Professional Documents

Culture Documents

Edmondson 1965

Uploaded by

Rani Juliarini RahayuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Edmondson 1965

Uploaded by

Rani Juliarini RahayuCopyright:

Available Formats

0CPTb5-oL/- 0 «

Effect of Temperature on Waterflooding

By T. A. EDMONDSON"

(Hea'vy Oil Seminar, The Petroleum Society of C.I.M., Calgary, Alay 5, 1965)

ABSTRACT INTRODUCTION

HERE is a great deal of current interest in ther-

This paper describes laboratory experiments im'oh'ing

waterflooding at eleYated temperatures using two refined

oils and two crudes_ The test core and injection ",.ater

T mal methods for recovering crude oil, especially

the heavy vise-ous crude!:;. Many forms of thermal I'C-

were both held at test temperatures for the duration of coyery inc:lude a phase where hot water displacef.l oil.

the flood, thus eliminating the problem of thermal front5_

The findings reported here 31lpl}' to waterflooding in gen- In such a process, two fronts will form: a leading

eral and thermal reco"er~' in particular, as most thermal cold-water front and a hOI-water front (2). Oil and

reco\"ery methods incJude a phase where "hot" water dis- water viscosities decrease and the liquids swell as

)llaces "hot" oil- the temperature increases. These effects ma)' influ-

\\raterflood tests were conducted at 75°F, lOooP, 150 D F, ence fluid flow in a way not described b.... simple rela-

200°F. 300°1i'. 400°F and 500°F using two refined oils:

No.5 white oil and No. 15 white oil. Two crude oils were tive permeability cOllcepts. However, all (ll"Ocesses ill-

used in waterflooding at 75°1", 150°F and 300°F_ "olved in hot waterflooding ottur slowly, ami thcl'nl,l!

The re~iUlt5 show that residual oil saturation decreases equilibrium rna.)' be con.:;idered tu prevail at ever....

with increasing temperature. Consequently, ultimate oil spac.e-time point during the flood. Con!:;equently, the

reco"ery increases with increasing temperature and the relative flow rates of oil and watel' are determined

relative permeability ratio is different for different tem~

perature,;;. The magnitude of the temperature effect va- b,y relative permeability ratios and viscmiitie::i, despite

ries, but in most cases it is appreciable, especiall:r for the the complicating thermal effects mentioned above.

crude oils. Crude oil waterflood behaviour in the labora-

tory tests differs significantly from refined oil behaviour. Although intensive re!ieal'ch intu thermal recovery

because in crude oil waterfloods "mter breakthrough is has taken place over the past ten years, little experi-

earlier and subordinate (lroduction is much higher. Conse- mental ,vork has been reported on the water displace-

quently, predictions of field hot waterfloods require dis- ment of oil at elevated temperature (ll. Theoretical

placement data at the actual field flood temperature, u,;:;-

ing res en oil' materials. work to date has predicted the performance of thiH

phase by assuming that the on1)' important temp ern-

ture effect is viscosity reduction (2). The implica-

tions of thi!i as!iumption are: (a) residual oil :-iatllrll~

;;"CalifoI'1lia. Re,';earc!l COI']}01'atirm, La Habra, tion after hot \...· aterflooding is independent uf tem-

Califo1"lIia_ perature and (b) the oil/water relative permeability

I'atio is also independent of temperature. If these as-

sumptions are valid, hot waterflood performance cun

1,00

" :: be predicted from room-temperature relative Jlerme~

50 0_ ability ratio data.

10 0

-

1\ --....,---..---"'T'"--..,.-,

IO ........

\

10 0

~. "I-+"":-+~-+-~ f----f--~

oJ

w 0

I \

0\ ~

6

~

-'

\ CRUDE 8

~

z 'y/

0:: \ \

w

,

U

, ,,~

>

~

5- ~ "-...

lQ

0 -

" ""

~ WHI;;~

"-

s::::::.-"'O I~ V.HITE OIL

- -

"

w

>

1- NO

"-

~~

CRUDE A

5

?- "- ----

-

~ /51--+--+--+-~"'k:---r-1

~

-

1

I

70 100 ISO 200 ,so

TEMPERATURE OF

----,

300

--

3,,0 HiO ~50 500 1O'-..-:!!:----;!:,....--±--~b_---d::_..J

~ 100 ~oo JOD

TEMPERATURE

400

aF

~oo

Fi.qurc 1.-0il and ll'uter "Fiscosily 'vs. Figw'e £.-Oil and Waler Deusil!! liS.

Tempcratllre. Tempcratul"f!.

236 The Journal af Canadian Pctralaum

Aeliel

Valve Relief

Valve

Charged wlcalorBd

-+-- White oil

trtg 0

Insula lian

•o :, .

,

~

Elec. Hlg Tape • '. '.

