Professional Documents

Culture Documents

BWD Electronics - 824 - Service, User - ID9079 PDF

Uploaded by

bob0 ratings0% found this document useful (0 votes)

15 views54 pagesOriginal Title

BWD Electronics--824--service,user--ID9079.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views54 pagesBWD Electronics - 824 - Service, User - ID9079 PDF

Uploaded by

bobCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 54

BWD Industries Ltd.

(Incorporated in South Australia)

Head Office, Manufacturing, Sales and Service

5 Dunlop Road,

MULGRAVE Phone: (03) 561 2888 (3 lines)

VICTORIA 3170 Cables: “OSCOPE” MELB.

AUSTRALIA. Telex: AA 35115

Postal Address

PO BOX 325

SPRINGVALE

VICTORIA 3171

824 35MHZ

OSCILLOSCOPE

OPERATION AND SERVICE

MANUAL

nsw

eter

Penta

ROPES ne (0 004 1800

pales

ya

TABLE OF CONTENTS

INTRODUCTION

SAFETY INFORMATION

PERFORMANCE SPECIFICATION

Vertical Amps & Time Base

Trigger & General Details

Dimensions

FUNCTION OF CONTROLS

Vertical Amplifiers

Time Base

CRT Controls & Rear Panel

INSTRUMENT FAMILIARISATION

Single Trace Operation

Dual Trace Operation

Time Base Operation

Horizontal Amplifier

APPLICATIONS.

Probe Compensation

Voltage Measurement AC

Voltage Measurement RMS

Voltage Measurement DC

Voltage Measurement AC&DC

Elimination of Common Mode

Current Measurement ACEOC

Time Measurement

Frequency Measurement

& Fall Times

Time Difference

Phase Measurement

BS] Phase Measurement

Video (TV) Displays

Page

1-1 CIRCUIT DESCRIPTION

1-2 Vertical Amplifiers

Trigger & Time Base

Horz Amplifier

Power Supplies & Calibrator

at CRT & Z Modulation

2-2

a4

ADJUSTMENTS & MAINTENANCE

3 Equipment Required

3-2 Power Supplies & CRT

3-3 Vertical Alignment

Attenuators

Time Base, Ii & Trigger

40 i

mat Parts Lists

a1

4-2

5-1 FIGURES

4 BWD 824 OSCILLOSCOPE

ey TRANSFORMER INTERCONNECTIONS

£5 DIMENSIONS

23 FRONT PANEL CONTROLS

Sp REAR PANEL FACILITIES

INSTRUMENT FAMILIARISATION

CONVERTER EHT & BLANKING

PCB

VERTICAL OUTPUT PCB

CHI & 2 ATTENUATORS

MAIN PCB

TIME BASE SWITCH

BKO 824 Introduction

Fig 1-1 BND 824 Oscilloscope

1.0 INTRODUCTION

The BWD €24 Oscilloscope provides the capability of making precision

measurements easily and quickly. It's 35MHz bandwidth, high sensitivity,

wide range time base and extremely stable triggering makes it suitable for

a broad range of applications in education, servicing or design

With an amplifier rise time of less than 10nsec fast digital pulses from

TTL-HCMOS or similar, circuits can easily be handled, it is suitable for

micro processors, small computers, video games and other digital circuits.

In TV applications the sync separator with automatic change over from

frame to line lock makes servicing of video recorders, colour TV, VOU's

and other video products a simple matter. The 2mV amplifiers can view

signals across recording or playback leads enabling measurements to be

made from input to output of VCR's etc.

The same features are also ideal for analog and audio applications.

Signals developed by the new digital recording techniques are readily

accommodated and an identical X-Y facility with low phase shift to above

100kHz can be used in audio and communication measurements.

range of accessories is available to further increase the BWD &24

s. These are listed at the end of Section 2.

BHD 821/824 Operation

SAFETY INFORMATION

1. At certain locations in this Handbook and on the instrument back or

front panels will be found statements, or symbols calling attention to a

safety requirement or feature.

2. Symbols used are as follows:

DANGER. HIGH VOLTAGE

CIRCUIT GROUND

POWER LINE GROUND

CAUTION = Check Handbook: to verify maximum input or output.

DANGER To alert of possible danger to either operator or equipment

that may be present during the next Handbook procedure.

WARNING To alert operator that damage may occur to equipment under

test if certain precuations as detailed, are not followed.

3.Dé not use this instrument in an explosive atmosphere.

4,Do not remove the covers unless you are experienced in servicing. this

class. of equipment, tethal voltages are present on several circuits.

