Professional Documents

Culture Documents

Concrete Bridge Loading

Concrete Bridge Loading

Uploaded by

Brad Borges0 ratings0% found this document useful (0 votes)

18 views16 pagesConcrete Bridge Loading

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentConcrete Bridge Loading

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views16 pagesConcrete Bridge Loading

Concrete Bridge Loading

Uploaded by

Brad BorgesConcrete Bridge Loading

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 16

208

CHAPTER - 7

BRIDGES

7.1 TYPES

Reinforced concrete is particularly well suited for use in bridges of all kinds

because of its durability, rigidity, and economy, as well as the comparative ease with

which a pleasing appearance can be achieved

FIGURE 7.1

Precast prestressed voided slab bridge.

For very short spans, from about 10 to 25 ft, one-way slab bridges are

economical. Somewhat longer spans, up to about 50 ft, can be achieved with bridges

of this same general type by fofining longitudinal voids with fiberboard tubes, thereby

reducing dead load. Figure 7.1 shows a voided slab bridge using precast elements.

Asphalt wecring

_eCement grout in keywoy

FIGURE 7.2

Precast integral-deck bridge

units: (a) voided slab;

(b) channel slab

Lntermediote tronsverse diophragmns

209

Typical cross sections are shown in Fig. 7.2. Such spans are often prestressed

by pretensioned strands, and may be laterally post-tensioned after the units are placed

side by side. Such construction offers low initial cost, as a result of standardized plant

production, and is characterized by fast, easy erection and low maintenance. For

highway spans, an asphalt-wearing surface is normally applied directly to the top face

of the concrete units (Refs. 7.1 and 7.2).

FIGURE 7.3

Cast-in-place deck-grider bridge.

Cast-in-place concrete girders such as shown in Fig. 7.3 may be used for spans

up to about 100 ff, although their use is less common now than before because of the

advantages of precasting for this range of spans. For cast-in-place bridges, the

monolithic concrete deck spans as a slab transversely and also provides a broad

cOmpression flange for the main girders. Such bridges may be single span and simply

supported as shown, or continuous over two or more spans.

FIGURE 7.4

Continuous bridge using cast-in-place concrete slab composite with welded

steel griders,

210

Most highway bridges in the United States of medium length, from 60 to about

120 ft, make use either of composite steel-concrete construction or composite pre-

stressed concrete construction. A continuous composite structure is shown in Fig. 7.4.

The concrete deck is made to act integrally with the steel beams through use of shear

connectors welded to the top flange of the beams and embedded in the slab. Although

such a bridge is not strictly a reinforced concrete structure, the design will be presented

in some detail in this chapter because of its widespread use. Prestressed concrete

bridges frequenfly make use of composite action also. Commonly the beams are precast

and placed in position by a crane, eliminating the need for obstructing traffic with

falsework. The deck slab is then cast in place and locked to the precast units by

stirrups that project upward into the slab. Figure 7.5 illustrates construction of this type.

FIGURE 7.5

Standard AASHTO bridge girders, precast and pretensioned, composite

with cast-in-place slab.

Requiremonts for long spans have led to the development of segmentally cast

post-tensioned prestressed concrete box-girder bridaes of the tvoe shown in Fig. 7.6

In typical construction, the work proceeds in two directions from each pier, using the

balanced cantilever method shown, and is advanced using either cast-in-place or precast

conerete units. Each is post-tensioned to the previously completed construction after

placement. Very long spans have been achieved in this way, the longest presently

(1990) being close to 1000 ft.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Ansi A-1264-1 2007Document31 pagesAnsi A-1264-1 2007Yimmy Moreno100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Structural Steel Det Train ManualDocument100 pagesStructural Steel Det Train Manualsuperpiojo86% (22)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

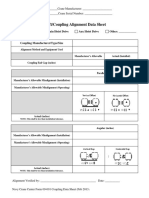

- Shaft/Coupling Alignment Data Sheet: Equipment (Check One) : Main Hoist Drive Aux Hoist Drive OtherDocument2 pagesShaft/Coupling Alignment Data Sheet: Equipment (Check One) : Main Hoist Drive Aux Hoist Drive OtherBrad BorgesNo ratings yet

- Vibration Mounts - Bumper Technical InformationDocument9 pagesVibration Mounts - Bumper Technical InformationBrad BorgesNo ratings yet

- WPS Guides For Plug and Slot WeldsDocument4 pagesWPS Guides For Plug and Slot WeldsBrad BorgesNo ratings yet

- Louden Catalog Dec 10Document1 pageLouden Catalog Dec 10Brad BorgesNo ratings yet

- Operation, Service AND Parts Manual: Single and Double Girder Top Running Bridges With Individual Motor Driven TrucksDocument20 pagesOperation, Service AND Parts Manual: Single and Double Girder Top Running Bridges With Individual Motor Driven TrucksBrad BorgesNo ratings yet

- Nucor Type III Structural FastenersDocument2 pagesNucor Type III Structural FastenersBrad BorgesNo ratings yet

- Nord Shaft Fixing Kit Bim1002 - UsDocument2 pagesNord Shaft Fixing Kit Bim1002 - UsBrad BorgesNo ratings yet

- ACCOLIFT - ELECTRIC CHAIN HOIST - CatalogDocument16 pagesACCOLIFT - ELECTRIC CHAIN HOIST - CatalogBrad BorgesNo ratings yet

- DTI Installation Instructions PDFDocument3 pagesDTI Installation Instructions PDFBrad BorgesNo ratings yet

- Wi Dot-Bridge Manual PDFDocument54 pagesWi Dot-Bridge Manual PDFBrad BorgesNo ratings yet

- Wampfler-US Load Diagrams Program 0170 Rubber BumpersDocument14 pagesWampfler-US Load Diagrams Program 0170 Rubber BumpersBrad BorgesNo ratings yet

- Irizar Technical Brochure PDFDocument84 pagesIrizar Technical Brochure PDFBrad BorgesNo ratings yet

- Falk Couplings Installation and Removal ManualDocument6 pagesFalk Couplings Installation and Removal ManualBrad BorgesNo ratings yet

- Astm A193Document12 pagesAstm A193Brad BorgesNo ratings yet