Professional Documents

Culture Documents

DISCUSSION

Uploaded by

Nur SalwaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DISCUSSION

Uploaded by

Nur SalwaniCopyright:

Available Formats

DISCUSSION

For classification of soil for engineering purposes, we oath to know the distribution of the grain

sizes in any given soil mass especially the one obtain from the construction aggregates. Particle size

distribution test, also known as sieve analysis test is a method used to determine the grain(granular) size

distribution of aggregates samples. Grain-size analysis is important to know the materials performance.

The standard grain size analysis test determines the relative proportions of different grain-sizes as they are

distributed among certain size ranges. The sieve analysis is a process where the grain size distribution of

aggregates is determined. This test is done by letting a sample of aggregates pass through a stack of sieves

of decreasing mesh opening sizes and by measuring the weight retained on each sieves. The main concept

in this process is to retain the large particles not able to pass through the varying sieve sizes. The sieve

analysis is primarily applied to soil particles with sizes from 75mm to75microns. Observation in this

experiment, the particulate nature of soil was greatly observed. It was also shown that certain

classifications in soil can be done through sieve analysis. One essential thing to do in this experiment is to

arrange the sieves properly. The accuracy of this experiment is very much dependent on the sieve

arrangement. The arrangement of sieves must be in decreasing mesh openings from top to bottom. This is

very useful in order to separate the particles from coarser to finer. Lastly, it was observed that for particles

having sizes larger that the sieve opening to which it will be retained. On the other hand, those with

smaller sizes were able to pass through. This phenomenon is the basic reason on how particles were

separated. Application for the grain-size analysis is one process that deals in the determination of strength

of the aggregates from its size. Knowing the distribution of soil is best applied in making engineering

judgements towards aggregates condition. There are some factors that might affect the loss of fine

aggregate of the experiment. Some particles that left in sieve apparatus for previous experiment may drop

into our sample during shaking. The aggregate that used is not really pure and may contain others material

such as dried leave or dust. Some dust or other material that contained in aggregate had lost when the

sieves were shaken and hence affect the accuracy of the experiment.

CONCLUSION

Sieve analysis is performed on coarse and fine aggregates to in order to check their gradation.

This gradation gives an indirect measure if the workability and average particle size. Fineness modulus is

an index to the particle size not the gradation. In fineness modulus, the finer the material the more the

water demand. The grading curve that plotted were stated that these sample of aggregate were classified

between fine and coarse

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Discussion Concrete Mix-1Document2 pagesDiscussion Concrete Mix-1Nur SalwaniNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Construction Roads DrainageDocument37 pagesConstruction Roads DrainageNur SalwaniNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Steady Non Uniform Flow in Open Channel: Prepared By: Amalina Amirah Abu BakarDocument58 pagesSteady Non Uniform Flow in Open Channel: Prepared By: Amalina Amirah Abu BakarNur SalwaniNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Topic 2: Steady Incompressible Flow in Pipelines: Learning OutcomesDocument60 pagesTopic 2: Steady Incompressible Flow in Pipelines: Learning OutcomesNur SalwaniNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Non-Uniform Flows in Open Channel: INTI University CollegeDocument73 pagesNon-Uniform Flows in Open Channel: INTI University CollegeNur SalwaniNo ratings yet

- OpenChannel Flow Lab ReportDocument8 pagesOpenChannel Flow Lab ReportNur SalwaniNo ratings yet

- Results: Calculation: Compacted WeightDocument3 pagesResults: Calculation: Compacted WeightNur SalwaniNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- BDocument3 pagesBNur SalwaniNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Frost Academy All Boys SchoolDocument361 pagesFrost Academy All Boys Schoolcam UyangurenNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Knowledge About Visha - Upavisha & Metalic Preparations - Knowledge of Formulations Containing Visha - Upavisha & Rasa AushadhisDocument154 pagesKnowledge About Visha - Upavisha & Metalic Preparations - Knowledge of Formulations Containing Visha - Upavisha & Rasa AushadhisPRASHNT SINGHNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Savage Cyberpunk 2020Document14 pagesSavage Cyberpunk 2020dmage_uNo ratings yet

