Professional Documents

Culture Documents

FDA - Potentially Hazardous Foods PDF

FDA - Potentially Hazardous Foods PDF

Uploaded by

pedroloxxx0 ratings0% found this document useful (0 votes)

16 views3 pagesOriginal Title

FDA - Potentially Hazardous Foods.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views3 pagesFDA - Potentially Hazardous Foods PDF

FDA - Potentially Hazardous Foods PDF

Uploaded by

pedroloxxxCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

Hazardous Foods - Appendix C. Scientific Data

Used to Develop the Framework

Fswee y rwter | in unKeon @ PIT RB eMAL | B PRINT

Back to Table of Contents

1. Determination of pH and water activity limits for TCS foods

To determine pH and water activity limits for TCS foods, as they are presented in the framework (see Chapter 8)

the panel used data from the literature and from the results of the survey (see appendix B). Data for products with

identified preservative systems were not included to assure that conservative data were used to determine limits.

Professional judgement of the panel was used to omit unrealistic data. For example, studies using artificially high

inoculum levels in laboratory media with no competitive microflora, using mild humectants (for example, glycerol) or

acidulants (for example, HCl) were not used if results varied significantly with substantial data in food systems.

While numerous studies have been done on growth of foodborne pathogens, many studies do not report the pH

and water activity of the growth medium. As a result, only limited data are available to study the interaction of pH

and ay on the growth of foodborne pathogens. The panel strongly encourages researchers to include pH and

water activity data in scientific publications to assist the incorporation of data into analyses such as the

‘one being performed here.

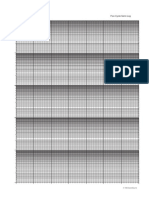

1.1. Spores

Data on water activity and pH interaction effects on growth or toxin production of foodborne pathogenic

sporeformers are illustrated below. The lines indicate the parameter limits that the panel considered to develop the

framework.

Spore Growth or Toxin Production

Potential TCS

too we

= C. botulinum toxin

C. botulinum no toxin

Zo

z #B. cereus growth

5 © B. cereus no growth

3 om *C. perfringens growth

©C. perfingens no growth

For foods that are treated to inactivate vegetative foodborne pathogens, the panel concluded that the following

parameters effectively control the growth of sporeforming foodborne pathogens:

* pH= 46, or

= ay vse,

# pH =5.6 and ay = 0.95

The panel believes that these parameters are conservative since numerous studies demonstrated lack of growth

and/or toxin production above these levels. Products that fall in the non-TCS area should be considered in a "safe-

harbor" that does not require time/temperature control. Products that fall in the potential TCS region may be stable

depending on shef life expectations, presence of preservatives, temperature, and other factors affecting growth

{see Chapter 3). Challenge studies may be performed for foods in the high pH and ay ranges and/or for those

foods with extended shelf life expectations.

‘An equation to fit the data could also be used to identify pH and ayy combinations that would inhibit sporeforming

pathogen growth; however, panel members believe that this would be more difficult to implement and/or

‘communicate to non-technical users of the information.

1.2. Vegetative cells

Literature data on interaction of pH and water activity on control of vegetative pathogens is more limited than that

for spore-formers. Published studies and modeling programs generally use broth media or foods with high aw that

ate not near the minimum for growth. Studies conducted for short shelf life products are relevant to foodservice

operators who are primarily interested in the potential for pathogen growth in hours or a few days; however, these

studies may not be applicable to extended shelf life products.

The following data were considered in developing the framework for vegetative pathogen control, in addition to the

imum pH and ayy values for vegetative pathogen growth (see Chapter 3). However, the panel belioves that

intended shelf life must be considered in addition to pH and av in determining the need for time/temperature

control. The lines indicate the parameter limits that the panel considered to develop the framework.

Cell Growth or Toxin Production

References

Asplund K, Nurmi E. 1991. The growth of salmonella in tomatoes. Int J Food Microbiol 13:177-82.

