Professional Documents

Culture Documents

Electronic Speed Switch PDF

Uploaded by

Swarup Nayak0 ratings0% found this document useful (0 votes)

19 views8 pagesOriginal Title

electronic_speed_switch.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views8 pagesElectronic Speed Switch PDF

Uploaded by

Swarup NayakCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

eae

Monitoring Rotary

ae Linear motion

PIONEERS IN ELECTRONIC SPEED SWITCHES

Over 2,00,000 units in operation Since 1980

INTRODUCTION

‘Monitoring Speed is essential in any automation process.

‘Speed of any equipment driven by an electric motor can

change due to a variety of reasons e.g.averload, under load,

breakage of transmission parts etc. This change should be

‘monitored continuously for corrective action and to save

costly equipment from damage. In case of @ open loop

control, a speed monitoring device is useful to either give an

alarm oF to ‘switch off' the motor. In case of a closed loop

control, e.9. 0.C. drive or V/F drive, a feedback is required

(4-20mAor 0-10) to take corrective action,

Jayashree Electron has been manufacturing Electronic Non

Contact type speed switches and speed monitoring systems

for over 35 years. We have more than 50 different models

10 suit individual applications. Over 2,00,000 units are in

‘operation throughout the world

By continuously upgrading to the latest technology, our

monitoring units keep pace with time, With over

2000 satisfied customers we are committed to maintain

high quality, reliability of product and prompt after sales

service.

‘TYPICAL APPLICATIONS.

‘The Electronic Speed Switches (Zero Speed, Under Speed or

Over Speed), Speed Indicators, and Speed Transducers find

wide applications in different industries. Some typical

applications are as below:

Thermal Power Plants, Steel Plants : Underspeed / Zero

Speed monitoring for ‘conveyors. Useful for Sequential

starting / stopping of conveyors, overspeed safety for

T

Cement/Fertilizer Conveyor Belts, Agitators, stacker

reclaimer, Mixers, Crushers, Bucket Elevators, Fans.

Sugar, Chemical and Process Industries : Centtifuge

‘Machines, Fluid Couplings,

Large Machines : Locked Rotor Protection.

Textile, Paper, Packaging and Automatic

‘Manufacturing lines : Speed feedback

Textile, Paper, Packaging and Automatic

‘Manufacturing lines: Speed feedback, synchronization,

Safety interlocks etc.

Ports / Docks Conveyor Safety, Auto Routing,

FEATURES

Following operational features are available for different

models. Appropriate model with relevant features should

be selectedas per application requirement.

Duty: Underspeed / Overspeed /Zerospeed

Enclosures : |P 30 / IP 55 / IP 65 / IP 67 in Plastic, CA, C,

Polycarbonate. Flameproof enclosures with Government

recognised house Certificate for Gas Group IA,I8 and iC

‘Supply Voltage: 12/24/110/240VAC/OC.

Speed Setting : The desired speed value can be set by

means of potentiometer / keypad / Trim pot. the

potentiometer type units have a calibrated dialin 1:10 ratio.

Standard Speed ranges are

1010 RPM ‘510.50 RPM

100 100 RPM ‘50 to 500 RPM

100 to 1000 RPM '500 0 5000 RPM

Non-standard ranges can be provided on request. A single

tunit covering from SRPM to 5000RPM (multirange) is

available for specific application.

‘Time Delay : Built in initial by pass or nuisance tripping time

delay.

Output Contacts : standard combinations available are

NO+INC, 2NO*2NC, 1€/0 oF 2C/0.

‘Output Signals : a) 0-10 V / 4-20 mA Proportional to

specified speedrange b) RS 485/RS 232 / MODBUS.

Display : 2) Dot LED for supply ON / Relay ON b) Speed

Pulses) Digital Seven Segment LED display up to 6 digits for

speed.

CONSTRUCTION

1. Series RM 221 /RMEZ1/RMP21: These units consist

‘of two parts namely the Monitoring unit and the Non-

‘contact type speedsensor probe.

a) Monitoring unit : These are available in a variety of

enclosures suitable for projection / flush mounting as

below:

‘Mounting Style | Protection Grade | Enciosure Material

Projection Wal | 1-30 Plastic MS

1P 55/65 Robust CA/CVABS

Fame Proof | CAVClas per Requirement

Fush/ Pane Front | 1°30 MsyPlaste

b) Speed Sensing Probe : The speed sensing probes are

specially designed to sense specified rotating flags. The

robes are available in standard M12/M18/M30/MS50/M80

size with sensing gaps from imm to 50mm. The probes

have a special frequency response characteristic to match

the monitoring unit.