,.;

.

o

~

Annular Vol. Filled

Colored

wI Red

"While" oil

,

Grove Back

z Press Reg. "

"

Steel Care Halder ,"

,','

.

, ~.~ " ,

Figure 3.-Hot IVate1'flood Experimental Apparatus.

,I (All heating tapes are controlled by Wheelco Controllers from strategically located thermocouples at the

positions noted above).

o.

The purposes of this experimental investigation using two refined oils: No.5 white oil and No. 15

,,,ere to look for changes in the residual oil saturation white oil. One run was also made using No.1 white

and relati,re permeability ratio as a result of tempera- oil at 75°F. Two crude oils of different viscosity

ture changes, and thus to test the validity of the above characteristics were also flooded at 75°F, 150°F and

assumptions, which are commonly used to describe 300°F to determine whether their behaviour could be

waterflood behaviour at elevated temperatures. predicted from that of the refined oils. Properties of

the oils as a function of temperature are presented in

EXPERIMENTAL PROCEDURE Figures 1 and 2.

The experiments were conducted to determine the The experiments were performed on consolidated

residual oil saturation and also to provide data to cores_ These were conditioned, mounted, saturated

calculate the relative permeability ratios by the with water and then flooded with the test oil to ir-

Welge method. That is, the test core and the injec- reducible water at room temperature. The core assem-

tion water were maintained at the same constant tem- bly was then heated to the test temperature and flood-

perature throughout a run. thus maintaining the con- ed with hot water. Samples of the effluent were col-

stant viscosities required in the relative permeability lected throughout the run and analyzed for t"he water ~.

ratio calculations. Waterflood tests were conducted at and oil content. A diagram of the apparatus is' pre-

75°F, 100°F, 150°F, 200°F, 300°F, 400°F and 500°F sented in Figu~'e 3.

TABLE 1

CORE PROPERTIES

Air Water

Permeability Permeability Porosity

Lenglh Diameler Pore Volume ka kw oj>

Core No, em em ee md md %

1. - ......... ... .... . 22.60 4.13 63.52 578 562 21.1

2 .......... ......... , ..... 66.04 5.09 274.8 550 510 20.5

Technology, October-December, 1965, Montreal 237

The h,;o test core:=; used in these experiments were RESULTS

shaped from samples of Berea sandstone. Their phys-

ical properties are listed in Table I. The cores were The results of all individual runs are listed in Table

conditioned by heating in a 750°F oven for 24 hours II, and the averaged results for duplicate floodti an'

to remove any organic material, to insure that the presented graphicall~' in Fi[Jllre.~ .4 through 11. These

core would be initially water-\'vet and to desensitize graph~ de:icl'ihe waterflood history in two ways: (1)

the cla,Y.s. They ,'..-ere then enclosed in a Hassler sleeve pore volumes of water injected vs. pore vulumes 01'

made of Viion "A" rubber. Air permeability ,,·as oil recovered, and (2) permeability ratio (lc,,/[(,,) vs.

measured after each roasting to determine whethe:,' water saturation (S" 1. (Volumes and saturations fl'·l!

the core had reverted to its original condition. l'eported at test temperature) _ Initial water saturation

'...-as normalized to 20 per eent on the relative pel'mc-

The water saturation was ascertained under vac-

uum, u.sing deaerated di.stilled water ,..-,hich had been 400"F

]OOPF

treated with iodine Lo prevent bacterial formation.

'Vater saturations of at lea:it 98 per cent. based on 2oo~~(1

pore volume calculations, were attained. The core was 10

oil-flooded at room temperature until only irreducible o

IO?-( ?"F

water remained. Irreducible water saturation varied w

f- 0

between 17 and 27 per cent; this was adju.sted to a U I-

ba::;e of 20 per cent, as described later. ~

Z

01----- - - - - - f---- -.. -. ---

Prior to high-temperature flooding. the core and

injection water were heated to the desired test tem- "

W

f-

perature. Temperatures were monitored by thermo-

couples at the entrance and exist as well as along the

~

axis of the core. Temperatures were controlled OJ' "o

\Vheelco Controllers, sensing the temperature of the w 'i-

annular bath from thermocouples. Heat was supplied

w

L

I/

~~

by electrical heating tapes wrapped around the core :> i-

-' 6

holder. The entire s}'stem was insulated to minimize ~ i-

heat losses. w

As the core was being heated some oil was produced "o l

by thermal expansion. This oil \vas not included as

water-flood production. None of the production dur-

" V

ing flooding was due to expansion, because constant

temperature was reached before the flood started,

'Vater was injected at a con:itant rate of 7 cc/min.

oI

o 10

/ 10

'" 50 60

POPE VOLUMES OF OIL RECovERED-"/.

