0% found this document useful (0 votes)

2K views10 pagesOperation Management MidTerm

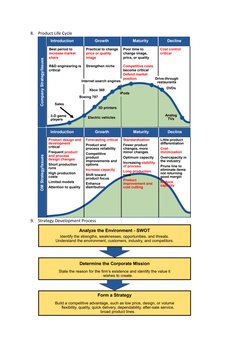

This document provides an overview of operations management. It discusses key topics including what operations management is, strategic decisions in OM such as product design and quality management, productivity measures, new challenges in OM like sustainability and mass customization, reasons for globalization, strategies for competitive advantage, issues in operations strategy, the product life cycle, and the product development process. The document is intended to introduce foundational concepts in operations management.

Uploaded by

Nicholas ChiewCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

2K views10 pagesOperation Management MidTerm

This document provides an overview of operations management. It discusses key topics including what operations management is, strategic decisions in OM such as product design and quality management, productivity measures, new challenges in OM like sustainability and mass customization, reasons for globalization, strategies for competitive advantage, issues in operations strategy, the product life cycle, and the product development process. The document is intended to introduce foundational concepts in operations management.

Uploaded by

Nicholas ChiewCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd