Professional Documents

Culture Documents

Mining & Geotechnical Engineering

Uploaded by

mornewp100%(1)100% found this document useful (1 vote)

14 views38 pagesMining & Geotechnical Engineering Handbook

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMining & Geotechnical Engineering Handbook

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

14 views38 pagesMining & Geotechnical Engineering

Uploaded by

mornewpMining & Geotechnical Engineering Handbook

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 38

‘Kudumane Mn Feasibility Study Report

enone

=

Table of Contents

Page i

5 Mining Geotechnical Engineering ... 54

5.1 Introduction... z 5-1

5.2. Summary of mining and geological conditions 5-1

5.3 Risks associated with the roll-over mining method. 5-3

5.4 Fieldwork and data collection 5-4

5.1 Geotechnical borehole fogging 36

5.4.2 Sample collection. 58

5.5 Laboratory test results 5-10

5.6 Empirical slope angle assessment. 5-11

5.7 Specific nature of the Kalahari sequence. 5-13

5.8 Geotechnical parameters 5-15

5.9 Impact of the groundwater regime on slope stability. 5-16

5.10 Limit Equilibrium Analysis 5-18

5.11 Stability of the Kalahari sequence 5-19

5.11.1 Fully drained slopes. 5-19

5.11.3 Slope stability assessment 5-21

5.12 Stability of the Dwyka, ironstone and ore sequences 5-25

5.13 Low wall waste dump stability 5-27

5.14 Summary of pit slope design recommendations. 5-28

5.14.1 Upper slope domain. 5-28

5.14.2 Lower slope domain. 5-28

5.15 Recommendations for pit slope management 5-29

5.15.1 Development and maintenance of a Mine Hazard Plan 5-29

5.15.2 Regular Inspections. 5-29

5.15.3 Scaling and cleaning of interim and final pit faces and crests. 5-30

5.15.4 Survey monitoring, 5-30

5.15.5 History of slope collapse. 531

5.15.6 Evacuation procedures. 5-32

5.15.7 Regular safety precautions. 5-32

5.15.8 Blasting practice 5-32

5.15.9 Pit depressurisation and groundwater monitoring. 5-33

SAK Consulting Rake fn eee ace

‘Kudumane Mn Feasibility Study Report ~ Page il

-

5.15.10 Storm water control 5-33

5.16 Conclusions and recommendations 5-33

5.17 References 5-35

List of Tables

Table 5.1: Summary of Joint Sets Identified on neighbouring sites 5-2

Table 5.2: Mining Geotechnical issues associated with the roll-over mining method 5-4

Table 5-3: Details of the geotechnically logged boreholes 5-6

Table 5.4: Kudumane geotechnical sample list... 5-8

Table 5.5: Summary of laboratory test results (Kudumane) 5-10

Table 5.6: Geomechanical properties (SRK data base) 5-11

Table 5.7: Summary of IOSA angles derived from MRMR rock mass classification 5-12

Table 5.8: Distribution of unit thickness (m) within the Kalahari sequence .. 5-15

Table 5.9: Design shear strength parameters (Kudumane). 5-16

Table 5.10: Design shear strength parameters (SRK data base) 5-16

5-18

Table 5.11: Depths and elevations of key horizons.

Table 5.12: Kalahari sequence: Factor of Safety and Probability of Failure for drained

slopes

5-23

Table 5.13: Kalahari sequence: Factor of Safety and Probability of Failure for partially

drained slopes...

5-24

== SAK Consuttin Decanter 2010

VT eee Soe sarae h 5 Rock Engineering fal (€tecive bat 31 Aug 2010

Kudumane Mn Feasibility Study Report Page iii

ames

ES

List of Figures

Figure 5.1: Typical north-south section : : 55

Figure 5.2: Typical north-east to south-west section (dip section) seesees 5-5

Figure 5.3: Site plan indicating the locations of the boreholes logged, section positions and

the location of the disused York pit. i 57

Figure 5.4: Photo of the core samples collected. 59

Figure 5.5: Photo of bulk samples collected from the disused York pit 5-9

Figure 56: General view of the aisused York pit showing an exposed face developed in

calerete...... oeees 510

Figure 5.7: IOSA chart (Haines and Terbrugge, 1991) so BAB

Figure 5.8: Schematic Kalahari sequence stratigraphy E 5-13

Figure 5.9: Thickness distribution of the Kalahari sequence... : 5-14

Figure 5.10: Groundwater flow indicating elevations of static groundwater levels (Water