This high rate was selected to minimize capillary end

effects. Sufficient core pre.ssllre ' ...· as maintained to FiyHl"l' .~.-Jrutl'rjlo(ld Hi,~tOl'!' at l'ariou,~

insure that the water would always be in a liquid Tem1JC1'(lfIl1"l:s.

state. Annular pressure always exceeded core pressure Core No. 1-010. 15 White Oil

by at least 200 psi.

In the white oil floods, the production samples were

'00". IIso"r I

00"

analyzed for oil content by adding a knO\\'n amount of

normal heptane and measuring the refractive index of " 1S"FZ /:--300"F

400 P F

the mixture. For crude oils. the produced emul.sion o -

was broken by adding a small amount of concentrated ~ ,•

hydrochloric acid and the oil volumes were read di- u

w

, C-

rectl~· from calibrated test tubes. Z

o

Hot waterflooding was terminated after the injec-

tion of eight to ten pore volumes. This corresponded

"

W

f- ~

to a ,,;ater-oil ratio of at lea::;t 1,000 for the white oil ~

floods. The crude oil floods were terminated at a

lower produced water-oil ratio-IOO to 1. "o

w 'c-

w

Following hot waterflooding, the core was cooled L f::

hy circulating water and again oil-flooded until ir- 3 •6

Ifl

o c-

reducible water remained. Another hot waterflood >

would be made if the irreducible water saturation was w c-

± :2 per cent of that for the preceding run. In the "o "J

event of a larger initial water saturation variance,

the apparatus would be dismantled and the core 'would

" f-- /

be fired at 750°F. This firing process removed all

the oil and water, and returned the core to its original

condition. .1

1/

'"

GO

All data were converted to test temperature by cor- POR E VOLUt....ES OF OIL RECOVERED - "I,

recting the volumes of oil and water for thermal ex-

Figm'c 5_-lVatcrflood Hil{tol'y at l'al"ilws

pansion. Generally, te::;t runs '.vere performed at least Tell~]J(;l'atIfl"{:,'l_

twice. ,,,'ith satisfactory reproducibilit)r. Core No.1-No.5 'White Oil

23B The Journol of Canadian Petroleum

ability ratio graphs, Fig,,;-.s 8 to 11, for ease of com- ized to 20 pel' cent, residual oil saturation, as deter-

parison. This normalizing was accomplished by shift- mined from adj llsted relative permeability ratio

ing the water saturation b~~ an amount equal to the curves, decreases regularly with increasing tempera-

difference between initial water saturation and 20 ture in all cases, as shown in FigUl"es 8 to 11. Oil re-

per cent. Sman variances in initial water saturation, covery, despite variations in initial water saturations.

as encollntered in the -repurted tests, usually do not systematicalb~ increased with increasing temperature

appreciably affect the displacement efficiency (3)_ for all oils tested. This is illustrated in Figures 4. to

The graphs show that residual oil saturation de- 7 and in Table II_ The effect of temperature on the

creased as the temperature increased. Residual oil sat- performance of a hot waterflood is not predictable

uration was defined as the amount of oil remaining from the change in viscosity or oil-water viscosity

,,'hen the slope of the kw/ka vs. S.. .· curve became in- ratio.

. finite. Variations in the initial water saturations men-

tioned earlier are reflected in the residual oil satura-

tions. However, if initial water saturation is llormal- " 0

I

:300D~

" I ..-s0O·F

I ,o~ , 200"F

I "IOO"F

'~f-----+----+---'OO~F 1 - ~OO·F-

, IOO::J.

M

~ "

8 6.01---+--+---+-+--+-++-1-----1

I- f--

Ir

,

'/,1//

8 '-

"z

f--

jf/J

oJ---+--+-----jf--++-H-+-----J ••

I

;I rt

•"o ,l:r-=-----+--+-----jf--+--+++-+---1 '.0 , '/ ~"

~ ::: 1/

3 o.61---+----'----+-J4---+++-I-----1 I ".: "

~::: "0' WHOlE m, '''·F ~~

DOD ,

· - 1/v-

~ O.31---+---I------;;4-"e:::----t---t------I

I

" 3D

" 50

" I' BD

WATER SATURAT10N- Sw -%

"~o---;,~':----.;,:,---:lO;---t,";---*50~-"""":'!" FiguTC B.-k.../k o 1JBTS'/LS' B.... at Various

TBm.pBratU?"BS_

PORE VOLUMES OF OIL RECOVERED - %

Core No. I-No. 15 White Oil

,

FiguTe a.-Water/lood History at VaTious

Temperatu1'es. ", 200"F

Core No_ 2-No. 15 White Oil 300 D F

-..

