Professional Documents

Culture Documents

Stacking Tubes PDF

Stacking Tubes PDF

Uploaded by

David Le0 ratings0% found this document useful (0 votes)

8 views21 pagesOriginal Title

Stacking_tubes.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views21 pagesStacking Tubes PDF

Stacking Tubes PDF

Uploaded by

David LeCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 21

Volume 8, Number 2, Ap 1985

Loads for Design of Stacking Tubes

for Granular Materials

SS. Sefarien and EC. Harris, USA

Avstract used, each par bolo staggered st 20° tom the pal above

2s yet, there Is Inadequate published Information for the 87 the pale below. Tho stacking tube is used to allow

Wal eign of acting tioes arse proves meth siocklng of granular mates wiheut cassia

Sa, This papa fie Rs Of 8 tec-penee Soe cae exceasia dust. Mata ontos th top of te te fone ea

eed conllens and toed cmbinntaes etwas Ovetnoad conveyer and opis cut of fre tte bythe Wevcet

lord In srucual design, Where the mathod of com. Svalable opening that i not already surcunded by tho con-

siinavo loads not Danae De paper aheiarcy alloc of mata ouice, Wont evel eater

ich tay be ted tr that ceepaon es covers an opening ofthe tube, cacharpe tem thd eens

Prato tha Towuta of qualatve tcl Perornen by tee, ceases and trhar dlcharge om the stocupe eoetmacs

‘ors on two email model sacking tubes ‘fom the next higher opening (or pal of openings).

Aecond paper wil address the design procedures for stack- Diameter and height of stacking tubes vary depending on the

Seca Seal ort easter aoe eee Sa doavad volume & ne aocieaa: Por edaeod oe

ole wil also be hen Stacking tubes, heighs aro as much aa 150% (6) and

. Giameter Uaualy range trom 61216 (8 to A

‘Stacking tubes are sometimes built directly on top of a’

reclaiming tunel (Fg. 2) containing a conveyor ty whlch

Introduction

tacking tube (also known as 2 “lowering tubo" of “ower

tower” i a vertical tube of other reinforced concrete or

having ‘openings in ts walls at various elovatione

1). Pairs of diametrically opposite openings aro ususlly

(sp00 sf 24 aR

‘payoaqoud aq Aews eueyew SIM} ‘BORON

Fg. Sucng tower on ap of reckiming te

Stacking, blending and reclaiming

mes me ts BA

stored material Is withdrawn from the stockplle around the

‘ube. In such cases, the tube will hava not only side openings

{or discharge onto ihe stockpla, but also & bottom, hopper

shaped opening for direct dlscharge from the tube onto the

tunnel conveyor. the matorial to be handled is prone to

‘deterioration due to longtorm storage and a bottom recta

‘tunnel is net provided, the tube bottom is eloped 60 thatthe

‘ube ls sotf-cleaning, the material flowing easily out of the

side openings nearest the bottom. For materials that are not

{pt 10 deteriorate under longterm storage (limestone or

‘sand, for example) thia precaution is not necessary and the

tube bottom may be fat

2. Design

Two types of design are required:

41. Funetionel design, which involves choosing he diameter,

helght, method of operation, opening size and opening

postion, 90 thatthe tube wil create tho desired volume

{td shape of stockpile and so that material fow wil be

satisfactory

2, Structural design, 20 that safely (and reasonable

economy) re assured under all loading condos.

“his paper adirossee only the latter concem — structural

Sesion.

To dato, no United States code or standard gives structural

design crterla special fr stacking tubes. The most badly

‘needed criteria are those concerning design loads. This

paper suggests design loadings end shows quale

txperimontal evidence to Support some of them.

‘Suggested Loadings

for Structural Design

Loadings which the authors beliove should be considered in

‘structural design of stacking tubes are the folowing:

A. Dead load

B. Live loads

1. Conveyor loads

2 Wind loads

3, Stored and stacked material loads

4, Selamic loads

3.4 Dead Loads

Dead loads to be considered for stacking-tube design

Include the weight ofthe tube itself and the dead-oad portion

Of the reaction of the overhoad conveyor system, If thet

system {s attached to the top of the tube. For purposes of

ccompuling horizontal seismic forces on the tube, the weight

of stored material contained within the tube should algo be

considered as dead load.

3.2 Live Loads

Stacking tube tive loads are of four kinds: conveyor loads,

wind loads, stored and stacked (outside) material loads, and

‘selsmie loads.

9.21 Conveyor Live Loads

‘Conveyor live toads that should be considered are:

1. Vertical raaction (at tha top of the tower) tothe weight of

‘material carried by the conveyor.