1) Special Model Type RM 013 / 015 : This is a very

compact and convenient type of speed switch suitable for

monitoring zero speed and to give signal to PLC / DCS. It

consists of only a Tubular enclosute (lke standard Sensor

Probe) with built on cable. The flag sensing cireuit, the pulse

rate comparing circuit and the output driving circuit are all

incorporatedinone housing.

PRINCIPLE OF OPERATION

The speed / motion of rotating / moving objectis sensed by

2 non-contact Inductive type sensor. The sensor probe is

installed with its sensing face in close vicinity of rotating

object. The metallic pieces (flags) with specified

dimensions are tobe mountedon the rotating object. When

these flags pass across the face of the probe, the frontally

radiated electromagnetic field of the probe is damped which

is converted to a corresponding output pulse. The pulse can

also be generated by any other types of probes.

These pulses are led to the monitoring unit via a separate

interconnecting cable. The sensor Probe can be mounted up

toa maximum distance of 100 meters from the monitoring

Unit. The interconnecting cable should be of minimum0.5 59

mm. size.

‘These pulses are digital in nature and the circuit is designed

to work in electrically noisy area. An LED provided on rear

side of the probe gives visual indication for sensing of the

flag. Incase of sensors other than Inductive type, the pulses

generated can be connected as specified for the individual

sensor.

The units are designed by using new advance

Miocontroller based circuit. ll operating features e.g. time

delay, speed comparison, speed display, output relay

‘operation are controlled precisely by the micro controler.

Some parameters, related to design / operation of a speed

‘switch, are as explained below.

Relay Logic

Different options of Relay operation logic are available. For

‘monitoring under speed it is recommended to have the

‘relay energised at healthy speed (fal safe logic) and to drop

out in case the speed drops. However, reverse or different

‘operational gic can be provided on request.

Initial by-pass time delay (ITD)

For monitoring under speed conditions it is essential tohhave

‘a by-pass arrangement during starting of the machine. The

output relay of the speed monitor is “OFF during starting

/under speed condition and is ‘ON’ (energised) during

healthy running speed. Hence it is essential to. bypass

(override) the relay contacts whilst starting. This can be

achieved by using either an external timer unit, by

programming through PLC or by using a built in by-pass time

delay (ITD). With the built in ITD feature the output relay

switches ‘ON' with ‘supply ON’ condition and remains ON til

the set time delay. If the equipment speed reaches its

‘normal healthy speed during ths time then the relay

Under Speed Switch : Characteristics and Typical Schematics

‘continues to remain ON. The relay drops out if the speed has

not reached the set value or when the speed drops below set

‘value during run.

Nuisance Tripping Time Delay (NTO)

During run, the equipment may lose its speed momentarily,

‘due to various reasons. To avoid unnecessary tripping due to

this, a builtin time delay fs provided. The output relay will

‘drop out after the preset time delay after the speed has

dropped below the set value. If the equipment speed

fecovers during this, then the relay continues toremain ON.

Hysteresis

The output relay has an inherent operating hysteresis

characteristic (differential between Relay ON/OFF) as given

in Fig. 1. All standard models are provided with about 5%

hysterisis value.

STANDARD MODELS

Models from a different classifications are distinct in

construction and circuit design. There are however some

standard models in each series, which are as described

below.

Model

RMZ2t1

RMEDH

EnolosureFeatures

Robust CA/Separae Terminals

Industial CA‘Single PCB with bult on terminal / Relay eo.

RMEZ51_| industrial CA with digital display

RM D161 | Brass / SS Tubular enclosure for directly working with PLC

GENERAL SPECIFICATIONS

Some technical specifications are common for all models as,

given below. For detailed specifications refer data sheets of

individual products.

Power consumption

Working Temperature

Repeat Accuracy

Contact Rating : 5A resistive at 240 V AC/8 A on request

Speed Range / No. of flags : The units are calibrated to work.

for the following calibration as per our standard.

2 SVAmax

-25°T0 70°C

+ Better than +19 of set value.

[operating Range, APM | 1-10

No.of Fags ela 2 i

5-80; 10-100] 50-800; 100-1000] 500-5000

The monitoring unitis calibrated for specific no. of pulses per

minute. A unit calibrated for range 5-60 RPM with 4 No. flags,

can be used for 10-100 RPM with 2 flags.