,,;

150 D F... ~,

G

/400 F

100 "F

y•

I , " 7i~

CRUDE 8

0

a

o - ( \

w

•r-

CRUDE A ~

"> ,

}-

o

",

z I- 150'F

\ II 1,0;) Y I- ;j,

• • ,., J ., "IOO"F-

"

}-

~

"o ..

l- / I/ ~OO'

V"'·'

NO 15

WHITE

"",

<

w

iii

::;

•"w ,.,,

w .I

30o·~B

200"F

ISO" IOO"F

7S"F

,•3w o., j, / V

>

I~~

o I- ~

> I- .--' •

w ,.

•o •,

~

" ",

w

• V

II

000

l- ;:, '

, .00 I

• 0

PORE VOLUMES

lD

'"

OF OiL RECOVERED -%

50

'" 0

" 10 3D

" 5'

" 10

"

WATER SATURATiON - Sw -%

FigUTe 7.-WatBTflood HiJJtm'y at l'm'ious Figure 9.-k w/k o versus Swat Various

Ternperatu1"es. Temperaiu1"BS. "

Core No.2-with Crude Oils Core No. I-No.5 White Oil

Technology, October-December, 1965, Montreal 239

A comparison of the behaviour of two different re- displacement, with venT little oil produced after watel'

fined oils (No.5 and No. 15 white oils) in hot water- breakthrollgh. Ultimate oil recovery for the refined

floods is given in FiguTes J,. and 5. The results show oil floods \....as only slightly more than the amollnt of

the same trend-decreasing residual oil saturation 01' all recover}' achieved with an injection of one por~

increa::>ing ultimate reco\'ery "lith increasing tempera- volume. On the other hand, the crude oil floods had

ture. The No. 15 ,vhite oil floods shmved greater tem- an earlier brl:!akthnmgh, with a very ~ignificlll1L

perature dependenc.e than the No.5 white oil floods. amount of :,;ubordinate production, as shown in Figll}'11

This I::; not unexpected, because the decrease in vis- 7. This Figure also presents, for comparisun, a :300 Ii' 0

cosit.y of No. 15 white oil with temperature i::; much flood using No. 15 \\.-hite oil. This oil and crude A

greater than that for No.5 white oil. have essentially equal "i~cosity at :lOocF, One pmisi-

The hot water - crude oil floods exhibited a dis- ble reason for the difference in Lehaviour is inter-

tinctly different behayiour tha.n the refined oil floods, facial tension. At 75°F, the intel'facial tension be-

The refined oil floods showed a typically piston-like tween distilled water and crudes A and B b 21 and

TABLE II

---- -

[niliul Rl'sidlwl

II'all r Oil Rccul'~r)' - I ( Pore Volume" Oil

Salrlrtllioll -------~- -----_.- - - '-- Salljmlimr"

fu.' I PI/n' Fol.

CUTC Oil Tellll)· Run S", @ Brw~'l"rollgJI n'{l{a 11l}f!Ch1d Uflimalt' Sur

-._------ ------- ------ ---- ----~--- - - - - - - - - - - - - - - - - ------ --- -- ._.

,11 #15 \\'0 10001' I 18,5 23,1 35,9 37.5 H.O

I 15 Iva 100"F ~ 1~,5 23.1 33, I 33.9 ·17.6

I 15 IVO 200"F I 17.2 ~4.7 41.2 .[1..[ ·11.,1

I 15 IVa 200"1' 2 20.n 34,5 ·11.0 <ll.-I :I~.G

1 15 IVO 200"F 3 20.0 3-1.5 ·11.3 ·12.0 :18.0

------ ----_.-- ----- ---- ------- ------- --------- ------- -- --- ----

.#1 #15 IVa 200°F 4 20.0 3-1.5 -10.2 .[O.G 39.<1

1 15 IVO 300"1' I 2-1.1 38,8 42.7 -1·1.2 31.7

1 151'10 300'1' 2 25.1 37.2 ·11.6 ·13.6 :11.3

---r----

1 15 IVO -100'1' 1 23.0 -12.2 ·15.9 4u,8 2~).8

I 15 \VO 400'1' 2 Run Failed

- - - - - . ----_. ---- - - - - - - - - ----_. ._- -----

;;11 #!5WO 400"1' 3 19,B -11.8 ,IG.6 '18.5 31.7

1 15 'WO 500"F 1 Run ailed

I 15 \\'0 500°F 2 22,0 42.3 ·lu.8 48.9 29.1

1 15 wa 500'1' 3 ~ 1.fj -19,1 5U.3 52.<1 26.0

1 15 wa 500"1' -I 17,0 .,19.2 51.0 52.7 30,3

- - - - _ . - - - - - - - - - - - - - - - - - - - - - ._------ - - - - - - - - ------ .- ._---.

jll ,#5 \\'-0 73°[-' I 25.0 25.7 35,9 3u.5 3~,5

1 5 \YO Q

73 F 2 25.0 25,3 369 37.7 37.3

1 5\\'0 73 c F 3 l{un Failed

1 5\\'0 73°F -I l{un Failed

I 5\\'0 73'1' 5 27.0 25,3 3u.5 37.9 35.9

- - - - - - - - - - - - - ----_. -.