5. Instrument Power” Source. This instrument is designed for operation from a

power source with its neutral at or near earth (ground) potential with a

separate 'safety-carth conductor. It is not intended for operation from .two

phases of a multi-phase system, or across the legs of a single-phase

three-wire system.

This instrument can be operated from either a 115 Volt or 230 Volt nom-

inal line voltage source, 48 to 62Hz. This instrument may be damaged if

operated with the line voltage connected to incorrect positions for the line

voltage applied.

6. NOTE Colour-coding of the

wdlee ST eB, cord conductors is as follows:~

ny eB Line Brown

ry Neutral Blue

sav 1) on Safety Earth Green/Yellow

Oo ° (Ground) Stripe

zooy The power transformer is pro-

oo ided with primary tappings.

ais which may be changed by resold-

38a ering the links to suit the local

oo power line voltages. The connec-

tions are as shown below. Instru~

ments sold in Australia are con-

nected for 195-264V operation.

Export instruments have a label

NOTE: LINKS TO BE INSULATED HOOK-UP WIRE

Fig 1-2 Transforaer Interconnections attached stating the operating

range the transformer has been

set to.

7.To avoid the possible hazard of fire or other internal damage, use only

the fuse type and rating as specified on the rear panel and listed in the

Handbook Parts List.

1-2E

2.0 PERFORMANCE

BND 824 Specification

2.1 VERTICAL AMPLIFIERS

Display Modes:

Bandwidth:

Rise Time:

Sensitivity:

Input R & C:

Maximum Input Voltage:

Calibration Accuracy:

Trace Inversion:

MRR:

2.2 CH2 AS X AMPLIFIER

Bandwidth:

Sensitivity:

Phase Shift

2.3. TIME BASE

Range:

Calibration:

CHI, CH2, Alt, Chopped (approx 300kHz), Add.

DC (or Hz AC, coupled) to 35MHz -3db from Smv

to 20V. Referred to 6 div deflection from a 50chm

terminated source with vernier to Cal.

DC to 18MHz -3db at 2mV (vernier clockwise).

1Onsec over a 6 div deflection SmV to 20V/div.

23nsec over a 6 div deflection 2mV/div.

2mV to 20V/div, SmV to 20V direct plus a vernier

control with a range approx 2.5:1 which extends

input sensitivity to 2mV/div.

1Mohm +/-2% paralleled by approx 30pF.

400V DC + peak AC. 800V p-p at IkHz or less.

) 48°C to +40°C

) add 2% 0° to 45° and

} 440% to 450%

SmV to 20V/div +/-3%

ImV/div +/-20%

CH2 may be inverted to provide @ single channel

differential facility in the Add mode.

At least 20db from DC to 5MHz. Common mode

signal {8 div with one vernier adjusted for

optimum rejection.

IN X-Y MODE

DC to IMHz -3db.

2mV to 20V/em.

Less than 2° from DC to 100kHz.

O.2psec to Isec/div, 21 steps in 1, 2, 5 sequence

with 2.5:1 vernier which extends range to 2.5

sec/div.

Mag X1 Mag XS

45° to 440° 45° to 440°

0.2psec to 1 sec/div SOnsec 10 0.1 see]

1-3 +/-Sh

4Onsec over centre 8

div +/-6%

0° Jo 45° & +40° to 0P fo +59 & 440° to}

+50 +50°

0.2 sec to 0.2 sec/div | 100nsec to 0.02 sec/

+/-5% div 4/-7%

0.5 & 1 sec/div +8% to] 20nsec over centre §

8% div +/-7%

0.05 & 0.1 sec/div

+8% to -10%

at

2.4 TRIGGER

Source: CHI, CH2, external or AC line frequency.

Video: Frame or line selection with automatic change-

over. Frame lock 0.1 sec to 100sec, line lock

50 sec/div, and above.

Slop Internal, + or ~ with level select over range

of amplitude visible on screen

External, + or - with level select over 4V

p-p

Sensitivity: Internal, 0.4 div 15Hz to 10MHz increasing to

1 div at SHz & 40MHz.

External, 100mV p-p 15Hz to 10MHz

250mV p-p Hz to 4OMHz

Maximum level select range 4V p-p

40V p-p with 10:1 probe

Ext. Input Impedance: IMR +/-8% paralleled by 20pF approx.

Max. Input: 200V DC of DC plus peak AC to IkHz.

Video Trigger: 2 div. to over 8 div of composite waveform for

frame or line lock.

