100% found this document useful (3 votes)

3K views83 pagesLaboratory and Field Testing of Rock

The document discusses laboratory and field testing of rocks. It provides an overview of laboratory tests including tension, shear, flexure, and elastic modulus tests. It also discusses in-situ tests like deformability, shear strength, and stress tests. The document outlines different types of rocks and factors that influence their response to loads. It describes methods of rock sampling, classification based on index properties, and tests to evaluate properties like durability and permeability.

Uploaded by

SANDEEP DANGDACopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (3 votes)

3K views83 pagesLaboratory and Field Testing of Rock

The document discusses laboratory and field testing of rocks. It provides an overview of laboratory tests including tension, shear, flexure, and elastic modulus tests. It also discusses in-situ tests like deformability, shear strength, and stress tests. The document outlines different types of rocks and factors that influence their response to loads. It describes methods of rock sampling, classification based on index properties, and tests to evaluate properties like durability and permeability.

Uploaded by

SANDEEP DANGDACopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Laboratory and Field Testing of Rocks: Introduction and cover of the module focused on lab and field testing processes for rocks.

- Overview: Summarizes the types of laboratory and insitu tests conducted on rocks, such as tensile and shear tests.

- Rocks: Discusses the formation, properties, and significance of rocks in construction and engineering.

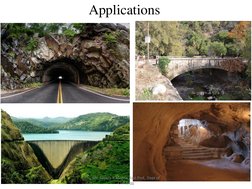

- Applications: Illustrates real-world applications of rocks in engineering projects like tunnels and bridges.

- Complexities in Rock Analysis: Explores the challenges in analyzing rock specimens due to their intrinsic properties.

- Primary Classification of Rocks: Classifies rocks into igneous, sedimentary, and metamorphic based on their origins and characteristics.

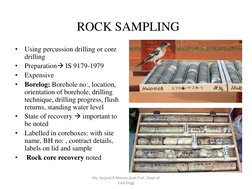

- Rock Sampling: Describes the methods of drilling and sampling rock cores for analysis.

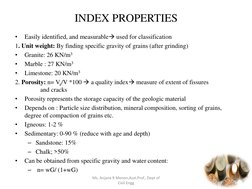

- Index Properties: Outlines the properties used for classifying rocks, such as unit weight and porosity.

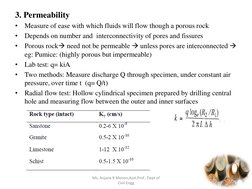

- Permeability: Explains how permeability tests determine the ability of rocks to allow fluid to pass through.

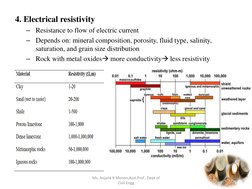

- Electrical Resistivity: Discusses how rocks resist electrical current, which can indicate various material properties.

- Slaking and Durability: Covers the resistance of rocks to disintegration under environmental conditions.

- Durability: Further elaborates on the factors affecting the durability of rock masses.

- Agencies Affecting Durability: Lists environmental and chemical factors impacting the durability of rocks.

- Slaking Process: Defines slaking as the process of material disintegration due to moisture exposure.

- Slake Durability Index Test: Depicts the testing apparatus used for measuring the slake durability index of rock samples.

- Objective and Apparatus: Details the objective of the slake durability test and the apparatus used.

- Sample Preparation and Procedure: Provides detailed steps for preparing rock samples and conducting the slake durability test.

- Continuation of Procedure: Continues the step-by-step procedure for the slake durability test.

- Equipment Illustration: Shows an image of equipment used in the slake durability test.

- Slake Durability Index Calculation: Explains the formula for calculating the slake durability index of rocks.

- Durability Classification: Categorizes rock durability based on the slake durability test results.

- Liquidity Index Changes: Discusses changes in the liquidity index and its correlation with slaking rate.

- Slaking Amount Table: Presents a table showing the correlation between liquid limit and amount of slaking.

- Rate of Slaking: Displays a table categorizing rocks based on their slaking rate.

- Sonic Velocity: Analyzes the sonic velocity of rocks and its implications for material characterization.

- Quality Index of Rock: Introduces the concept of rock quality index based on velocity measurements.

- Point Load Strength: Details the method of determining point load strength as a classification measure.

- Point Load Test Details: Provides additional data and test conditions for conducting point load tests.

- Mechanical Properties Tests: Lists tests for evaluating mechanical properties such as triaxial and shear strength.

- Triaxial Test Procedure: Outlines the procedure of conducting a triaxial test on rock samples to assess features under confining pressure.