#1 jl5 \\-() 100'1' I 27.0 29.5 37.6 3~.1 3·1.9

I 5 \YO 100"1' 2 270 29.6 38.4 38,7 301.3

1 5 \YO 150"1' I 270 33.~ 38.0 39.3 33.7

1 5 \YO 150"1' 2 26,~ 33.8 39.3 39.7 33.5

1 511'0 200"1' I 27.0 37.1:~ 39.~ 40.0 33.0

-- ---- ------

,fl #5 WO 200'1' 2 2/.0 3G.7 ~9.7 ,0.2 32,8

1 5 WO 300"F 1 Run ailed

1 5 WO 300"1' 2 I{un Failed

1 5WO 300°F 3 27.0 37.1 40..1 ,11.5 :n,5

1 5WO 300"F 4 26.:3 37.:~ 40.2 40,5 :-13.5

1 5\\'0 -IOO"F 1 26.3 3~,0 42.5 -12.7 :n,o

----- ------_. - - - _ . - - - ----

jl2 ,415 \IIlO LOO°F I 20.2 26.0 37.7 37.1 ,12.7

2 15 WO LOO°F 2 2-1.8 24.6 34.~ 35.8 39.<1

2 15 \VO LOO°F 3 2-1.8 23.5 34.0 3ol.7 ·10.5

2 15 WO 100'1' 4 24..,1 23.2 35.5 36.2 39.01

2 15 WO 100'1' 5 2.,l,.13 23.2 35.7 37,0 38.2

- - - - - - -----._- ---_. ----- .-

&'2. 1511'0 200"F 1 24 1 37.3 42,4 42.7 33.2

2 1511'0 200'1' 2 2 , _0 36.3 -13.0 ·1:1.2 29.8

2 15 \VO 300"1' I 17.0 4-1.1 ·15.1 ·15.2 :l7,~

2 1511'0 300"1' 2 17,0 .,12.1 -13.8 H.2 38,8

2 111'0 73"F 1 26.5 32.1 3·1.7 3,1.7 3B,~

------- -------- .- ._----- - - - - - -

,2 Crude A

c

73 F I 17.0 8.0 32,0 .- -

2 Crude A 73"1' 2 17.0 B.G :31.7 .- -

2 Crude A 300"1' I 17.0 27.2 50.2 .- .-

2 Crude A 300"1' 2 17.0 26.1 49.1 -

------ ------~ ._----- ---- - - - - - - - -- - - - - - - _ . - - - - --- - - - -

jl2 Crude B 150'F I 18A 12,1 29.1 - -

2 Crude [3 150"F 2 20..1 11.G 27.3 -

2 Crude 13 300'F 1 23.0 21.8 3~.0 -

2 Crude B 300"1' ~ 210 2U 37.3 - ..

:tAt test temperature

240 The Journal of Canadian Petroleum

10 0 00

20,OP

'" ,

0 V

OD F

' - 10

]

lo'ZD

o 0

/

NOJWHIT~~ ;::

• 1/ '.

75°F

~ ,.

L"

I.0 > .0

/ ,

.. /I ~

J 1/./ '1 r '

:,,'

iii ••

1/ •w

J

/

~

~

CRUDE A

/\1 ~ /

on , 1/1 W

Q

.I

l~

75" F /

r/ II

r7 W Q]

•

'"W1/

>

;:: CRUDE B

o. 01 •"

W .0 I

/'-..

150¥F_300"F

, r

000

~

000 , /

.0 01

ID 20· lD 40 50 6D 10

.00 I

/

WATER SATURATION - Sw·%

'" 10 10

WATER

3D

'" 50

SATURATIO~- Sw

60 10

- %

80

Figure 10.-k... /k o 'lJeTS~ S.. . at Va.l"iolls Figw'e 11.-k w /k o 'l1erSltS S", at Val'ious

Tem.pel'atW"es_ TempeTatm'es_

Core No_ 2-No. 15 White Oil Core No.2-with Crude Oils

4.1 dynes/em, respectively. The interfacial tension be- 75 ° F No. 1 oil flood, but also exhibited a much later

1

j

tween distilled water and the refined oils is much water breakthrough. This behaviour illustrates that

higher, 49 dynes/em, at this temperature. the effect oJ temperature on waterflooding perform-

i ance is greater than that due solely to the reduction

!, Temperature had a significant effect on the rela-

tive permeability ratio, as shown in Figures 8 to 11. of the viscosity ratio_

Characteristically. the permeability ratio increased

with temperature at low autfIm\' water saturations. CONCLUSIONS

However, at a permeability ratio of approximately The contribution of this study is a presentation of

unity, the higher temperature curves crossed those experimental results showing that ultimate oil recov-

for the lower temperature. No special significance is ery and consequently residual oil saturation and rela-

attached to this observation at this time. tive permeability are affected by temperature. The