2.6 GENERAL DETAILS

Timebase Gate Output: — +3V_ falling to OV during sweep from 4.7kohm

source.

Z Modulation: DC coupled to 10MHz. Input impedance 10kohm.

+4V will blank trace at normal intensity.

Max. input +/-30V p-p.

Probe Adjust.: Output 0.5V p-p approx rectangular positive

going with respect to ground, line frequency.

CRT: Rectangular 8 x 10 div (1 div = 9.5mm).

Internal graticule and mesh PDA operating at

approx. 6.0KV.

Fitted with P31 phosphor and Blue filter.

Trace Rotation: Rear panel preset enables trace to be aligned

with graticule.

2.7 POWER REQUIREMENTS

AC: 98 to 132V and 195 to 264V by internal selection.

48 to 62H. 25 Watts max.

2.8 ENVIRONMENTAL

Specification is met less otherwise stated between +8°C to +40°C at a

relative humidity of less than 95% and from O°C to +50°C at a relative

humidity of less than 50%.

Weight: Instrument only: 7.8K9

Shipping Weight: Instrument only: 9.1K

Ordering Code: Standard Model: BWD 824

Instrument supplied complete with 2 x P32 1:1/10:1 probes, power cord and

Handbook.

2.9 OPTIONAL ACCESSORIES

1:1 & 10:1 Duo Range Probe P32 Folding View Hood Hes

100:1 1500V Probe P37 Protective Front Cover SC53

Demodulator Probe P34 Dust Cover 30

100 AMP DC-ikHz Current Probe Paz Oscilloscope Troiley Tél

2-28 Cameras, details on request

BRD 624 Operation

Fig 2 BW0 824 Diaensions in aw

3.1 FUNCTION OF CONTROLS

The following descriptions are to assist an operator to become fami!-

jarised with the location, operation and function of the BWD 824 controls

and connectors.

VERTICAL AMPLIFIERS SECTION (numbers refer to Fig 3-1 page 3-2)

@ and @ CHI and CH2 Volts/Div Control selects the vertical factor in a

1,2,5 sequence. (Vernier must be in the detent position for the indicated

factor). Calibration accuracy is better than 3%.

Vernier Provides continuously variable deflection between the

calibrated settings of the VOLTS/DIV switches and at max sensitivity

increases the sensitivity to approx 2mV/di

® } Positions the display vertically.

©® Inputs Connectors For application of signals to the vertical

amplifiers. In the mode, signals applied to CH2 input provide the

horizontal deflection.

© 0c - GND — AC Slide switch selects the input coupling to the. vertical

amplifiers. In the AC position signals are capacitively coupled to the

vertical amplifier so the DC component of the signal is blocked, In the DC

tosition, ‘all components of the Input signal are passed. te the anplitiers

When switched to GND the input connectors are disconnected from the

amplifiers and the attenuator input is grounded.

@ Vertical Display Rotary switch selects 5 modes of operation for the

amplifier.

CHI CHI only displayed.

CH2 —-CH2 only displayed.

ALT. Dual trace display where the display is switched between

channels at the end of each sweep.

CHOP. Dual trace display where the display is switched between

channels at a rate of approx 300kHz.

ADD. Signals applied to CHI and CH2 inputs are algebraically added

and displayed as one trace on the CRT. With the CH2 INVERT

switch engaged, the display is CHI minus CH2, i.e. differential

‘operation when both VOLTS/DIV are at identical settings.

St

BHD 824 Operation

INT TRIGGER, CHI or CH2 Push button to select source of internal

trigger. :

@ CHa NORM-INV Push button, Trace is displayed normally when push

button is out and inverted when in.

EGag semen oncusoscone

22 O a

z= "@

© 06 66 6 bob o)

ae bod OOO® bods

Fig d-1 Front Panel Controls

3.2 TIME BASE SECTION

@ SEC/DIV Time base range switch controls the sweep time from 0.2ysec

to 1 SEC/DIV in 21 steps. Turned fully clockwise, it switches off the time

base and connects CH2 vertical amplifier to provide the X display for

operation with a sensitivity from 2mV to 20V/div. When the vernier. is at

CAL the calibration is 3% over the entire range. Another function

performed by the switch is to change over the video sync separator from

frame selection to line selection at sweep speeds of S0psec/div and above.

@ Vernier Control & x5 MAG When the central is rotated counter

clockwise, it reduces the time base speed by at least 2.5 times.

When the knob is pulled out, the sweep speed is increased by x5.

® = Control positions the trace horizontally on the sereen.