Baird-Parker TC. 1990. The staphylococci--an introduction. J Appl Bacteriol Symposium Suppl:1S-8S. (cited in

ICMSF 1996a).

Barbut S, Tanaka N, Maurer AJ. 1986. Effects of varying levels of chloride salts on Clostridium botulinum toxin

production in turkey frankfurters. J Food Sci §1:1129-31. (cited in ICMSF 1996a).

Bartsch AG, Walker HW. 1982. Effect of temperature, solute and pH on the tolerance of Clostridium perfringens to

reduce water activities. J Food Sci 47:1754-5.

KC, Goepfert JM. 1970. Growth of Salmonella at low pH. J Food Sci 36:326-8.

Clavero MRS, Beuchat LR. 1996. Survival of Escherichia coli 0157:H7 in broth and processed salami as influenced

by pH, water activity, and temperature and suitability of media for its recovery. Appl Environ Microbiol 62:2735-40.

Clavero MRS, Brackett RE, Beuchat LR, Doyle MP. 2000. Influence of water activity and storage conditions on

survival and growth of proteolytic Clostridium botulinum in peanut spread. Food Microbiol 17:53-61.

KL. 1989. Combined effect of water activity and pH on inhibition of toxin production by Clostridium botulinum in

cooked, vacuum-packed potatoes. Appl Environ Microbiol 55:656-60.

KA, Doyle MP. 1991. Relationship between water activity of fresh pasta and toxin production by proteolytic

Clostridium botulinum. J Food Prot §4:162-5. P. 2001. Clostridium botulinum toxin production in various foods.

Personal communication.

Hauschild AHW, Hilscheimer R. 1979. Effect of salt content and pH on toxigenesis by Clostridium botulinum in

caviar [proteolytic strains onlyl. J Food Prot 43:245-8. (cited in ICMSF 1996a),

{ICMSF} International Commission on Microbiological Specification for Foods. 1996. Microorganisms in foods.

Volume 5, Characteristics of microbial pathogens. London: Blackie Academic & Professional. 513 p.

JY. 1991. Clostridium botulinum growth and toxigenesis in shelf stable noodles. J Food Sci 56:264-5. KA, Chen JK,

Lerke PA, Seeger ML, Unverferth JA. 1976. Effect of acid and salt concentrations in fresh-pack pickles on the

growth of Clostridium botulinum spores. Appl Environ Microbiol 32:121-4. (cited in ICMSF 1996a).

Jakobsen M, Trolle G. 1979. The effect of water activity on growth of clostridia. Nord Vet-Med 31:206-13. CK,

Woodbum M, Pagenkopf A, Cheney R. 1969. Growth, sporulation and germination of Clostridium perfringens in

media of controlled water activity. Appl Microbiol 18:789-808. (cited in ICMSF 1996a). K-Y, Torres JA. 1993. Water

activity relationships for selected mesophiles and psychrotrophs at refrigeration temperatures. J Food Prot

56:612-5, (cited in ICMSF 1996a).

McClure PJ, Roberts TA, Otto Oguru P. 1989. Comparison of the effects of sodium chloride, pH and temperature

on the growth of Listeria monocytogenes on gradient plats and in liquid medium. Lett Appl Microbiol 9:95-9. (cited

ICMSF 1996a),

Miller AJ. 1992. Combined water activity and solute effects on growth and survival of Listeria monocytogenes Scott

A. J Food Prot 55:414-18. (cited in ICMSF 1996a)..

Notermans S, Heuvelman CJ. 1983. Combined effect of water activity, pH and sub-optimal temperature on growth

and enterotoxin production of Staphylococcus aureus. J Food Sci 48:1832-5, 40.

Petran RL, Aottola EA. 1989. A study of factors affecting growth and recovery of Listeria monocytogenes Scott A. J

Food Sci 54(2):45-60. (cited in ICMSF 1996a)

Raewori M, Genigeorgis C. 1975. Effect of pH and sodium chloride on growth of Bacillus cereus in laboratory

media and certain foods [rice and meat data only]. App! Microbiol 29:68-73.