A further demonstration of the effect of tempera- findings reported here apply to waterflooding in gen-

ture is shown in Figu1·e 6, where a 75 Cl F No.1 white eral and thermal recoverJr in particular, as most ther-

oil flood may be compared with No_ 15 white oil floods. mal recovery methods include a phase where ·'hot"

ComparisoIL of the 75 Cl F No_ 1 white oil flood with water displaces "hot" oiL

the 100°F No. 15 white oil waterflood shows that the The results presented here lead to the following con-

recoveries, residual saturations and relative perme- elusions:

ability ratio are about the same. The flood histories,

however, are different. In the 100°F No. 15 white oil I.-Residual oil decreases and consequently ultimate "~,A

flood, water breakthrough occurred earlier and con- oil recovery increases with temperature.

siderably more water throughput 'vas required to ar- 2_-The water-oil permeability ratio changes with

rive at residual oil saturation_ This is conventional temperature for a given oil.

behaviour which could be predicted, as the No. 15 3.-Field waterflood recovery predictions l'equire

white oil- water viscosity ratio at IOOClF is much relative permeability ratio data at the actual

higher than the No.1 white oil- water viscosity ratio flood temperature using reservoir fluids. In-

at 75°F. Figure 10 shows that the relative permeabil- correct behaviour will be predicted if room-tem-

ity ratio function of the 75°F No.1 white oil flood perature relative permeability ratios are extra-

is identical to that for the 100°F No. 15 white oil polated or if displacement data are based on

flood, therefore substantiating the fact that the rela- refined oils.

tive permeability ratio function is independent of vis-

cosity ratio when refined oils are used at temperatures The results of this 'work are valid where the forma-

between 75°F and 100°F. At 300°F, the oilfwate,· tion is completely heated; that is, in the region behind

viscosity ratio of No_ 15 white oil is the same as that the heat front. More theoretical and experimental work

of No.1 white oil at 75°F. Conventionally, one would will be needed for an adequate understanding of the

expect equal oil recoveries and similar flooding his- extent that displacement efficiency is affected by a

tories if viscosity ratio were the only important tem- heat front moving through an oil-bearing formation,

perature-dependent variable. The 300°F flood, how- where the formation and the injection water are at

ever, not only showed greater oil recovery than the different initial temperatures.

TechnolDgy, October-December, 1965, MDntreal 241

REFERENCES

(1) H"llIlHaJI, B. T., l'allcl'oll. 1'. F., R1/lIber,lJ. G, JF..

COJ l/elw8, .-1.. J. and Powenl. L. H',. "Laboratory T. A. Edmondson was born in BokC!rs-

Studies of Oil Rec'Dvery by Stealll Injeetion/' .I0/l?'_ field, California, and attended the Uni-

Pet. Tcch_, .July, l!)GL versity of California at Berkeley. He ab-

I ~) .hll·dftll, J fC, RaYI/f', .I. n., and JluTshall. S. l-F., HI, tOlned a B.S. in petroleum engineenng

"A Calculation P~'ocedure for Estimating the Produc- In 1960 and on M.S. in petroleum engi-

tion Hi.~tory during Hot \Vater [njection in Linear neering In 1961. He jOined Chevron [le-

Ke.~l'r\'(.;r;:;." Unpubli."hed-prepared for presenbdon search Company a t the La Habra Labor-

at the T",,·enlieth Technical Conference on Petl"oleum atory In 1961 and completed lh(! sub-

Pl"oduction, The PE'nnsJrlvania State University, Uni- ject experiments while assigned to their

vet'sity Park. Pa., j'day 9-10, 1!.l57, Oil Recovery Section. He is now working

(3 ) SareIH, A. M., ".-\. Significance of \Vater-Oil Re.la- in Chevron Research's Producing Tech-

tive Pel"lueability Data Calculated from Di~place nology Section, which IS also located at

lllent Tests." Digc.~·t P'-occr.d., Confet'eoce on Theory (he La Habra Laboratory.

of Fluid Flow in Porous Media, at the Univ. of

Okla., A[ar. 23-.2-1. 1959.