380

2. Friction load, parallel to the conveyor and acting in ete

Jongitudinal direction. This would be the trictlon fre ue

to expansich or contraction of the conveyor suppent sive

ture, The authors feol that If he magnitude of fis fre

le nol specified by the ownor, the structural eine

‘should assume a force of at ioast 1096 ofthe total (dst

‘lus five) vertical reaction of the conveyor ayster ontop

ff the tube,

‘8. Belttensio, i the conveyor is so constructed thalthebet

‘onsion must be transferred tothe tube, rather than bog

resisted by the conveyor support structure Het

3.2.2 Wind Loads

Tis permited by the applicable code or standard beg

observed, the allowable stress for load cases thal inc.

Wind may be Increased abovo that allowed for dead at

chor lve loads alono. (Or, the design is by sige

methods, the combined factored loading may be reduce)

Wind loads acting on the tube vary according othe doe

to which the tubo Is surounced by the stockiled matt

Spectfe cases that the slrctural designer should conte

4. Stale wind pressure onthe projected area ofthe ei

height of the tube, with the tube empty and no seit

‘matoralagelnst ine outside of the tube. Various cx

{and standards [1], 2 ve design wind pressures xc

colar structures. if wind pressures for design em

specified by the appleable code or standard the autos

Suggest using the American National Standard ANS

‘AS8.1 [2]. This standard gives design wind presse

various heights onthe siructure and considers sua

shape, purpose, and locality. In special fcatons, kal

records may Indicate tat the specified loads are wal

in these cases, the designer should seriously cone

Using wind pressures higher than the minimum spect

Wind fece transterrod othe tp ofthe tube by he oe

veyor structure shouldbe considered in combinations

the force from wind on the tube its.

2. ‘Static wind pressure on the portion of the tube ta

exposed above the level of stackod material, 7

pressure should be considered along with the lad

Dressure appled by the stacked materi. Parpe

worst, but ently possible condton would be wi

the exposed portion ofthe tube, with the stockpile a

foeward side being parally or completely absent. M4

‘eccentric condition wil result winen mater Is rr

‘only from onesie of tho stockpile, This load

may be ctl for vertical compression onthe ec

{ube wall. Again, wind force from the conveyer steht

‘above should be combined with forces of wind

tube.

8. Variation of wind pressure around the cca

‘This wil cause horizontal bending moments In Be bt

‘wal. Tho varying radil pressures have a resltet

ection of the wind, and this resultant i rk

Shaaring forces in the wall, 2s shown in Fi. 3. Gem

‘moments duo to these vaning pressures ar me

1 be signicant In stel stacking tubes than cone

Janssen of Ri

‘54 (6), 7.

8.2.3 Stored Material Loads 7

‘These should include loads both by material within

and by mete stacked eutsde, Except as noted #284

Conditions under dead loads, above, all prassure® 3% fg

tional forces due fo stored materials should be eats

‘Stacking, blending and reclaiming

and acting no

ne friction cae

vepceipor

inca

‘tructural deaget

Wott ar

eyo oytom one

structod thatthe bq

erator then beat

cture tse,

© oF standard being

2808 that inca

towed for dood ang

sign Is by stengs

9 may be rods

‘Ording tothe deg

stockplled mater,

mer should constn.

od area of the enty

ty and no stockpiee

tube. Various odes

ind pressures lor cr.

for design are ra

tandard, the athen

> Standard ANS,

ind prossures x

> wonelsers struction

‘cial locations, la

led loads aro tooo,

3 seriously conse

9 minimum species

the tube by the con

din combination wa

ot.

1 of the tube that «

[eked material. Ths

ong with the tates

aleriel. Perhaps

fon would be wind o

Inthe stockpile on be

/nplotely absent. Te

material is remove

This toad combinaton

ion on the siackeg

he conveyor struct

‘orces of wind on

JAR]

pd

: 2

a

ts. The following stored-materal load conditions are sug-

(pd, ond these are based partly on the qualitative

esiartal studios reported later in this paper:

1 Saeldng tube ful, but the outside stockpile absont. This

| andlion ls, perhaps, only remotely possible, but it might

‘earl tho supposedtysell-opening gates'on the sides

tine tubo wore frozen of rusted shut, or the tube were

‘Wed with molst material that had become frozen or

caonted together so that N would not flow as expected.

Faris toed case, the radial outward pressures would bo

‘ampuied 28 for @ sil, using, for example, elther tho

danssen or Fleimbert equations for lateral pressure

i617.

Fer computing the vartcal force In the tube wall, etion

‘oo ho stored materia in the tube should also be con-

seared.