@ Levels Selecis the precise point on the triggering waveform that

Initiates the time base. Selection ic available over 8 div deflection, or up

to 4V p-p external. When the level knob is pushed in, the time base will

free run if'a trigger signal Is mot present, or it the control ts turned out

Of the range of the signal.

With the knob out, the automatic base tine is eliminated and no trace is

present in the absence of a trigger signal.

@ EXT TRIGGER input socket for application of signals to provide

external trigger.

® cn * 4mm socket for Ext connection to chassis.

WD 824 Operation

3.3 PUSH BUTTON SWITCHES

NORM/TV, out position is normal trigger; in position selects the video

syné separator. When the time base is switched between 0.1 sec and

0.Imsec/div, the syne separator supplies frame pulses to trigger the time

base. From 50sec and above, the TV line will trigger the time base.

+/- Out position enables the positive or rising slope of the trigger

waveform to initiate the time base. With the button in, the negative or

falling slope triggers the time base.

@ Ac Line our is norma! operation, in selects the line frequency

powering the Oscilloscope to trigger the trace. Phase of the trigger point is

adjustable by the LEVEL control and the +/- switch.

INT/EXT Out position connects the internal trigger signals as selected

by the trigger source button in the vertical amplifier section. In po:

selects signals from the EXT TRIGGER BNC socket.

3.4 CRT CONTROLS

Intensity Fully counter clock this control switches off the Oscilloscope.

When turned clockwise, the Oscilloscope is switched on and rotation

clockwise increases the trace intensity.

Focus Adjusts the CRT focus at any setting of the intensity control.

Adjustment is made in conjunction with the rear panel astigmatism preset

contro! to obtain the optimum trace sharpness.

3.5 GENERAL FEATURES

LED Power Indicator I/luminates when the Intensity contro! is turned

on. :

@ Probe Adjust 0.5V p-p Approx, Line Frequency rectangular positive

going waveform.

3.6 REAR PANEL FACILITIES

@ Astigmatism Preset used in conjunction with the front panel focus

contro! to adjust the trace sharpness. Will’ rarely ‘need adjustment ‘once

correctly set.

Trace Rotate Preset control enables the CRT trace to be aligned with

the internal graticule.

T.B. Gate Time base blanking waveform. OV during sweep. +5V during

blanking, 4&7 source impedance.

@ Z MOD input socket for

Intensity modulating the CRT. Max-

imum input is 4/-30V and input

impedance is 10kohm. Modulation

requires a positive input of +4V to

blank trace at normal intensity.

® Ac Line Fuse Fuse size and

value is shown in Parts List and

must be adhered to for maximum

instrument safety.

Fig 3-2 Rear Panel

3.36

BD 824 Operation

INSTRUMENT FAMILIARISATION

4.1 One of. the major features of the BWD 824 Oscilloscope is that normal

operation is obtained when all controls are in their normal position, i.e.

when all push buttons are OUT and all. controls are pushed in. A quick

scan over the panel therefore immediately indicates any variations from

normal and assists in quick familiarisation of the instrument's operation.

POSTON,

CENTRED,

a8

ALL OUT

CENTRED.

VERTICAL AMPLIFIERS

4.2 For first time operation, if you are unfamiliar with an Oscilloscope,

set the controls as above and follow the steps outlined until each feature is

understood.

4.3 Apply power to the Oscilloscope, switch on and turn the Intensity

Cantro! to approx 2 o'clock position. Within 15 seconds a trace will appear.

Adjust intensity, focus. and position to set trace centrally across screen. If

trace is not aligned with the graticule, adjust the Trace Rotation preset on

the rear panel to al it.

Now connect a BWD P32 Probe to CHI input and set it to 1:1. Touch the

Probe tip to the 0.5V CAL waveform output socket.

A rectangular wave will be displayed 5 div high and one waveform per 5

ons horizontally. Slide the CHI input switch to DC, the trace will rise

and the bottom of the waveform will now correspond with the CRT centreline

indicating the input signal is @ waveform positive going with respect to

ground. Slide the input switch to GND, the square wave will be removed

and replaced by a bright reference base line as the Auto time base

operates. The GND switch disconnects the input signal in this condition, but

grounds the amplifier. Slide the switch back to DC and the waveform will

again be standing on the centreline.

40

2 gcuocK,

BWD 824 Operation

4.4 DUAL TRACE OPERATION

Set CH2 amplifier as for CHI, then turn the Vertical Display to CH2, then

press the INT TRIG button to select CH2. Take a parallel signal from the

calibrator output, (or @ similar waveform) to CH2 input leaving CHI signal

connected.