DiscussiolD • • •• • • • • •• • •

AS.:-iuming that the effect resideH

T HE su b.ied pape.r is an excel-

lent presentation of much

needed experimental information

most of the runs conducted on core

1. the product LV.. . !J.... :::: 2. 'which

is l:oIlsidel"ab1}r below the l:ritical

primarily in the k" \·.due, the re-

.suits are in fair agreement with

exLending the temperature range value of 5. For these runs. end ef- thoRe previously obtained (5, 6),

uver which displacement of oil br fect may be significant and the re- At a higher water saturation,

water has been closely examined. sults of waterfloods could be con- the nil flow becomes more discon-

The care exercised in the experi- siderably influenced b)r it. tinuous in natul'e and leRs subject

mental wurk is reflected in the In reference to relative perme- to laminar flow concepts. At very

data obtained. The papel" mentions ability ratio results as described high water-oil ratios. the oil flow

the effect of tempel"ature on the in Figl/re,') 8, !} and 10, a qualita- is particulate. or corpuscular, and

oil-water interfacial tension. It is ti\'e explanation of the tempera- less dependent all viscosity .mel

unfol"tunate that interfacial ten- ture effect may relate to the be- more dependent on oil-water inter-

sion nata were not obtained on haviour noted earlier by Yuster facial tension, Assuming that in-

each s}'~tem at the conditions stud- (3) and studied later by .several terfacial tension decreases with

iecL Such data would be of value inve:itigators (4, 5, 6). Relative increased temperature, the limiting

in correlating and interpreting the permeability [s considered primar- pOl'e size opening through which

results obtained, particularly in the ily as a fundion of saturation; the the discontinuous flow can OCCLlr

calculation uf relative permeability condition of the boundary between will be smaller at higher tempera-

hy \Velge's (1) method, which ap- the liquid phases is not specified. tureR. Alternately stated, an in-

plies to the performance obtained In the subject stud,).., neglecting in- crease in temperature permitfi a

after water breakthrough. The de- terfacial ten.sion effects at high oil gi'i"en level of oil permeability ttl

termining and reporting in the im- satun"'!.tion:i, the primary difference be extended into a slightly lower

mediate future of appropriate in- created by temperature i.s in the oil saturation range.

terfacial tension values of the oil viscosity of the oil 'Phase. At high Finally, on page 241 the author

and water samples used in the ex- oil saturations, oil flow could be states that "the relati'i"e permeabil-

perimental \.. ' ork would enhance the complemented by the wetting ity ratio function of the 75 Cl F No.

value of the investigation. phase, which is either flowing or 1 white oil flood is identical to that

\Yith regard to the interpreta- \\·hich provides a "lubricating" la.r- for the lOO°F No. 1:3 white oil

tion of the results obtained, the fol- er or moving boundary for the non- flood." He concludes from this that

lowing ~pecific comments are of- wetting phase. Although this be- "relative permeability ratio func-

fered. haviour is operative \\'ith either a tion is independent of viscosity

On page 238, the author states lo\\'- or high-viscosity non-wetting ratio when refined oils are used nt

that an injection rate of 7 cc/min phase, its effect on the permeabil- temperatures between 75°F and

was used. This was selected to ity to a high-viscosity non-wetting 100°F." It was pointed out above

minimize capillary end effects. 'Phase is relatively greater. From that the relative permeability cnl-

Rapoport and Leas (2) showed that this it follows that at a given high culated by 'Velge's method is af-

for the linear \vaterflood to be in oil saturation. the oil permeability fected by water-oil interfacial ten-

the stable region, i.e., no capillmT at low temperature (high oil vis- sion. Therefore, unless the author

end effect, the product of LV.. . !L.... cosity) may be effectively higher shows that the intel'facial tension

should be > 5. (L is the length of than that of the same system at for No.1 oil at 75"F is equal to

the sample in cm. V" is the 'i\'ater high temperature (low oil viscos- tlwt of No. 15 oil at LOO°F, he can-

flow velocity in em/min and !1." is ity). Hence, the observed higher not conclude the independence of

the water viscosity in cp.) For k . . /ko ratios at high temperatures. relative penneabilit:y on viscosity.

A. S. Odell and E. L. Cook

Socon}" Mobil Oil Company, Inc.,

Field Research Laboratory,

Dallas, Texas

00000000000000000000000000000000000000000000000000000000000

242 The Journol of Canadian Petroleum

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Cover Letter Non MigasDocument1 pageCover Letter Non MigasRani Juliarini RahayuNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Plan of DevelopmentDocument28 pagesPlan of DevelopmentRani Juliarini RahayuNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Waterflooding SurveillanceDocument6 pagesWaterflooding SurveillanceRani Juliarini RahayuNo ratings yet