Ih te exact opposite of Load 1 above, with the stockpil

ompetly In place all the way to the uppermost opening

tnd unlormly distributed all around the outside of the

‘be, but with the tub itself empty. This would be poss

‘only If the tubo had a bottom discharge opening ino

{to conveyor tunnel below. This load condition would

‘use a hoop compression in the tube wall

1 Te sams as Load 2 above, but withthe tube ful also,

‘is condtion would cause lossor horizontal hoop com:

‘scion or tension in the tube walls, but would result in

‘ largest value of vertical load in the wall due to

‘emard fiction of both the Inside and outside material.

JS eeinaton cf the design lero lode (one ath of stocks

rome

1d the ckcumfrerct

‘moments Inthe Wt

‘ave aresutnt inte

fultant fe resisted >.

sun in Fg. 3. Benes

‘Seuces are more it

‘tubes than conc

avail within te 12

plas noted for si

fh presoures ard #8

ould be treated

Fig. Unio sete scepter sopng aang ot ope @

{tthe outer lateral prossure for this condition i larger than

‘the slo pressure computed for the matoral stored within

the tube, then the inside pressure resisting inward move-

‘ment ofthe tube wall may be taken as high asthe passive

[pressure forthe Inside material. Tho authors suggest @

limit for this passive pressure equal to twice the active

‘pressure value computed by the Janssen or Reimbert

‘equations (Fig. 4).

4. Tube ether full or empty (whichavar is more serious) and:

‘one sixth ofthe outside stockplo removed In a 60° sec-

lor, as shown In Fig.6, This lateral load condition,

ilustrated clearly by the qualtatve experiments, causes

‘an overturning moment. This moment, in tum, causes

large vertical bending strasses which must be combined

‘with the stresses due to the simultaneous vertical loads.

(A method of analyzing for this condhion Is Mlustrated

Tater)

91.24 Salami Loads

Seismic forces ecting on a stacking tube ate Mustratéd in

Fig. 6. Thay consist of:

1. A lateral force E, due to seismic action on the weight of

‘the conveyor and the materia caries

2. Allatoral force £; due to eoismic action on the weight of

{the tower salt and on the weight of material stored in the

‘ower. Tho authors recommend using the entire welght of

the inside stored material to compute the seismic force,

rather than the 80% used for slo design in ACI313—A77

6.

1049 =90-4 pp FY

°¥ 5, xlane OED

sa

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Meyerhof Method - Pile CapacityDocument2 pagesMeyerhof Method - Pile CapacityTee Bun Pin77% (26)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Astm D610 PDFDocument6 pagesAstm D610 PDFAmbarNo ratings yet

- 04 Ansari PDFDocument23 pages04 Ansari PDFchristopherapssNo ratings yet

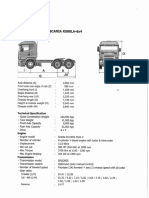

- Specification of Scania Truck R580LA-6x4Document11 pagesSpecification of Scania Truck R580LA-6x4christopherapss100% (1)

- Flat JacksDocument3 pagesFlat JackschristopherapssNo ratings yet

- Allpile ManualDocument103 pagesAllpile ManualKang Mas WiralodraNo ratings yet

- CE270 Stress Mohrs S10 Purdue UniversityDocument24 pagesCE270 Stress Mohrs S10 Purdue UniversitychristopherapssNo ratings yet

- ENCE 4610 - Foundation Analysis and DesignDocument30 pagesENCE 4610 - Foundation Analysis and DesignchristopherapssNo ratings yet

- Deep Foundation Design MethodsDocument30 pagesDeep Foundation Design MethodschristopherapssNo ratings yet

- AP-Foundation Concepts and FoundationDocument40 pagesAP-Foundation Concepts and FoundationYogesh ChauhanNo ratings yet

- Overseas Qualified Engineers CV - April2013Document12 pagesOverseas Qualified Engineers CV - April2013christopherapssNo ratings yet

- Report Des 2010Document67 pagesReport Des 2010Yehezkiel HalauwetNo ratings yet

- Perhitungan Nilai CB CB Value Calculation Untuk Balok Dan Kolom LenturDocument17 pagesPerhitungan Nilai CB CB Value Calculation Untuk Balok Dan Kolom Lenturchristopherapss100% (1)

- Materi Precast Concrete - PT KOBE Oleh Pono Budi Handoko (Edit)Document66 pagesMateri Precast Concrete - PT KOBE Oleh Pono Budi Handoko (Edit)christopherapssNo ratings yet

- Pile Design and Construction - GEO Publication No1/96 - HongkongDocument365 pagesPile Design and Construction - GEO Publication No1/96 - Hongkongchristopherapss100% (4)

- Diagram Interaksi Spun Pile Dia 450 Kelas A1 R00 F C 52MPa 2014Document11 pagesDiagram Interaksi Spun Pile Dia 450 Kelas A1 R00 F C 52MPa 2014christopherapss100% (1)