zablocki Lighting Standards (In Progress)Document22 pagesZablocki Lighting Standards (In Progress)Thomas MartinNo ratings yet

- Striplight Ej PDFDocument2 pagesStriplight Ej PDFThomas MartinNo ratings yet

- Andrew Tips & Considerations - GraybarDocument10 pagesAndrew Tips & Considerations - GraybarThomas MartinNo ratings yet

- Features & Specifications: Enclosed Linear FluorescentDocument2 pagesFeatures & Specifications: Enclosed Linear FluorescentBrook ChanNo ratings yet

- Visual Basic Cheat SheetDocument19 pagesVisual Basic Cheat SheetWy Teay100% (2)

- Smart BuildingDocument162 pagesSmart Buildinggoutam_trip_acharjeeNo ratings yet

- Review: Power System Analysis Software ToolsDocument6 pagesReview: Power System Analysis Software ToolsTaoplayer100% (2)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Review: Power System Analysis Software ToolsDocument6 pagesReview: Power System Analysis Software ToolsTaoplayer100% (2)

- Reference DAPPERDocument124 pagesReference DAPPERVictor Luiz MerlinNo ratings yet

- Notice AXT25TC BoschDocument14 pagesNotice AXT25TC BoschPatrice GervoisNo ratings yet

- Books PDFDocument1 pageBooks PDFoghaleudoluNo ratings yet

- Joel McClain & Norman Wootan Magnetic Resonance Amplifier Collected PapersDocument102 pagesJoel McClain & Norman Wootan Magnetic Resonance Amplifier Collected Papersfrancisrpassaro3346100% (1)

- Lecture-4 - The Radar EquationDocument20 pagesLecture-4 - The Radar EquationZeeshan JavedNo ratings yet

- KSD301 Snap Action ThermostatDocument6 pagesKSD301 Snap Action ThermostatAntonio Carlos Del CastilloNo ratings yet

- Eaton 9130 DSP Firmware Upgrade Guide 2.543Document11 pagesEaton 9130 DSP Firmware Upgrade Guide 2.543AlejandroNo ratings yet

- D-5450-1-B HS60G80GL SM EngDocument84 pagesD-5450-1-B HS60G80GL SM EngRuslan Valiakhmetov100% (2)

- EN Datasheet Copper SB RevCDocument1 pageEN Datasheet Copper SB RevCRoger Valenzuela HuamanNo ratings yet

- Ds 11011Document3 pagesDs 11011Walther EstevezNo ratings yet

- Protecta: Normal and Emergency LightingDocument4 pagesProtecta: Normal and Emergency LightingcharlnnmdNo ratings yet

- DMTE ABB 2csm445001d0202Document12 pagesDMTE ABB 2csm445001d0202Marco VolpeNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Vacuum Circuit Breaker (VCB) Working and ApplicationsDocument11 pagesVacuum Circuit Breaker (VCB) Working and ApplicationsMoe Oo KoNo ratings yet

- Protection in 400kvDocument18 pagesProtection in 400kvmanoharmanishNo ratings yet

- Inverse Time Overcurrent Relaying Decision For Protection of Three Phase Transmission LineDocument5 pagesInverse Time Overcurrent Relaying Decision For Protection of Three Phase Transmission LineNandi ?No ratings yet

- TEPZZ - 9 - 6 - 6B - T: European Patent SpecificationDocument15 pagesTEPZZ - 9 - 6 - 6B - T: European Patent Specificationzweisteine777No ratings yet

- Handouts EIM. SS1 Week 2Document4 pagesHandouts EIM. SS1 Week 2myco sauraNo ratings yet

- Linear Link™: Installation, Operation and Maintenance ManualDocument44 pagesLinear Link™: Installation, Operation and Maintenance ManualAlan Barros SallesNo ratings yet

- LM 5023Document38 pagesLM 5023Kartik hegdeNo ratings yet

- Elektor (Nonlinear - Ir) 1979-07 - 08 - TextDocument123 pagesElektor (Nonlinear - Ir) 1979-07 - 08 - TextQuincheNo ratings yet

- Intelligent Mobile ROBOT Navigation Technique Using RFID TechniqueDocument29 pagesIntelligent Mobile ROBOT Navigation Technique Using RFID TechniquenehakolheNo ratings yet

- 710AA90L7BV-EMD26CLT 59w (LBP) - DatasheetDocument5 pages710AA90L7BV-EMD26CLT 59w (LBP) - Datasheetmohamad tajvidiNo ratings yet

- Groundfos - SP 9-48Document10 pagesGroundfos - SP 9-48suwono radukNo ratings yet

- Single-Chip IC: For Home Stereo IC With Electronic Tuning SupportDocument9 pagesSingle-Chip IC: For Home Stereo IC With Electronic Tuning SupportVicenteAlvarezNo ratings yet

- Scp-C. Instruction Manual 2009Document62 pagesScp-C. Instruction Manual 2009Arkady ZabrovßkyNo ratings yet

- EMI Troubleshooting Cookbook For Product Designers (PDFDrive)Document252 pagesEMI Troubleshooting Cookbook For Product Designers (PDFDrive)Rudra Banerjee100% (1)

- Manual Sinamics G120Document120 pagesManual Sinamics G120David AndreicaNo ratings yet

- Lighting Controls Patterns For Design PDFDocument299 pagesLighting Controls Patterns For Design PDFJankovski22 MaksNo ratings yet

- FINPLAN Case Study: Safa Dhouha HAMMOU Mohamed Bassam BEN TICHADocument6 pagesFINPLAN Case Study: Safa Dhouha HAMMOU Mohamed Bassam BEN TICHAKhaled HAMMOUNo ratings yet

- Ecet321l - E1 - Single Stage Ce AmplifierDocument9 pagesEcet321l - E1 - Single Stage Ce AmplifierKenneth DomingoNo ratings yet

- 10 - Operating Instruction - DSC... - CAN Bus, Serial Bus - BEA - 209283-En-03Document8 pages10 - Operating Instruction - DSC... - CAN Bus, Serial Bus - BEA - 209283-En-03jose mondacaNo ratings yet