- Sedimen Cambro Ordovician Res Quality Messaoud Area Saharan PlatformDocument8 pagesSedimen Cambro Ordovician Res Quality Messaoud Area Saharan PlatformRani Juliarini RahayuNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Hamra ReservoirDocument3 pagesHamra ReservoirRani Juliarini RahayuNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Monitoring Water FloodDocument9 pagesMonitoring Water FloodRani Juliarini RahayuNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Paper Sabria TunisiaDocument12 pagesPaper Sabria TunisiaRani Juliarini RahayuNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Brun Dred 1955Document6 pagesBrun Dred 1955Rani Juliarini RahayuNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Nadella Cam Follower PF810EDocument22 pagesNadella Cam Follower PF810EAldair MezaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Statistics Hand NotesDocument16 pagesStatistics Hand NotesAtul VermaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Olympus UT Catalog PDFDocument52 pagesOlympus UT Catalog PDFGTpianomanNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- GenMath11 Q1 Mod26 Domain and Range of Logarithmic Functions 08082020Document19 pagesGenMath11 Q1 Mod26 Domain and Range of Logarithmic Functions 08082020Charity Myrh Pasquin ArzagaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Time Value of Money:: "Money Is An Arm or Leg. You Either Use It or Lose It." - Henry FordDocument33 pagesTime Value of Money:: "Money Is An Arm or Leg. You Either Use It or Lose It." - Henry FordramunagatiNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Fiitjee Fiitjee Fiitjee Fiitjee: Fortnightly Assessment QuizDocument8 pagesFiitjee Fiitjee Fiitjee Fiitjee: Fortnightly Assessment QuizIshaan BagaiNo ratings yet

- Reading Report Student's Name: Leonel Lipa Cusi Teacher's Name: Maria Del Pilar, Quintana EspinalDocument2 pagesReading Report Student's Name: Leonel Lipa Cusi Teacher's Name: Maria Del Pilar, Quintana EspinalleonellipaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Back-to-Back Accelerometer CalibrationDocument3 pagesBack-to-Back Accelerometer CalibrationAekDzLaiNo ratings yet

- Mathematics (0580/13) October/November 2019Document12 pagesMathematics (0580/13) October/November 2019kdebipershadNo ratings yet

- Quiz 3 Basic ProbabilityDocument38 pagesQuiz 3 Basic ProbabilityjacobtianNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Virtual Memory & Demand PagingDocument22 pagesVirtual Memory & Demand PagingAli AhmadNo ratings yet

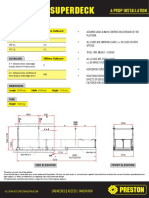

- SuperDeck All ModelsDocument12 pagesSuperDeck All Modelsarthur chungNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- CFR 2011 Title49 Vol3 SubtitleBDocument626 pagesCFR 2011 Title49 Vol3 SubtitleBmgmqroNo ratings yet

- VSF2 ND EdDocument345 pagesVSF2 ND EdRyanNo ratings yet

- Electrical Submersible Pump HandbookDocument67 pagesElectrical Submersible Pump HandbookAnonymous Xy309m9Sm9No ratings yet

- Datasheets A S50ib enDocument2 pagesDatasheets A S50ib envantuan17792No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- How To Find Equilibrium Price and Quantity MathematicallyDocument2 pagesHow To Find Equilibrium Price and Quantity MathematicallyJoshua S Mjinja100% (1)

- NOJA 520 05 SCADA Interface Description PDFDocument24 pagesNOJA 520 05 SCADA Interface Description PDFsergio torrez vargasNo ratings yet

- FMC - Novolastic Subsea Thermal Insulation - LOW RESDocument3 pagesFMC - Novolastic Subsea Thermal Insulation - LOW RESalphading50% (2)

- APCO Air Valve 613Document4 pagesAPCO Air Valve 613jones0055No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Sony SDM-N50R PDFDocument76 pagesSony SDM-N50R PDFFöldi BélaNo ratings yet

- Truefire Guitar Chord Cookbook PDFDocument101 pagesTruefire Guitar Chord Cookbook PDFeuripides7794% (17)

- Tesp12205pi R1Document36 pagesTesp12205pi R1arabsniperNo ratings yet

- Fixed Frequency, 99% Duty Cycle Peak Current Mode Notebook System Power ControllerDocument44 pagesFixed Frequency, 99% Duty Cycle Peak Current Mode Notebook System Power ControllerAualasNo ratings yet

- Project Robot ArmDocument62 pagesProject Robot ArmTechs Solutions RobotsNo ratings yet

- Camber For Construction StageDocument18 pagesCamber For Construction StageOanh PhanNo ratings yet

- Experiment 08-A2dDocument3 pagesExperiment 08-A2dapi-277396867No ratings yet

- Genetic Variability and Correlation Studies in Okra (Abelmuschus Esculentus (L) Moench)Document67 pagesGenetic Variability and Correlation Studies in Okra (Abelmuschus Esculentus (L) Moench)rajsign5100% (3)

- Ball BearingsDocument31 pagesBall Bearingsnike_y2kNo ratings yet

- Change ManDocument17 pagesChange Mansrikanth9gannuNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)