Razavilar V, Genigeorgis C. 1998. Prediction of Listeria spp. growth as affected by various levels of chemicals, pH,

temperature and storage time in a model broth. Int J Food Microbiol 40:149-57.

Simpson MV, Smith JP, Dodds KL, Ramaswamy HS, Blanchfield B, Simpson BK. 1995. Challenge studies with

Clostridium botulinum in a sous vide spaghetti and meat sauce product. J Food Prot 58:229-34.

‘Swanson KMJ. 2001. Clostridium botulinum toxin production in various foods. Personal communication.

Tienungoon S, Ratkowsky DA, McMeekin TA, Ross T. 2000. Growth limits of Listeria monocytogenes as a function

of temperature, pH, NaCl, and lactic acid. Appl Environ Microbiol 66:4979-87.

[USDA] U.S. Dept. of Agriculture, Agricultural Research Service, Eastern Regional Laboratory. 2001. USDA

Pathogen Modeling Program Version 5.1

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Clostridium Botulinum, Clostridia: and NeurotoxigenicDocument4 pagesClostridium Botulinum, Clostridia: and NeurotoxigenicpedroloxxxNo ratings yet

- SporeDocument8 pagesSporepedroloxxxNo ratings yet

- FDA 2011 - Guide For The Control of Molluscan ShellfishDocument516 pagesFDA 2011 - Guide For The Control of Molluscan ShellfishpedroloxxxNo ratings yet

- 20xx - Ball's Formula Method RevisitedDocument6 pages20xx - Ball's Formula Method RevisitedpedroloxxxNo ratings yet

- Eurobarometer 2010 - Report PDFDocument168 pagesEurobarometer 2010 - Report PDFpedroloxxxNo ratings yet

- 2010 - Thermal Process Calculations Through Ball's Original FormulaDocument16 pages2010 - Thermal Process Calculations Through Ball's Original FormulapedroloxxxNo ratings yet

- 20xx - Ball's Formula Method RevisitedDocument6 pages20xx - Ball's Formula Method RevisitedpedroloxxxNo ratings yet

- EFSA - Risk Assessment Vs Risk Management PDFDocument1 pageEFSA - Risk Assessment Vs Risk Management PDFpedroloxxxNo ratings yet

- Review Histamine ProducingbacteriaDocument10 pagesReview Histamine ProducingbacteriapedroloxxxNo ratings yet

- 2013 - A New Mathematical Model For Food Thermal Process PredictionDocument9 pages2013 - A New Mathematical Model For Food Thermal Process PredictionpedroloxxxNo ratings yet

- 2000 - FDA Kinetics of Microbial Inactivation For Alternative Food Processing TechnologiesDocument228 pages2000 - FDA Kinetics of Microbial Inactivation For Alternative Food Processing TechnologiespedroloxxxNo ratings yet

- Thermal Properties of FoodsDocument12 pagesThermal Properties of FoodspedroloxxxNo ratings yet

- Papel Semilog 5 SaltosDocument1 pagePapel Semilog 5 SaltospedroloxxxNo ratings yet

- Breidt 2013 - Determination of 5-Log Reduction Times in Acidified Foods With PH 3.5 or 3.8Document5 pagesBreidt 2013 - Determination of 5-Log Reduction Times in Acidified Foods With PH 3.5 or 3.8pedroloxxxNo ratings yet

- Breidt 2005 - Determination of 5-Log Pathogen Reduction TimesDocument6 pagesBreidt 2005 - Determination of 5-Log Pathogen Reduction TimespedroloxxxNo ratings yet

- Breidt 2010 - Use of Linear Models For Thermal Processing of Acidified FoodsDocument5 pagesBreidt 2010 - Use of Linear Models For Thermal Processing of Acidified Foodspedroloxxx100% (1)