Geosciences Report - 2010). faci 57

Figure 5.11: Base case model construction cn a 5-19

Figure 5.12: Detailed model for analysis of Kalahari sequence slopes (drained). 5-20

Figure 5.13: Detailed model for analysis of Kalahari sequence slopes (Partially drained) 5-21

Figure 5.14: Kalahari sequence: slip circle for minimum safety factor (drained slopes) 5-23

Figure 5.18: Kalahari sequence: slip circle for minimum safety factor (partially drained

slopes) eee : cesses BDH

Figure 5.16: Typical slope section showing Kalahari and banded ironstone domains... 5-25

Figure 5.17: Safety factors in blasted ironstone; left showing local bench failure in weathered

material, middle showing overall slope stability and far right showing stability in

the lower competent ironstone slope (over 2 benches). 5-26

Figure 5.18: Original dump profile undercut at the toe to an average machine height of 10m

resulting in effective slope angle of 51 ° and a safety factor of 0.6. 5-27

Figure 5.19: Example of a Survey Monitoring Pipe Beacon. 5-30

rane ard Soentts Reedaceeettieeil Atta (Elective Date 31 August 2010)

=~ Consulting December 2010

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Geotechnical OverviewDocument20 pagesGeotechnical OverviewmornewpNo ratings yet

- Digital Outcrop CharacterizatiDocument14 pagesDigital Outcrop CharacterizatimornewpNo ratings yet

- Rock Mass RatingsDocument2 pagesRock Mass RatingsmornewpNo ratings yet

- Surface Blasting Handbook: What Every Miner Should KnowDocument52 pagesSurface Blasting Handbook: What Every Miner Should Knowconfidentminer100% (7)

- Sa Coordinate Ref System Aug2011 PDFDocument15 pagesSa Coordinate Ref System Aug2011 PDFeye4aneye1989No ratings yet

- Dump Failure at Heritage CollieryDocument51 pagesDump Failure at Heritage CollierymornewpNo ratings yet

- The geological formations and environmental features around PietennaritzburgDocument13 pagesThe geological formations and environmental features around PietennaritzburgmornewpNo ratings yet

- Analytical Study of Dolomite SinkholesDocument122 pagesAnalytical Study of Dolomite SinkholesmornewpNo ratings yet

- Minister withdraws SCA appeal on BEE ownership recognitionDocument2 pagesMinister withdraws SCA appeal on BEE ownership recognitionmornewpNo ratings yet

- Origin of The South African Measurement SystemDocument3 pagesOrigin of The South African Measurement SystemmornewpNo ratings yet

- Xstrata Pit Wall ControlDocument75 pagesXstrata Pit Wall Controlmornewp100% (2)

- Hazard of Sinkhole Formation CenturionDocument7 pagesHazard of Sinkhole Formation CenturionmornewpNo ratings yet

- Dear Mine Operator, Contractor, Other Interested PartiesDocument18 pagesDear Mine Operator, Contractor, Other Interested PartiesmornewpNo ratings yet

- Charaterizatinof The Coal Resources in SaDocument8 pagesCharaterizatinof The Coal Resources in SamornewpNo ratings yet

- Spoil Pile SafetyDocument94 pagesSpoil Pile SafetymornewpNo ratings yet

- Gap 032Document123 pagesGap 032mornewpNo ratings yet

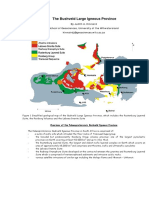

- Bushveld Igneous ProvinceDocument39 pagesBushveld Igneous ProvincemornewpNo ratings yet

- A Review of Rockfall Mechanics and Modelling Approaches: Luuk K.A. DorrenDocument19 pagesA Review of Rockfall Mechanics and Modelling Approaches: Luuk K.A. DorrenmornewpNo ratings yet

- Preliminary Geotech Report For The Guba SeamDocument9 pagesPreliminary Geotech Report For The Guba SeammornewpNo ratings yet

- Georisk2011 Final ProgramDocument16 pagesGeorisk2011 Final ProgrammornewpNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)