[ Relay Operation Recommended Schematics

Wi bain ial Bs Wi sera ne lp

a a

t ut ne

8 0 ‘2

5

ot

‘eeu yacht with ey nd op uae st ne Po'SepPO ct Ceol Conair SS Eaten Sond Satin

over tte eqspmorteped xcs efomavexawenmbatne) e0:ComelFice St sun Pw

Seveay nt crue eran OX ‘1 Teoma t_Gt_ ON uy Tne

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- DynamicBalancingandShaftAlignment PDFDocument35 pagesDynamicBalancingandShaftAlignment PDFSwarup NayakNo ratings yet

- Earthing Training PDFDocument6 pagesEarthing Training PDFSwarup NayakNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- STD 137 PDFDocument43 pagesSTD 137 PDFSwarup NayakNo ratings yet

- Best Practice For Thermal Power PlantsDocument186 pagesBest Practice For Thermal Power Plantsnao100% (27)

- OM 6-5-A Earthing PracticesDocument16 pagesOM 6-5-A Earthing PracticesAnurag PugaliaNo ratings yet

- Balance Quality Requirements of Rigid Rotors - The Practical Application of ISO 1940-1Document11 pagesBalance Quality Requirements of Rigid Rotors - The Practical Application of ISO 1940-1FabbroxNo ratings yet

- MANAGER (SAFETY) - RFCL - 092018 PDFDocument1 pageMANAGER (SAFETY) - RFCL - 092018 PDFSwarup NayakNo ratings yet

- Mom 16052017 PDFDocument71 pagesMom 16052017 PDFSwarup NayakNo ratings yet

- New Doc 2018-09-03 PDFDocument1 pageNew Doc 2018-09-03 PDFSwarup NayakNo ratings yet

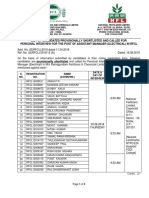

- ASSISTANT MANAGER ELECTRICAL - RFCL - 092018 PDFDocument1 pageASSISTANT MANAGER ELECTRICAL - RFCL - 092018 PDFSwarup NayakNo ratings yet

- New Doc 2018-09-02 PDFDocument1 pageNew Doc 2018-09-02 PDFSwarup NayakNo ratings yet

- Bcts PDFDocument10 pagesBcts PDFSwarup NayakNo ratings yet

- RFCL ASSISTANT MANAGER (ELECTRICAL) PDFDocument5 pagesRFCL ASSISTANT MANAGER (ELECTRICAL) PDFSwarup NayakNo ratings yet

- 40MVA Power Transformer Bid (Final) - May 17 PDFDocument132 pages40MVA Power Transformer Bid (Final) - May 17 PDFSwarup NayakNo ratings yet

- New Doc 2018-09-04 PDFDocument1 pageNew Doc 2018-09-04 PDFSwarup NayakNo ratings yet

- Monitor Lightning Arresters OnlineDocument5 pagesMonitor Lightning Arresters OnlineJoshi DhvanitNo ratings yet

- RecSafetyOfficer RFCL 052017 PDFDocument1 pageRecSafetyOfficer RFCL 052017 PDFSwarup NayakNo ratings yet

- Scan Doc by CamScannerDocument1 pageScan Doc by CamScannerSwarup NayakNo ratings yet

- Field Procedure For Overhauling Job of Power Transformer: Voltamp Transformers LTDDocument2 pagesField Procedure For Overhauling Job of Power Transformer: Voltamp Transformers LTDSwarup NayakNo ratings yet

- NewDocument1 pageNewSwarup NayakNo ratings yet

- Brouchere PDFDocument2 pagesBrouchere PDFSwarup NayakNo ratings yet

- CommitteeDocument17 pagesCommitteeSwarup NayakNo ratings yet

- New Doc 2018-08-25 PDFDocument1 pageNew Doc 2018-08-25 PDFSwarup NayakNo ratings yet

- Brouchere PDFDocument2 pagesBrouchere PDFSwarup NayakNo ratings yet

- New Doc 2018-08-25 PDFDocument1 pageNew Doc 2018-08-25 PDFSwarup NayakNo ratings yet

- List of Candidates Provisionally Shortlisted and Called For Personal Interview For The Post of Senior Manager (Chemical) in RFCLDocument1 pageList of Candidates Provisionally Shortlisted and Called For Personal Interview For The Post of Senior Manager (Chemical) in RFCLSwarup NayakNo ratings yet

- SWITCH NEW PageDocument6 pagesSWITCH NEW PageSayak BoseNo ratings yet

- New Doc 2018-08-20 PDFDocument1 pageNew Doc 2018-08-20 PDFSwarup NayakNo ratings yet

- Teoria de SwitchgearDocument108 pagesTeoria de SwitchgearMarcos GoianoNo ratings yet