ALT

Reduce attenuator settings of both amplifiers to 0.2V/div then switch

VERTICAL DISPLAY to ALT. Two traces will appear which can be positioned

above and below CRT centreline with their respective controls.

With the traces positioned above each other, turn the time base range

switch to slower sweep speeds and observe how flicker between the traces

increases, until at 10msec/div the switching between the traces is readily

visible, This is the useful lower limit of the ALTernate switching mode. Now

increase the time base speed, the traces will remain locked right through to

0.2psec/div.

cHOP

Return time base range to 10msec/div again and switch the VERTICAL

DISPLAY to CHOP. Trace flicker immediately stops. When the time base

frequency is reduced, the two traces appear simultaneously down to the

lowest sweep frequency.

Increase time base speed and note that at speeds above S0psec/div the

waveforms will start to show the individual chopping sections indicating the

useful upper limit of CHOP displays.

As has been shown, a wide overlap exists where both forms of dual trace

display can be used satisfactorily.

ADD

Apply a 1V p-p IkHz sine wave to CH! and CH2 inputs. Set the time base

to .Smsec/div and both attenuators to .5V/div so that the waveform on each

trace is 2 div high. Turn the Vertical Display switch to ADD.

A single trace will appear with a 4 div display, i.e. the two traces

have been added together. Now press CH2 NORM/INV button; the waveform

| disappear leaving only a line. This is the difference between the two

signals or the result when one is subtracted from the other. Applications

for this form of measurement are described later. Return Vertical Display

switch to CHI and the NORM/INV switch to NORM.

4.5 TIME BASE

Increase sine wave input to CHI to present a 6 div high display and

select CHI trigger.

4.6 TRIGGER LEVEL

With the Level knob pushed in, turn the control and observe that the

trigger point moves up or down the waveform. When it reaches the top or

bottom of the waveform the trace blanks out for a fraction of a second when

trigger is lest, then the trace free runs in the Auto condition until the

level control is readjusted to select a trigger signal. Now push in the +/-

button to select -ve trigger. The waveform will now trigger on a —ve going

slope. Clockwise rotation of the LEVEL contro! will increase the trigger

point towards the positive point of the waveform, anti-clock rotation

towards the negative point.

Revert to +ve trigger selection, then pull out the LEVEL knob to normal

or NON-AUTO operation. When the LEVEL contro! is now turned, the trace

disappears when the trigger point extends past the waveform limits.

ot

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- MerlinProlift230TUserManual1002851 1570790567Document12 pagesMerlinProlift230TUserManual1002851 1570790567bobNo ratings yet

- CNC 6040 Setup For Mach3Document2 pagesCNC 6040 Setup For Mach3bob100% (1)

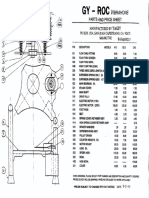

- Gy-Roc "B": ROCK Grinding & Polishing InstructionsDocument2 pagesGy-Roc "B": ROCK Grinding & Polishing InstructionsbobNo ratings yet

- Gy-Roc "B": Metal Polishing Instructions - Including For Precious MetalsDocument2 pagesGy-Roc "B": Metal Polishing Instructions - Including For Precious Metalsbob100% (1)

- 1994 Kawasaki Ninja 250R Owner ManualDocument124 pages1994 Kawasaki Ninja 250R Owner ManualbobNo ratings yet

- Jayco Scematic Wiring Diagram PDFDocument1 pageJayco Scematic Wiring Diagram PDFbob100% (1)

- Johnson Repair Manual 1971-89 Outboard 1 To 60hp PDFDocument631 pagesJohnson Repair Manual 1971-89 Outboard 1 To 60hp PDFbob100% (1)

- ST III User Manual DDocument11 pagesST III User Manual DbobNo ratings yet

- Mercury 6 - 8 - 9,9 - 10 - 15HP (1986) Service Manual (PDF, ENG, 2.49 MB) PDFDocument149 pagesMercury 6 - 8 - 9,9 - 10 - 15HP (1986) Service Manual (PDF, ENG, 2.49 MB) PDFbobNo ratings yet

- GME Electrophone CX294 GX294 CB Radio ImDocument12 pagesGME Electrophone CX294 GX294 CB Radio ImraymihregNo ratings yet

- ST III User Manual DDocument11 pagesST III User Manual DbobNo ratings yet

- Gyroc Tumbler InstructionsDocument7 pagesGyroc Tumbler Instructionsbob0% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)