Professional Documents

Culture Documents

Sheet Metal Processes

Uploaded by

Nhk TokCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sheet Metal Processes

Uploaded by

Nhk TokCopyright:

Available Formats

SHEET METAL PROCESSES

BENDING

Bending is one very common sheet metal forming operation used not only to form shapes

like seams, corrugations, and flanges but also to provide stiffness to the part (by increasing its

moment of inertia).

As a sheet metal is bent (Fig 6.1), its fibres experience a distortion such that those nearer

its outside, convex surface are forced to stretch and come in tension, while the inner fibres come

in compression. Somewhere, in the cross section, there is a plane which separates the tension and

compression zones. This plane is parallel to the surface around which the sheet is bending, and is

called neutral axis. The position of neutral axis depends on the radius and angle of bend. Further,

because of the Poisson's ratio, the width of the part L in the outer region is smaller, and in the

inner region it is larger, than the initial original width.

Fig 6.1 Sheet metal bending. It may be noted that the bend radius is measured to the inner

surface of the bent part.

BEND ALLOWANCE

It is the length of the neutral axis in the bend, Fig 6.1. This determines the blank length

needed for a bent part. It can be approximately estimated from the relation

Lb = a ( R + kt )

where, Lb = bend allowance (mm)

a = bend angle (radian)

R = bend radius (mm)

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Pipe Steel Pipe CatalogueDocument16 pagesPipe Steel Pipe Cataloguezishanf_1No ratings yet

- Free PPT Templates: Insert The Subtitle of Your PresentationDocument48 pagesFree PPT Templates: Insert The Subtitle of Your PresentationSyafa NauraNo ratings yet

- Contoh Proposal Bisnis PlanDocument31 pagesContoh Proposal Bisnis PlanHadianto Nugroho100% (4)

- Hempathane Topcoat 5521911370 En-UsDocument11 pagesHempathane Topcoat 5521911370 En-UsNhk TokNo ratings yet

- Upper Tool: Controlled Dimension After BendingDocument1 pageUpper Tool: Controlled Dimension After BendingASHOKNo ratings yet

- NIKO Track Roller Bearing CatalogueDocument29 pagesNIKO Track Roller Bearing CataloguezhiqianxuNo ratings yet

- C1BxaOC0 IS PDFDocument92 pagesC1BxaOC0 IS PDFSrinivas ReddyNo ratings yet

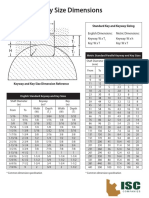

- Vol 56 No 03 - Shaft and Hub Keyway and Key SizesDocument4 pagesVol 56 No 03 - Shaft and Hub Keyway and Key SizesramsesluNo ratings yet

- 427-140 Manual DrawingDocument1 page427-140 Manual DrawingNhk TokNo ratings yet

- MitutoyoDocument1 pageMitutoyoNhk TokNo ratings yet

- Keyway and Key Size DimensionsDocument1 pageKeyway and Key Size DimensionsShashank Saxena100% (1)

- WaterLubeSeal EVKDocument1 pageWaterLubeSeal EVKNhk TokNo ratings yet

- Keyway and Key Size DimensionsDocument1 pageKeyway and Key Size DimensionsShashank Saxena100% (1)

- DC29 55Document4 pagesDC29 55jdrsantNo ratings yet

- Fabrication TolerancesDocument1 pageFabrication TolerancesNhk TokNo ratings yet

- Upper Tool: Controlled Dimension After BendingDocument1 pageUpper Tool: Controlled Dimension After BendingASHOKNo ratings yet

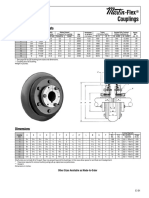

- Martin Flex CouplingsDocument2 pagesMartin Flex CouplingsNhk TokNo ratings yet

- DPX Sample Commercial Invoice and Packing List 1Document6 pagesDPX Sample Commercial Invoice and Packing List 1Nhk TokNo ratings yet

- Mancal 1Document0 pagesMancal 1Wagner Barbosa MendonçaNo ratings yet

- Sample Business PlanDocument1 pageSample Business PlanNhk TokNo ratings yet

- Ogura Mobile (Magnetic) ClutchDocument1 pageOgura Mobile (Magnetic) ClutchNhk TokNo ratings yet

- Swan Air CompressorDocument1 pageSwan Air CompressorNhk TokNo ratings yet

- Structural Calculations of Bridge GirderDocument3 pagesStructural Calculations of Bridge GirderNhk TokNo ratings yet