- Business Management Business ManagementDocument31 pagesBusiness Management Business ManagementDoyieNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- SLS Ginopol L24 151-21-3-MSDS US-GHSDocument8 pagesSLS Ginopol L24 151-21-3-MSDS US-GHSRG TNo ratings yet

- Andrea Falcon - Aristotle On How Animals MoveDocument333 pagesAndrea Falcon - Aristotle On How Animals MoveLigia G. DinizNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Dela Cruz vs. Atty. DimaanoDocument8 pagesDela Cruz vs. Atty. DimaanoMarga CastilloNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Carim JR Et Al (2016) - Using Procedures Doens't Mean Follow It - A Cognitive Approach To How A Cockpit Manages EmergenciesDocument11 pagesCarim JR Et Al (2016) - Using Procedures Doens't Mean Follow It - A Cognitive Approach To How A Cockpit Manages EmergenciesFrancisco SilvaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Short Question: Computer Science For 9 Class (Unit # 3)Document5 pagesShort Question: Computer Science For 9 Class (Unit # 3)Yasir MehmoodNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Aditya Man BorborahDocument4 pagesAditya Man BorborahAditya BorborahNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Traverse AdjustmentDocument22 pagesTraverse AdjustmenthabteNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Calcium Carbonate Lab ReportDocument2 pagesCalcium Carbonate Lab ReportAlexander Weber0% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

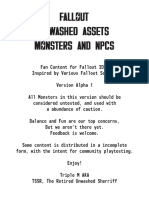

- Fallout Unwashed Assets Monsters and NpcsDocument4 pagesFallout Unwashed Assets Monsters and NpcsVeritas VeritatiNo ratings yet

- Department of Education: Wawa Elementary SchoolDocument2 pagesDepartment of Education: Wawa Elementary SchoolJONATHAN CALAGUINo ratings yet

- Federal Election Commission Complaint Filed Against Tennessee State Sen. Brian Kelsey, OthersDocument66 pagesFederal Election Commission Complaint Filed Against Tennessee State Sen. Brian Kelsey, OthersUSA TODAY NetworkNo ratings yet

- How To Perform A Financial Institution Risk Assessment: Quick Reference GuideDocument15 pagesHow To Perform A Financial Institution Risk Assessment: Quick Reference GuideYasmeen AbdelAleemNo ratings yet

- Annual 2005Document128 pagesAnnual 2005KarredeLeonNo ratings yet

- RSC SCST Programme Briefing For Factories enDocument4 pagesRSC SCST Programme Briefing For Factories enmanikNo ratings yet

- Abdukes App PaoerDocument49 pagesAbdukes App PaoerAbdulkerim ReferaNo ratings yet

- Notice: List of Eligible Candidate(s)Document3 pagesNotice: List of Eligible Candidate(s)Ram KumarNo ratings yet

- Small Scale Business ReportDocument28 pagesSmall Scale Business ReportJatin PahujaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Swot Analysis of PiramalDocument5 pagesSwot Analysis of PiramalPalak NarangNo ratings yet

- CAPEX Acquisition ProcessDocument5 pagesCAPEX Acquisition ProcessRajaIshfaqHussainNo ratings yet

- Preview-90187 Pno H UnlockedDocument5 pagesPreview-90187 Pno H UnlockedFilip SuciuNo ratings yet

- Out To Lunch: © This Worksheet Is FromDocument1 pageOut To Lunch: © This Worksheet Is FromResian Garalde BiscoNo ratings yet

- How To Be A Well Rounded Jazz PianistDocument3 pagesHow To Be A Well Rounded Jazz PianistNelson Danny Junior100% (1)

- Maths-Term End Examination-2020-2021 (2020-2021, MATHS)Document6 pagesMaths-Term End Examination-2020-2021 (2020-2021, MATHS)Venkat Balaji0% (1)

- Youth Policy Manual: How To Develop A National Youth StrategyDocument94 pagesYouth Policy Manual: How To Develop A National Youth StrategyCristinaDumitriuAxyNo ratings yet

- City Marketing: Pengelolaan Kota Dan WilayahDocument21 pagesCity Marketing: Pengelolaan Kota Dan WilayahDwi RahmawatiNo ratings yet

- Brochure Selector Guide EN-web-protectedDocument16 pagesBrochure Selector Guide EN-web-protectedPierre-Olivier MouthuyNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)